As urbanization continues to advance, the number of building demolition and renovation projects is increasing, leading to a significant surge in the total amount of construction waste. Rational crushing and resource utilization have become key measures for practicing energy conservation and environmental protection, and promoting resource recycling. Construction waste is composed of a complex mix of materials, primarily concrete blocks, bricks, and reinforced concrete waste. Different materials have varying hardness, particle sizes, and crushing requirements, necessitating different types of crushing equipment. Currently, a variety of suitable models are available on the market, with the main types including mobile, jaw, impact, and cone crushers. Each type of equipment has significant differences in performance and applicable scenarios. This article will analyze the applicability of various models in detail, based on practical applications, to provide scientific guidance for selecting crushing equipment for construction waste processing.

With the acceleration of urbanization, the amount of construction waste generated from building demolition and renovation is increasing. Rational crushing and resource utilization have become important measures for energy conservation, environmental protection, and resource recycling. Construction waste has a complex composition, mainly including concrete blocks, bricks, crushed stone, and reinforced concrete waste. Different material characteristics and crushing requirements correspond to different types of crushers. Currently, there are many types of equipment suitable for crushing construction waste on the market, with the main models including mobile crushers, jaw crushers, impact crushers, and cone crushers. Each type of equipment has its own focus in terms of crushing principle, performance advantages, and applicable scenarios. The following will analyze the applicability of various crushers in detail based on actual application needs, providing a reference for construction waste crushing operations.

Mobile crushers are the preferred choice for on-site crushing of construction waste. Thanks to their flexible and convenient core advantages, they are widely used in decentralized construction waste treatment scenarios such as demolition sites, community renovations, and road repairs. This equipment does not require fixed installation and can be flexibly moved according to the work location, allowing for "on-site crushing and on-site utilization," significantly reducing construction waste transportation costs and environmental pollution. According to relevant cases, using a mobile crushing solution can save more than 30% in transportation and external processing costs. Based on the different modes of movement, mobile construction waste crushers are mainly divided into two categories: wheeled and tracked. Wheel-mounted mobile construction waste crushers, represented by the PP series impact crushers, feature a compact structure and excellent mobility. They can be quickly transported by flatbed trucks and are suitable for small and medium-sized construction waste processing projects. They can handle feed sizes up to 400-1520mm and have a production capacity of 50-250 t/h. Equipped with high-chromium blow bars and wear-resistant impact plates, they offer a high crushing ratio and excellent product particle shape. They are divided into coarse crushing and medium crushing categories, efficiently processing mixed materials such as concrete blocks and bricks. They are also flexible in configuration and easy to maintain, and can operate independently or in combination depending on crushing requirements. Track-mounted mobile crushers, represented by the MP-PH series, are multi-purpose compact equipment developed through a Sino-German joint venture. They offer even better mobility and can operate without paved roads. They can handle feed sizes up to ≤1000mm and have a maximum production capacity of 480 t/h. They can process reinforced concrete and asphalt concrete into high-quality recycled aggregates. The optional high-performance magnetic separator effectively recovers metal impurities from the material, making them particularly suitable for large-scale operations such as large demolition sites and construction waste disposal sites.

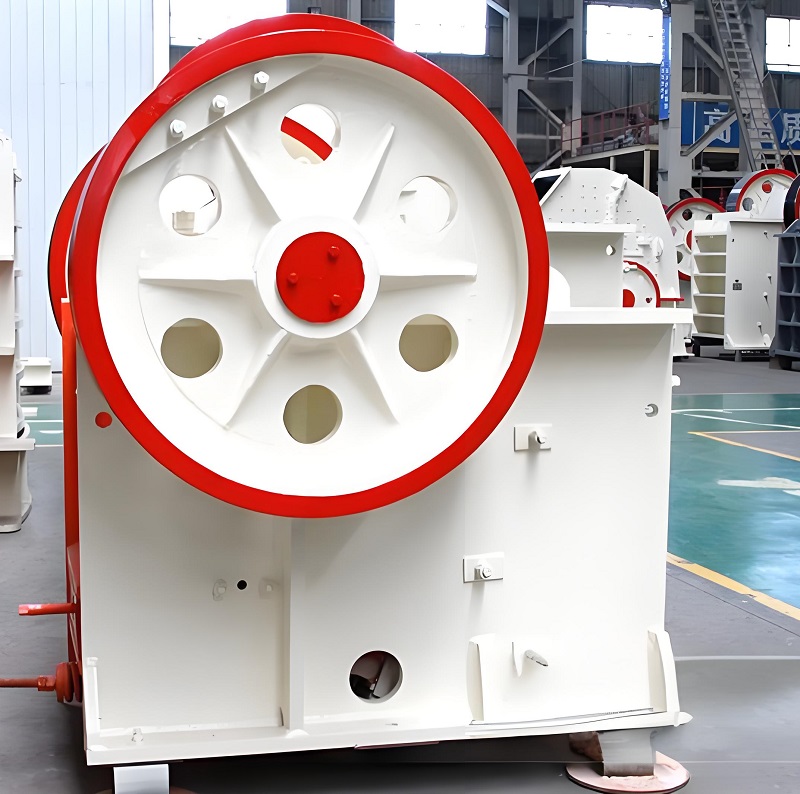

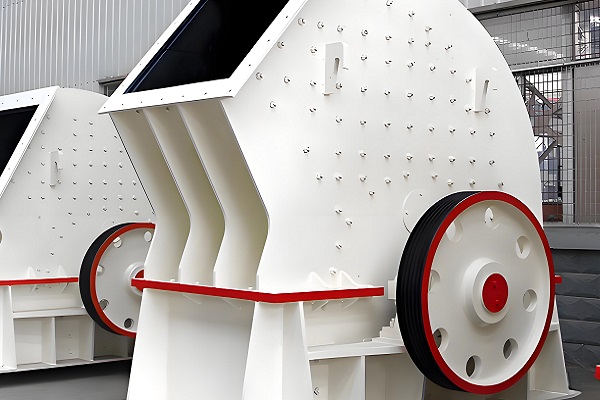

Jaw crushers are the core equipment in the coarse crushing stage of construction waste processing and the basic model for various crushing production lines. They are mainly used for the initial crushing of large pieces of construction waste, crushing concrete blocks and stones with a diameter of more than 500mm to a suitable size, laying the foundation for subsequent medium and fine crushing operations. This equipment has a simple structure, low cost, stable operation, and outstanding wear resistance. Specifically designed for construction waste containing rebar and with high abrasiveness, the dedicated jaw crusher adopts a deep cavity structure to prevent rebar jamming. The low-speed, large-stroke design enhances the tearing force on reinforced concrete blocks, and it is equipped with hydraulic adjustment and overload protection functions to quickly handle uncrushable materials and reduce downtime risks. Its jaw plates are made of wear-resistant alloy material, and the optimized wave-shaped tooth profile enhances gripping and material guiding capabilities, making it suitable for coarse crushing of construction waste of various hardnesses. It is widely used in the primary crushing stage of large-scale construction waste resource utilization projects and is often used in combination with impact and cone crushers to build a complete crushing production line. Impact crushers are primarily used for the medium and fine crushing of construction waste, processing the coarse materials from jaw crushers to further reduce them to particle sizes that meet recycling standards. They are suitable for applications requiring high-quality finished product particle shapes, such as the production of recycled concrete, recycled blocks, and road base materials. This equipment utilizes the principle of impact crushing, where a high-speed rotating rotor drives hammers to strike the material, causing the material to repeatedly collide between the hammers and the impact plates for crushing. The resulting product is cubic in shape, with low needle-like and flaky content and a reasonable gradation, effectively increasing the market value of recycled aggregates. Impact crushers are suitable for medium-hardness construction waste such as concrete blocks, bricks, and crushed stone. They offer flexible adjustment of the output particle size and have a certain shaping function. They can also handle construction waste containing small amounts of rebar; the rebar is discharged with the material after crushing, facilitating subsequent separation and recycling. They are key equipment for the fine processing of recycled aggregates from construction waste and are often paired with mobile crushers to form mobile crushing production lines.

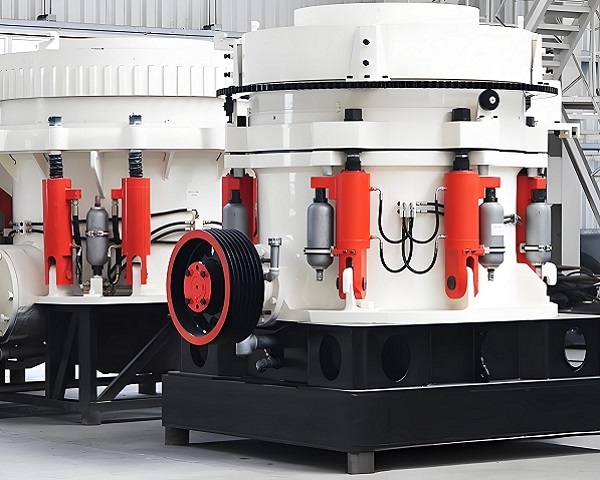

Cone crushers are suitable for the medium and fine crushing of higher-hardness materials in construction waste, especially suitable for processing high-hardness construction waste containing large amounts of reinforced concrete and basalt crushed stone, compensating for the shortcomings of impact crushers in processing high-hardness materials (fast wear and low efficiency). This equipment uses the principle of layered crushing, resulting in a stable crushing process, low noise, and low dust, meeting environmental protection requirements. The crushing chamber type can be adjusted according to the output requirements, resulting in uniform and stable finished particle sizes and a long service life of wear parts, leading to lower maintenance costs. Cone crushers have a compact structure and occupy a small footprint, making them suitable for fixed construction waste crushing production lines. They are often used in large-scale construction waste resource utilization plants to process materials coarsely crushed by jaw crushers, producing high-quality recycled aggregates for high-end building material processing.

In addition to the above mainstream models, there are various specialized equipment options to meet the specific construction waste crushing needs of different scenarios. Hammer crushers have a simple structure and high crushing efficiency. Their screenless design prevents clogging, making them suitable for small construction waste treatment plants or rural construction waste disposal scenarios, especially for crushing brittle materials such as bricks and tiles. Double-stage crushers utilize a two-stage rotor series design, offering a large crushing ratio and uniform output. Their screenless design is suitable for wet or sticky construction waste and can directly produce sand, making them ideal for projects requiring high-efficiency production of fine materials. Double-toothed roll crushers, with their compact structure, low noise, and low energy consumption, are suitable for construction sites with limited space and high requirements for finished product particle size.

The selection of construction waste crushing equipment requires a comprehensive assessment based on actual needs. Key considerations include the composition of the construction waste, crushing capacity, intended use of the finished product, operating site, and environmental requirements. If the operating sites are dispersed and frequent relocation is necessary, mobile crushers should be prioritized for on-site crushing. If coarse crushing is the main requirement and cost-effectiveness is a priority, jaw crushers are a good choice. If high-quality finished product shape is required for the fine processing of recycled aggregates, impact crushers should be prioritized. For processing high-hardness construction waste and ensuring long-term stable operation, cone crushers can be selected. Simultaneously, auxiliary facilities such as light material separators, magnetic separators, and dust removal equipment are necessary. Light material separators remove impurities such as wood chips and plastics, magnetic separators recover metal resources, and dust removal equipment controls dust pollution during the crushing process, ensuring that operations meet environmental standards.

my country's annual production of construction waste is expected to exceed 3.5 billion tons, but the resource utilization rate is still less than 60%. The rational selection of crushing equipment is crucial for improving resource utilization. With increasingly stringent environmental policies and continuous upgrades in construction waste resource utilization technology, crushing equipment is developing towards intelligence, environmental friendliness, and integration. New products such as mobile crushing and screening integrated equipment and intelligent monitoring crushing equipment are constantly emerging, not only improving crushing efficiency and product quality but also further reducing energy consumption and maintenance costs. In the future, combining the advantages of different crushing equipment to build efficient, environmentally friendly, and energy-saving construction waste crushing production lines will become the mainstream trend in construction waste resource utilization, promoting the efficient transformation of construction waste from "waste" to "recycled resources." my country's annual production of construction waste is approaching 3.5 billion tons, but its resource utilization rate remains below 60%. The scientific selection of crushing equipment is crucial to overcoming this challenge and improving resource recovery efficiency. By rationally combining various crushers and auxiliary facilities based on the composition of construction waste, crushing output, and the intended use of the finished product, it is possible to reduce processing costs and ensure the quality of recycled aggregates. With tightening environmental policies and technological advancements, crushing equipment is evolving towards intelligence, environmental friendliness, and integration. In the future, optimizing equipment combinations to build efficient and energy-saving crushing production lines will undoubtedly promote the efficient transformation of construction waste into recycled resources, contributing to the construction of green and low-carbon cities.