Trommel screening machines play a vital role in industries such as mining, solid waste management, construction, and agriculture. They are essential for efficient material separation and processing. To maintain optimal performance and prolong equipment life, regular inspection, maintenance, and dismantling are necessary. This article provides a comprehensive explanation of the principles and procedures involved in dismantling a Trommel screen. By understanding each step—from safety precautions to reassembly—technicians and engineers can carry out dismantling operations efficiently, safely, and in a way that ensures the equipment's continued reliability.

1. Introduction

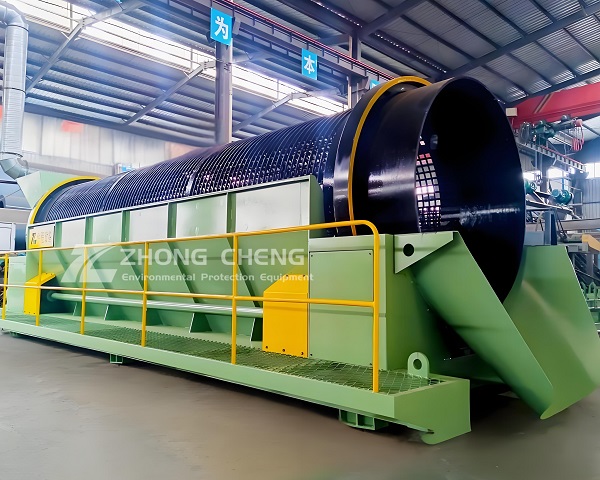

Trommel screening machines, also known simply as Trommel screens, are essential equipment in many industries, particularly in waste processing, mining, aggregate separation, compostig, and recycling. Their rotating cylindrical drums facilitate the separation of materials by size, allowing finer materials to pass through screen openings while larger objects continue along the drum’s length for further processing.

With time and usage, Trommel screens require regular maintenance, overhauls, or even component replacements. This necessitates dismantling, which involves carefully taking apart the machine in a methodical way. Dismantling is not a random disassembly; it is a structured engineering process guided by mechanical principles, safety standards, and the equipment’s design specifications.

2. Overview of Trommel Screening Machines

2.1 What is a Trommel Screen?

A Trommel screen is a mechanical screening machine that separates materials based on size. The basic components include:

Rotating cylindrical drum (the Trommel)

Frame and support structure

Feed and discharge mechanisms

Drive system (motor, gear, chain or belt)

Screening media (perforated plates or mesh)

2.2 Applications

Trommel screens are widely used in:

Municipal solid waste sorting

Mining operations

Compost screening

Sand and gravel sorting

Biomass and wood chip filtering

3. Working Principle

The Trommel operates on a rotating drum principle. Material is fed into one end of the drum. As the drum rotates, smaller particles pass through the screen holes, while larger particles are carried to the end of the drum and discharged separately. The screening efficiency is influenced by:

Rotation speed

Drum diameter and length

Screen size

Inclination angle

4. Why Dismantle a Trommel Screen?

Dismantling is performed for several reasons:

Routine maintenance: Cleaning, inspection, and lubrication

Repair: Replacing worn or damaged parts

Upgrades: Installing improved components

Relocation: Moving the machine to a different site

Decommissioning: End-of-life disposal or recycling

5. Principle of Dismantling

Dismantling a Trommel screen is based on several core principles:

5.1 Systematic Disassembly

Each part is removed in a specific sequence, starting from the outermost or easiest components to reach. This avoids damaging other parts and ensures proper reassembly.

5.2 Reversibility

The process should allow for later reassembly. Proper labeling and documentation of each removed component is essential.

5.3 Safety

Workers must use protective gear and follow lockout/tagout procedures. Mechanical parts under tension or load (e.g., springs, belts) require special care.

5.4 Tool Compatibility

Correct use of tools is critical to avoid damage to bolts, shafts, and delicate components.

6. Tools and Equipment Required

6.1 Basic Tools

Adjustable wrenches

Socket sets

Screwdrivers

Pliers

Hammers and mallets

6.2 Specialized Tools

Hydraulic pullers

Bearing extractors

Chain hoists

Torque wrenches

Welding and cutting tools (if needed)

6.3 Safety Gear

Hard hats

Gloves

Steel-toe boots

Eye protection

Hearing protection

7. Pre-Dismantling Procedures

Before starting the actual dismantling, the following steps must be taken:

7.1 Documentation Review

Consult the equipment’s technical manual to understand the assembly and identify potential challenges.

7.2 Risk Assessment

Identify potential hazards such as rotating parts, stored energy, or electrical risks.

7.3 Shutdown and Lockout

Power off the machine

Use lockout/tagout procedures

Discharge stored energy (hydraulic, pneumatic, electrical)

7.4 Cleaning

Remove any residual material from the drum and frame. This ensures visibility and cleanliness during the dismantling process.

8. Step-by-Step Dismantling Process

8.1 Remove the Protective Covers

Start by detaching any safety guards and covers. This exposes internal components like gears and shafts.

8.2 Disconnect Electrical and Control Systems

Label and disconnect wires

Isolate control panels

Store delicate electronics safely

8.3 Remove Feed and Discharge Chutes

These parts are generally bolted to the frame. Carefully unscrew and label all fasteners.

8.4 Detach Drive System

Loosen tensioners

Remove belts or chains

Unbolt motor and gearbox

Use a hoist if necessary for heavy motors

8.5 Remove Drum Support Structure

Unbolt the supporting rollers and frame arms

Detach rubber wheels or trunnion rollers

Keep track of bearing positions

8.6 Extract the Drum

The Trommel drum is often the heaviest and most delicate part. Follow these steps:

Position lifting equipment securely

Remove locking bolts or retaining rings

Carefully slide the drum off its axis

8.7 Remove Screening Media

Unbolt and slide out the perforated plates or mesh screens from inside the drum. Inspect for wear or breakage.

9. Precautions and Challenges

9.1 Heavy Components

Use proper lifting techniques and machinery to prevent injury or damage.

9.2 Rusted or Seized Bolts

Use penetrating oil or heat to loosen stubborn fasteners.

9.3 Bearing Removal

Bearings may need to be pulled off with hydraulic tools to prevent shaft damage.

9.4 Alignment

During reassembly, components must align precisely. Improper alignment can reduce efficiency or cause failure.

10. Maintenance During Dismantling

While the machine is open, it is wise to perform:

Lubrication of shafts and bearings

Inspection of drive belts or chains

Replacement of worn screen plates

Cleaning of clogged perforations

Realignment of supporting structures

11. Environmental and Safety Considerations

11.1 Oil and Grease Disposal

Waste oil from bearings or gearboxes should be collected and disposed of according to local environmental laws.

11.2 Dust and Debris

Use industrial vacuums or dust suppression to minimize airborne particles.

11.3 Noise Hazards

Some dismantling processes are noisy (grinding, hammering). Use hearing protection and isolate the work area.

12. Reassembly Principle

The reassembly process is the reverse of dismantling:

Replace damaged parts with OEM-compatible components

Reinstall drum, align and secure

Mount support rollers and check free rotation

Attach the drive system and set belt tension

Connect control wiring and test circuits

Calibrate sensors and test drum rotation

Reattach chutes and safety guards

Perform test runs with no load, then under load

13. Documentation and Reporting

Record parts replaced

Note any deviations from standard procedures

Photograph critical stages

Update maintenance logs

14. Case Study: Trommel Screen in Composting Plant

To illustrate the principle, consider a Trommel screen used in an organic composting facility. Over time, moisture, microbial activity, and heavy use degraded the screen mesh and drum bearings.

Dismantling steps included:

Draining water and organic waste

Removing the outer guard and access covers

Detaching motor and gearbox

Hoisting the drum with chain blocks

Cleaning internal residues

Replacing screen media and bearings

The plant saw a 25% efficiency improvement after reassembly due to smoother drum rotation and better screening accuracy.

15. Conclusion

The principle of dismantling a Trommel screening machine is rooted in careful planning, safety, and methodical mechanical procedures. Understanding the equipment’s design, following documented procedures, and using proper tools ensures the process is safe and efficient.

Dismantling a Trommel screening machine is a detailed and strategic process that demands technical knowledge, careful planning, and adherence to safety protocols. When executed correctly, dismantling not only supports preventive maintenance but also enhances equipment lifespan and operational efficiency. A structured approach helps identify wear points, perform critical repairs, and ensure precise reassembly. By following the principles outlined in this guide, maintenance teams can effectively manage Trommel screen upkeep and minimize downtime. This article serves as a practical and theoretical reference for engineers involved in equipment care and plant operations.