A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Optical Sorting Machine

Optical Sorting Machine is a high-precision automatic sorting equipment based on image recognition and intelligent control technology. It is widely used in solid waste recycling, food processing, plastic sorting, mineral metallurgy, agricultural processing and other fields. The equipment uses high-resolution optical sensors (such as CCD cameras, near-infrared NIR, short-wave infrared SWIR) and high-speed jet systems, combined with image recognition and artificial intelligence algorithms, to achieve rapid recognition and automatic separation of multi-dimensional features such as material color, shape, size, surface defects and material.

The working principle of the optical sorting machine mainly includes three core links: material supply, optical recognition and airflow removal. First, the material is transported to the conveyor belt or free fall area through a uniform feeding device and enters the optical recognition area; then, the high-speed camera or multi-spectral imaging device scans the material frame by frame, and identifies and analyzes its appearance characteristics or material through the image processing system; finally, the control system determines which materials should be retained or removed, and quickly controls the corresponding jet valve action to remove impurities or foreign matter that do not meet the standards, thereby achieving automatic sorting.

Modern optical sorting machines use advanced AI deep learning technology, which can continuously optimize recognition models and adapt to complex and diverse sorting needs. It can not only accurately distinguish plastics of different colors and materials, and separate organic and inorganic substances, but also detect spots, mildew, foreign matter and other defective products in food industries such as fruits, vegetables, nuts, and grains, effectively ensuring product quality and safety.

Compared with traditional manual or mechanical sorting methods, optical sorting machines have many advantages such as high precision, fast speed, high efficiency, low pollution, and manpower saving. Its sorting accuracy can reach more than 99%, and its processing capacity ranges from several tons to tens of tons per hour, which is suitable for various production scales from small workshops to large industrial assembly lines.

The equipment has a compact structure and modular design for easy installation and maintenance. It can be configured with a variety of functional modules according to different customer needs, such as dust removal system, metal detection, electromagnetic sorting, etc., to further expand its application range and sorting effect.

Optical sorting machines are one of the core equipment for realizing industrial automation and intelligent sorting, and play an increasingly important role in many industries such as environmental protection, food, and resource recycling.

Operating principle of Optical Sorting Machine

Optical Sorting Machine is an efficient and automated equipment that uses optical recognition and intelligent control technology to realize automatic identification and separation of materials. Its working principle is mainly based on physical characteristics such as color, shape, size and material. It uses high-speed image acquisition system and intelligent algorithm to make real-time judgments to achieve accurate sorting. It is widely used in solid waste recycling, food processing, ore processing, plastic classification and other fields.

The core components of the photoelectric sorting machine include feeding system, optical detection system, image processing system, blowing system and control unit. First, the material is evenly distributed on the conveying path through a conveyor belt or a vibrating feeding device to form a single-layer fluidized state, which is conducive to subsequent identification.

Next, the optical detection system starts working. The system usually consists of a high-resolution industrial camera, an LED light source and a spectral sensor, which can capture the image information of each material particle in real time. Some high-end equipment is also equipped with near-infrared (NIR), short-wave infrared (SWIR) or multi-spectral imaging systems to analyze the reflectance spectrum of the material to distinguish material differences. For example, the type of plastic can be identified by NIR, and different colors of glass or food can be distinguished by a color camera.

After image acquisition, the data is immediately transmitted to the image processing module. This module usually integrates artificial intelligence (AI) algorithms and machine learning models to perform high-speed identification, classification and defect judgment on each object. The processing system will set screening criteria, such as color mismatch, foreign matter, damage or size mismatch. Once the non-compliant material is identified, the system will instruct the spraying device to start in real time.

The spraying system usually uses a high-pressure airflow nozzle to complete precise spraying within milliseconds according to the signal sent by the processor, and remove the unqualified materials from the normal materials. Its response speed is extremely fast and suitable for large-flow continuous operation. In high-end equipment, tens of thousands of particles can be processed per second to ensure high efficiency and high precision.

The control system is responsible for the coordinated operation of various parts, recording production data, supporting remote monitoring, data export and parameter setting. Some equipment can also be connected to the production management system through the network to meet the needs of digital factories.

Optical Sorting Machine realizes accurate identification and efficient sorting of materials through the coordinated work of optical recognition, image processing and intelligent spraying system, which not only improves product quality and resource utilization, but also significantly reduces labor costs. It is an indispensable intelligent device in modern sorting technology.

Advantages and features of Optical Sorting Machine

Optical Sorting Machine is an automated sorting equipment based on image recognition and intelligent analysis technology. It is widely used in solid waste treatment, food grading, plastic recycling, mineral screening, metal identification and other industries. It uses high-precision sensors (such as RGB cameras, near-infrared NIR, short-wave infrared SWIR, X-rays, etc.) to detect multi-dimensional features of materials, and combines high-speed airflow nozzles to achieve intelligent rejection and grading.

1. The optical sorting machine has extremely high recognition accuracy. With the help of advanced image processing technology and artificial intelligence algorithms, the equipment can identify material characteristics such as color, shape, size, transparency, and material in real time. For complex mixed materials, such as plastic bottles and metal impurities, glass fragments of different colors, and organic and inorganic solid waste, the optical sorting machine can achieve accurate recognition and efficient classification, with an accuracy rate of more than 95%.

2. High sorting efficiency and strong processing capacity. The equipment adopts continuous feeding and multi-channel image processing system, combined with a high-speed response jet control system, to achieve rapid processing of large quantities of materials while maintaining high precision. The common model can process several tons to more than ten tons per hour, which greatly improves production efficiency and is suitable for industrial large-scale sorting scenarios.

3. The system is highly intelligent and easy to operate. Most photoelectric sorting equipment is equipped with a touch operation interface, which can monitor the operating status in real time, set classification parameters, and support automatic calibration and remote diagnosis functions. Users can easily debug and manage without complex technical backgrounds, which greatly reduces the operating threshold and labor costs.

4. The photoelectric sorting machine has good adaptability and modular design. Users can freely configure different types of sensors (such as infrared, ultraviolet, X-ray, laser, etc.) and blowing modules according to material types and sorting requirements, and even integrate AI intelligent learning systems to achieve complex sorting strategies and self-optimization capabilities to adapt to a variety of complex application scenarios.

5. The equipment is environmentally friendly and energy-saving, and easy to maintain. The photoelectric sorting machine adopts a non-contact identification method, without mechanical wear and dust pollution during operation, supports closed or negative pressure environment installation, and meets modern environmental protection standards. At the same time, it has a compact structure, a long maintenance cycle, low operating costs, and is suitable for long-term stable operation.

Optical Sorting Machine have become key core equipment in modern sorting and recycling systems due to their advantages of accurate identification, high efficiency, intelligence, wide applicability, environmental protection and energy saving. They play an important role in promoting resource recycling and sustainable development.

Technical Parameter Table of Optical Sorting Machine

| Model | Sorting Width (mm) | Capacity (t/h) | Detection Technology | Resolution (mm) | Air Jet Nozzles | Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| OSM-600 | 600 | 1–2.5 | RGB + NIR | 0.2 | 64 | 1.5 | 1800×1000×1600 |

| OSM-900 | 900 | 2–4 | RGB + NIR + AI | 0.2 | 96 | 2.2 | 2000×1300×1700 |

| OSM-1200 | 1200 | 3–6 | RGB + SWIR | 0.2 | 128 | 3.0 | 2200×1500×1800 |

| OSM-1600 | 1600 | 4–8 | Multispectral + AI | 0.2 | 160 | 4.0 | 2400×1800×1900 |

| OSM-1800 | 1800 | 5–10 | Full-Spectrum + AI | 0.2 | 192 | 4.5 | 2600×1900×2000 |

| OSM-2100 | 2100 | 6–12 | Multisensor Fusion | 0.2 | 224 | 5.5 | 2800×2000×2100 |

| OSM-2400 | 2400 | 7–14 | RGB + NIR + X-Ray | 0.2 | 256 | 6.5 | 3000×2200×2200 |

If you have any special requirements, we will customize according to your special needs.

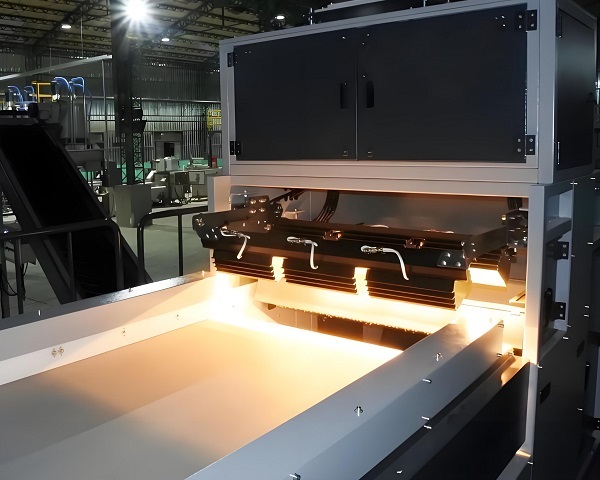

Product Picture Display of Optical Sorting Machine

FAQ about Optical Sorting Machine

>1. How long is the return on investment of Optical Sorting Machine?

In the recycling industry or food processing field, the optical sorting machine can greatly improve the sorting efficiency and purity, reduce labor and material loss, and usually recover the investment cost in 6-18 months.

>2. What types of materials can the Optical Sorting Machine sort?

Optical sorting machines can be widely used in the color, shape, size or material difference sorting of materials such as plastics, metals, ores, grains, nuts, fruits and vegetables, glass, paper, etc., and are suitable for a variety of solid particles.

>3. How does the Optical Sorting Machine identify color differences?

The RGB image sensor captures the surface color information of the material, and the algorithm identifies the specific color pixel area, so as to distinguish the targets or impurities of different colors and achieve high-precision color separation and rejection.

>4. Will there be a prompt when the Optical Sorting Machine fails to sort?

The equipment is equipped with an alarm system and data statistics function. If there are problems such as valve blockage, camera abnormality, high false detection rate, etc., the system will automatically alarm and display error information for troubleshooting.

>5. Will the Optical Sorting Machine misjudge?

Occasionally, misjudgments may occur in complex or heavily contaminated materials, but modern photoelectric sorting equipment is equipped with AI algorithms and self-learning functions, which can continuously optimize recognition accuracy and keep the misjudgment rate at a very low level.

>6. What is the sorting accuracy of the Optical Sorting Machine?

The recognition accuracy of high-end photoelectric sorting machines is usually above 95%, and some AI-enhanced equipment can even reach 99% for complex mixtures.

>7. What is the processing capacity of the Optical Sorting Machine?

The processing capacity varies depending on the model, with small equipment being about 1-3 tons/hour and large equipment being able to reach more than 10 tons/hour, depending on the type of material, particle size and target sorting method.

>8. Does the Optical Sorting Machine require professionals to operate?

Photoelectric sorting machines are usually equipped with a friendly touch interface and intelligent operating system, which is easy to use and can be independently operated and maintained by non-professional technicians after simple training.

>9. How long is the maintenance cycle of the Optical Sorting Machine?

The equipment structure is relatively stable. Generally, routine inspection and cleaning are carried out once a month, and optical components, gas system and electrical modules are checked quarterly. The overall maintenance cost is low.

>10. Does the Optical Sorting Machine support multiple language interfaces?

Most manufacturers provide multi-language operating system interfaces, including English, Chinese, Spanish, etc., which are convenient for users in different countries and regions to operate and use.

>11. Can the Optical Sorting Machine be moved?

Some models support modular design and can be equipped with casters or installed in a slide rail system to achieve position adjustment; large equipment is mostly fixedly installed and suitable for industrial production line matching.

>12. Can the Optical Sorting Machine be integrated with other equipment?

It can be seamlessly integrated with other equipment such as conveyor belts, crushers, screening machines, dust removal systems, etc. to build a fully automated material handling system to achieve continuous sorting and intelligent control.

>13. How to set the sorting parameters of the Optical Sorting Machine?

Target recognition parameters such as color threshold, shape features, response delay, etc. are set through the touch screen. Some devices support automatic learning mode to autonomously optimize the recognition model.