As a continuously operating heavy equipment, the lifespan and operational stability of waste balers are directly dependent on the quality of their daily maintenance. According to industry statistics, standardized maintenance can reduce equipment downtime by over 60% and extend service life by 30%. From hydraulic fluid management to mechanical wear monitoring, every maintenance step can impact the overall performance of the equipment. This article systematically outlines key daily maintenance points, common troubleshooting methods, and long-term maintenance strategies, providing comprehensive technical support for efficient equipment operation.

Daily Maintenance: Building a Preventive Maintenance System

The core of daily maintenance lies in eliminating potential problems before they occur through regular inspections and adjustments. A standardized daily pre-startup inspection process should be implemented. First, check the hydraulic oil tank level to ensure it's between the upper and lower limits of the level gauge. If insufficient, refill with the same type of hydraulic oil (No. 46 anti-wear hydraulic oil is recommended). Mixing different brands of oil is strictly prohibited. Second, check that the power supply voltage is stable within 380V ± 5% and that the ground resistance is ≤ 4Ω to prevent damage to the control module due to voltage fluctuations. Finally, test protective components such as the emergency stop button and safety door interlock to ensure their responsiveness and reliability.

Periodic maintenance should be scheduled based on the equipment's operating time. Clean the feed inlet and compression chamber every 8 hours to prevent fiber debris from entangled in the drive shaft. Check the hydraulic system filter every 40 hours and replace the filter element immediately if the pressure gauge indicates a differential pressure exceeding 0.3 MPa to prevent contaminants from entering the cylinder. Perform a comprehensive lubrication every 200 hours, adding lithium-based grease to moving parts such as slide rails and chains. Use a grease gun to apply a fixed amount of grease to bearings to ensure thorough penetration. Before lubrication, be sure to clean the surface of components to prevent dust from mixing with grease and forming abrasives.

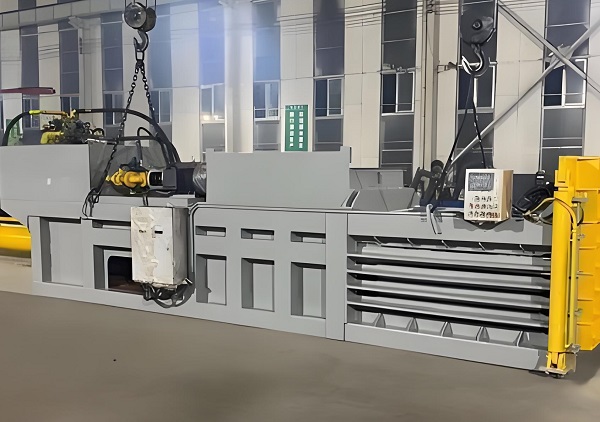

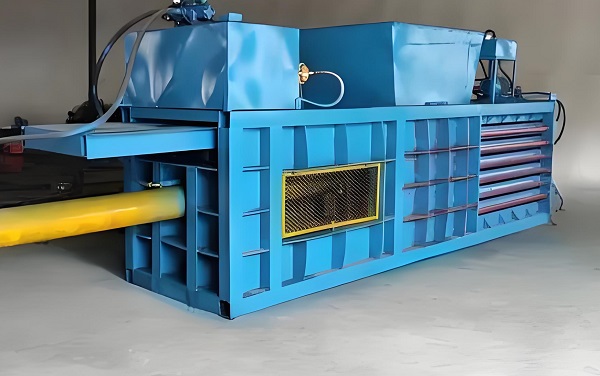

Specific maintenance measures are required based on the varying characteristics of different types of equipment. The conveyor belt tension of horizontal balers should be adjusted weekly to maintain a deflection of 10-15mm. Any deviation should be corrected by adjusting the driven roller bearing seat. The guide column of the ram on vertical balers should be wiped daily with a clean cotton cloth to remove the surface oxide layer and then coated with anti-rust oil. The compression chamber of food waste balers should be flushed with a high-pressure water jet after each shift to prevent food residue from rotting, causing odor, and corrosion. The integrity of the sealing strips should also be checked, and any damage should be replaced immediately to prevent leakage.

Core System Maintenance: Accurate Diagnosis and Efficient Repair

The hydraulic system, as the core power source of the baler, accounts for over 70% of equipment failures. Maintenance should adhere to the principle of "diagnosis before disassembly." When insufficient pressure occurs, check the following: whether the hydraulic pump is leaking (this can be determined by measuring pump outlet pressure fluctuations), whether the relief valve setting is drifting (calibrate to the specified value using a pressure gauge), and whether the cylinder seal is worn (when disassembling, carefully observe the piston chamber for oil leakage). When repairing or replacing seals, use specialized tools to remove the old seals. Before installing the new seals, soak them in hydraulic oil for 10 minutes to avoid dry friction and damage to the lip.

Mechanical structural failures often manifest as unusual noises, vibrations, and sticking. Compression mechanism sticking is usually caused by excessive clearance between the slider and the guide rail or obstruction from foreign matter. After disassembly, measure the guide rail wear. If the clearance exceeds 0.5mm on a single side, repair it by grinding or replacing the guide rail inserts to adjust the clearance. Strapping problems with the strapping mechanism are often caused by uneven wear of the feed pulleys. Use a micrometer to measure the groove wear depth. If the wear exceeds 0.3mm, the pulleys must be replaced. Also, check the guide pulley bearing clearance. If it exceeds the standard, replace the bearing and reposition it immediately. Troubleshooting electrical control system problems requires specialized instruments. When the PLC control cabinet indicates a sensor fault, first use a multimeter to check the proximity switch output signal. Normally, it should be a high level of 5V. If no signal is present, check for loose terminals or sensor misalignment. If the touch screen displays a black screen, check the power module output voltage (should be 24V DC) and the grounding of the communication cable shield. If necessary, replace the screen to determine if the fault is with the screen itself. When repairing electrical components, always disconnect the main power supply and discharge the capacitors before proceeding to prevent electric shock.

Common Troubleshooting: Quick Response and Standard Operation

The efficiency of handling sudden faults during equipment operation directly impacts the execution of production plans. The inability to build pressure is the most urgent fault type, and the machine should be shut down and inspected immediately. If the hydraulic pump is not operating, it may be due to a motor phase loss or a damaged contactor. Use a phase sequence meter to check the power phase and replace the damaged contactor contacts. If the pump is operating normally but the pressure is zero, it is likely a stuck relief valve. Disassemble the valve core and remove burrs with fine sandpaper. Before reassembly, clean the valve body with kerosene to ensure there are no residual impurities. When restarting the equipment, run it at no load for 3 minutes and wait until the system pressure stabilizes before resuming operation.

Slow cylinder movement is often caused by insufficient flow or leakage. The repair steps are as follows: First, check whether the throttle valve is properly opened. Turning it counterclockwise can increase the flow rate. Next, measure the cylinder back pressure. If it exceeds 0.5 MPa, it indicates a blockage in the oil return line, and the filter and pipes need to be cleared. For double-acting cylinders, check whether the piston seal is defective. This can be determined by closing the oil line to the rod chamber and observing the pressure in the rodless chamber. If the seal is defective, the entire cylinder seal kit must be replaced.

Abnormal noise in the mechanical transmission system requires precise location of the source. Abnormal noise in a gearbox may be due to lubricant deterioration or gear wear. Take samples to test for oil contamination. If metal particles are detected through ferrography, disassemble and inspect the gears. Gear tooth surfaces showing pitting or spalling require replacement. Periodic noise in a chain drive is often due to chain link wear and elongation. Use a tensioner to measure chain tension. If it exceeds the specified value by 15%, remove excess links or replace the entire chain. Also, inspect the sprocket tooth profile for wear and, if necessary, replace them in pairs to ensure meshing accuracy.

Long-term Maintenance: Strategies for Extending Equipment Lifecycles

Long-term maintenance requires establishing a complete equipment lifecycle archive, detailing each maintenance session, troubleshooting procedures, and key component replacement times. It is recommended to implement an IoT monitoring system to collect real-time equipment operating parameters (such as hydraulic oil temperature, motor current, and compression counts). Using big data analysis, potential faults can be predicted. For example, if the cylinder extension and retraction speed decreases by 5%, the system will automatically prompt a prompt to check the hydraulic pump flow characteristics. Additionally, quarterly precision calibration should be performed, using a dial indicator to measure the pressure head parallelism error. If the error exceeds 0.1mm/m, the cylinder mounting bracket should be adjusted to correct the error. Preventive replacement of key components can significantly reduce the risk of sudden failures. Hydraulic hoses must be replaced after 1,000 hours of use or 12 months (whichever comes first). During replacement, ensure the hose bend radius is ≥10 times its diameter to avoid excessive bending that can lead to premature aging. Seals are consumable parts and are recommended to be replaced every 3,000 hours. Choose fluororubber materials to withstand operating environments ranging from -20°C to 120°C. While there's no fixed replacement cycle for electronic components like servo motors and PLCs, functional testing is required every six months to ensure stability in high-temperature, dusty environments.

Seasonal maintenance of equipment should adapt to environmental changes. During high summer temperatures, the hydraulic system should be equipped with a cooler to maintain the oil temperature between 35°C and 55°C. If the temperature exceeds 60°C, the machine should be shut down immediately for cooling. During low winter temperatures, the hydraulic oil should be preheated to above 20°C before starting the machine. This can be achieved by circulating the machine with no load to prevent increased oil viscosity at low temperatures, which can lead to pump cavitation. During the rainy season, electrical cabinets should be protected from moisture by installing a dehumidifier to maintain relative humidity at ≤60%. Control panels should be cleaned weekly with a hair dryer to prevent dust buildup on the surface to prevent short circuits.

Safety Regulations: The Bottom Line for Maintenance Operations

Maintenance operations must strictly adhere to safety operating procedures. All maintenance personnel must be certified and equipped with appropriate protective equipment. Before entering the work area, the main power supply must be disconnected and a "Do Not Close" warning sign must be displayed. Residual pressure in the hydraulic system must be released through the unloading valve. Disassembly can only begin when the pressure gauge shows zero. When working at height (such as inspecting the top cylinder of a horizontal machine), a safety belt must be worn and a stable operating platform must be established. Stepping on the equipment's protective covers is strictly prohibited. When handling broken or sharp waste residues, cut-resistant gloves must be worn and specialized cleaning tools must be used to avoid scratches caused by bare hands.

Maintenance of special types of equipment has additional safety requirements. Medical waste balers must be disinfected before maintenance. Operators must wear protective clothing, goggles, and a respirator. After work, all tools must be autoclaved at 121°C. When maintaining explosion-proof balers, explosion-proof tools must be used. Welding, cutting, and other hot work are strictly prohibited while the equipment is operating. After maintenance, the equipment's explosion-proof performance must be retested to ensure compliance with Ex dⅡBT4 requirements.

Emergency response mechanisms are an important supplement to safety maintenance. Develop a detailed "Equipment Maintenance Emergency Plan" that clearly defines procedures for handling emergencies such as hydraulic oil leaks and motor fires. Dedicated firefighting equipment (dry powder fire extinguishers are required for hydraulic system fires) should be provided and regular drills conducted. All maintenance personnel should master first aid skills such as CPR, maintain on-site first aid kits, and regularly update supplies. Through systematic safety management, maintenance risks can be minimized.

By establishing a maintenance system that prioritizes prevention, precise maintenance, and safety, we can not only ensure the continued stable operation of waste balers but also significantly reduce overall operating costs. Practice has shown that every ¥1 spent on maintenance can reduce ¥5-8 in losses due to failures, demonstrating the economic value created by professional maintenance. Equipment managers should incorporate maintenance into their daily management priorities and maximize the value of equipment throughout its lifecycle through standardized, data-driven management methods.