Among many waste disposal equipment, shredders occupy an important position in the field of waste sorting due to their powerful crushing ability and unique working characteristics. Shredders crush large and complex waste materials, change the physical form of the materials, and facilitate subsequent sorting, recycling and processing. They are of great significance to improving waste disposal efficiency, realizing resource recycling and environmental protection.

Application scenarios of shredders in waste sorting

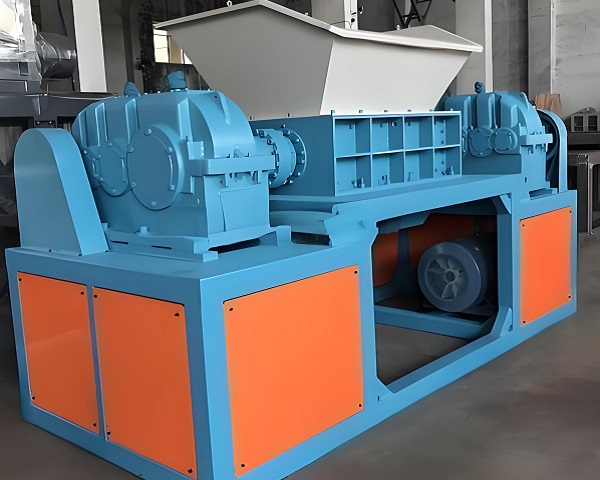

Shredder

1. Sorting of domestic waste

In the sorting of urban domestic waste, shredders are widely used. Domestic waste has complex components, including kitchen waste, paper, plastic, fabric, wood, and waste household appliances. For large-volume waste furniture, mattresses, etc., shredders can break them into smaller pieces, which is convenient for further separation of recyclable materials such as metals and plastics through magnetic separation, wind separation and other equipment. For waste household appliances, shredders can break their outer shells, internal parts, etc., so that the metals, plastics, glass and other materials in them can be initially separated to improve recycling efficiency. In addition, for some difficult-to-handle mixed waste, such as kitchen waste wrapped in plastic bags, the shredder can break it up and separate different types of waste, creating conditions for subsequent classification and treatment.

2. Industrial waste sorting

The waste generated in the industrial production process is of various types and different natures. In the plastic processing industry, the shredder can be used to process waste plastic scraps and scrap plastic products, breaking them into small particles and re-investing them in production as raw materials for recycled plastics. In the metal processing industry, the shredder can crush waste metal sheets, pipes, profiles, etc. The broken metal fragments are more convenient for transportation and remelting, thereby increasing the metal recovery rate. For waste tires and rubber products generated by the rubber products industry, the shredder can break them into rubber blocks or rubber powder for the production of recycled rubber products or other industrial purposes. In addition, in the field of electronic waste treatment, the shredder can crush waste circuit boards, electronic components, etc., so that precious metals and useful materials can be extracted through subsequent physical and chemical methods.

Shredder

3. Sorting of construction waste

Construction waste mainly includes waste concrete, bricks and tiles, stones, wood, metal, etc. In the sorting of construction waste, the shredder can crush the waste concrete blocks, bricks and tiles, etc. After screening, the crushed materials can be recycled aggregates of different particle sizes for road bases, non-load-bearing structures of buildings, etc. For recyclable materials such as wood and metal in construction waste, the shredder can crush them into suitable sizes for easy classification and recycling. By crushing and sorting construction waste, not only the amount of construction waste is reduced, but also the recycling rate of resources is improved, and the dependence on natural sand and gravel and other resources is reduced.

4. Sorting of garden waste

Garden waste mainly includes branches, leaves, trunks, etc. The shredder can crush these garden wastes into smaller pieces or debris. The processed garden waste can be used as raw materials for organic fertilizers, raw materials for biomass fuels, or used to cover the soil and improve soil structure. For example, composting crushed garden waste with other organic waste can accelerate the composting process and improve the quality of compost; using it as biomass fuel can be used in small boilers, biomass power generation and other fields to achieve energy recycling.

The key role of shredders in waste sorting

Shredder

1. Improving sorting efficiency

Shredders can break large, irregularly shaped waste materials into smaller, relatively regular pieces, changing the physical form of the waste and making it more suitable for subsequent sorting equipment to process. For example, for large-volume waste furniture, it is difficult to effectively sort it through magnetic separation and wind separation equipment before it is broken. After being broken by a shredder, the metal parts in it can be more fully exposed, which is convenient for magnetic separation equipment to separate and improve the metal sorting efficiency. At the same time, the shredder has a large processing capacity and can process a large amount of waste materials in a short time, reducing the residence time of waste in the sorting link and speeding up the speed of the entire waste sorting process.

2. Realizing refined sorting

By breaking the waste materials into a suitable particle size, the shredder creates conditions for refined sorting. In the sorting of domestic waste, after the shredder crushes the mixed waste, the waste of different materials and densities can be better separated, which improves the sorting purity of recyclables. For example, for mixed waste of plastic and paper, the difficulty of separating the two is reduced after crushing, and they can be separated more accurately by air separation, flotation and other methods. In the sorting of industrial waste, the crushing of scrap metal and plastic by the shredder helps to achieve high-precision separation of metal and plastic through subsequent screening, magnetic separation, electric separation and other processes, and improve the quality of resource recovery.

Shredder

3. Reduce subsequent processing costs

The crushing of waste by the shredder reduces the volume of waste and reduces the transportation and storage costs of waste. The crushed waste is easier to compress and pack, reducing the number of loading times of transport vehicles and the occupancy of storage space. At the same time, the waste processed by the shredder can be more fully contacted with the treatment agent in the subsequent treatment process, improving the treatment effect and reducing the treatment cost. For example, in waste incineration, the crushed waste burns more fully, which can improve the incineration efficiency and reduce the generation of pollutants such as dioxins; in landfill treatment, the crushed waste is easier to compact, which can reduce the occupation of landfill space and extend the service life of the landfill.

4. Promote resource recycling

The application of shredders in waste sorting has greatly promoted the recycling of resources. By crushing and sorting various types of waste, the recyclables can be more effectively recycled and reprocessed. In the field of domestic waste, shredders help recycle resources such as plastics, paper, and metals, reducing dependence on primary resources; in the field of industrial waste, the recycling rate of scrap metals, plastics, rubber, etc. is improved, and the production cost of enterprises is reduced; in the field of garden waste, the recycling of organic resources is realized, providing raw material support for ecological agriculture and energy industries. The application of shredders has promoted the development of the circular economy and is of great significance to the sustainable use of resources.

Shredder

5. Enhance the adaptability of waste treatment

The shredder can adapt to a variety of different types and properties of waste materials, whether it is hard construction waste, tough waste tires, or soft fabrics, plastic films, etc., all can be effectively crushed. This wide adaptability enables the shredder to play an important role in various waste treatment scenarios, enhances the overall flexibility and reliability of the waste treatment system, and can better cope with complex and changing waste treatment needs.

With its unique structure and working principle, the shredder plays an irreplaceable role in the field of waste sorting. From domestic waste to industrial waste, from construction waste to garden waste, the application of shredders runs through multiple links of waste treatment, which has a far-reaching impact on improving waste treatment efficiency, realizing resource recycling and environmental protection. With the continuous improvement of environmental protection requirements and the continuous development of waste treatment technology, shredders will also continue to innovate technology and optimize and upgrade to better adapt to the needs of future waste sorting and make greater contributions to building a green and sustainable society.