With increasing emphasis on waste sorting and resource utilization, garbage balers have become crucial equipment for improving processing efficiency and reducing transportation costs. Whether operating in municipal sanitation, waste recycling, or large-scale factories, choosing the right garbage baler can significantly optimize operational processes. However, with the wide variety of baler types on the market and widely varying specifications, accurately matching the right one to your needs becomes a key consideration. This article will provide a systematic guide to purchasing by analyzing core equipment parameters, comparing different types, key purchasing considerations, evaluating maintenance costs, and predicting market trends.

Core Parameters: Building a Coordinate System for Evaluating Equipment Performance

The performance of a garbage baler is determined by a number of key parameters that directly impact its ability to meet operational needs. Processing capacity is the primary consideration and should be determined based on daily waste generation. Small recycling stations processing 5-10 tons of waste per day can choose equipment that processes 1-2 tons per hour. Large sanitation centers processing over 50 tons per day require equipment with a capacity of 5 tons per hour or more. It's worth noting that the "theoretical processing capacity" listed on the equipment is often calculated based on continuous full-load operation. In actual use, a margin of approximately 20% should be reserved to avoid malfunctions caused by prolonged overload.

Baling density determines volume reduction and transportation efficiency, and density requirements vary significantly depending on the type of waste: waste paper requires a packing density of 300-500 kg/m³, plastic bottles should have a density of ≥200 kg/m³ after compression, and food waste, due to its high moisture content, typically maintains a density of 400-600 kg/m³. Insufficient packing density will increase the number of transport trips, while excessively high packing density may crush recyclables, reducing their economic value. Therefore, precise control is required based on the composition of the waste.

Power system parameters are also critical. Hydraulic balers typically operate at an operating pressure of 10-30 MPa. Higher pressures increase packing density, but energy consumption also increases. The motor power must match the equipment specifications. A 30-ton press machine typically uses a 7.5-11kW motor, while larger machines with presses exceeding 100 tons may require a power source exceeding 37kW. Furthermore, the opening size of the equipment must be adapted to the waste feeding method. Manual feeding uses an opening of 800×600mm, while mechanical loading requires a size of 1200×1000mm or larger to avoid material jams.

Type Differences: Matching Equipment Characteristics to Scrap Utilization

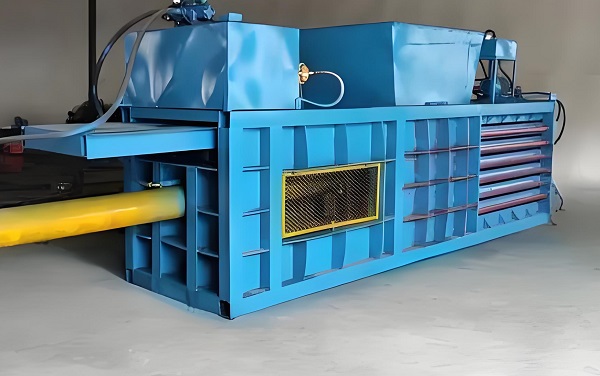

Waste balers on the market can be categorized into various types based on structure, power, and purpose, each with its own application scenarios. Vertical balers, due to their compact size (typically 2-3 meters in height) and low price (approximately 10,000-50,000 yuan), are suitable for small recycling stations or shops, and are particularly effective at handling lightweight waste such as waste paper and plastic bottles. However, their drawbacks are significant: they require manual feeding, have low baling density, and typically handle no more than 500kg per load, making them difficult to meet the needs of large-scale operations. Horizontal balers are the preferred choice for medium- to large-scale processing sites. They utilize a horizontal compression mechanism and are automatically fed via a conveyor. They can bale 1-5 tons per run, achieving a baling density 30%-50% higher than vertical models. This type of equipment has a wide price range (100,000 to 1,000,000 RMB). High-end models feature a PLC control system that automatically bundles, pushes, and provides fault alarms, significantly reducing labor costs. Horizontal balers are particularly suitable for processing bulk recyclables such as cartons and woven bags. Some enhanced models can also compress metal scrap.

Specialized models are required for specific waste types. Food waste balers must feature corrosion-resistant designs, use food-grade lubricants in their hydraulic systems, and incorporate heating devices into the compression chamber to reduce material viscosity. Medical waste balers must meet anti-leakage and anti-contamination standards and are typically equipped with double-sealed doors and sterilization ports to meet biosafety requirements. Furthermore, mobile balers (such as those mounted on trucks) are suitable for temporary processing sites, but their power and processing capacity are limited by the vehicle's power supply.

Key Points for Purchasing: From Short-Term Adaptability to Long-Term Value

When choosing a waste baler, consider more than just the equipment specifications; a comprehensive evaluation should be conducted in conjunction with the operational scenario. Site conditions are the primary limiting factor: Horizontal models require an operating space of at least 5 x 3 meters, and the floor must have a load-bearing capacity of 5 tons/m2 or higher. Vertical models are more advantageous if the site is narrow or located on a multi-story building, but ensure the floor's load-bearing capacity meets the impact forces during operation. Furthermore, the equipment should be installed near a power source (primarily 380V industrial power) and a drainage system. For hydraulic models, consider heat dissipation space.

Operating cost calculation is also crucial. Hydraulic system fuel (or electricity) consumption accounts for approximately 30%-40% of total operating costs. Choosing an energy-saving motor (such as one with IE3 efficiency rating) can reduce energy consumption by over 15%. The frequency of replacement of wearing parts directly impacts maintenance costs. High-quality brand wear-resistant liners have a service life of over 10,000 cycles, while inferior products may require replacement after only 3,000 cycles. Furthermore, labor costs can vary significantly—a fully automatic model can eliminate two to three operators. Assuming a monthly salary of 5,000 yuan per person, the price difference can be recouped in two years.

The equipment's compatibility and scalability determine its future adaptability. Choosing a modular model allows for the addition of automatic loading devices, weighing systems, or IoT monitoring modules as business grows. Equipment with standardized interfaces facilitates integration with other processing equipment (such as crushers and sorters) to build a complete processing line. Also, ensure that the equipment complies with industry standards. For example, municipal projects require certification under the "General Technical Requirements for Municipal Waste Treatment Equipment," while exported equipment must meet international standards such as CE and UL.

Maintenance and After-Sales Service: Ensuring the Equipment's Lifecycle

High-quality after-sales service can significantly extend the equipment's lifespan and reduce the risk of downtime. When purchasing, consider the manufacturer's service network coverage—whether it has a local service station, a response time of 24 hours or less, and whether key components are available within seven days. Some brands offer "lifetime maintenance" services, but be careful to see if the contract includes additional costs for parts replacement.

Easy routine maintenance is also crucial. The equipment should be equipped with easily removable protective covers, and key components (such as hydraulic cylinders and strapping mechanisms) should have access to maintenance areas. Lubrication points should be easily accessible. While automatic lubrication systems increase initial investment, they can reduce manual maintenance workload by 70%. Furthermore, choose smart models equipped with remote diagnostics, which monitor equipment status in real time via the cloud, providing early warning of potential failures and reducing the likelihood of unplanned downtime.

The stability of spare parts supply is equally important. Standard parts from mainstream brands (such as seals and hydraulic oil filters) are readily available, while specialized parts from niche brands may face supply shortages. It's recommended that the contract stipulate that the manufacturer provides a spare parts supply guarantee for at least five years, and also confirm whether spare parts rental services are available to handle emergency repairs.

Market Trends: Towards Intelligence and Environmental Protection

With rising environmental protection requirements and the application of intelligent manufacturing technologies, garbage balers are moving towards greater efficiency and greener development. Intelligent upgrades are becoming a mainstream trend. New-generation equipment is equipped with image recognition systems that automatically distinguish waste types and adjust compression parameters. Multi-machine collaboration is enabled through IoT platforms, optimizing scheduling efficiency. Some manufacturers have launched AI-assisted maintenance systems that combine vibration sensors and oil analysis technology to accurately predict faults.

Enhancing environmental performance has also become a competitive focus. New hydraulic systems use biodegradable hydraulic oil to reduce leakage pollution; motors are equipped with energy recovery devices that convert kinetic energy from the return stroke of compression into stored electrical energy; and equipment casings are constructed of recyclable steel, achieving a recycling rate of over 90%. These environmentally friendly features not only meet increasingly stringent environmental regulations but also help companies obtain green certifications and enhance market competitiveness.

When purchasing equipment, in addition to focusing on current needs, it's also important to consider development plans for the next three to five years. If you plan to expand your processing capacity, choose a model with upgrade potential. If your region is likely to introduce stricter environmental standards, prioritize equipment with superior environmental performance. Only by comprehensively evaluating technical parameters, operating costs, after-sales service and development trends can we select a garbage baler that truly suits our needs and achieve a win-win situation in terms of economic and environmental benefits.