Jaw crusher is a common primary crushing equipment. It crushes materials through the relative squeezing and rolling action of the moving jaw and the static jaw ......

What is the Swing Screen for Sale

As a highly efficient and fine screening equipment, the swing screen(gyratory screen) is widely used in many fields such as chemical industry, food, mining, etc. Its unique working principle simulates the action and process of manual screening, and realizes accurate screening of materials through a unique three-dimensional elliptical motion trajectory.

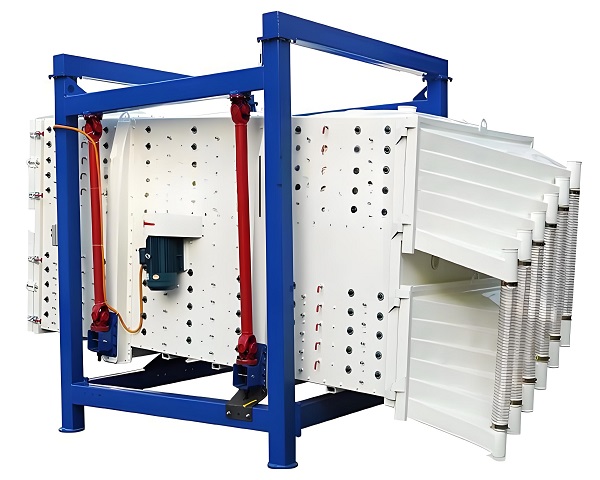

Structurally, the swing screen is mainly composed of a screen box, a drive device, a screen mesh, etc. The drive device generates an exciting force through an eccentric block, driving the screen box to make a three-dimensional elliptical motion, so that the material is displaced in three directions: horizontal, vertical, and inclined on the screen surface. This composite motion allows the material to be quickly and evenly dispersed on the screen surface, greatly improving the screening efficiency.

Compared with traditional screening equipment, the swing screen has significant performance advantages. First, the screening accuracy is extremely high, reaching more than 95%, which can meet the screening needs of various fine materials; second, the processing capacity is large, and the amount of material that can be processed per unit time is far more than that of ordinary screening equipment; third, the equipment runs stably, has low noise, and is easy to maintain, effectively reducing production costs and workers' labor intensity. In addition, the oscillating screen can flexibly adjust the screen angle, amplitude and vibration frequency according to different material characteristics and screening requirements to achieve customized screening.

In practical applications, the oscillating screen performs well. In the chemical industry, it can be used to screen and grade materials such as fertilizers and resins; in the food industry, it can finely screen flour, powdered sugar, etc. to ensure product quality; in the mining field, it is also effective in grading and screening ores. With its excellent performance and wide applicability, the oscillating screen has become an indispensable and important equipment in modern industrial production.

Operating principle of Swing Screen for Sale

The working principle of the swing screen(gyratory screen) is based on a unique mechanical motion and screening structure design. By simulating manual screening actions, efficient and fine material classification is achieved.

Its core motion mode is three-dimensional elliptical motion, that is, the screen box forms an elliptical trajectory under the superposition of horizontal circular motion and vertical up and down motion. The screen drive device drives the main shaft to rotate, and the eccentric block of the main shaft generates centrifugal force, which prompts the screen box to make elliptical motion along the set direction. Under this motion mode, the material not only has horizontal displacement on the screen surface, but also produces up and down jumps, simulating the action of the material being thrown up, falling, and sliding during manual screening.

The coordination of the screen surface angle and motion parameters is the key to achieving accurate screening. The screen surface usually maintains a certain inclination angle, combined with the adjustment of parameters such as the speed and eccentricity of the screen machine, to control the movement speed and residence time of the material on the screen surface. When a smaller screen hole is used to process fine materials, a slower movement speed and a smaller jump amplitude will be used to allow fine particles to have sufficient time to pass through the screen hole; a large screen hole screen surface that processes coarse materials will increase the movement speed and jump amplitude, and speed up material transportation and screening efficiency.

During the screening process, the material enters the screen box from the feed port, and after falling on the screen surface, it keeps rolling and jumping under the action of three-dimensional elliptical motion. Fine particles that meet the size of the screen holes pass through the screen and become underscreen materials, while larger particles move to the discharge port under the movement of the screen surface and are finally discharged as overscreen materials. In addition, factors such as the tension of the screen and the sealing structure of the screen box will also affect the screening effect and the stability of equipment operation.

The swing screen simulates the efficient action of manual screening through ingenious mechanical motion design and parameter control, and realizes the precise classification of materials of different particle sizes and properties, playing an important role in many fields such as chemical industry, food, and mining.

Advantages and features of Swing Screen for Sale

In the field of industrial production, material screening is an indispensable key link, and the swing screen (gyratory screen)stands out with its unique design and excellent performance. The swing screen simulates the manual screening action and process, so that the screen surface produces three-dimensional spatial movements such as horizontal rotation, projection, and vibration. This innovative movement mode gives it many significant features and advantages.

The most prominent advantage of the swing screen is its ultra-high screening accuracy. Its unique motion trajectory can make the material evenly dispersed on the screen surface and fully contact the screen, effectively avoiding the problem of material accumulation and clogging of the screen holes. The screening accuracy can reach more than 95%, far exceeding traditional screening equipment. Taking the fine chemical industry as an example, for powder materials with small particle size differences, the swing screen can accurately separate them to ensure the stability and uniformity of product quality.

In terms of screening efficiency, the swing screen also performs well. Its processing capacity is 1.5-2 times that of ordinary vibrating screens, and it can process more materials per unit time. This is due to its scientific motion parameter design. The movement speed and trajectory of the material on the screen surface are optimized, so that the material can pass through the screen surface quickly and achieve efficient screening. In the ore processing industry, facing a large number of ore raw materials to be screened, the swing screen can greatly improve production efficiency and reduce the production cost of the enterprise.

The maintenance cost of the swing screen is low. Its structural design is reasonable, and the key components are made of high-strength and wear-resistant materials with a long service life. At the same time, the equipment has low vibration and low noise during operation, which reduces the impact and wear on the equipment parts, and reduces the failure rate and maintenance frequency of the equipment. Daily maintenance work is simple and easy, and no professional personnel are required to operate frequently, which further saves manpower and maintenance costs.

The swing screen also has a wide range of applicability. It can flexibly adjust the parameters such as the screen surface inclination, amplitude, vibration frequency, etc. according to the characteristics and screening requirements of different materials. It is suitable for the screening of various forms of materials such as particles, powders, and mucus. It can play an important role in many industries such as food, medicine, and building materials.

The swing screen has become an ideal choice in the field of industrial screening with its high precision, high efficiency, low maintenance cost

Technical Parameter Table of Swing Screen for Sale

| Model | Screen Diameter (mm) | Screen Layers | Screening Area (m²) | Capacity (kg/h) | Motor Power (kW) | Vibration Frequency (rpm) | Dimension (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| SS-600 | 600 | 1–3 | 0.28 | 100–1500 | 0.75 | 180–260 | 900×900×1200 |

| SS-1000 | 1000 | 1–5 | 0.75 | 200–3000 | 1.5 | 180–260 | 1460×1460×1580 |

| SS-1200 | 1200 | 1–5 | 1.13 | 500–5000 | 1.5 | 180–260 | 1800×1800×1650 |

| SS-1500 | 1500 | 1–5 | 1.75 | 800–8000 | 2.2 | 180–260 | 2200×2200×1720 |

| SS-1800 | 1800 | 1–5 | 2.54 | 1200–12000 | 3.0 | 180–260 | 2500×2500×1800 |

| SS-2000 | 2000 | 1–5 | 3.14 | 1500–15000 | 4.0 | 180–260 | 2700×2700×1900 |

If you have any special requirements, we will customize according to your special needs.

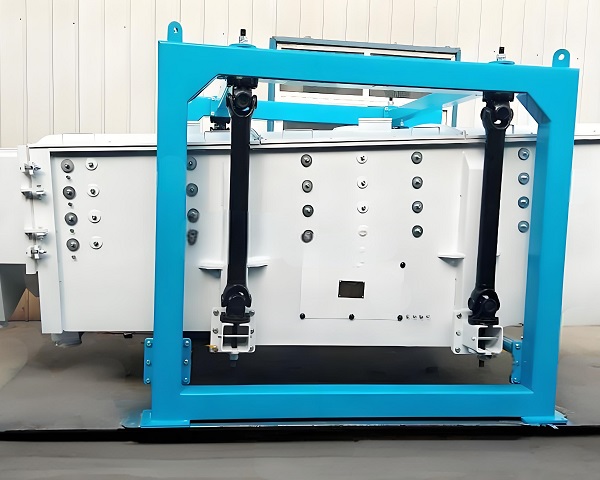

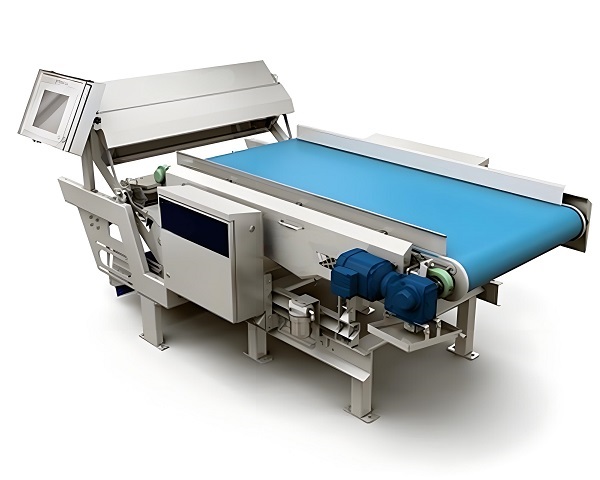

Product Picture Display of Swing Screen for Sale

FAQ about Swing Screen for Sale

What are the main structural components of the Swing Screen?

It is mainly composed of screen box, screen mesh, transmission device, frame and other parts. The screen box carries the screen mesh for screening materials, the transmission device gives the screen box movement, and the frame plays a supporting and fixing role.

What industries are the Swing Screen suitable for?

It is widely used in food, medicine, chemical industry, building materials, minerals and other industries, and can screen, grade, remove impurities and other operations on materials in different forms such as particles, powders, mucus, etc.

What is the difference between the Swing Screen and ordinary vibrating screen?

The Swing Screen simulates manual screening, with a softer motion trajectory and higher screening accuracy, which can reach more than 95%; ordinary vibrating screens vibrate violently, with a large processing capacity but low accuracy, and are suitable for rough screening.

> What is the screening accuracy of the Swing Screen?

The Swing Screen optimizes the material movement trajectory and reduces the blockage of the screen holes. The screening accuracy can reach more than 95%, and it can accurately separate materials with small particle size differences.

> What is the processing capacity of the Swing Screen?

Its processing capacity is 1.5-2 times that of ordinary vibrating screens. It can process more materials per unit time and can effectively meet the needs of large-scale production.

>What materials can Swing Screen handle?

It can handle particles and powder materials ranging from a few microns to tens of millimeters, such as flour, powdered sugar, quartz sand, chemical raw materials, etc., and can also perform solid-liquid separation on mucous materials.

>How to choose the screen of Swing Screen?

The screen material (stainless steel, polyurethane, etc.), mesh number and weaving method should be selected according to the material characteristics (particle size, hardness, humidity, etc.) and screening requirements to ensure the screening effect and screen life.

>Is the operation noise of Swing Screen loud?

It has small vibration and low noise during operation. Compared with traditional screening equipment, it has less impact on the working environment and meets environmental protection and occupational health requirements.

>How to install and debug Swing Screen?

During installation, it is necessary to ensure that the frame is horizontal and stable, connect various components and check the operation of the transmission device; during debugging, adjust the parameters such as the screen surface inclination, amplitude, frequency, etc. to achieve the best screening effect.

>What are the key points of daily maintenance of Swing Screen?

It is necessary to regularly check the wear of the screen and the tightness of the connection of each component, clean the residual material on the screen surface, keep the equipment clean, and regularly lubricate and maintain the transmission parts.

>What are the vulnerable parts of Swing Screen?

The main vulnerable parts are screen, transmission belt, bearing, etc. The screen is easy to wear due to direct contact with the material, and the belt and bearing will also age and damage during long-term operation.

>What should I do if the screening efficiency of Swing Screen decreases?

It may be that the screen is blocked, the screen surface inclination is not appropriate, or the vibration parameters are abnormal. The screen needs to be cleaned, the parameters need to be adjusted, and the equipment needs to be checked for faults.

>Can Swing Screen be customized?

Yes. According to the user's material processing volume, screening accuracy, installation space and other requirements, the screen surface size, number of layers, material and automatic control function can be customized.

>Is the energy consumption of Swing Screen high?

Compared with similar screening equipment, Swing Screen has stable operation, high movement efficiency and low energy consumption, which can effectively reduce the production cost of enterprises.

>Can Swing Screen realize automatic operation?

Yes. It can be equipped with automatic feeding, discharging, screen cleaning and other devices, combined with PLC control system, to realize full process automation and reduce manual intervention.

>How long is the service life of Swing Screen?

Under normal use and maintenance, the service life of Swing Screen can reach 5-8 years, and the service life of key components such as screen box and frame is longer.

>How does Swing Screen ensure the hygiene of screening?

The equipment is mostly made of stainless steel, with a smooth and easy-to-clean surface; the sealing design prevents material leakage and external contamination, and meets the hygiene standards of food, medicine and other industries.

>What is the price range of Swing Screen?

The price varies depending on the equipment specifications, configuration, material and customization requirements. Small and simple models may cost tens of thousands of yuan, and large customized equipment may cost hundreds of thousands of yuan.

The above 20 questions and answers cover the key information of Swing Screen. If you want to learn more about some of the answers, or have other questions, you can tell me at any time.