As a highly efficient screening device, Swing Screen are widely used in numerous industrial production processes, including mining, chemical processing, food processing, and pharmaceuticals. Choosing the right vibrating screen not only improves production efficiency but also reduces costs, bringing significant economic benefits to businesses. However, faced with the vast variety and diverse brands of vibrating screens on the market, many corporate buyers face the challenge of making the right selection and purchasing decision. The following detailed tips on selecting and purchasing a vibrating screen are provided as a reference.

Clear Your Needs

Before selecting a Swing Screen, it's crucial to first clarify your production needs; this is the foundation for making the right choice. Specifically, consider the following aspects:

Material properties are the primary consideration. Different materials exhibit different characteristics during screening, placing varying demands on vibrating screens. The particle size and distribution of the material directly influence the choice of screen. Materials with larger, more uniform particles may require a larger mesh, while materials with smaller, more widely distributed particles require a finer mesh. Material moisture is also crucial. If the material is too moist, it is prone to clumping. This requires the vibrating screen to have good anti-clogging capabilities, such as a special screen surface design or an additional screen cleaning device. Furthermore, the material's specific gravity, viscosity, and corrosiveness must also be considered. For corrosive materials, a vibrating screen made of corrosion-resistant materials, such as stainless steel, should be selected.

Production output requirements are also crucial. Companies should determine the required vibrating screen capacity based on their production scale and pace. Larger production volumes require a vibrating screen model with a higher capacity to avoid overloading, which could affect the equipment's lifespan and screening efficiency. Furthermore, fluctuations in the production process should be considered, and equipment with a certain margin should be selected to ensure continuous production.

Screening accuracy is a key indicator of vibrating screen performance. Different industries and products have different requirements for screening accuracy. For example, in the pharmaceutical industry, the screening accuracy of pharmaceutical particles is extremely high, requiring a vibrating screen to accurately separate particles of different sizes. Therefore, when selecting a vibrating screen, it's important to clearly define the required screening accuracy and review the relevant equipment parameters and actual screening performance to ensure it can meet production needs.

The installation environment is also crucial to consider. Vibrating screens require a certain amount of space, so choose an appropriately sized device based on the layout and space available in your production workshop. Also, consider the installation site's power supply, water supply, ventilation, and other conditions to ensure proper operation.

Understanding the Performance Parameters of a Swing Screen

After clarifying your needs, it's important to understand the performance parameters of vibrating screens in detail to facilitate comparison and selection. Key performance parameters include the following:

Processing capacity refers to the amount of material a Swing Screen can process per unit time and is an important indicator of equipment production capacity. Processing capacity depends on factors such as the equipment model, screen surface size, and material characteristics. When selecting a device, choose one with the appropriate processing capacity based on your production needs to avoid insufficient capacity or waste.

Screening efficiency refers to the proportion of particles in the material that a vibrating screen can separate that meet the requirements, and it directly impacts product quality. Screening efficiency is dependent on factors such as the equipment's structural design, screen quality, and motion parameters. When purchasing, choose equipment with high screening efficiency to ensure consistent product quality.

The screen size determines the particle size range of the screened material. Different screen sizes are suitable for different screening needs. When selecting a screen, choose the appropriate material and aperture based on the material's particle size and the required screening accuracy. Also, consider the screen's service life and ease of replacement.

Equipment power refers to the amount of electrical power consumed during operation by the swing screen. It depends on factors such as the equipment model and processing capacity. When selecting a device, try to choose a device with lower power, while still meeting production requirements, to reduce energy consumption and production costs.

Equipment weight and size are also important parameters to consider, as they affect installation, transportation, and layout. When selecting a device, choose one with the appropriate weight and size based on the actual installation site.

Investigate the Equipment's Structural Design

The structural design of a swing screen directly affects its performance and service life, and requires careful consideration when selecting it. This primarily includes the following aspects:

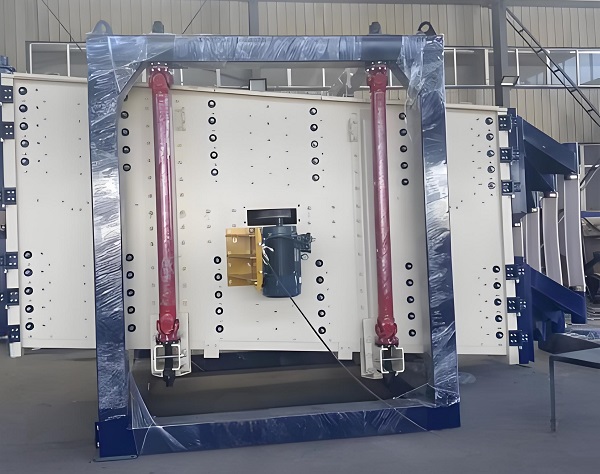

The frame is the supporting structure of the swing screen and must possess sufficient strength and stability to prevent shaking or deformation during operation. The frame is typically made of steel. Choose a frame with high-quality material and secure welding.

The screen box holds the material and screen mesh. Its structural design should facilitate material flow and screening. The tightness of the screen box is also crucial; good sealing prevents material leakage and reduces environmental pollution. Cleaning and maintenance should also be quick and easy.

The transmission system is a core component of a swing screen, responsible for driving the swinging motion of the screen box. The performance of the transmission system directly impacts the equipment's operational stability and service life. Common transmission methods include motor-driven eccentric shaft drive and hydraulic drive. When selecting a transmission system, choose one that offers smooth operation, low noise, and a low failure rate.

A screen cleaning device effectively prevents screen clogging, improving screening efficiency and screen life. Common screen cleaning devices include bouncing ball cleaning and ultrasonic cleaning. For materials prone to agglomeration or high viscosity, a swing screen with a high-efficiency screen cleaning device should be selected.

Choose a reputable manufacturer

Choosing a reputable manufacturer is crucial for ensuring the quality and after-sales service of a swing screen. When selecting a manufacturer, consider the following aspects:

The manufacturer's qualifications and reputation are primary considerations. Choose a manufacturer with legitimate production qualifications and a complete business license. Also, review customer reviews and industry reputation to gauge their credibility. Choosing a reputable manufacturer can reduce purchasing risk.

Production capacity is also a key factor in evaluating a manufacturer. Consider the manufacturer's production scale, equipment, and technical expertise. Strong manufacturers are generally able to guarantee product quality and delivery time. Also, check whether the manufacturer has a comprehensive quality control system to ensure that products meet relevant standards and requirements.

After-sales service is an essential step after purchasing equipment. Excellent after-sales service can help companies resolve problems encountered during equipment operation. When selecting a manufacturer, understand their after-sales service offerings and measures, such as equipment installation and commissioning, technical training, repair and maintenance, and spare parts supply. Choosing a manufacturer with comprehensive after-sales service can improve equipment efficiency and longevity.

Conduct an on-site inspection and test run

After initially shortlisting suitable manufacturers and products, it's best to conduct an on-site inspection and test run to gain a firsthand understanding of the equipment's performance and quality. An on-site inspection allows you to understand the manufacturer's production environment, production processes, and management level, further verifying the manufacturer's strength and reputation. During the inspection, you can communicate with the manufacturer's technical staff to understand the equipment's design principles, performance characteristics, and operating instructions.

A trial run is an important means of verifying equipment performance. During the trial run, the equipment should be operated according to normal production processes using the same or similar materials as in actual production. The equipment's operating conditions, throughput, screening efficiency, noise, vibration, and other indicators should be observed. Furthermore, all components should be checked for proper operation and any abnormalities. A trial run provides a comprehensive understanding of the equipment's actual performance, providing a basis for your final selection.

Comparing Prices and Payment Methods

While ensuring equipment quality and performance, price is also an important factor in selecting a vibrating screen. Compare quotations from different manufacturers to understand the price structure and differences, and select products with the best value for money. At the same time, be careful to avoid products that are too low in price, as this may compromise quality.

Payment methods are also important to consider. Different manufacturers may offer different payment methods, such as full payment, installment payments, and prepayment. Choose an appropriate payment method based on your financial situation and actual needs, and clearly stipulate the payment amount, payment time, and method in the contract.

Sign a Detailed Contract

After deciding to purchase a swing screen, sign a detailed contract with the manufacturer to clarify the rights and obligations of both parties. The contract should include the equipment model, specifications, quantity, price, quality standards, delivery date, installation and commissioning, after-sales service, payment method, and liability for breach of contract. Carefully read the contract terms to ensure they are legal, reasonable, and clear to avoid disputes.

Selecting and purchasing a swing screen requires comprehensive consideration of multiple factors, from clarifying your needs, understanding the equipment's performance parameters, examining the equipment's structural design, selecting a reputable manufacturer, conducting an on-site inspection and trial run, to comparing prices and payment methods, and signing a detailed contract. Every step is crucial. Only through thorough preparation and research can you select a swing screen that suits your production needs and provides strong support for your business operations.