A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

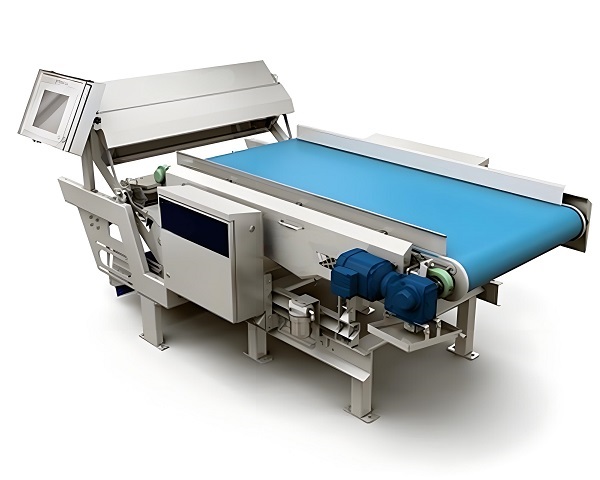

What is the Optical Sorter for Sale

The optical sorter is an intelligent sorting tool in modern industrial production and is playing an increasingly important role. It uses advanced optical principles to accurately screen and classify various materials.

The working principle of the optical sorter is based on the different reflection and absorption characteristics of materials to light. When a specific light source irradiates the material, the optical sorter detects the reflected light through an optical sensor. For example, in some ore sorting scenarios, different minerals have different reflectivities to light, and the optical sorter can select the target mineral from the mixed ore based on this characteristic.

In terms of type, the optical sorter is mainly divided into two types: sorting according to the color of the object and sorting according to the shape of the object. Regardless of the type, it is inseparable from the collaboration of high-speed cameras and image processing systems. High-speed cameras quickly capture the optical information of the material, and the image processing system analyzes and processes this information to quickly and accurately determine whether the material meets the screening criteria.

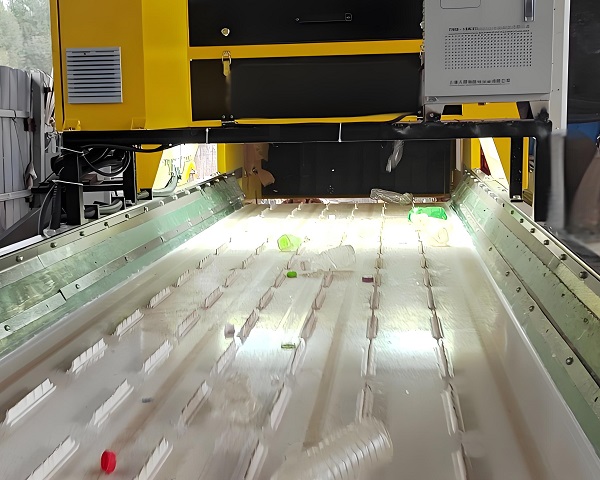

The application field of the optical sorter is extremely wide. In the food processing industry, it can be used to sort fruits, vegetables, nuts and other foods. For example, it can select fruits with poor color and damage to ensure the high quality of fruit products and enhance the market competitiveness of products; in the pharmaceutical industry, optical sorters can screen materials such as drug particles and capsules to ensure the purity and consistency of drugs and ensure the safety of drug use; the sorting and screening of chemical raw materials are also inseparable from optical sorters, which can improve the quality of chemical products by removing impurities; in the field of agricultural product processing, optical sorters can improve the purity of agricultural products such as grains and beans; even in the field of environmental protection, optical sorters can be used for garbage recycling and treatment, separating recyclables from other garbage, improving recycling efficiency, and promoting resource recycling.

Compared with traditional screening methods, optical sorters have significant advantages. Its high efficiency is reflected in the ability to quickly complete the sorting of materials, greatly improving production efficiency; high precision, can accurately identify subtle differences in materials, and ensure screening quality; it can also save a lot of manpower and reduce the labor intensity and cost of manual sorting; and it adopts advanced technology, high reliability, stable equipment operation, and reduces the frequency of failures. With the continuous advancement of science and technology, optical sorters will continue to upgrade and play a greater role in more fields.

Operating principle of Optical Sorter for Sale

The core of the optical sorter is to utilize the differences in the optical properties of materials, and to achieve efficient and accurate automatic sorting through photoelectric detection and intelligent processing technology, which plays an important role in the fields of ore processing and agricultural product grading.

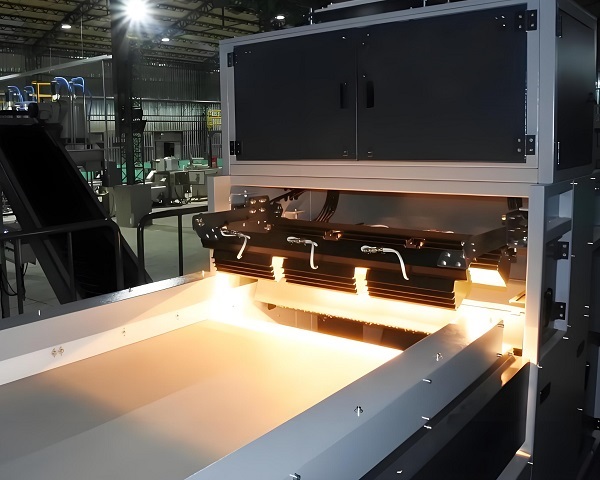

The work flow of the optical sorter starts with material transportation. The material enters the detection area of the optical sorter at high speed in a uniform single layer state through a vibrating feeder or a belt conveyor. In this critical area, the high-precision optical detection system begins to play a role. It consists of multiple high-resolution photoelectric sensors and light sources. The light source emits light of a specific wavelength to the material, and the light reflected or transmitted by the surface of the material is received by the photoelectric sensor. Materials of different types or qualities have different reflection, absorption, and transmission capabilities for light due to their chemical composition, surface structure and other factors, thereby generating unique optical signals, such as color differences, spectral reflectivity differences, etc.

The optical signals captured by the optical detection system are converted into electrical signals and transmitted to the intelligent control system. The system has built-in powerful algorithms and databases, which can quickly analyze and process these electrical signals, compare them with pre-set standard parameters, and determine the category and quality of the materials. Once the target material to be sorted is confirmed, the control system will immediately issue a command to trigger the actuator. The actuator usually uses a high-pressure air valve or a pulse jet device to eject a high-pressure airflow in a very short time, blowing the target material away from the conveying flow and making it fall into the designated collection area, while the material that does not meet the requirements continues to enter other collection areas with the conveying flow, thus completing the entire sorting process.

With the continuous development of technology, the detection accuracy and sorting efficiency of optical sorters continue to improve, and in the future, they will be more widely and intelligently applied in more industries.

Advantages and features of Optical Sorter for Sale

The most prominent feature of the optical sorter is high-precision screening. It uses advanced optical detection technology to accurately identify the color, shape, size, material and other characteristics of the material. Taking the food industry as an example, when screening raisins, the optical sorter can keenly distinguish the dull color, shriveled particles and impurities mixed in it, and accurately select high-quality raisins to ensure uniform and stable product quality.

The screening efficiency of the optical sorter is extremely high. The traditional manual screening method is slow and easily affected by factors such as fatigue. The optical sorter can process several tons or even tens of tons of materials per hour with its high-speed transmission device and fast-response detection system. In the field of ore sorting, an optical sorter can process tens of tons per hour, greatly improving the mining and processing efficiency of mineral resources.

Its intelligence is also a highlight. The optical sorter is equipped with an intelligent operating system, which can flexibly set the screening parameters according to the screening requirements of different materials. The operator only needs to enter relevant instructions on the control interface, and the machine can automatically complete the screening work, and can monitor the screening process in real time. Once an abnormality occurs, it will issue an alarm and automatically adjust it in time, reducing manual intervention and labor intensity.

Optical optical sorters have a wide range of applications. They can be used in many industries such as food, medicine, chemical industry, mining, environmental protection and recycling. In pharmaceutical production, they are used to screen medicinal materials to ensure the quality of medicines; in the field of environmental protection and recycling, they can sort waste plastics, metals, etc. to help recycle resources.

The optical optical sorter has good stability and durability. It uses high-quality materials and precision manufacturing processes, and key components have been specially treated to adapt to harsh working environments such as high temperature, humidity, and dust. It can operate stably for a long time, reduce equipment failures and maintenance costs, and provide strong guarantees for the company's continued efficient production.

Technical Parameter Table of Optical Sorter for Sale

| Model | Sorting Width (mm) | Capacity (t/h) | Resolution (mm) | Air Jet Nozzles | Power Consumption (kW) | Detection System | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| OS-600 | 600 | 1–3 | 0.2 | 64 | 1.5 | RGB + NIR | 1800×1000×1600 |

| OS-900 | 900 | 2–5 | 0.2 | 96 | 2.2 | RGB + NIR + AI | 2000×1300×1700 |

| OS-1200 | 1200 | 3–7 | 0.2 | 128 | 3.0 | RGB + NIR + SWIR | 2200×1500×1800 |

| OS-1600 | 1600 | 4–10 | 0.2 | 160 | 4.0 | RGB + SWIR + AI | 2400×1800×1900 |

| OS-1800 | 1800 | 5–12 | 0.2 | 192 | 4.5 | Multispectral + AI | 2600×1900×2000 |

| OS-2100 | 2100 | 6–15 | 0.2 | 224 | 5.5 | Multisensor Fusion | 2800×2000×2100 |

| OS-2400 | 2400 | 8–18 | 0.2 | 256 | 6.0 | Full-Spectrum + AI | 3000×2200×2200 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Optical Sorter for Sale

FAQ about Optical Sorter for Sale

>1. How to train operators for an optical sorter?

Operators should receive comprehensive training on the operation and maintenance of the optical sorter. The training should cover the basic principles of how the sorter works, the different components and their functions, and the user interface of the control system. Operators should learn how to start and stop the sorter, adjust the sorting parameters, and monitor its performance. They should also be trained on troubleshooting common problems and performing routine maintenance tasks. Hands - on training and practical exercises can be very effective in helping operators become proficient in using the optical sorter.

>2. What are the future development trends of optical sorters?

The future trends of optical sorters include increased automation and intelligence. Advanced artificial intelligence and machine - learning algorithms will be integrated into the image - processing systems to improve the sorting accuracy and adaptability to different materials and production conditions. There will also be a focus on developing more compact and portable optical sorters for small - scale applications. Additionally, the use of multi - spectral and hyperspectral imaging technologies will enable the detection of more subtle differences in the optical properties of objects, opening up new possibilities for sorting and quality control in various industries.

>3. What are the main components of an optical sorter?

The main components include a feeding system, a detection system, an image - processing unit, and an ejection system. The feeding system ensures a consistent and even flow of material onto the conveyor belt. The detection system consists of cameras, sensors, and lighting sources that capture and measure the optical properties of the objects. The image - processing unit is the brain of the sorter, which analyzes the data from the detection system and makes sorting decisions. The ejection system, such as air nozzles or mechanical flippers, removes the unwanted objects from the material stream based on the instructions from the image - processing unit.

>4. What industries commonly use optical sorters?

Optical sorters are widely used in the food, recycling, mining, and pharmaceutical industries. In the food industry, they are essential for quality control in processing fruits, vegetables, nuts, grains, and other agricultural products. In the recycling sector, they help separate different types of plastics, metals, and other recyclable materials. In mining, they can be used to upgrade ore by removing waste materials. In the pharmaceutical industry, they ensure the purity and quality of drugs by detecting and removing foreign particles or defective tablets.

>5. What are the advantages of using an optical sorter?

One of the major advantages is high accuracy in sorting. It can detect and remove even small or subtle defects that may be missed by human inspectors. It also offers high efficiency, as it can process large volumes of material in a short time. Additionally, optical sorters are non - destructive, meaning they do not damage the good products during the sorting process. They can also improve product quality and safety, reduce labor costs, and increase the overall profitability of a business.

>6. How to choose the right optical sorter for a specific application?

When choosing an optical sorter, several factors need to be considered. First, understand the specific requirements of the application, such as the type of material to be sorted, the size range of the objects, and the desired sorting accuracy. Then, evaluate the performance specifications of different sorters, including their detection capabilities, processing speed, and ejection accuracy. Consider the ease of use and maintenance of the sorter, as well as the availability of technical support from the manufacturer. It may also be helpful to conduct trials or refer to case studies of similar applications to make an informed decision.

>7. What factors affect the sorting accuracy of an optical sorter?

Several factors can influence the sorting accuracy. The quality and resolution of the cameras and sensors play a crucial role. Poor image quality may lead to misidentification of objects. The lighting conditions in the detection zone are also important, as inadequate or uneven lighting can affect the accuracy of color and shape detection. The speed of the material flow on the conveyor belt can impact the time available for detection and analysis. Additionally, the complexity of the material itself, such as the presence of overlapping or similar - looking objects, can pose challenges to the sorting accuracy.

>8. How to maintain an optical sorter regularly?

Regular maintenance is essential to ensure the optimal performance of an optical sorter. This includes daily cleaning of the cameras, sensors, and lighting systems to remove dust, dirt, and debris that may accumulate and affect their performance. Check the conveyor belt for wear and tear and replace it if necessary. Lubricate the moving parts of the ejection system to prevent friction and ensure smooth operation. Periodically calibrate the sorter to maintain its accuracy and adjust the sorting parameters as needed based on changes in the material or production requirements.

>9. What are the common problems of an optical sorter and how to solve them?

Common problems include mis - sorting, where good products are ejected along with the unwanted ones, or vice versa. This can be caused by incorrect calibration, changes in the material properties, or sensor malfunctions. To solve this, recalibrate the sorter and adjust the sorting parameters. Another problem is clogging of the air nozzles or mechanical ejectors, which can reduce the ejection efficiency. Clean the ejectors regularly and check for any blockages. Additionally, electrical or software glitches may occur, which can be resolved by restarting the sorter or contacting the technical support team.

>10. Can an optical sorter handle wet or sticky materials?

Some optical sorters are designed to handle wet or sticky materials, but it depends on the specific model and its features. For wet materials, the sorter may need to have special water - resistant components and a proper drainage system to prevent water from damaging the electronics. For sticky materials, the conveyor belt and the detection zone may require additional cleaning mechanisms to remove the residue. It is important to consult with the manufacturer to determine if a particular optical sorter is suitable for handling wet or sticky materials in a specific application.

>11. How to integrate an optical sorter into an existing production line?

Integrating an optical sorter into an existing production line requires careful planning. First, assess the available space and layout of the production line to determine the optimal location for the sorter. Ensure that there is enough clearance for the feeding and ejection systems. Then, coordinate with the manufacturer or a professional installer to connect the sorter to the conveyor system and the control system of the production line. This may involve installing additional sensors, actuators, and communication interfaces. Test the integration thoroughly to ensure smooth operation and proper synchronization with the rest of the production line.

>12. What are the energy consumption characteristics of an optical sorter?

The energy consumption of an optical sorter mainly depends on the power requirements of its components, such as the cameras, sensors, lighting systems, and ejection devices. Generally, modern optical sorters are designed to be energy - efficient. They may use LED lighting, which consumes less power compared to traditional lighting sources. The image - processing unit may also be optimized to reduce energy usage. However, the energy consumption can increase with higher processing speeds and more complex sorting tasks. It is important to consider the energy efficiency when choosing an optical sorter and to implement energy - saving measures, such as turning off the sorter when not in use.

>13. What is the lifespan of an optical sorter?

The lifespan of an optical sorter can vary depending on several factors, including the quality of the components, the operating conditions, and the level of maintenance. With proper care and regular maintenance, a well - built optical sorter can last for 10 - 15 years or even longer. However, some components, such as cameras, sensors, and conveyor belts, may need to be replaced periodically due to wear and tear or technological obsolescence.