A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

Vietnam Industrial Waste Sorting System Introduce

With the rapid advancement of industrialization and urbanization in Vietnam, the volume and complexity of industrial solid waste are increasing significantly. To promote efficient resource utilization and sustainable development, our company has developed a high-efficiency, intelligent, and environmentally friendly industrial waste sorting system tailored specifically for the Vietnamese market. This system is designed to improve the recovery rate of industrial solid waste, reduce disposal costs, and comply with increasingly stringent environmental regulations.

The system features a modular design structure. The core processing flow includes bag-breaking, pre-screening, trommel screening, magnetic separation, eddy current separation, air separation, and manual quality inspection. It is capable of efficiently handling mixed industrial waste such as plastics, paper, metals, rubber, fabrics, and stones. The system is equipped with an automated control platform, using sensors and PLC intelligent control technology to monitor equipment operation in real time and enable remote management, significantly improving operational efficiency and stability.

For equipment selection, the trommel screen provides preliminary classification to enhance the effectiveness of downstream sorting. Magnetic separators effectively remove ferrous metals, while eddy current separators are highly effective in identifying and recovering non-ferrous metals such as aluminum and copper. The air separator removes lightweight impurities and increases the purity of recovered materials. Additionally, optical sorting devices can be integrated upon request to automatically identify and separate plastics and paper materials.

The entire system features low energy consumption, high processing capacity, and ease of operation and maintenance. It is suitable for industrial parks, processing plants, electronics manufacturing facilities, and centralized urban industrial waste treatment centers. To adapt to Vietnam’s local climate and power conditions, the system can be equipped with rainproof and dustproof protection, as well as customized electrical specifications, ensuring stable and reliable operation.

This solution not only supports the resource utilization and harmless treatment of Vietnam’s industrial waste, but also provides both economic and environmental benefits for enterprises. By implementing this sorting system, businesses can achieve waste reduction, lower landfill and incineration costs, and improve the recovery rate of recyclable materials, aligning with Vietnam’s long-term goals for green economic development.

Advantages and features of Vietnam Industrial Waste Sorting System

In order to cope with the solid waste treatment pressure brought about by Vietnam's rapid industrialization process, this industrial waste sorting system solution combines local actual needs with international advanced technology, and has the remarkable characteristics of reasonable structure, strong adaptability, efficient operation, intelligent and environmental protection, etc., which can provide customers with full-process and efficient industrial waste treatment solutions.

1. Modular design, flexible configuration

The system adopts modular structural design, and each unit equipment such as bag breaker, drum screen, magnetic separator, air separator, eddy current separator, optical sorting system, etc. can be flexibly combined on demand, which is convenient for installation, expansion and maintenance, and can meet the use of industrial enterprises of different scales and process requirements.

2. High degree of automation, intelligent and reliable operation

The system is equipped with advanced PLC control system and human-machine interface (HMI), which can realize centralized control, automatic start and stop, status monitoring, fault warning and other functions of equipment, reduce manual operation, and improve operation safety and stability. At the same time, it supports remote monitoring and remote fault diagnosis, which is convenient for after-sales support and equipment management.

3. Multi-stage efficient sorting, high resource recovery rate

Through the combination of pretreatment and multi-stage screening, the system can efficiently separate recyclable metals (iron, aluminum, copper), plastics, paper, cloth, rubber and other materials. The use of advanced magnetic separation, eddy current and wind separation technology ensures sorting accuracy and recovery rate, effectively reduces the landfill ratio, and achieves the goal of "reduction, resource utilization, and harmlessness".

4. Energy saving and environmental protection, low operating cost

The equipment fully considers energy consumption and emission control in the design, adopts energy-saving motors, low noise structures and environmentally friendly dust removal devices, and there is no secondary pollution during the operation process. At the same time, it is easy to maintain, has few consumables, and has low long-term operating costs, which is suitable for the input-output ratio requirements of developing markets.

5. Strong adaptability, in line with the working conditions in Vietnam

In view of the humid and high temperature climate characteristics of Vietnam and the complex composition of industrial waste, the system uses high-strength corrosion-resistant materials and sealing design to ensure that the equipment can still operate stably and long-term in harsh environments. It can also be customized according to requirements such as power specifications and language systems.

6. Economic and social benefits

By improving the recycling rate and resource utilization rate, the system helps enterprises reduce waste disposal costs and create considerable renewable resource value. At the same time, the system helps Vietnam promote green economic development, complies with the government's environmental protection policies and sustainable development strategies, and has good social benefits.

The industrial waste sorting system is an ideal choice for Vietnam to promote the resource treatment of solid waste, with broad application prospects and significant economic and environmental dual value.

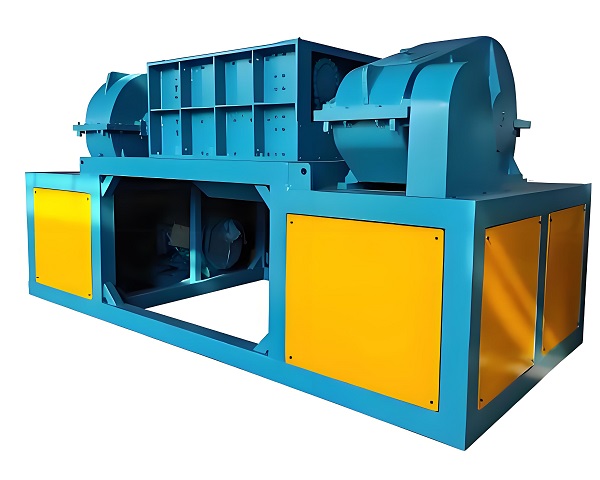

Main Machine

Customer Feedback

After using the Vietnamese industrial waste sorting system solution, our company's waste treatment efficiency and resource recycling benefits have achieved a qualitative leap! The modular design makes the system deployment extremely flexible. We select the adapter module according to the scale of the plant, install and debug quickly, and put it into use soon. The high-precision sorting technology is even more surprising. The originally mixed industrial waste has been processed, and the metal, plastic and other classifications are accurate. The metal recovery rate is far beyond expectations, and the plastic purity is also extremely high, which greatly improves the economic value of the recyclables.

The intelligent control system greatly reduces labor costs and management difficulties. The equipment fault warning function reduces downtime and maintenance time, and the operation and maintenance efficiency is significantly improved. In terms of environmental protection, dust, noise, and wastewater are effectively controlled, which fully meets environmental protection requirements. It not only solves the company's environmental protection problems, but also helps us shape a green corporate image. This solution truly achieves a win-win situation for environmental protection and economic benefits, and is worth recommending!