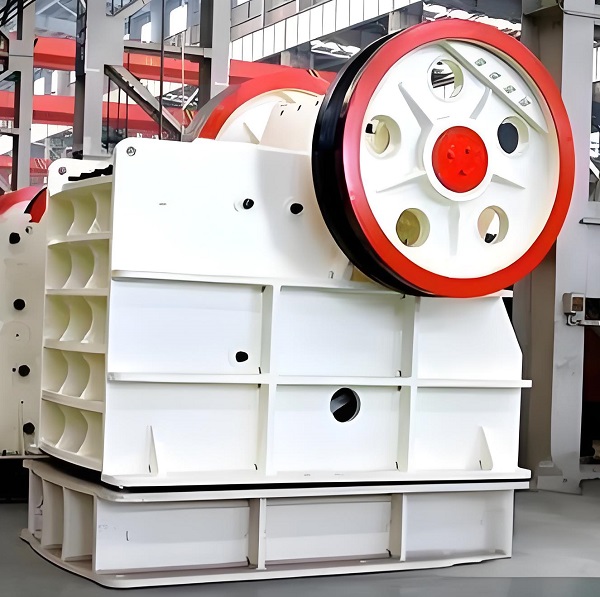

With accelerating urbanization, my country generates over 3 billion tons of construction waste annually, of which inorganic waste, such as concrete blocks and masonry, accounts for over 70%. Jaw crushers, with their efficient crushing capabilities for hard and brittle materials, have become a core piece of equipment for reducing and recycling construction waste. They are used throughout the entire process of material volume reduction, impurity separation, and aggregate recycling. Compared to traditional landfill disposal, resource-recycling production lines using jaw crushers can increase construction waste utilization to over 95% while reducing disposal costs by 30%. The following analyzes the key role of jaw crushers in construction waste management from three perspectives: process adaptability, technical advantages, and application scenarios.

Pre-treatment Crushing and Volume Reduction: Laying the Foundation for Subsequent Treatment

Construction waste often begins as a mixed mass of large pieces (such as concrete blocks and floor slab components after wall demolition), ranging in size from 1 to 3 meters. These pieces are often entangled with rebar, wood, and other impurities, making them extremely difficult to transport or recycle directly. During this stage, the jaw crusher performs the "primary crushing and volume reduction" task, mechanically transforming irregular, large lumps of material into uniform particles, creating conditions for subsequent sorting and recycling.

Crushing and reducing the volume of bulk material is the core goal of pretreatment. For large concrete components (each weighing several tons) generated at demolition sites, a mobile jaw crusher (such as a crawler crusher equipped with a PE-900×1200 model) is required for on-site crushing. The hydraulically driven movable jaw applies periodic compression to the material, reducing a 3-meter square concrete block to less than 300 mm in 10-15 minutes, achieving a volume reduction of 70%-80%, significantly reducing transportation costs (the transport capacity per truck can be increased by 2-3 times). Data from a demolition project in a city shows that after adopting on-site jaw crushing pretreatment, the number of construction waste trucks transported dropped from an average of 50 to 22 per day, reducing transportation costs by 56%.

The initial separation of impurities relies on the selective crushing properties of the jaw crusher. The bond strength between the rebar and concrete in construction waste is far lower than the concrete's own compressive strength (approximately 20-40 MPa). During the crushing process, the jaw crusher preferentially breaks along the interface between the two, stripping rebar with a diameter of 16 mm or less from the concrete block. These exposed rebar can be separated by the device's built-in magnetic separator (installed below the discharge port), achieving a recovery rate of over 90%. The impact of the jaw crusher shreds light impurities such as wood and plastic into fragments smaller than 50 mm, facilitating subsequent air separation (using wind to separate impurities with significantly different densities). One processing line, using a combination of jaw crushing, magnetic separation, and air separation, achieved a rebar recovery rate of 92% and a plastic impurity removal rate of 88%.

Material homogenization ensures stable subsequent processing. After pre-treatment, the jaw crusher crushes the construction waste to a particle size distribution concentrated within the 50-300 mm range, eliminating the problem of material jamming in sorting equipment caused by large size variations. This homogenization process increases the subsequent vibrating screen screening efficiency to 90% (uncrushed material screening efficiency is only 65%) and facilitates the separation of different material compositions (e.g., separate recycling of masonry and concrete).

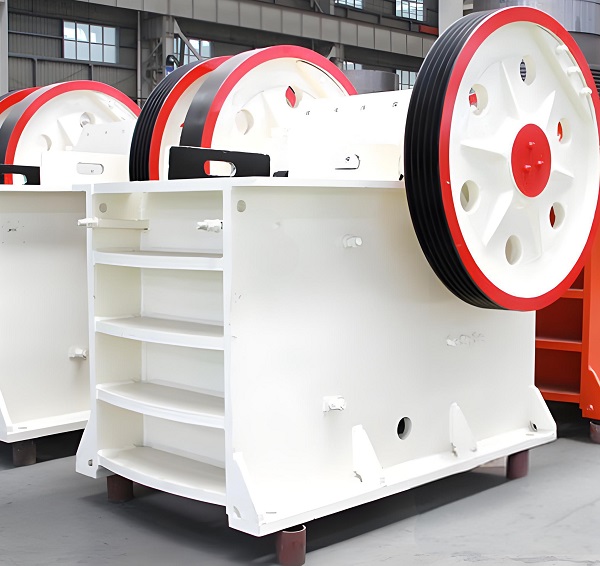

Precision crushing in recycled aggregate production: a key factor in determining the quality of the finished product

Converting construction waste into recycled aggregate (for use in road bases, concrete admixtures, etc.) is an advanced form of resource utilization. During this stage, the jaw crusher must achieve "controllable crushing," precisely controlling crushing strength and particle shape to produce recycled building materials that meet national standards.

Particle size control meets the needs of various projects. According to GB/T 25177-2010, "Recycled Coarse Aggregate for Concrete," recycled aggregate must be sorted into multiple particle sizes, such as 31.5mm, 25mm, and 20mm. By adjusting the discharge opening width (a hydraulic adjustment system allows for stepless adjustment within a range of 10-150mm), a jaw crusher precisely controls the particle size of its crushed product. A 50mm discharge opening produces 20-50mm coarse aggregate (for roadbed filling); a 20mm setting yields 5-20mm fine aggregate (for mortar preparation). A recycled aggregate plant used a jaw crusher's multi-stage crushing process (coarse crushing opening 80mm → medium crushing opening 30mm) to increase the aggregate grade ratio in its finished product from 68% to 94%.

Optimizing particle shape improves the performance of recycled aggregate. Recycled aggregate produced by traditional crushing methods often exhibits a needle-like shape (accounting for over 25%), which reduces the fluidity of concrete. The jaw crusher's deep, curved crushing chamber design (with a 20°-22° bite angle) allows the material to undergo multiple compression and grinding processes within the crushing chamber, keeping the needle-like and flake-like content to less than 10%. Furthermore, the optimized motion trajectory of the movable jaw (280-320 strokes/minute) reduces over-crushing of the material, increasing the apparent density of the aggregate by 5%-8% and reducing water absorption to below 8% (meeting the standard for Class III recycled aggregate). Experimental data shows that the compressive strength of C30 concrete produced using recycled aggregate produced by the optimized jaw crusher increased from 82% to 96%.

Deep impurity removal ensures aggregate purity. Even after pre-treatment, trace impurities (such as paint coatings and gypsum lumps) may still remain in construction waste. During the crushing process, the jaw crusher removes some of these impurities through friction (for example, the paint removal rate on the concrete surface reaches 60%). Impurities remaining in the aggregate after crushing (such as plastic particles with a diameter of less than 5mm) can be separated by a subsequent gravity separator. The crushing action of the jaw crusher exposes these impurities to the aggregate surface, creating conditions for deep removal. The final product's impurity content can be controlled to less than 1%, meeting the requirements for recycled concrete aggregate.

Targeted Treatment of Special Construction Waste: Technical Solutions for Complex Composition

Construction waste has a complex composition. Besides common concrete and masonry, it also includes special materials such as asphalt concrete and lightweight partition boards. Jaw crushers require equipment modifications and process adjustments to achieve targeted treatment.

The crushing and recycling of asphalt concrete requires temperature and crushing strength control. Asphalt concrete tends to become brittle at low temperatures and tends to stick at high temperatures. Therefore, the jaw crusher must be equipped with a temperature control system. When the material temperature is below 15°C, hot air heating (maintained at 20-30°C) is used to prevent aggregate brittleness. When the temperature is above 50°C, a cooling air device is activated to prevent asphalt softening and sticking to the jaw plates. Furthermore, a low crushing speed (moving jaw speed of 200-250 times/minute) is used to reduce frictional heat generated between the material and the jaw plates, ensuring the integrity of the asphalt film (facilitating the preparation of recycled asphalt mixtures). In a municipal road renovation project, the asphalt concrete recycled material processed by the jaw crusher had an asphalt content loss rate of less than 3%, allowing it to be directly used in road base construction.

The crushing and separation of lightweight partition panels relies on the principle of selective crushing. Lightweight partition panels (such as aerated concrete panels) have low compressive strength (only 3-5 MPa), significantly different from the strength of the embedded steel mesh. The jaw crusher can adjust the crushing pressure (down to 30-50 MPa) to achieve "light crushing": the aerated concrete is partially crushed into 5-20 mm particles, while the steel mesh remains intact, facilitating magnetic separation. This process achieves a 95% recovery rate for lightweight aggregate and a 98% recovery rate for steel, eliminating the problem of over-crushing and loss of lightweight materials in traditional crushing methods.

Graded crushing of mixed materials is achieved through a multi-stage jaw crusher combination. When construction waste contains a variety of materials, such as concrete, bricks, and wood, a two-stage jaw crushing process (coarse crushing + secondary crushing) is used. Coarse crushing (discharge opening 150mm) breaks down large lumps of material and separates steel bars and light impurities through magnetic separation and air separation. Secondary crushing (discharge opening 50mm) finely crushes the concrete and bricks. The resulting aggregates are separated by density (concrete density 2.4-2.5g/cm³, bricks 2.2-2.3g/cm³) using a heavy media separator and are then used to produce recycled building materials of varying strength grades.

Process System Integration: Coordinated Operation of Jaw Crusher and Ancillary Equipment

A jaw crusher does not operate independently in construction waste processing. It must form a complete system with feeding, screening, and dust removal equipment. Its performance depends on the synergistic efficiency of each link.

Interconnected feeding and crushing control ensures stable production. A material level sensor installed at the jaw crusher's feed inlet monitors material accumulation in real time and automatically adjusts the vibrating feeder's feed rate (steplessly adjustable from 0-100 tons/hour) to maintain a 70%-80% fill rate within the crushing chamber (optimal crushing). If a large, hard object (such as uncleaned steel components) is detected, the feeder immediately stops, and the jaw crusher activates its hydraulic retraction function (moving the movable jaw 50-100mm) to remove the foreign object and prevent equipment damage. Using this coordinated control system, one automated production line has increased its equipment availability to over 90%, a 30% improvement over manual operation.

A closed-loop crushing and screening system increases aggregate production. Crushed product from the jaw crusher is screened for classification. The oversize aggregate is returned to the jaw crusher via a belt conveyor for further crushing, forming a closed-loop system. The system controls the return material volume via a PLC (limited to 15%-20% of the total processing capacity) to prevent excessive return material from overloading the equipment. In one case study, this closed-loop system increased the qualified aggregate yield from 85% to 98% while reducing material waste.

The environmental protection system meets green production requirements. Dust (primarily SiO₂ and cement dust) and noise (which can reach over 100dB) generated during the crushing of construction waste are major sources of pollution. Jaw crushers must be equipped with: ① a high-efficiency dust removal system (dust hoods at the feed and discharge ports, combined with bag filters, achieving a dust removal efficiency of ≥99.9%); ② sound insulation and noise reduction devices (spring shock absorbers installed at the equipment base and soundproofing cotton wrapped around the machine body, reducing noise to below 85dB); and ③ a wastewater recovery system (wastewater from aggregate washing is treated in sedimentation tanks and then recycled, with a water recycling rate of ≥90%). A treatment plant located in an urban built-up area, using this comprehensive environmental protection system, has achieved dust emission concentrations of ≤10mg/m³ and daytime noise levels of ≤70dB, meeting environmental protection requirements for residential areas. The use of jaw crushers in construction waste management goes beyond simple crushing operations; they are a crucial component of a resource recycling system. Through targeted treatment of different types of construction waste, they transform waste from "garbage" into "renewable resources," addressing the land occupation and pollution issues associated with landfill disposal while providing the construction industry with a low-cost alternative building material. With the advancement of the "dual carbon" goals, jaw crushers are being upgraded towards intelligent features (such as AI-powered material composition identification and automatic parameter adjustment) and low-carbon features (using electric drives instead of diesel). In the future, they will play a greater role in the resource utilization of construction waste and promote the construction industry's transition to a circular economy model.