Aged municipal solid waste (MSW) refers to mixed waste that has accumulated in landfills or open dumps for extended periods, undergoing years of fermentation, leachate infiltration, and compaction. It represents a significant environmental challenge left behind by urbanization. Its screening treatment, as a core process for achieving waste reduction, harmlessness, and resource utilization, presents distinct characteristics compared to ordinary household waste screening due to the inherent properties of the material, placing extremely high demands on the adaptability and stability of screening machinery. A thorough understanding of the characteristics of aged MSW screening and the rational selection of suitable machinery are crucial for improving screening efficiency, reducing operating and maintenance costs, and promoting waste resource recovery, which has significant practical implications for ecological environment management.

The most prominent characteristic of aged MSW screening is the complex and highly mixed composition of the material, lacking clear particle size boundaries. This type of waste, after long-term accumulation, contains various components such as humus, plastics, rubber, metals, bricks, stones, aged fabrics, and glass fragments, with different components adhering to and enveloping each other, forming clumps of varying sizes. The fermented humus is in a fine powder form and easily adheres to other materials; large bricks and concrete blocks are hard and prone to causing equipment wear; and lightweight materials such as plastics and fabrics easily entangle equipment components, posing significant challenges to the screening operation. Therefore, layered screening and multi-equipment collaboration are necessary to achieve effective separation.

High moisture content and strong cohesiveness, leading to clogging and jamming, are another significant characteristic of aged MSW screening. Aged MSW is exposed to a humid environment for extended periods, with a moisture content generally ranging from 20% to 40%, and in some areas, due to leachate infiltration, the moisture content can exceed 50%. The wet and sticky humic substances will coat the surface of other materials, forming clumps. This not only clogs the screen and affects screening efficiency but also adheres to the inner wall of the equipment, leading to poor material transport, jamming, and increased manual cleaning costs. Therefore, screening machinery needs to have strong self-cleaning and anti-clogging capabilities.

Aged MSW screening also features high pollutant content and a harsh working environment. Long-term fermentation of waste produces malodorous gases, and the leachate contains heavy metals, harmful organic substances, and other pollutants. This not only corrodes screening equipment but also affects the health of operators. Simultaneously, the screening process generates a large amount of dust, requiring the use of environmental protection devices to ensure both equipment corrosion resistance and environmental protection during operation. Furthermore, aged waste exhibits a wide range of particle sizes, from fine powders of a few millimeters to large debris of several tens of centimeters, demanding high processing capacity and impact resistance from the screening machinery.

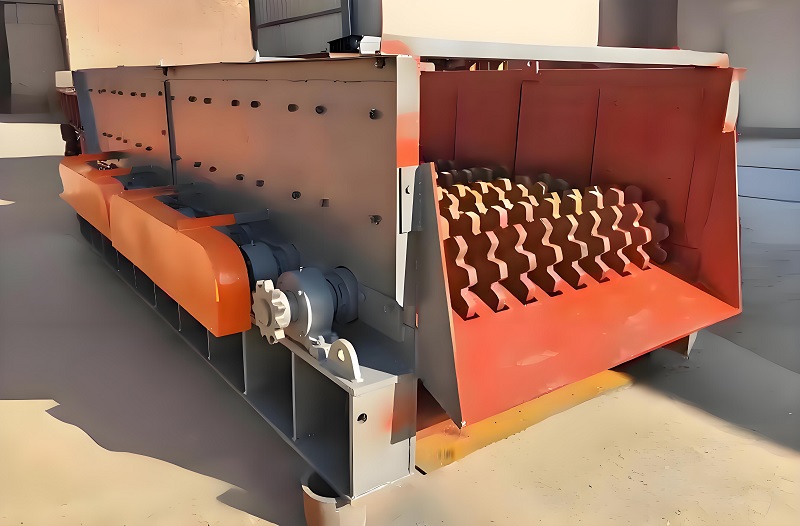

Based on these characteristics of aged waste screening, specialized screening machines with strong specificity and high adaptability are required, combined with multi-equipment collaborative operation, to achieve efficient screening. Currently, the most widely used and fundamental machine in the field of aged waste screening is the bar screen, primarily used for pre-treatment, adapting to the wet, sticky, and easily clogging characteristics of aged waste.

The bar screen uses parallel-arranged rigid bars as the screen surface. The bars are made of high-strength alloy steel, offering impact resistance, wear resistance, and corrosion resistance, capable of withstanding repeated impacts from large bricks and stones without deformation. Its open screen surface design, combined with high-frequency vibration, utilizes the vibration projection effect to automatically scrape off wet and sticky materials adhering to the bars, achieving self-cleaning and fundamentally preventing clogging. During operation, the bar screen can intercept large debris with a diameter greater than the bar spacing, such as bricks and old furniture, allowing fine and medium-sized materials to pass through, completing preliminary classification and clearing obstacles for subsequent fine screening. Its single-machine processing capacity can reach 30-250 tons/hour, meeting the large-scale needs of medium and large-sized waste treatment plants.

The shaftless trommel screen is the core machine for fine screening of aged waste, perfectly adapting to its complex composition, large particle size differences, and tendency to tangle. Compared with traditional shafted trommel screens, the shaftless trommel screen eliminates the central drive shaft, leaving the inside of the drum unobstructed, allowing materials to tumble freely and effectively preventing entanglement and jamming of materials such as plastics and fabrics. The screening machine can adopt a multi-layer design to achieve multi-stage classification, separating both fine powdery humus and medium-sized recyclable materials. It also boasts strong anti-clogging capabilities, maintaining stable operation even when processing high-humidity, highly cohesive aged waste.

For ferromagnetic recyclable materials in aged waste, a magnetic separator is required for synergistic operation. The magnetic separator utilizes the principle of magnetic field adsorption to precisely separate ferromagnetic substances such as nails, wires, and scrap steel from the waste as it passes through the magnetic field area. This achieves resource recovery and prevents metal impurities from wearing down subsequent equipment. The magnetic separator can be linked with bar screens and shaftless trommel screens, installed at the discharge end of the trommel screen, to achieve simultaneous screening and recycling. The recovery rate can reach over 95%, balancing economic and environmental benefits.

A soil and stone separator is also an important auxiliary machine in aged waste screening, mainly used to separate soil and sand components from the waste. The humus and sand in aged waste are severely agglomerated. Through high-frequency vibration and classification screening by the soil and stone separator, clean sand and gravel can be separated for recycled aggregate preparation, and the humus can be used for landscaping or composting after harmless treatment, further improving resource recovery and utilization. Additionally, some large-scale waste treatment lines will also incorporate vibrating screens for subsequent fine classification to improve screening accuracy.

Various screening machines need to work together, each performing its specific function, to form a complete aged waste screening production line: the bar screen is responsible for pre-treatment and intercepting large debris; the shaftless trommel screen is responsible for fine classification, separating materials of different particle sizes; the magnetic separator is responsible for recovering ferromagnetic materials; and the soil and stone separator is responsible for separating soil and sand. These are then combined with air separators, crushing equipment, etc., to achieve comprehensive screening and resource recovery of aged waste.

Aged waste screening presents challenges due to the complex material composition, high humidity, and high pollutant content, resulting in high anti-clogging requirements, strict equipment compatibility requirements, and harsh operating environments. Specialized machines such as bar screens, shaftless trommel screens, magnetic separators, and soil and stone separators, leveraging their respective structural advantages, are adapted to the needs of various screening stages. Through collaborative operation, they effectively solve the challenges of screening aged municipal solid waste. The rational selection and optimization of these screening machines can improve screening efficiency, reduce operating and maintenance costs, and promote the resource utilization and harmless disposal of aged municipal solid waste, contributing to ecological environment management and the development of a circular economy.