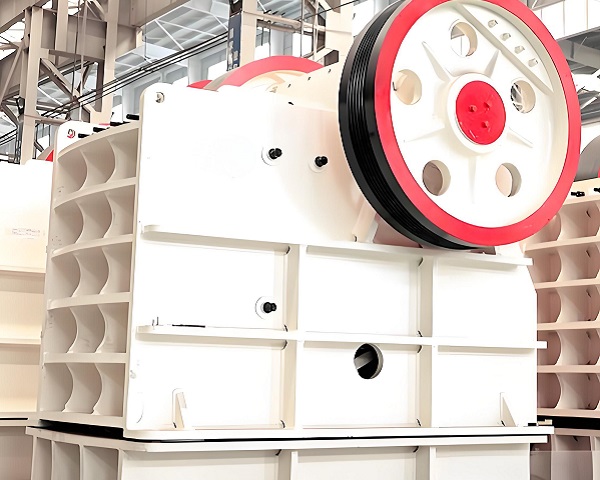

Jaw crushers are core crushing equipment in industries like mining, construction, and metallurgy. Choosing the right model directly impacts production efficiency and operating costs. Faced with a wide variety of products on the market, selecting the most cost-effective equipment based on your specific needs requires a comprehensive consideration of multiple factors, including equipment performance, material characteristics, and production requirements. The following is a systematic purchasing guide to help you avoid selection errors and accurately match your model to your production needs.

Clear Core Needs: Identify Production Scenario and Objectives

The first step in selecting a jaw crusher is to clearly define your production scenario and key specifications. Material properties are the primary consideration: For crushing hard rock like granite and basalt (compressive strength >150 MPa), choose a model with a deep cavity and high-strength jaw plates. For crushing soft rock like limestone and shale (compressive strength <100 MPa), prioritize high-speed, high-capacity equipment. Also, pay attention to the material's moisture content. If the moisture content exceeds 10%, choose a model with a dust cover and a discharge opening adjustment device to prevent material sticking and clogging. Capacity requirements must be comprehensively calculated in conjunction with production line design. The processing capacity of a single jaw crusher typically ranges from 1 to 1,000 tons/hour. When selecting a model, allow for 10%-20% capacity redundancy to prevent overload during peak periods. For example, a sand and gravel plant plans to produce 800 tons of aggregate daily. Based on a 10-hour workday, it would require equipment with a rated capacity of ≥80 tons/hour. Considering post-crushing screening losses, it is recommended to adjust the capacity upwards to 100 tons/hour.

The required particle size of the finished product determines the range of the discharge opening. The width of the jaw crusher's discharge opening directly affects the particle size of the output. The adjustable range for coarse crushers (such as the PE series) is generally 100-300mm, while for secondary crushers (such as the PEX series), it is 20-100mm. If you need to produce a variety of particle sizes, you should choose a hydraulically adjustable discharge opening. It offers an adjustment accuracy of ±5mm and is easy to operate, saving 30% of downtime compared to manual adjustment.

Analyzing Key Parameters: Core Indicators of Performance and Reliability

The performance parameters of a jaw crusher directly reflect the equipment's capabilities. Focus on the following key indicators:

The crushing chamber type determines crushing efficiency and product quality. A deep crushing chamber (chamber depth to feed opening width ratio ≥ 0.7) increases primary crushing efficiency, reduces return material, and achieves 15%-20% higher production efficiency than a shallow-chamber type. Furthermore, the curved crushing chamber design allows the material to move along a curve, avoiding dead corners and jamming, making it particularly suitable for crushing flaky materials.

The movable jaw speed affects crushing frequency and energy consumption. Excessively high speeds prevent material from being discharged quickly, causing "blockage" and increasing motor load. Excessively low speeds reduce crushing efficiency. Generally, the ideal speed for small and medium-sized jaw crushers (processing capacity <100 tons/hour) is 250-350 rpm, while for large equipment (processing capacity >500 tons/hour), the speed can be reduced to 180-250 rpm. For the PE-600×900 model, the optimal speed setting of 275 rpm achieves the lowest specific energy consumption (kW/ton).

Equipment material affects service life and maintenance costs. Jaw plates, as consumable parts, are particularly critical. High-manganese steel (ZGMn13) offers excellent toughness but moderate wear resistance, making them suitable for crushing soft rock. A composite material of high-chromium cast iron and high-manganese steel (Cr26+Mn13) offers 3-5 times greater wear resistance and is suitable for crushing hard rock, but costs approximately 20% more. For the frame, it is recommended to use solid cast steel, which offers 40% greater fatigue resistance than welded frames and can withstand greater crushing impact forces.

The motor power must match the equipment specifications. Insufficient power can lead to frequent equipment overload shutdowns, while excessive power wastes energy. For example, the PE-500×750 model comes standard with a 15kW motor. If used for crushing hard rock like granite, it can be upgraded to an 18.5kW motor to ensure adequate power output. For limestone crushing, a 15kW motor is sufficient.

Evaluating the Manufacturer's Capabilities: A Comprehensive Review from Quality to Service

Jaw crushers are high-value fixed assets, and the manufacturer's technical strength and after-sales service directly impact the equipment's lifecycle cost. When selecting a manufacturer, consider the following aspects:

Production qualifications and accumulated technical experience are the foundation of quality assurance. Prefer manufacturers with more than 10 years of production experience and ISO9001 quality management system certification. Core components (such as spindles and bearings) are often from internationally renowned brands (such as Swedish SKF bearings and German Siemens motors), with assembly accuracy within 0.05mm. You can request the manufacturer to provide operating videos or customer case studies of the equipment to verify its performance in crushing similar materials.

Customization capabilities demonstrate technical flexibility. Different industries have varying requirements for jaw crushers: the mining industry prioritizes high crushing strength, while construction waste recycling requires both volume reduction and impurity removal. High-quality manufacturers can customize the crushing chamber and adjust speed parameters based on material characteristics. For example, they can design special jaw plates with rebar shearing devices for construction waste crushing to prevent rebar from entanglement in the movable jaw.

The after-sales service system determines the efficiency of equipment operation and maintenance. Comprehensive service should include: equipment installation and commissioning (detailed basic construction drawings and installation instructions are required), supply of wearing parts (delivery to the surrounding area within 48 hours is guaranteed), and regular inspections (at least twice a year). Some manufacturers also offer "trade-in" services, offering a 30%-40% discount on the original price after five years of use, reducing replacement costs.

A cost-effectiveness analysis requires a comprehensive consideration of both initial investment and operating costs. The market price difference between a certain brand's PE-750×1060 model can reach over 100,000 yuan. Lower-priced equipment may skimp on materials (e.g., using ordinary carbon steel instead of high-manganese steel jaw plates) or processes (omitting heat treatment), resulting in a shortened equipment lifespan of 2-3 years. High-quality equipment, on the other hand, can have a service life of 5-8 years, resulting in lower annualized costs. It's recommended to create an "equipment life cycle cost table" to factor in purchase costs, maintenance costs, energy consumption, and downtime losses.

Avoiding Selection Mistakes: Common Problems and Solutions

In actual purchases, users often make inappropriate choices due to cognitive bias. Pay special attention to the following points:

Blindly pursuing large-scale equipment can waste resources. To increase production capacity, a quarry purchased a PE-1200×1500 large jaw crusher. However, its raw material handling capacity was only 500 tons/hour, resulting in long-term underload operation and a specific energy consumption 30% higher than that of a comparable model. The correct approach is to select equipment specifications that best suit the weak links in the entire production chain, based on the capabilities of the entire process: "raw material supply - crushing - screening - transportation."

Ignoring equipment compatibility impacts production line coordination. Jaw crushers must be properly graded with subsequent equipment (such as cone crushers and sand making machines). For example, the particle size of the material after primary crushing should match the feed opening size of the secondary crusher (typically 80% of the feed opening width). If the jaw crusher's discharge opening is too large, it will overload the secondary crusher; if it is too small, the load on the jaw crusher will increase, creating a "bottleneck effect."

Ignoring the installation foundation design poses safety risks. Jaw crushers generate strong vibrations during operation, so the foundation design must meet anti-overturning and vibration damping requirements: the concrete strength grade must be no less than C30, the foundation weight must be 3-5 times the weight of the equipment, and rubber shock-absorbing pads must be installed to isolate vibration transmission. In one project, shoddy foundation work resulted in cracked frames after six months of operation, resulting in repair costs exceeding 100,000 yuan.

Decision-making Reference: Selection Process and Contract Key Points

To ensure a scientific and reasonable selection process, we recommend the following process:

Material Testing: Commission a third-party agency to measure material parameters such as compressive strength, moisture content, and particle size distribution;

Capacity Calculation: Calculate the required processing capacity based on finished product demand and equipment utilization (usually 70%-80%);

Parameter Matching: Initially screen 3-5 eligible models based on material characteristics and production capacity;

Site Inspection: Visit the manufacturer's production base and similar customer production lines to verify the equipment's actual performance;

Proposal Comparison: Request the manufacturer to provide a detailed technical proposal, including equipment parameters, configuration list, and energy consumption calculations;

Contract Signing: Clarify equipment specifications, material standards, warranty period (recommended ≥1 year), and after-sales service terms.

The contract should specifically specify details such as the warranty period for consumable parts (e.g., a 3-month warranty for jaw plates), the division of responsibilities for installation and commissioning, and acceptance criteria (based on actual processing capacity and compliance with finished product particle size standards) to avoid subsequent disputes. Selecting a jaw crusher is a systematic process, requiring a comprehensive decision based on a full understanding of your needs, combined with factors such as equipment performance, manufacturer strength, and cost-effectiveness. Only through scientific evaluation and careful investigation can you select high-quality equipment that not only meets production needs but also achieves long-term economic benefits, laying a solid foundation for the stable and efficient operation of the production line.