PS: With the acceleration of urbanization and the continuous growth of population, the amount of waste generated is becoming increasingly huge. waste disposal has become an important topic of urban management and environmental protection, and waste screening, as a key link in the waste disposal process, is of self-evident importance. There are many types of waste screening stand-alone equipment, each of which has its own unique working principle and applicable scenarios, and plays a different role in waste disposal. This article will comprehensively introduce common waste screening stand-alone equipment and its functions, so as to better understand the application of these key equipment in the field of waste disposal.

Screening is the process of using a sieve to divide a group of particles with a wide range of particle sizes into several levels according to the particle size. In waste screening, waste separation and grading are mainly achieved through different types of screening equipment based on the differences in the physical properties of waste materials such as particle size, shape, density, magnetism, and conductivity. The screening process usually includes two stages: stratification and screening of materials. When the material moves on the screen surface, due to the influence of factors such as particle size, shape and density, large particles and small particles will be separated. Small particles gradually move to the lower layer and pass through the screen holes to become the under-screen products, while large particles remain on the screen surface to become the over-screen products, thereby realizing the separation of materials of different particle sizes.

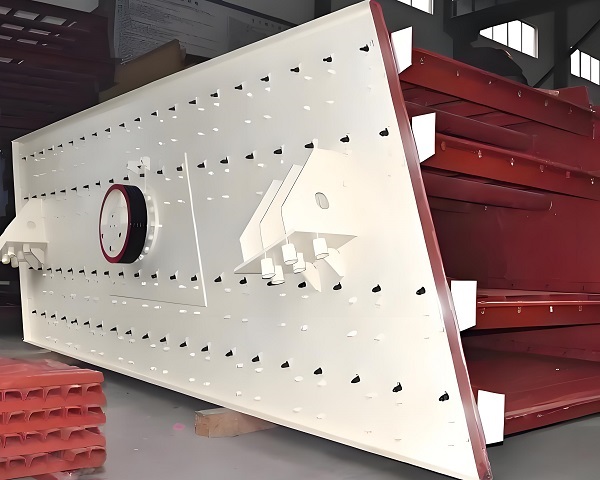

1.Vibrating screen of screening machine

Vibrating Screen

Introduction to vibrating screen: Vibrating screen is a widely used single-machine equipment for waste screening. Its working principle is based on the exciting force generated by the vibration motor or eccentric block. When the vibrating screen is working, the exciting force causes the screen box to vibrate at a high frequency. The waste material on the screen surface is constantly thrown up and falls under the action of vibration, and moves linearly or circularly along the screen surface. In this process, material particles smaller than the size of the screen hole pass through the screen hole during movement, while material particles larger than the size of the screen hole remain on the screen surface, thereby realizing the screening and grading of waste. According to different vibration modes, vibrating screens can be divided into linear vibrating screens and circular vibrating screens. The material movement trajectory of the linear vibrating screen is a straight line, which is suitable for screening fine-grained materials; the material movement trajectory of the circular vibrating screen is a circle, which has a large processing capacity and is often used for screening coarse and medium-grained materials.

Function of the vibrating screen:

waste pretreatment screening: In the pretreatment stage of the waste treatment plant, the vibrating screen can perform preliminary screening of mixed waste, separating large pieces of waste such as branches, bricks, plastic barrels, etc. from small waste such as kitchen waste and dust. By removing large pieces of waste, the wear of subsequent processing equipment can be reduced, and the operating efficiency and service life of the equipment can be improved. For example, in a waste incineration plant, after the vibrating screen screens out large pieces of non-combustibles, the waste entering the incinerator can be more uniform, the incineration effect can be improved, and problems such as inadequate incineration caused by large pieces of waste can be reduced.

Material classification: The vibrating screen can classify waste materials according to particle size according to different sieve hole sizes. In the process of waste resource utilization, the classified waste can be treated in a targeted manner. For example, the fine-grained materials after screening are used to make organic fertilizers, the medium-grained materials are used as cover materials for landfills, and the coarse-grained materials can be further crushed and reused. This precise classification can improve the efficiency and quality of waste resource utilization.

Improve sorting accuracy: The high-frequency vibration of the vibrating screen makes the materials fully dispersed on the screen surface, avoiding the blockage and accumulation of materials, thereby improving the screening accuracy. In the process of waste sorting, accurate screening can better separate waste of different particle sizes and provide a better material basis for subsequent sorting processes. For example, before metal sorting, screening the waste through a vibrating screen can better expose the metal particles and improve the recovery rate of metal sorting equipment.

2. Screening machine trommel screen

Trommel Screen

Drum screen introduction:

The trommel screen is also called a rotary screen. Its main body is an inclined cylindrical drum. There are sieve holes on the drum wall of the drum screen. When the drum rotates slowly under the drive of the drive device, the waste material enters from the high end of the drum. As the drum rotates, the material moves downward along the drum wall under the action of gravity and friction. The material particles smaller than the mesh size pass through the mesh during the movement and become the under-screen product; the material particles larger than the mesh size continue to move in the drum and are finally discharged from the lower end of the drum to become the over-screen product. The rotation speed of the drum screen is low, usually between 10 and 30 revolutions per minute, and the material stays in the drum for a long time, which can ensure sufficient screening effect.

Introduction to the role of the trommel screen:

Handling sticky waste: The drum screen has unique advantages in handling sticky waste. Because the movement of the drum screen is relatively gentle, the material keeps rolling in the drum, and the sticky material will not clog the mesh due to violent vibration like the vibrating screen. For example, when handling kitchen waste, the drum screen can effectively separate the fine particles from the large impurities in the kitchen waste, and the viscosity of the kitchen waste will not affect the screening effect.

Continuous and stable screening: The drum screen has a simple structure and stable operation, and can achieve continuous screening operations. In the waste treatment production line, the drum screen can be used as the main screening equipment to continuously screen a large amount of waste. Its stable operating performance reduces the maintenance frequency of equipment, reduces operating costs, and improves the efficiency of waste disposal.

Remove impurities: In the process of waste resource utilization, the drum screen can effectively remove impurities in the waste. For example, when the waste is used to produce building materials, the drum screen can screen out impurities such as stones and metals in the waste to ensure that the quality of the produced building materials meets the requirements. By removing impurities, the working efficiency of subsequent processing equipment can also be improved and the occurrence of equipment failure can be reduced.

3. Screening machine ballistic screen:

Ballistic Screen

Introduction to ballistic screen:

The ballistic screen is a device that uses the bouncing characteristics of waste materials for screening. Its main working part is a screen plate with a certain angle, on which a special bouncing plate or a raised structure is installed. When the waste material is transported to the screen plate of the bouncing screen through a conveyor belt, the waste material bounces on the screen plate due to the inclination angle of the screen plate and the effect of the bouncing plate. Materials with low density and good elasticity, such as plastics and paper, can jump over the gap of the screen plate during the bouncing process and become the products on the screen; while materials with high density and heavy weight, such as stones and metals, cannot jump over the gap due to gravity and directly pass through the screen plate to become the products under the screen. The bouncing screen has a unique movement mode and can achieve efficient screening according to the physical property differences of the materials.

Function of the ballistic screen:

Light material sorting: The ballistic screen performs well in the sorting of light materials and can quickly and effectively separate light materials such as plastics, paper, and fabrics from heavy materials in waste. In waste recycling, the separated light materials can be further classified, recycled and processed, such as plastics can be recycled and granulated, and paper can be recycled into recycled paper. This not only improves the recycling rate of waste resources, but also reduces the amount of waste landfill and incineration.

Improve sorting efficiency: Compared with other screening equipment, the ballistic screen has a fast screening speed and strong processing capacity. Its unique bouncing sorting principle can effectively screen a large amount of waste in a short time, greatly improving the efficiency of waste sorting. In the large-scale production line of the waste treatment plant, the bouncing screen can be used in conjunction with other screening equipment and sorting equipment to form an efficient waste treatment system.

Reduce the difficulty of subsequent processing: After the light materials and heavy materials are separated by the ballistic screen, the subsequent processing process can be more targeted. For example, for heavy materials, they can be directly crushed, landfilled, etc.; for light materials, they can be further processed by washing, drying, etc. This treatment method reduces the difficulty of subsequent processing and improves the efficiency and quality of the entire waste treatment process.

4. Wind Sifte for Screening Machines

Wind Sifter

Introduction to Wind Sifte:

The wind sorting machine is a device that uses aerodynamic principles to screen and sort waste materials according to the difference in the suspension speed of waste materials in the airflow. Its working process is to send waste materials into the sorting chamber of the wind sorting machine, and form an airflow of a certain speed and direction in the sorting chamber. Materials with low density and small particle size, such as plastic film and paper fragments, have a low suspension speed under the action of airflow and are easily carried away by the airflow, becoming light material products; while materials with high density and large particle size, such as stones and metal blocks, have a high suspension speed and quickly settle under the action of gravity, becoming heavy material products. Wind separators are usually used in conjunction with other screening equipment to improve the sorting effect.

Function of wind separators:

Separation of light and heavy materials: Wind separators can effectively separate light and heavy materials in waste, which is of great significance for the subsequent treatment and resource utilization of waste. For example, in a waste incineration plant, separating light combustible materials such as plastics and paper can improve the combustion efficiency of the incinerator and increase power generation; while separating heavy non-combustible materials such as stones and metals can reduce wear on the incinerator and reduce maintenance costs.

Recycling of light materials: Light materials separated by wind separators, such as plastics and paper, have high recycling value. These materials can be further processed to make new products. For example, recycled plastics can be used to make plastic products, and paper can be used to produce recycled paper. This not only saves resources, but also reduces pollution to the environment.

Improve the waste disposal process: The wind separator plays an optimization role in the waste disposal process. It can initially separate waste materials of different properties, making the subsequent treatment process more reasonable and efficient. For example, in a landfill, after separating light materials, the landfill volume can be reduced and the service life of the landfill can be extended; before the waste is crushed, the light materials can be removed by wind separation, which can reduce the load of the crusher and improve the crushing efficiency.

5. Screening machine magnetic separator:

Magnetic Separator

Introduction to magnetic separator:

Magnetic separator is a device that uses the magnetic difference of different components in waste materials for screening and sorting. Its working principle is based on the attraction of magnetic field to magnetic substances. When the waste material passes through the magnetic field area of the magnetic separator, magnetic materials such as iron, nickel, cobalt, etc. and their alloys will be affected by the magnetic field force, adsorbed on the magnetic pole surface of the magnetic separator or move along the magnetic force line, thereby separating from non-magnetic materials. According to the way the magnetic field is generated, the magnetic separator can be divided into permanent magnetic separator and electromagnetic magnetic separator. Permanent magnetic separator uses permanent magnets to generate magnetic fields, with simple structure and low operating cost; electromagnetic magnetic separator generates magnetic field by energizing electromagnetic coils, and the magnetic field strength can be adjusted, which is suitable for occasions with high requirements for magnetic material separation.

The role of magnetic separator:

Recycling metal resources: One of the most important roles of magnetic separators in waste disposal is to recycle metal resources. Mixed waste often contains various metal wastes, such as cans, scrap steel products, etc. Through magnetic separators, these metals can be quickly and effectively separated for recycling and reuse. After processing, the recovered metal can be reused in production, saving a lot of mineral resources, and also reducing energy consumption and environmental pollution in the metal smelting process.

Protecting subsequent equipment: Removing metal impurities from waste can effectively protect subsequent processing equipment. In the waste disposal process, metal impurities such as nails and wires may damage equipment such as crushers and screening machines, affecting the normal operation and service life of the equipment. By separating the metal impurities in advance through the magnetic separator, these equipment can be prevented from unnecessary wear and tear, reducing the maintenance cost and repair frequency of the equipment.

Improve the quality of waste disposal: After the metal is separated from the waste, the nature of the waste is more uniform, which is conducive to the subsequent treatment process. For example, in the process of waste incineration, removing metals can avoid affecting the incineration effect due to the high melting point of metals, and improve the stability and efficiency of incineration; in the process of landfilling, reducing the metal content can reduce the risk of pollution to the soil and groundwater.

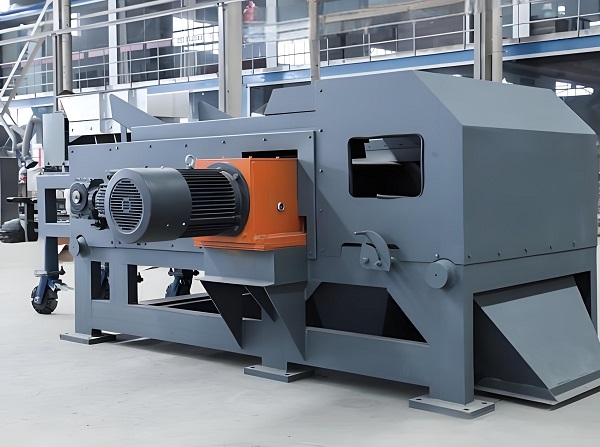

6. Eddy current separator of screening machine

Eddy Current Separator

Introduction to eddy current separator:

Eddy current separator is a device for sorting non-ferrous metals, and its working principle is based on the principle of electromagnetic induction. When conductive non-ferrous metals such as aluminum and copper enter the alternating magnetic field area of the eddy current separator, induced eddy currents will be generated inside the metal. According to Lenz's law, the magnetic field generated by the induced eddy current interacts with the original magnetic field, which will produce a repulsive force, causing the non-ferrous metal to be ejected by the outward force, thereby separating it from the non-metallic material. The magnetic field of the eddy current separator is generated by a high-speed rotating magnetic roller. The speed and magnetic field strength of the magnetic roller can be adjusted to meet the needs of sorting non-ferrous metals of different types and particle sizes.

The role of the eddy current separator:

Recycling non-ferrous metals: The eddy current separator can efficiently recycle non-ferrous metals such as aluminum and copper from waste. In modern society, non-ferrous metals are widely used, and recycling these metals has important economic value. Through the eddy current separator, non-ferrous metals in waste can be separated, and after further purification and processing, they can be put back into the production field to realize the recycling of resources.

Improve resource utilization: In waste disposal, the recycling of non-ferrous metals improves the utilization of resources. Separating non-ferrous metals that were originally regarded as waste not only reduces the waste of resources, but also reduces the dependence on primary mineral resources. At the same time, the process of recycling non-ferrous metals has the advantages of low energy consumption and low pollution compared to primary metal smelting, which meets the requirements of sustainable development.

Improve the waste sorting process: Eddy current separator is an indispensable part of the waste sorting process. It is used in conjunction with other screening and sorting equipment to achieve comprehensive recovery of various valuable components in waste. For example, after the magnetic separator recovers ferrous metals, the eddy current separator can further recover non-ferrous metals, so that the metal resources in the waste can be fully utilized, and the efficiency and economic benefits of the entire waste sorting system can be improved.

7. Optical Sorter of screening machine

Optical Sorter

Introduction of Optical Sorter :

Optical Sorter is a device that uses photoelectric devices to identify and sort materials of different colors, reflectivity and transparency. Its working process is to evenly transport the waste material to the identification area of the separator. When the material passes through the identification area, the light source irradiates the material, and the light reflected by the material is received by the photoelectric device. Materials of different properties have different degrees of reflection, absorption and transmission of light. The photoelectric device converts the received light signal into an electrical signal and compares it with the pre-set standard signal. When the difference between the detected signal and the standard signal reaches a certain degree, the control system will trigger the actuator to separate the material. The photoelectric sorter can accurately sort the material according to its color, shape, size and other characteristics.

The role of the Optical Sorter:

Accurate sorting of materials: The photoelectric sorter can achieve high-precision sorting of waste materials, especially suitable for sorting materials with obvious differences in color, shape and other characteristics. For example, in the field of plastic recycling, the photoelectric sorter can accurately separate different types of plastics according to the color and transparency of the plastic, thereby improving the purity and quality of plastic recycling.

Improve the quality of resource recycling: Through the precise sorting of the photoelectric sorter, materials with higher recycling value in the waste can be more accurately separated and the mixing of impurities can be reduced. This makes the recycled materials of higher quality and more in line with the requirements of subsequent processing, thereby improving the economic benefits of resource recycling.

High degree of automation: The photoelectric sorting machine has a high degree of automation and can operate continuously and stably. It can form a complete waste sorting production line with other automated equipment to reduce manual operations, improve production efficiency, and reduce labor intensity. At the same time, the sorting accuracy of the photoelectric sorting machine can be precisely controlled by adjusting parameters, ensuring the stability of the sorting effect.

8. Other types of waste screening stand-alone equipment

In addition to the above-mentioned common waste screening stand-alone equipment, there are some other types of equipment that also play an important role in specific scenarios. For example, the hydrocyclone uses centrifugal force and gravity to classify waste materials, which is suitable for processing materials with finer particle sizes; the shaking table realizes the sorting of materials of different densities through the reciprocating asymmetric motion of the bed surface and the action of water flow. It is often used for the sorting of metal mines and is also used in some special waste treatment. Although the application range of these devices is relatively narrow, they play an irreplaceable role in specific waste treatment processes.

PS: There are many types of waste screening equipment, each with its own unique working principle and important role. In the process of waste disposal, the reasonable selection and application of these equipment can improve the efficiency and quality of waste disposal, realize the effective recycling of waste resources, and have important significance for environmental protection and sustainable development. With the continuous development of technology, waste screening equipment will play a more important role in the field of waste disposal, providing more effective technical means to solve the increasingly severe waste disposal problem.