The main equipment in the construction waste crushing process is designed around "multi-stage crushing and step-by-step refinement", and the core includes jaw crushers, impact crushers, cone crushers and impact crushers: jaw crushers, as coarse crushing equipment, are responsible for the initial crushing of large pieces of construction waste (such as 1-2m concrete blocks), reducing the particle size to 80-150mm, suitable for high-hardness materials; impact crushers are responsible for medium/fine crushing, optimizing the shape of aggregates through impact crushing, and refining 80-150mm materials to 30-50mm, suitable for brittle materials such as concrete and bricks; cone crushers are designed for high-hardness materials or fine particle size requirements, achieving 5-20mm ultra-fine crushing and reducing the needle-like content of aggregates; impact crushers process 30-50mm particles into regenerated sand that meets the standards. The core equipment in the screening process is a heavy-duty vibrating screen, a heavy-duty drum screen, and a high-frequency vibrating screen. The first two are used in the pre-processing stage to separate dirt, dust, and light debris, reducing wear on the crushing equipment. The high-frequency vibrating screen is used for post-crushing classification, producing recycled aggregate of varying sizes, such as 5-10mm and 10-20mm, through three to four layers of screens, suitable for different applications.

Construction Waste Crushing Equipment

Crushing is a key step in construction waste recycling. Multiple stages are required to reduce large lumps of material (such as 1-2m concrete blocks) into particles suitable for recycling (such as 5-30mm recycled aggregate). The equipment must possess high wear and pressure resistance.

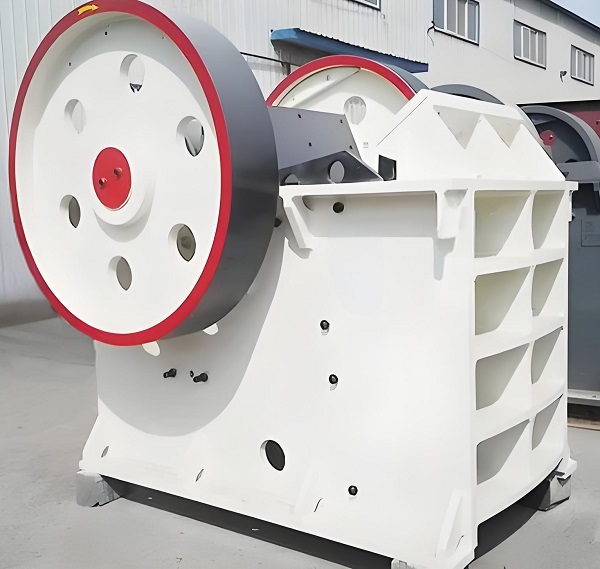

2.Jaw Crusher (Coarse Crushing Equipment)

Function: As the "first crushing step" in the production line, it crushes pre-processed large lumps of construction waste (such as concrete blocks and bricks) to a particle size of 80-150mm, reducing the burden on subsequent fine crushing equipment. It is a core piece of equipment for handling high-hardness materials. Working Principle: A V-shaped crushing chamber is formed by fixed and movable jaw plates. A motor drives the eccentric shaft, causing the movable jaw plate to oscillate back and forth. This creates a squeezing and shearing action against the fixed jaw plate, crushing bulky materials. The deep-chamber crushing design allows for feed opening sizes ranging from 300-1200mm (for example, the PE-600×900 jaw crusher has a feed opening of 600×900mm and a processing capacity of 50-120 tons/hour), adapting to varying production requirements. The jaw plates are made of high-manganese steel (ZGMn13), offering excellent wear resistance and a service life of 3-6 months (depending on material hardness).

2. Impact Crusher (Secondary/Fine Crushing Equipment)

Function: Performs secondary crushing on materials after jaw crushing, reducing particle sizes from 80-150mm to 30-50mm. Impact crushing also improves aggregate particle shape (reducing needle-like particles) through impact crushing, enhancing the quality of recycled aggregate. Suitable for brittle materials such as concrete and masonry.

Operating Principle: The machine features a rotor and impact plates. The rotor rotates at high speed (800-1500 rpm), driving the hammers to strike the material. The impacted material rebounds onto the impact plates, where it undergoes multiple impacts and grinding, reaching the desired particle size before being discharged from the discharge port. A hydraulic opening mechanism allows for quick access to the housing for replacement of wearing parts (hammers and impact plates). The hammers are made of a high-chromium alloy (Cr20-Mn2), offering impact and wear resistance. Suitable for processing concrete blocks with a hardness of ≤300 MPa.

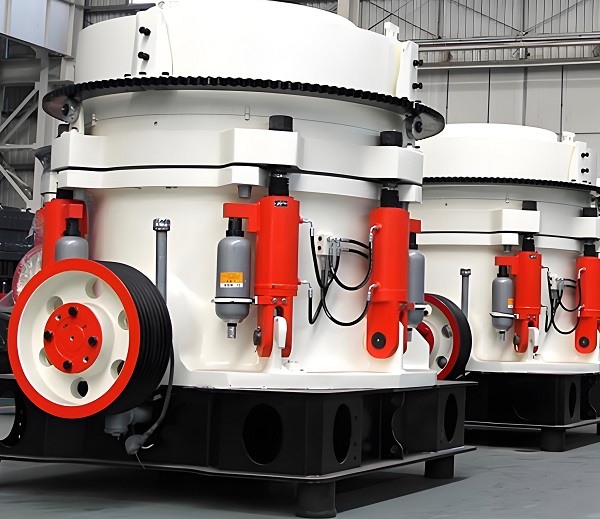

3. Cone Crusher (Fine/Ultra-Fine Crushing Equipment)

Function: Targets extremely hard construction waste (such as granite gravel and high-strength concrete blocks), or where a finer particle size (e.g., 5-20mm) of recycled aggregate is required. This provides "ultra-fine" crushing, ensuring uniform aggregate particle size and meeting the needs of high-end applications such as recycled concrete and bricks.

Working Principle: Composed of a fixed cone (outer cone) and a movable cone (inner cone), the movable cone rotates around an eccentric axis, forming a periodically changing crushing chamber with the fixed cone. Within this chamber, the material is squeezed, ground, and crushed. Utilizing the "laminated crushing principle," the material is compressed against each other during the crushing process, reducing wear on vulnerable parts and lowering the aggregate's flake content (≤10%). Depending on production capacity, choose between a spring cone crusher (capacity of 50-200 tons/hour) or a hydraulic cone crusher (capacity of 100-500 tons/hour). The hydraulic cone crusher also features an overload protection function that automatically discharges uncrushable materials (such as metal lumps).

4. Impact Crusher (Sand Making Equipment)

Function: Processes crushed construction waste (such as 30-50mm concrete particles) into reclaimed sand (particle size 0.15-5mm) that meets construction sand standards. This equipment can replace natural sand in concrete and mortar preparation, making it a key device for the "high-value utilization" of construction waste.

Working Principle: After entering the feed inlet, the material is accelerated and thrown out by the high-speed rotating impeller (2000-3000 rpm). It collides with the impact block or the material itself within the casing, resulting in multiple impacts and grinding, resulting in fine particles. Qualified reclaimed sand is then separated through a screening device. The machine is equipped with two crushing modes: "rock-on-rock" for sand production (reducing iron contamination) and "rock-on-iron" for shaping (improving sand grain roundness). The reclaimed sand yield can reach over 80%, with a mud content of ≤3%, meeting the GB/T 14684-2022 "Construction Sand" standard.

Construction Waste Sorting and Purification Equipment

Crushed construction waste still contains impurities such as metal, plastic, and wood, which require specialized sorting equipment to remove. This ensures the purity of recycled aggregate and reclaimed sand while also recovering high-value resources.

Eddy Current Separator (Non-Ferrous Metal Separation)

Function: Separates non-ferrous metals (such as aluminum alloy window frames, copper pipes, and stainless steel components) from the crushed material. These metals account for approximately 1%-3% of construction waste and have high recycling value, making them a key revenue driver for the production line.

Operating Principle: The eddy current separator uses the same principle as the one used for household waste separation, but is optimized for the specific characteristics of construction waste. It utilizes a wide-width sorting drum (1.2-2.0m wide) suitable for high-volume crushing lines (processing capacity of 50-200 tons/hour). Its magnetic field strength is increased to 18,000-22,000 gs, allowing it to separate non-ferrous metal particles (such as aluminum alloy fragments and copper shavings) with a diameter of 2-50 mm. The drum surface is coated with a wear-resistant ceramic coating to prevent concrete particles from abrading the drum, extending its service life.

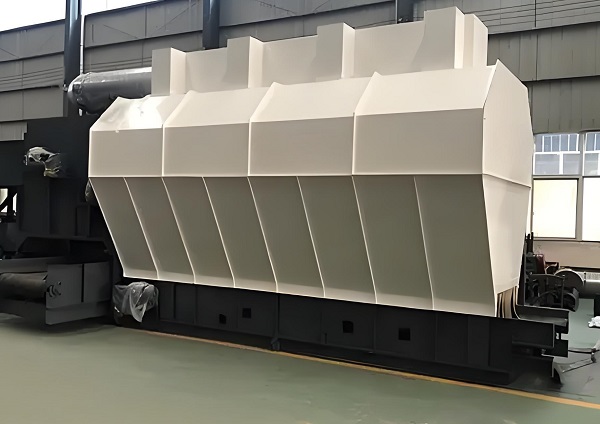

2. Air Separator (Light Impurity Separation)

Function: Removes light impurities (such as plastic fragments, wood chips, and paper scraps) from the crushed material. If these impurities remain in the recycled aggregate, they can reduce the aggregate's strength and affect subsequent use (e.g., causing cracking in recycled concrete).

Applicable Type: Using a "vertical air separation tower," the crushed material falls evenly from the top, while a fan blows high-pressure air from the bottom (at a speed of 15-25 m/s). Light impurities (density ≤ 0.5 g/cm³) are lifted upward by the airflow and discharged through the top outlet (collected by a bag filter). Heavy aggregate (density ≥ 2.0 g/cm³) overcomes the airflow resistance and falls to the bottom. The air separation efficiency can reach over 95%, ensuring that the light impurity content in the recycled aggregate is ≤ 0.5%.

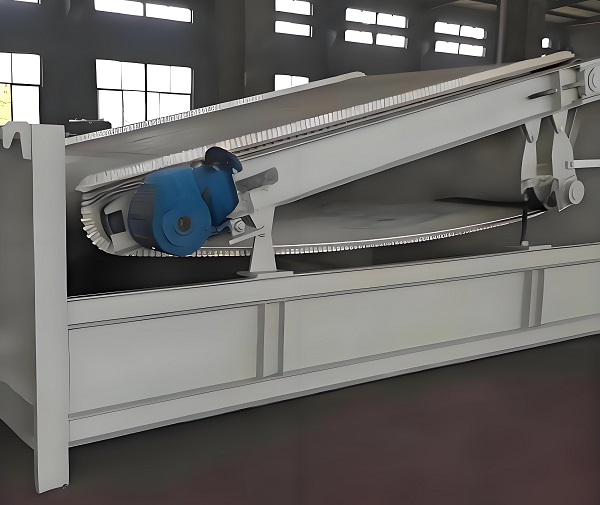

3. Screening Equipment (Aggregate Grading)

Function: Classifies crushed materials by particle size, producing recycled aggregate of varying sizes (e.g., 5-10mm, 10-20mm, 20-30mm) to meet the needs of various applications (e.g., 5-10mm for recycled mortar, 20-30mm for road base backfill).

Common Type: A "high-frequency vibrating screen" is used, equipped with 3-4 layers of screen mesh, with mesh apertures set according to the target particle size (e.g., 50mm for the upper layer, 30mm for the middle layer, 10mm for the lower layer, and 5mm for the bottom layer). High-frequency vibration (50-60Hz) reduces material clogging and ensures grading accuracy. The screen mesh is made of "polyurethane woven mesh," which is 3-5 times more wear-resistant than ordinary steel mesh and has a service life of 6-12 months. The moisture content of the graded aggregate is ≤15%, allowing direct storage or subsequent processing.

Construction waste crushing and screening equipment, through the synergistic cooperation of "crushing and refining + screening and purification," constitutes the core link in the resource utilization of construction waste. The crushing equipment, with its multi-stage design, not only solves the problem of reducing the volume of large, high-hardness construction waste, but also meets the diverse output needs from coarse aggregate to regenerated sand through the complementary functions of different models. Screening equipment runs through the entire process of pretreatment and post-crushing grading, not only removing impurities in advance to protect the crushing equipment, but also improving the purity and specification adaptability of the recycled aggregate through precise grading. The efficient operation of these two types of equipment not only ensures a high proportion of concrete, sand and gravel components in construction waste are recovered, producing recycled building materials that meet standards, but also lays the foundation for subsequent processing (such as recycled brick production), promoting the transformation of construction waste from "waste" to "resource."