In the huge system of waste treatment and resource utilization, the vibrating screen is like a precise "sorting master". With its unique working principle and efficient screening ability, it plays an irreplaceable key role in the waste screening process. With the increasing global attention to environmental protection and resource recycling, a deep understanding of the role of vibrating screens in waste screening is of great significance to optimizing waste treatment processes and improving resource recovery efficiency.

The working principle of the vibrating screen lays the foundation for screening

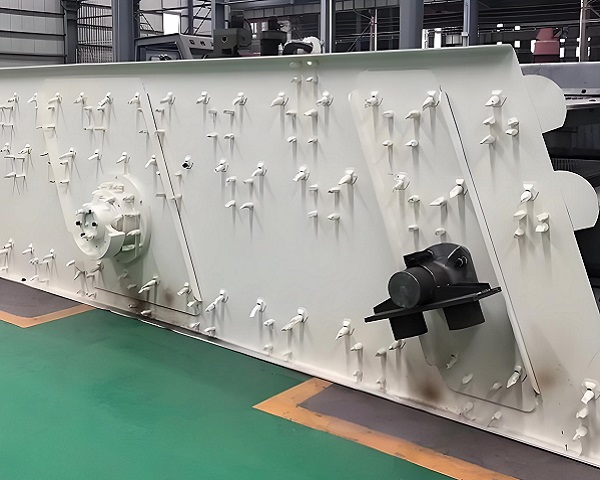

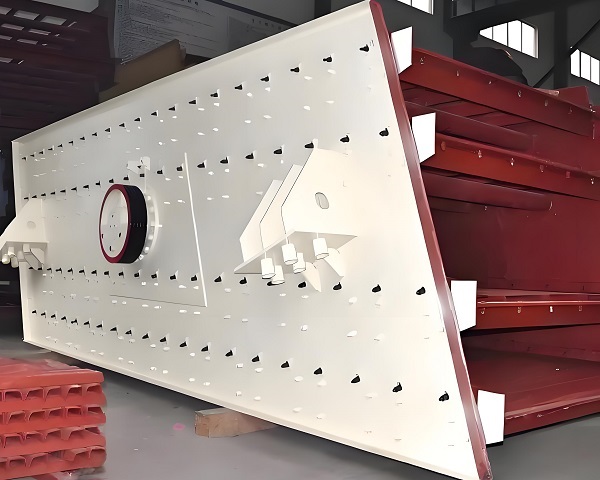

Vibrating Screen

The working principle of the vibrating screen is based on mechanical vibration. The motor drives the exciter to generate periodic excitation force, so that the screen box vibrates in a specific direction, frequency and amplitude. When the waste material is transported to the screen surface, under the action of vibration, the material is constantly thrown up and down. The smaller particle size material passes through the screen hole and becomes the undersize material, while the larger particle size material remains on the screen surface, moves along the screen surface, and finally becomes the oversize material, thereby realizing the separation of materials of different particle sizes. According to the different vibration directions and movement trajectories, common types of vibrating screens include circular vibrating screens, linear vibrating screens, etc. The screen surface of the circular vibrating screen moves in a circular trajectory, with a large projection angle, and the material jumps forward on the screen surface, which is suitable for screening coarse and medium-sized materials; the screen surface of the linear vibrating screen moves in a linear trajectory, and the material moves forward in a straight line on the screen surface, with high screening efficiency, and is often used for screening fine-grained materials and dehydration, desludging and other operations.

Preliminary screening role in the waste pretreatment stage

Vibrating Screen

Before the waste enters the formal sorting process, the pretreatment stage is crucial, and the vibrating screen bears the heavy responsibility of preliminary screening at this stage. Waste generated by industrial production and daily life is often mixed with materials of various sizes, among which large pieces of debris will not only affect the normal operation of subsequent equipment, but may also cause blockage and damage. The vibrating screen can quickly separate large pieces of material from fine particles by reasonably selecting the mesh size. For example, in the treatment of construction waste, the vibrating screen can first screen out large pieces of materials such as bricks and concrete blocks to prevent them from causing excessive wear on the equipment when entering the crusher. At the same time, it can separate sand, gravel, dust and other materials with smaller particle sizes, providing more suitable material particle sizes for subsequent crushing and sorting processes. In addition, in the pretreatment of domestic waste, the vibrating screen can initially separate fine organic matter and larger packaging materials from kitchen waste, thereby improving the efficiency of subsequent treatment. Preliminary screening effectively reduces the load of subsequent treatment equipment and ensures the stable operation of the entire waste treatment system.

Realize fine classification and separation of waste

Vibrating Screen

One of the core functions of the vibrating screen is to achieve fine classification and separation of waste, which is of great significance for improving the purity and quality of resource recovery. In industrial waste treatment, the combination of multi-stage vibrating screens can accurately classify materials according to different particle size ranges. Taking mine tailings treatment as an example, the vibrating screen can separate different mineral particles in the tailings according to particle size, so that the subsequent mineral processing process can use more appropriate methods to treat materials of different particle sizes and improve the recovery rate of useful minerals. In the field of scrap metal recycling, the vibrating screen can screen the mixed metal waste according to the size, so that different types of metals can be further separated by magnetic separation, eddy current separation and other equipment. In addition, in the process of plastic recycling, the vibrating screen can classify plastic particles of different shapes and sizes, so as to facilitate the subsequent targeted cleaning, granulation and other processing according to the particle size and shape, and improve the quality of plastic recycled products. Refined classification and separation allow various resources in the waste to be recycled more efficiently and accurately.

Improve resource recycling efficiency and quality

Vibrating Screen

The efficient screening ability of the vibrating screen directly affects the efficiency and quality of resource recycling. On the one hand, its fast screening speed and large processing capacity can enable a large amount of waste to be processed in a short time, improving the production efficiency of the entire resource recycling system. In the recycling of waste paper, the vibrating screen can quickly screen the waste paper according to different impurity content and paper quality, so that high-quality waste paper can enter the pulping process faster, shortening the waste paper recycling cycle. On the other hand, the precise screening effect ensures the quality of recycled resources. For example, in the process of recycling waste glass, the vibrating screen can accurately screen the glass fragments according to the particle size, remove the impurities and large particles that do not meet the requirements, and provide pure and uniform raw materials for the subsequent glass recycling process, thereby producing high-quality recycled glass products. By improving the efficiency and quality of resource recycling, the vibrating screen has effectively promoted the process of waste resource utilization.

Collaborative operation with other sorting equipment

Vibrating Screen

In the complete waste screening and processing system, the vibrating screen does not work in isolation, but works closely with other sorting equipment to form an efficient collaborative operation mode. When used with a crusher, the vibrating screen can screen the crushed materials, return the materials that do not meet the particle size requirements to the crusher for re-crushing, form a closed loop, and ensure that the particle size of the crushed products meets the requirements of subsequent processing. When used with a magnetic separator, eddy current separator, etc., the materials pre-screened and graded by the vibrating screen can enter these sorting equipment more evenly, improving the sorting effect. For example, in the treatment of urban domestic waste, the material that has been initially screened by the vibrating screen enters the magnetic separator to separate the ferromagnetic material, and then enters the eddy current separator to separate the non-ferrous metals, which can achieve efficient recovery of metal resources. This collaborative operation mode gives full play to the advantages of each device and improves the overall performance of the entire waste treatment system.

The vibrating screen plays a vital role in all aspects of waste screening due to its unique working principle. From the initial screening in the pretreatment stage, to the realization of refined classification and separation, to the improvement of resource recovery efficiency and quality and the collaborative operation with other equipment, the vibrating screen has demonstrated powerful functions. With the continuous advancement of technology, the performance of the vibrating screen will continue to be optimized, and it will surely play a greater role in the future field of waste treatment and resource utilization, and contribute more to the promotion of sustainable development.