In the process of industrial production, screening operations, as a key link, directly affect product quality and production efficiency. Traditional screening equipment often exposes problems such as low efficiency, poor precision, and frequent maintenance when facing complex materials and high production demands. The new version of the swing screen launched by Zhongcheng eco has emerged in the market with its cutting-edge technology and innovative design, providing high-quality solutions for screening problems in various industries, and is expected to reshape the application pattern of screening equipment.

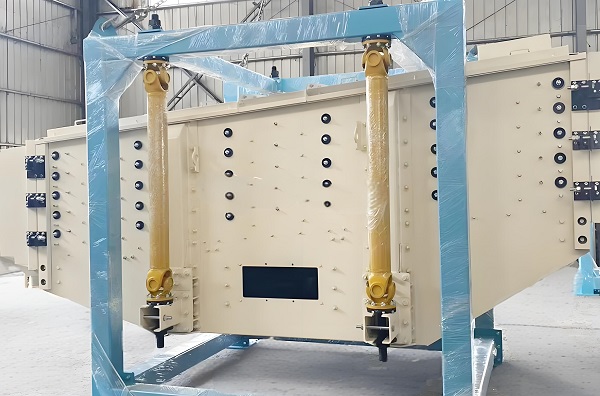

Wobbler Screen

Zhongcheng eco's new version of the swing screen abandons the traditional single vibration mode, simulates manual screening actions, and realizes a unique three-dimensional composite motion. The motor drives the eccentric device to give the screen box coordinated swing in horizontal, vertical, and inclined directions. When the material enters the screen surface, it is first evenly spread under horizontal swing to avoid local accumulation; vertical swing helps the material to be quickly layered, large particles float up, and small particles sink; the inclined swing causes the material to advance along the screen surface in a spiral trajectory, prolonging the contact time between the material and the screen, and increasing the chance of screening. Compared with the simple linear vibration of the traditional vibrating screen, the material movement path of the new version of the swing screen is more complex and reasonable, and the breakthrough in the screening principle is the foundation of its excellent performance.

1. Innovation of working principle

Wobbler Screen

Zhongcheng eco's new version of the swing screen abandons the traditional single vibration mode, simulates manual screening action, and realizes a unique three-dimensional compound motion. The motor drives the eccentric device to give the screen box a coordinated swing in the horizontal, vertical, and inclined directions. When the material enters the screen surface, it is first evenly spread under the horizontal swing to avoid local accumulation; the vertical swing helps the material to be quickly layered, large particles float up, and small particles sink; the oblique swing causes the material to advance along the screen surface in a spiral trajectory, prolonging the contact time between the material and the screen and increasing the chance of screening. Compared with the simple linear vibration of the traditional vibrating screen, the new version of the swing screen material movement path is more complex and reasonable, and the breakthrough in the screening principle is the foundation of its excellent performance.

2. Excellent screening efficiency

Wobbler Screen

a. Efficient motion trajectory design

The new version of the swing screen material forms a long-distance spiral motion trajectory on the screen surface under three-dimensional compound motion. Taking the processing of granular materials as an example, in the same time, the material travels 2-3 times the path of the traditional vibrating screen on the screen. For example, in a chemical raw material screening scenario, the processing capacity can reach 15-20 tons per hour, which is more than 50% higher than that of traditional equipment of the same specification, greatly improving the production capacity per unit time and meeting the stringent requirements of large-scale production on screening efficiency.

b. Collaborative operation of multi-layer screens

The equipment supports multi-layer screen configuration, up to 5 layers. The aperture of each layer of screen is set in descending order according to the material screening requirements, and the material is screened layer by layer from top to bottom. Taking ore classification as an example, a single screening can accurately separate a variety of products of different particle sizes, without repeated screening, reducing the process time and greatly improving the overall screening efficiency.

3. High-precision screening performance

Wobbler Screen

a. Gentle screening process

The new version of the swing screen moves relatively gently, and the material mainly rolls and slides on the screen surface, reducing the impact on the screen and reducing the risk of material damage. Screening of fragile materials such as food raw materials and pharmaceutical particles can ensure product integrity while maintaining high-precision screening. In the screening of powdered sugar, the particle size deviation can be controlled within a very small range to ensure the uniformity of the product particle size, meet the strict quality standards of the high-end food industry, and the screening accuracy can reach more than 98%.

b. Accurate screen matching and adjustment

Zhongcheng eco provides a variety of materials and different mesh screen options to adapt to the characteristics of various materials. And the screen installation design is unique, the screen tension and inclination angle can be fine-tuned, and the screening conditions can be flexibly optimized for the screening difficulties of different materials, and the screening accuracy can be further improved to ensure that the high-precision requirements of material particle size classification in different industries can be achieved.

4. Strong material adaptability

Wobbler Screen

a. Wide range of material types covered

Whether it is granular, powdery materials, or sticky materials and wet materials, the new version of the swing screen can effectively handle them. For sticky materials, by configuring a special anti-sticking screen and combining it with the unique movement of the equipment, the material is not easy to adhere to the screen and maintain normal screening; for wet materials, the screen aperture is appropriately increased and the movement parameters are adjusted to prevent the material from clogging the screen holes due to water aggregation. It has been successfully applied to complex working conditions such as wet ore screening in the mining industry and sticky raw material processing in the chemical industry.

b. Customization of applications in different industries

In view of the differences in material characteristics and production processes in industries such as chemical, food, and mining, Zhongcheng eco's new version of the swing screen provides customized solutions. The food industry uses food-grade stainless steel to ensure that the equipment meets hygiene standards; the mining field strengthens the structural strength of the equipment to adapt to harsh production environments and large processing volume requirements; the chemical industry uses corrosion-resistant materials to make key components based on the chemical properties of the materials to ensure stable operation of the equipment and expand the application boundaries of the equipment.

5. Convenient maintenance

Wobbler Screen

a. Modular structure design

The equipment adopts a modular concept, and each functional component such as the screen box, drive device, and screen cleaning system is independently designed for easy disassembly and installation. When a component fails, the corresponding module can be quickly replaced without disassembling the equipment as a whole, greatly shortening the maintenance time. For example, it only takes 15-20 minutes to replace the screen on the new version of the swing screen, while traditional equipment often takes 1-2 hours, which effectively improves the utilization rate of the equipment.

b. Long life and easy access to wearing parts

Key wearing parts such as screens and bearings are made of high-quality materials and are treated with special processes to significantly extend their service life. Taking the screen as an example, compared with the traditional screen, the life of the new version of the swing screen can be increased by 2-3 times. At the same time, Zhongcheng eco has established a complete parts supply system, with sufficient inventory of wearing parts, and customers can obtain them in time to ensure the continuous and stable operation of the equipment.

6. Environmental protection and energy-saving advantages

Wobbler Screen

1. Low energy consumption drive system

The new version of the swing screen uses a high-efficiency energy-saving motor with an optimized transmission device to reduce the energy consumption of the equipment. According to tests, under the same production scale, its energy consumption is 30%-40% lower than that of the traditional vibrating screen. At the moment when energy conservation and emission reduction are advocated, it saves a lot of electricity expenses for enterprises, which is in line with the concept of green production.

2. Fully sealed and dust removal design

The equipment adopts a fully sealed structure to reduce dust spillage during material screening. At the same time, it is equipped with a professional dust removal interface, which can be easily connected to the factory dust removal system to effectively collect and treat the dust generated by screening, improve the working environment of the workshop, reduce dust pollution, comply with environmental protection regulations, and protect the occupational health of workers.

7. Practical application case results

Wobbler Screen

a. Chemical industry case

A large chemical company produces plastic particles. In the past, it used traditional screening equipment with low screening efficiency and poor accuracy, and a large number of unqualified products needed to be reworked. After introducing the new version of Zhongcheng eco swing screen, the screening efficiency increased by 60%, the product particle size accuracy reached 99%, the rework rate decreased by 80%, and the annual production cost was saved by more than 1 million yuan, and the product market competitiveness was significantly enhanced.

b. Food industry case

When a food processing company screened flour, it was limited by traditional equipment, and the flour was easy to agglomerate and the screening was not thorough, affecting product quality and production efficiency. The new version of the swing screen, with its gentle screening and high-precision characteristics, effectively solves the problem of flour agglomeration, improves screening efficiency by 50%, steadily improves product quality, meets the needs of the high-end food market, and increases the company's order volume by 30%.

Zhongcheng eco's new version of the swing screen has many advantages, such as innovative working principle, efficient screening, high precision, strong adaptability, convenient maintenance, and environmental protection and energy saving, showing great application potential in various industries. It can be seen from actual application cases that it brings significant economic and environmental benefits to enterprises, and effectively promotes the efficient and green development of industrial production. Looking to the future, with the continuous iteration of technology, Zhongcheng eco's new version of the swing screen is expected to expand its application in more fields and lead the new trend of screening equipment technology development.