As a key link in achieving waste reduction, harmlessness and resource utilization, waste classification has received increasing attention. Traditional waste classification methods are inefficient and inaccurate, and it is difficult to meet the growing demand for waste disposal. As an intelligent sorting device based on optical principles, optical sorting machines can quickly and accurately identify and separate different components in waste, bringing new solutions to waste sorting and showing great application potential and development prospects in the field of waste disposal.

This article focuses on the application of optical sorting machines in waste sorting, and elaborates on its working principle, core role and significant advantages. By analyzing the specific performance of optical sorting machines in the sorting process of different types of waste such as urban domestic waste and industrial solid waste, it reveals its important value in improving the utilization rate of waste resources and promoting the refinement of waste sorting, and provides theoretical basis and practical reference for the further promotion and application of optical sorting technology in the waste disposal industry.

The role of optical sorting machines in waste sorting

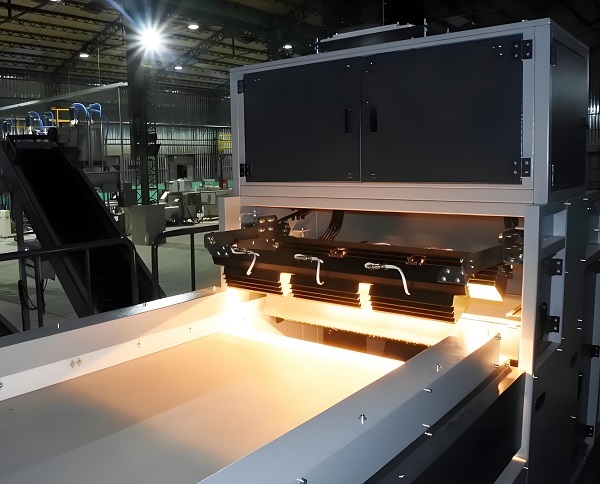

Optical Sorter

1. Realize refined waste classification

The composition of urban domestic waste is complex, including plastics, glass, paper, fabrics, kitchen waste and other substances. Optical sorting machines can make fine distinctions between these waste of different materials. For example, in the field of plastic sorting, the optical sorter can identify different types of plastics such as PET (polyethylene terephthalate), PE (polyethylene), and PP (polypropylene), providing high-quality raw materials for the recycling and reprocessing of plastics. For glass waste, the optical sorter can classify according to color (such as colorless, green, and brown) to improve the purity of glass recycling. Through refined classification, a good foundation has been laid for the resource utilization and harmless treatment of subsequent waste.

2. Improve resource recycling rate

The application of the optical sorter can efficiently separate the materials with recycling value from the waste. In the treatment of electronic waste, the optical sorter can separate the metal components and plastic shells on the circuit board, so that the metals and plastics can be recycled separately, and the recovery rate of precious metals and plastics in electronic waste can be improved. In the treatment of industrial solid waste, the optical sorter can separate reusable materials such as ceramics and glass from the waste residue, reducing the waste of resources, promoting the recycling of resources, and meeting the requirements of the development of a circular economy.

3. Reduce the cost of subsequent processing

The waste sorted by the optical sorter has a more single and pure composition. Before the incineration of waste, the optical sorter can be used to remove high calorific value materials such as plastics and rubber, which can improve the combustion efficiency of the incinerator and reduce equipment failures and maintenance costs caused by impurities. In terms of landfill, it reduces the leachate pollution problem that may be caused by the mixed landfill of different waste, reduces the processing pressure and environmental risks of the landfill, and indirectly reduces the comprehensive cost of subsequent waste treatment.

4. Assisting the intelligent development of waste sorting

As an intelligent equipment, the optical sorter can be combined with the automatic conveying system, data management system, etc. to build an intelligent waste sorting and processing production line. Through real-time monitoring and data analysis, managers can clearly understand the efficiency of waste sorting, the proportion of various types of waste and other information, which is convenient for optimizing and adjusting the production process. At the same time, the intelligent operation of the optical sorter reduces manual intervention, reduces labor intensity, improves the automation level of waste sorting, and promotes the entire waste treatment industry to move towards intelligence.

Advantages of optical sorters in waste sorting

Optical Sorter

1. High sorting efficiency

The optical sorter adopts high-speed optical detection and automatic separation technology, and has a fast processing speed. In actual applications, a large optical sorter can process several tons or even tens of tons of waste per hour, which is much more efficient than manual sorting. For example, on the plastic sorting line of a large waste treatment plant, the optical sorter can quickly identify and separate a large amount of mixed plastics in a short time, greatly improving the capacity of waste treatment and meeting the needs of large-scale waste treatment.

2. High sorting accuracy

With advanced optical detection technology and precise algorithms, the optical sorter can identify tiny optical differences and achieve high-precision sorting. Its sorting accuracy can usually reach more than 90%, and even more than 95% in some specific scenarios. Even waste with similar appearance, such as plastic particles of different colors and materials, can be accurately distinguished by the optical sorter, effectively ensuring the quality of recycled resources and improving the economic benefits of resource recycling.

3. Strong adaptability

The optical sorter can adapt to the needs of waste sorting of different types and compositions by adjusting equipment parameters and optimizing algorithms. Whether it is urban domestic waste, industrial solid waste, or construction waste, the optical sorter can play a role. In addition, it can flexibly adjust the sorting strategy according to the differences in waste composition in different regions, and has strong environmental adaptability. At the same time, the optical sorter can handle waste materials of different shapes and sizes, from large pieces of waste furniture to small plastic fragments, and can be effectively sorted.

4. Environmental protection and energy saving

Compared with some traditional sorting methods, the optical sorter does not produce pollutants such as wastewater and waste residue during operation, and does not require the use of chemical agents, which is environmentally friendly. Its energy consumption is mainly concentrated in the operation of light sources, detection systems and separation execution systems. Compared with large-scale mechanical equipment, the energy consumption of optical sorters is relatively low. Moreover, through efficient sorting, the resource recovery rate is improved, and the energy consumption and environmental pollution caused by resource mining and production are reduced, which has significant environmental protection and energy saving advantages.

5. Reduce labor costs

Traditional waste sorting relies on a large number of manual sorting, which is not only inefficient, but also requires high labor costs. The automated operation of the optical sorter greatly reduces the dependence on labor. An optical sorter operation team only needs a few technicians to monitor and maintain the equipment. As labor costs continue to rise, the advantages of optical sorters in reducing labor costs have become increasingly obvious, helping waste disposal companies to reduce operating costs and improve market competitiveness.

Challenges and coping strategies faced by optical sorters in waste sorting

Optical Sorter

1. Challenges faced

Complexity of waste composition: There are a lot of cases in actual waste that are contaminated and mixed, which will interfere with the optical detection of optical sorters and reduce the recognition accuracy. For example, plastics covered with oil stains and glass with dirt on the surface will change their original optical properties and increase the difficulty of sorting.

Equipment cost and maintenance: Optical sorters are high-end intelligent equipment with high initial purchase costs. For some small waste disposal companies with limited funds, there is a certain economic pressure. In addition, optical detection components, high-pressure gas valves and other components in the equipment need to be regularly maintained and replaced, and the maintenance cost is relatively high.

Shortage of technical talents: The operation and maintenance of optical sorters require professional technicians who are not only familiar with the operating principles of the equipment, but also have certain data analysis and algorithm optimization capabilities. At present, there is a relative shortage of such professional and technical talents in the market, which restricts the wide application and performance improvement of optical sorters in waste sorting.

2. Response strategies

Optimize technology and algorithms: Develop more advanced optical detection technology and intelligent algorithms to improve the ability of optical sorters to identify complex waste components. For example, use multispectral imaging, hyperspectral imaging and other technologies to obtain richer waste optical information; use deep learning algorithms to continuously optimize the recognition model and improve the accuracy of sorting polluted and mixed waste.

Reduce costs and improve reliability: Reduce the manufacturing cost of optical sorters through technological innovation and large-scale production. At the same time, improve equipment design, increase the service life and reliability of key components, and reduce maintenance frequency and costs. In addition, the government can introduce relevant support policies to provide financial subsidies or tax incentives to companies that purchase optical sorters to encourage companies to use advanced equipment.

Strengthen talent training: Colleges and vocational schools can offer relevant majors or courses to cultivate professionals in the operation, maintenance and research and development of optical sorters. Enterprises can also cooperate with scientific research institutions to carry out technical training and exchange activities to improve the professional level of existing technical personnel and provide talent guarantee for the application of optical sorters in waste sorting.

Optical Sorter

Optical sorting machines, with their unique working principles and technical advantages, play an important role in refined classification, improving resource recycling and utilization rates, and reducing processing costs in waste sorting. They have significant advantages such as high sorting efficiency, high precision, strong adaptability, environmental protection and energy saving, and reduced labor costs. Although optical sorting machines are currently facing challenges such as complex waste composition, high equipment costs, and shortage of technical personnel in the application process, these problems will be gradually resolved through continuous technological innovation, policy support, and talent training. In the future, optical sorting machines are expected to be more widely used and developed in the field of waste sorting, and play a greater role in promoting the sustainable development of the waste treatment industry and realizing the efficient recycling of resources.