A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

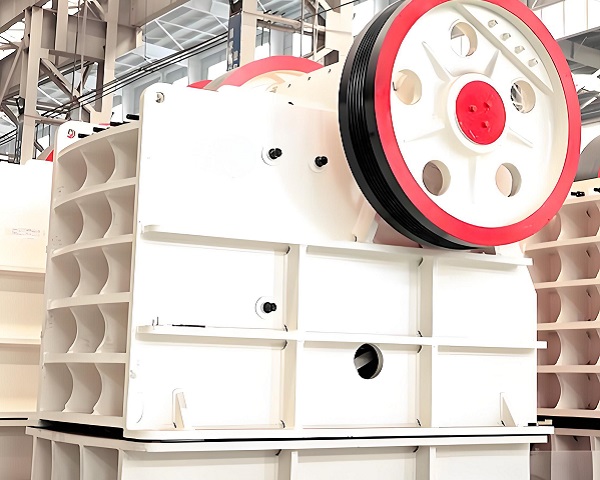

What is the Jaw Crusher for Sale

As the cornerstone equipment of mining, building materials and other industries, jaw crusher occupies a core position in the material pre-processing link with its powerful crushing capacity and stable performance. Its working principle is based on the extrusion and splitting action between the movable jaw and the fixed jaw: the motor drives the belt and pulley to drive the eccentric shaft to rotate, so that the movable jaw reciprocates according to the predetermined trajectory, and the material entering the crushing chamber is continuously squeezed and crushed until it meets the particle size requirements and is discharged.

From the perspective of structural design, the jaw crusher is mainly composed of a frame, a movable jaw, an eccentric shaft, a jaw plate and other components. The jaw plate made of high manganese steel has strong wear resistance and can withstand high-intensity impact; the wedge-shaped adjustment device can flexibly control the discharge particle size to meet different production needs. According to the movement mode of the movable jaw, the jaw crusher is divided into a simple swing type and a compound swing type. The former is suitable for coarse crushing of hard materials, and the latter is widely used in small and medium-sized crushing production lines due to its higher efficiency and compact structure.

In terms of application scenarios, the jaw crusher can be called an "all-round player". Whether it is hard ores such as granite and quartz, or solid waste such as construction waste and cement blocks, it can be crushed efficiently and is indispensable in the fields of mining, road construction, concrete production, etc. Its advantages are not only large crushing ratio and stable output, but also simple operation and low maintenance cost. Through modular design, it can quickly replace wearing parts, greatly shorten downtime, and ensure continuous operation of the production line. With the iteration of technology, the new jaw crusher is integrated with the intelligent monitoring system to provide real-time feedback on the operating status of the equipment, providing dual guarantees for safe production and efficient operation.

Operating principle of Jaw Crusher for Sale

The working principle of the jaw crusher is based on the theory of extrusion crushing, and the material is crushed by the relative movement of the movable jaw and the fixed jaw.

The jaw crusher is mainly composed of a frame, a movable jaw, a fixed jaw, an eccentric shaft, a connecting rod, an adjusting device and other components. The fixed jaw is fixed to the front wall of the frame, and the movable jaw is connected to the frame through an eccentric shaft, and can swing periodically within a certain range. When the jaw crusher is started, the motor drives the eccentric shaft to rotate through the pulley, and the eccentric movement of the eccentric shaft causes the connecting rod to move up and down, thereby driving the movable jaw to swing periodically.

During the swinging process of the movable jaw, when the movable jaw approaches the fixed jaw, the material entering the crushing chamber is squeezed, split and bent by the movable jaw and the fixed jaw. Under the extrusion between the movable jaw and the fixed jaw, the internal stress of the larger material exceeds its own strength limit, and it is gradually broken into smaller particles; while the smaller material is further refined under repeated extrusion and friction. As the movable jaw continues to approach the fixed jaw, the material in the crushing chamber is continuously squeezed and crushed until the particle size meets the requirements.

When the movable jaw leaves the fixed jaw, the crushed material is discharged from the discharge port at the bottom of the crushing chamber under the action of gravity. By adjusting the width of the discharge port, the particle size of the crushed material can be controlled. The larger the width of the discharge port, the larger the particle size of the discharged material; conversely, the smaller the particle size of the discharged material.

The jaw crusher continuously squeezes, crushes and discharges the material through the periodic reciprocating motion of the movable jaw, realizing continuous and efficient crushing operations. Due to its simple structure, reliable operation, and large crushing ratio, it occupies an important position in the crushing field.

Advantages and features of Jaw Crusher for Sale

Jaw crushers are widely used in mining, building materials production and other fields, and their characteristics and advantages are remarkable.

In terms of crushing capacity, the jaw crusher adopts a crushing chamber composed of a movable jaw and a fixed jaw. The material is squeezed through the periodic reciprocating motion of the movable jaw. The crushing ratio is large, and the larger particle size material can be quickly crushed into smaller particles. It is suitable for a variety of hardness materials, from limestone to granite. It can be efficiently processed. Its powerful crushing force enables the jaw crusher to easily deal with large pieces of material and meet the stringent requirements of industrial production for primary crushing of materials.

In terms of use cost, the jaw crusher has a simple structure and is mainly composed of a frame, a movable jaw, an eccentric shaft and other components. The parts are highly versatile, easy to purchase and replace, and have low maintenance costs. At the same time, the equipment runs stably and has relatively low energy consumption. It can maintain efficient operation under long-term work, reducing energy consumption and equipment loss in the production process, saving a lot of operating costs for the enterprise.

In terms of operation and maintenance, the jaw crusher is easy to operate, and the operator can master it after simple training. Its daily maintenance is convenient. You only need to regularly check the wear of the parts and add lubricating oil to ensure the normal operation of the equipment. In addition, the jaw crusher is also equipped with a variety of safety protection devices, such as protective covers and overload protection systems, which can effectively prevent operator injuries and equipment damage and ensure production safety.

With its excellent crushing capacity, low cost of use and convenient operation and maintenance, the jaw crusher has become the preferred equipment for primary crushing in industrial production, providing strong support for enterprises to improve production efficiency and reduce production costs.

Technical Parameter Table of Jaw Crusher for Sale

| Model | Feeding Opening Size (mm) | Max Feeding Size (mm) | Discharge Size Range (mm) | Capacity (t/h) | Motor Power (kW) | Machine Weight (t) |

|---|---|---|---|---|---|---|

| PE250×400 | 250×400 | 210 | 20–60 | 5–20 | 15 | 2.8 |

| PE400×600 | 400×600 | 340 | 40–100 | 16–60 | 30 | 6.5 |

| PE500×750 | 500×750 | 425 | 50–100 | 40–100 | 55 | 10.5 |

| PE600×900 | 600×900 | 500 | 65–160 | 60–160 | 75 | 17 |

| PE750×1060 | 750×1060 | 630 | 80–180 | 110–320 | 110 | 28 |

| PE900×1200 | 900×1200 | 750 | 100–200 | 220–450 | 132 | 50 |

| PE1200×1500 | 1200×1500 | 1020 | 150–300 | 400–800 | 160–220 | 100 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Jaw Crusher for Sale

FAQ about Jaw Crusher for Sale

>How to choose a suitable jaw crusher model?

When purchasing, you need to consider the production scale, material properties, feed size and discharge size requirements, budget and other factors. Choose a model with appropriate processing capacity according to the expected output; choose equipment with corresponding structure and material according to the hardness and characteristics of the material; at the same time, refer to the energy consumption, maintenance convenience and after-sales service of the equipment to ensure that production needs are met.

>What fields are jaw crushers mainly used in?

Jaw crushers are widely used in mining, metallurgy, building materials, road and railway construction, chemical industry and other industries. It is used to process various types of ores and rocks such as limestone, granite, quartz stone, etc. It is a key equipment for primary crushing in the production of sand and gravel aggregates and the pretreatment of raw materials in ore dressing plants.

>What types of jaw crushers are there?

There are mainly two types: simple swing jaw crusher and compound swing jaw crusher. The simple swing type has a simple structure and a large swing stroke of the movable jaw, which is suitable for crushing hard materials; the compound swing type has a compact structure, a large crushing ratio, and high production efficiency, and is more widely used in modern industrial production.

>What is the crushing ratio of the jaw crusher?

The crushing ratio of a jaw crusher is usually between 4 and 12, and the specific value varies depending on factors such as the equipment model, material properties, feed size, and discharge port adjustment. A larger crushing ratio enables it to efficiently crush large pieces of material into smaller sizes.

>How to adjust the discharge size of a jaw crusher?

The discharge size can be controlled by adjusting the size of the discharge port. Common adjustment methods include shim adjustment, which changes the size of the discharge port by increasing or decreasing the number of shims; wedge adjustment, which adjusts the width of the discharge port by the relative movement of the wedge to meet different production needs.

>What are the wearing parts of a jaw crusher?

The wearing parts of a jaw crusher mainly include jaw plates (moving jaw plates and fixed jaw plates) and toggle plates (thrust plates). The jaw plates are in direct contact with the material, subject to huge extrusion and friction, and wear faster; the toggle plates are easy to break when the equipment is overloaded, which plays a role in protecting other parts.

>What should I do if the jaw crusher has abnormal vibration?

Abnormal vibration may be caused by uneven feeding, loose anchor bolts, worn or unbalanced parts. The machine should be stopped for inspection first, and the feeding method should be adjusted to make the material enter evenly; tighten the anchor bolts; check the worn parts and replace them in time; calibrate or replace the unbalanced parts.

> Does the jaw crusher have high energy consumption?

Compared with other types of crushers, the jaw crusher has a simple structure, stable operation and relatively low energy consumption. However, the actual energy consumption will be affected by factors such as material hardness, feed particle size, equipment model and operating conditions. Energy consumption can be further reduced by optimizing operation and equipment selection.

> What factors affect the production efficiency of the jaw crusher?

The production efficiency is affected by factors such as material properties (hardness, humidity, particle size), feed uniformity, discharge port size, equipment speed and maintenance status. When the material hardness is low, the feed is uniform, the discharge port is reasonable, and the equipment is well maintained, the production efficiency is higher.

> How to perform daily maintenance on the jaw crusher?

Daily maintenance requires regular inspection of the wear of vulnerable parts such as jaw plates and elbow plates; check the bearing temperature and lubrication condition, and replenish or replace lubricating oil in time; clean the residual materials on the surface of the equipment and in the crushing chamber; check whether the connecting bolts of each component are loose to ensure the normal operation of the equipment.

>Can the jaw crusher crush wet materials?

The jaw crusher can crush materials with a certain humidity, but too wet materials can easily cause blockage in the crushing chamber, reduce production efficiency, and aggravate component wear. If wet materials need to be crushed, the materials can be dried first or appropriate anti-blocking measures can be taken.

>What are the precautions when installing the jaw crusher?

During installation, a solid and flat foundation must be selected to ensure the level of equipment installation; strictly assemble components according to the installation drawings to ensure that the connections of each component are accurate and firm; after installation, check whether the rotating parts of the equipment are flexible and whether the electrical system is connected correctly. It can be put into use only after qualified commissioning.

>How long is the service life of the jaw crusher?

The service life of the jaw crusher is affected by many factors such as frequency of use, material properties, and maintenance. Under normal use and proper maintenance, the main machine can last for 8 to 15 years, and wearing parts need to be replaced regularly according to wear conditions.

>What are the advantages of jaw crusher compared with other crushers?

Jaw crusher has simple structure, convenient operation and low maintenance cost; it has strong adaptability to materials and can crush materials of various hardness and particle size; it has a large crushing ratio and is suitable for primary crushing; it has stable and reliable operation and perfect safety protection measures, and has unique advantages in the field of primary crushing.