A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Square Gyratory Screen

The square gyratory screen is a high-efficiency precision screening equipment designed to imitate the principle of manual screening. It has a large processing capacity and screening accuracy. It is widely used in the classification of powder and granular materials in the chemical, metallurgical, pharmaceutical, food, building materials, plastics, mining and other industries. Its unique square structure and horizontal rotary motion mode make the material present a spiral progressive motion on the screen, thereby realizing a soft and efficient screening process. It is particularly suitable for materials with high specific gravity, wide particle size distribution and high screening accuracy.

The core working principle of the square gyratory screen is to drive the screen body to perform low-frequency, large-amplitude horizontal swing motion through the excitation device, so that the material is thrown and rolled back and forth along the screen surface, thereby prompting fine particles to pass through the screen quickly, while large particles move along the screen surface toward the outlet and are finally discharged. The screen surface is mostly designed with multiple layers, which can simultaneously perform multi-level classification of materials, improve production efficiency and screening effect.

In terms of structure, the square gyratory screen usually adopts a fully enclosed design with good sealing, which can effectively prevent dust from spilling and improve the working environment. At the same time, the equipment has low noise, low energy consumption, stable operation, long service life, and the screen replacement and cleaning are also very convenient. Some high-end models can also be equipped with automatic screen cleaning devices and frequency conversion control systems to further improve their automation level and ease of operation.

Compared with traditional vibrating screens or rotary vibrating screens, square gyratory screens not only have advantages in production capacity and screening accuracy, but also perform well in non-destructive material processing and avoiding crushing. They are very suitable for industry applications with high requirements for particle integrity. For example, it is used for screening of sugar powder, starch, and milk powder in the food industry, for grading of catalysts and plastic particles in the chemical industry, and for fine screening of Chinese medicine powder and pharmaceutical particles in the pharmaceutical industry.

With its advantages of high efficiency, low noise, high precision, and easy operation, the square gyratory screen has become an important equipment in the field of modern industrial screening, especially suitable for fine screening tasks of medium and fine particles and high value-added materials.

Operating principle of Square Gyratory Screen

The square swing screen is an efficient screening device that imitates manual screening action. Its unique square structure and multi-degree-of-freedom motion trajectory give it significant advantages in screening accuracy and processing capacity. Its core working principle is based on the composite motion of plane rotation and swinging, which can achieve high-precision screening of various powdery and granular materials.

After the equipment is started, the motor drives the eccentric shaft or exciter to rotate, generating nonlinear motion of plane rotation. The entire screen box performs an elliptical rotation in the horizontal plane, accompanied by slight up and down tossing and back and forth swinging, thereby pushing the material to move forward in a spiral shape on the screen. Because the motion trajectory is close to the manual screening action, the material stays on the screen surface for a longer time, is more evenly distributed, and jumps more fully, which can effectively prevent particles from accumulating on the screen surface and improve screening efficiency.

The screen is generally divided into 1 to 5 layers, and the material can be graded in multiple levels. Each layer of the screen is set with different mesh sizes according to the material particle size and screening requirements. The material is separated layer by layer during the movement of the screen, achieving high-precision grading from coarse to fine. At the same time, in order to prevent the screen from clogging, the equipment is usually equipped with an automatic screen cleaning system such as a bouncing ball, an ultrasonic device or a screen cleaning brush to ensure continuous operation.

The vibration frequency of the square swing screen is low (generally between 180-300 rpm) and the screen surface swing is large, so it has little effect on the crushing of the material. It is particularly suitable for screening fragile, lightweight, highly electrostatic or highly viscous materials, such as quartz sand, battery materials, resin powder, ceramic powder, calcium carbonate, food additives, etc.

Advantages and features of Square Gyratory Screen

The square gyratory screen is a high-efficiency precision screening equipment, which is widely used in many industries such as chemical industry, food, medicine, metallurgy, building materials, etc., for fine screening of powdered and granular materials. Its design is inspired by the manual screening action. It adopts a composite motion mode of plane rotation and swinging, which can effectively protect the integrity of the material while maintaining high screening efficiency. It is suitable for screening processes with high screening accuracy requirements or fragile materials.

1. The square gyratory screen has extremely high screening accuracy and processing capacity. Because its motion trajectory is similar to manual screening, it can achieve full dispersion, rolling and advancement of materials on the screen surface, thereby maximizing the screening efficiency, and the screening accuracy can reach more than 95%, which is especially suitable for multi-level classification and fine screening of fine particle materials.

2. The equipment runs stably, has low noise and long service life. The square gyratory screen adopts eccentric shaft and belt drive, starts smoothly, and has adjustable vibration amplitude, which not only reduces mechanical shock and noise, but also reduces the loss of the equipment body and foundation, and extends the service life of the whole machine. Its main components are mostly made of high-quality carbon steel or stainless steel, and the structure is strong and corrosion-resistant.

3. The square gyratory screen has good humanized design and flexibility. The screen is easy to replace, and the screen cleaning device effectively prevents blockage; the number of screening layers can be flexibly configured according to needs to meet the screening requirements of materials of different particle sizes. In addition, the equipment can be equipped with a negative pressure conveying system and a dust removal system to achieve closed and dust-free operation, which meets the requirements of modern environmental protection and clean production.

4. The equipment has low energy consumption and easy maintenance. Its overall energy consumption is much lower than that of traditional vibrating screens, and its structure is simple, the maintenance workload is small, and daily maintenance is mainly lubrication and tightening, which is easy for operators to master.

The square gyratory screen has become the preferred equipment for high-end precision screening applications with its high screening accuracy, large output, low energy consumption, low noise, and easy operation. It is especially suitable for industrial occasions with high requirements for screening quality and production efficiency.

Technical Parameter Table of Square Gyratory Screen

| Model | Screen Size (L×W mm) | Screen Area (m²) | Screen Layers | Capacity (t/h) | Motor Power (kW) | Amplitude (mm) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| SGS-1030 | 1000×3000 | 3.0 | 1–4 | 2–5 | 1.5 | 25–40 | 3200×1600×1200 |

| SGS-1235 | 1200×3500 | 4.2 | 1–4 | 3–7 | 2.2 | 25–40 | 3700×1800×1350 |

| SGS-1540 | 1500×4000 | 6.0 | 1–4 | 4–10 | 3.0 | 25–40 | 4200×2000×1500 |

| SGS-1845 | 1800×4500 | 8.1 | 1–4 | 6–14 | 4.0 | 25–40 | 4700×2300×1600 |

| SGS-2050 | 2000×5000 | 10.0 | 1–4 | 8–18 | 5.5 | 25–40 | 5200×2500×1700 |

| SGS-2255 | 2200×5500 | 12.1 | 1–4 | 10–22 | 7.5 | 25–40 | 5800×2700×1800 |

If you have any special requirements, we will customize according to your special needs.

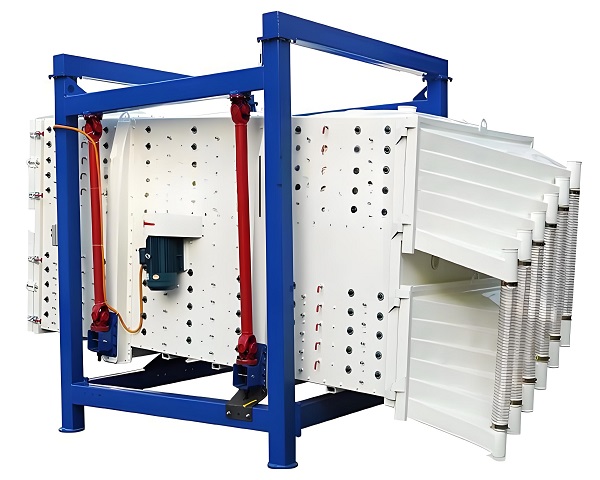

Product Picture Display of Square Gyratory Screen

FAQ about Square Gyratory Screen

>1. What are the energy consumption characteristics of a Square Gyratory Screen?

The energy consumption is mainly determined by the power of the driving motor and the operating parameters. Generally, Square Gyratory Screens are relatively energy - efficient compared to some other types of screening equipment. The gyratory motion requires less energy to achieve the desired screening effect. However, factors such as high feed rates, large amplitudes, and frequent starts and stops can increase energy consumption. Optimizing the operating parameters and maintaining the screen properly can help reduce energy consumption.

>2. What are the future development trends of Square Gyratory Screens?

The future trends include increased automation and intelligence. Smart sensors and control systems will be integrated to monitor the screening process in real - time, optimize operating parameters automatically, and predict maintenance needs. There will also be a focus on developing more energy - efficient and environmentally friendly designs. Additionally, advancements in material science will lead to the use of more durable and high - performance screen meshes and components, further improving the reliability and performance of Square Gyratory Screens.

>3. What materials can a Square Gyratory Screen handle?

It can handle a wide variety of materials. In the food industry, it can screen grains, spices, and powdered food products. In the chemical sector, it's suitable for screening chemicals, pigments, and fertilizers. In the mining and mineral processing industry, it can be used to screen ores, coal, and sand. It can handle both dry and wet materials, as well as materials with different moisture contents and particle shapes.

>4. What are the advantages of a square shape in a gyratory screen?

The square shape offers several advantages. Firstly, it provides a larger effective screening area compared to a circular screen of the same outer dimensions. This means more material can be processed at once, increasing the throughput. Secondly, the square shape allows for better utilization of space in a production facility. It can be arranged more easily in a production line, and multiple square screens can be stacked or placed side by side without wasting much space.

>5. How to select the right screen mesh for a Square Gyratory Screen?

The selection of screen mesh depends on the desired particle size separation. You need to know the particle size distribution of the feed material and the required particle size range of the final products. For example, if you want to separate fine powder from coarse particles, you'll need a mesh with smaller openings. Also, consider the material's properties, such as its hardness, shape, and tendency to stick. Softer or sticky materials may require a mesh with a special coating or a larger opening to prevent clogging.

>6. What factors affect the screening efficiency of a Square Gyratory Screen?

Several factors play a role. The properties of the material, including particle size, shape, density, and moisture content, are crucial. For instance, irregularly shaped particles may be more difficult to screen than spherical ones. The screen mesh parameters, such as mesh size, opening shape, and tension, also affect efficiency. A loose or damaged mesh will reduce the screening accuracy. Additionally, the operating parameters, like the amplitude, frequency, and feed rate, need to be optimized to achieve the best screening results.

>7. How to adjust the amplitude and frequency of a Square Gyratory Screen?

The amplitude and frequency are usually adjusted through the drive system. For amplitude adjustment, some screens have adjustable eccentric weights. By changing the position or weight of these eccentric weights, you can increase or decrease the intensity of the gyratory motion. Frequency adjustment is often achieved by varying the speed of the motor. Modern Square Gyratory Screens may come with electronic control panels that allow for precise adjustment of these parameters to suit different materials and production requirements.

>8. What are the common maintenance tasks for a Square Gyratory Screen?

Regular maintenance is essential. Daily tasks include checking the screen mesh for wear, damage, and blockage. Clean the mesh regularly to prevent material buildup. Inspect the drive components, such as the motor, belts, and gears, for proper operation and tension. Lubricate the moving parts according to the manufacturer's recommendations. Periodically, check the overall structural integrity of the screen, including the frame and support legs, for any signs of cracks or deformation.

>9. What are the common problems of a Square Gyratory Screen and how to solve them?

Common problems include screen mesh blinding, where material gets stuck in the mesh openings. This can be solved by using anti - blinding screen meshes or installing cleaning devices like ball trays or ultrasonic cleaners. Excessive vibration may be caused by an unbalanced screen body or worn - out damping components. Balancing the screen body and replacing damaged damping parts can resolve this issue. Abnormal noise may indicate loose parts or bearing failure, which requires tightening or replacing the affected components.

>10. How to ensure the safety when operating a Square Gyratory Screen?

Operators should receive proper training on the operation and maintenance of the screen. Before starting the machine, check for any loose parts, foreign objects, or signs of damage. Wear appropriate personal protective equipment, such as safety glasses and gloves. Do not reach into the screen while it is in operation. Install safety guards around the screen to prevent accidental contact with moving parts. Also, follow the manufacturer's safety guidelines and local regulations.

>11. Can a Square Gyratory Screen be used for multi - layer screening?

Yes, it can be designed for multi - layer screening. By installing multiple screen meshes with different mesh sizes on different layers, it is possible to separate materials into multiple particle size fractions in a single screening process. For example, in a three - layer screen, the top layer can separate the largest particles, the middle layer can separate medium - sized particles, and the bottom layer can separate the finest particles. This is very useful in industries where multiple product grades are required.

>12. What is the lifespan of a Square Gyratory Screen?

The lifespan of a Square Gyratory Screen depends on various factors. The quality of the materials used in its construction, such as the screen body, mesh, and drive components, is crucial. Operating conditions, including the type of material being screened, the feed rate, and the environment (e.g., temperature, humidity), also affect the lifespan. With proper maintenance and under normal operating conditions, a well - built Square Gyratory Screen can last for several years.

>13. How to install a Square Gyratory Screen?

Installation should be carried out according to the manufacturer's instructions. First, ensure that the installation site is level and stable. Place the support frame in the designated position and secure it. Then, carefully lift the screen body onto the support frame and connect it to the drive device. Align the components properly and tighten all the bolts. Connect the electrical connections as per the wiring diagram. After installation, conduct a trial run to check for any abnormal vibrations, noise, or malfunctions.