In the entire process of waste resource utilization, screening is a crucial link connecting waste collection and subsequent processing (such as crushing, incineration, landfill, and recycling). Its screening efficiency directly determines the quality of waste treatment and the resource utilization rate. As a screening equipment specifically adapted to the characteristics of waste materials, the bar screen, with its unique structural design, plays an important role in the pre-treatment screening of various types of waste, including municipal solid waste, construction waste, and industrial waste. It is mainly used to achieve the graded separation of materials of different particle sizes in waste, removing large impurities and sorting recyclable coarse materials, providing a guarantee for accurate feeding in subsequent processes. Compared with other screening equipment, the bar screen is suitable for working conditions with complex waste composition, high impurity content, and easy clogging, possessing both practicality and stability, making it one of the indispensable core equipment in waste treatment production lines.

1. Core Uses of Finger Screen in Waste Screening

The uses of Finger Screen in waste screening revolve around the needs of waste pre-treatment and grading, covering various waste treatment scenarios. The core is to achieve material grading, impurity removal, and process (process connection), improving quality and efficiency for subsequent processing steps. In municipal solid waste treatment, the bar screen is mainly used for the initial screening of raw waste, removing large and hard impurities such as large pieces of bricks and stones, old furniture, metal components, branches and trunks, preventing these impurities from entering subsequent crushing and incineration equipment, thus avoiding equipment jamming and wear, extending equipment service life, and reducing equipment downtime, thereby improving the operating efficiency of the entire production line.

For construction waste screening, the role of the bar screen is even more prominent. Construction waste contains a large amount of crushed stone, concrete blocks, and broken bricks, as well as impurities such as soil, dust, and scrap steel bars. The bar screen can grade construction waste of different particle sizes according to the needs of subsequent recycling, screening out coarse materials that meet the requirements for making recycled aggregates, which are used for road base paving, wall construction, etc., achieving the resource utilization of construction waste; at the same time, it removes fine materials such as soil and dust, and impurities such as scrap steel bars, improving the quality of recycled aggregates and reducing the difficulty of subsequent processing. In industrial waste treatment, Finger Screen are adapted to the characteristics of high-hardness and high-impurity waste, used for screening industrial waste residue and scrap materials. They separate recyclable coarse-grained materials and remove non-recyclable large impurities, providing precise feeding for incineration, landfill, or recycling of industrial waste. In addition, Finger Screen can be used for pre-treatment in landfills, removing large pieces of waste to prevent the formation of trenches and collapses, thus improving the utilization rate of landfill space. In pre-treatment before waste incineration, graded screening can select materials suitable for incineration, controlling the uniformity of feed particle size, improving incineration efficiency, and reducing harmful gas emissions.

2. Significant Features of Finger Screen in Waste Screening

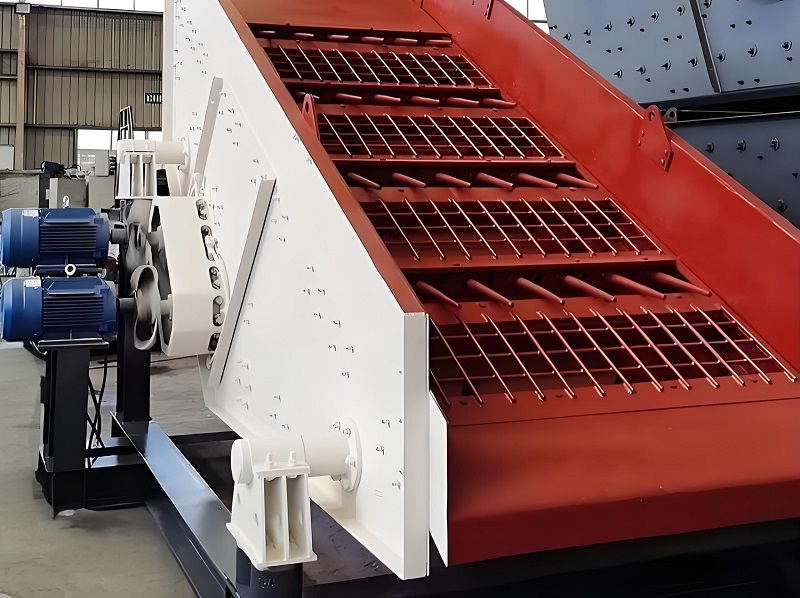

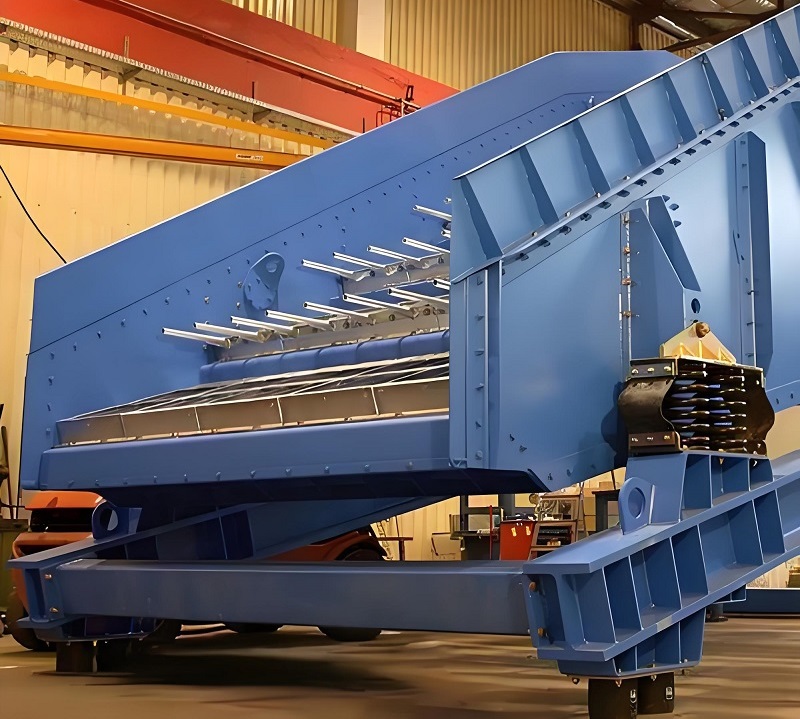

The reason why Finger Screen are widely used in the field of waste screening lies in their unique characteristics that adapt to the complex working conditions of waste. Compared with other screening equipment such as vibrating screens and trommel screens, they are more suitable for the actual needs of waste screening. Firstly, they have a simple structure and high reliability. Finger Screen mainly consist of a screen frame, bars, and a vibrating device. They have a small number of components, a compact structure, and no complex transmission mechanism. In environments with high impurity content and harsh working conditions, they are less prone to failure, have high operational stability, and can operate continuously for a long time, reducing the frequency of equipment maintenance.

Secondly, they are anti-clogging, wear-resistant, and highly adaptable. Waste often contains soil, fibrous materials, and flexible materials, which can easily cause clogging in ordinary screening equipment. However, Finger Screen have reasonable gaps between the bars, and the bar surface is smooth. The vibrating device drives the bars to vibrate at high frequency, effectively preventing material clogging, especially suitable for handling wet and sticky waste materials. In addition, the bars are made of high-strength wear-resistant steel, which can withstand the impact and wear of hard impurities in the waste, extending the service life of the equipment. They can adapt to the screening needs of different types and compositions of waste, including municipal solid waste, construction waste, and industrial waste.

Thirdly, they offer high screening efficiency and precise grading. The bar screen utilizes directional vibration generated by a vibrating device to cause waste materials to move and stratify rapidly on the screen surface. Coarse particles are intercepted by the bars, while fine particles fall through the gaps between the bars, achieving precise classification. Compared to trommel screens, the bar screen's vibration frequency can be adjusted according to material characteristics, resulting in faster screening speed and higher efficiency. Compared to vibrating screens, the bar screen's screen surface gap can be flexibly designed, allowing for adjustment of the classification particle size according to subsequent processing needs, meeting different screening requirements and providing precise material support for subsequent processes.

3. Low operating and maintenance costs and convenient operation. The bar screen has a simple structure and low maintenance difficulty. Routine maintenance mainly involves checking bar wear, tightening components, and adding lubricating oil, resulting in low maintenance workload and cost. At the same time, the equipment is easy to operate, requiring no professional operators. Starting, stopping, and adjusting the vibration frequency can be done through the control panel, making it easy to use and manage, reducing labor costs, and suitable for various waste treatment plants and recycling stations.

The finger screen's application in waste screening aligns with the core needs of waste pretreatment, serving as a fundamental tool for removing large impurities and classifying materials. It also provides a solid foundation for waste resource utilization, reduction, and harmless treatment. While adapting to various complex waste conditions, it effectively connects with subsequent processing steps. Its simple structure, anti-clogging and wear-resistant properties, and strong adaptability compensate for the shortcomings of traditional screening equipment in waste screening, such as easy clogging, rapid wear, and poor adaptability, reducing equipment operating and maintenance costs and labor input. As the waste treatment industry continues to upgrade, the bar screen will further optimize its structure and performance to adapt to more complex waste compositions, playing a more important role in improving screening efficiency and promoting the process of waste resource utilization, contributing to the high-quality development of the green and environmentally friendly industry.