A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Industrial waste shredder

Industrial waste shredder is a device specially designed for crushing various types of waste generated in the industrial production process. Its core function is to tear large-sized, irregular industrial waste into small pieces for subsequent recycling, reuse or disposal. The following is a detailed introduction and summary of the industrial waste shredder:

Working principle and structure

The industrial waste shredder is mainly composed of a motor, a reducer, a tool system, a crushing chamber, a discharge port and other parts. When working, the motor drives the tool system to rotate through the reducer, and the tool tears, squeezes and shears the input waste to break it into small pieces. The tool system is usually made of high-strength alloy steel, which has the characteristics of wear resistance and impact resistance, and can adapt to the waste treatment needs of different materials.

Application field and scope

The application field of industrial waste shredder is wide, covering almost all industries that generate industrial waste. Specifically including:

Metal processing industry: processing waste automobile shells, metal scraps, aluminum profiles, etc., to facilitate metal recycling and reuse.

Plastic recycling industry: crush plastic scraps, packaging materials, waste plastic products, etc. to improve plastic recycling efficiency.

Rubber products industry: process waste tires, hoses, rubber seals, etc. to achieve the recycling of rubber resources.

Wood processing industry: crush waste wood, pallets, furniture scraps, etc. for biomass energy or board manufacturing.

Electronic waste treatment: crush waste circuit boards, electrical housings, etc. to facilitate subsequent extraction of valuable metals.

Advantages and characteristics

Efficient processing: can quickly crush large-sized waste and improve processing efficiency.

Strong adaptability: can handle waste of various materials to meet the needs of different industries.

Energy saving and environmental protection: the volume of the crushed waste is reduced, which is convenient for transportation and storage, and at the same time reduces pollution to the environment.

Easy operation: the equipment has a high degree of automation, easy operation, and reduced labor costs.

Development trend

With the improvement of environmental awareness and the increase in demand for resource recycling, industrial waste shredders will develop in a more efficient, intelligent and environmentally friendly direction. In the future, equipment will pay more attention to energy saving and consumption reduction, reducing noise and dust emissions, while improving crushing efficiency and output quality.

Operating principle of Industrial waste shredder

With the acceleration of industrialization, the output and types of industrial waste have increased dramatically. How to deal with these wastes efficiently and environmentally friendly has become the focus of global attention. As a key equipment for resource recycling, industrial waste shredder converts large-sized and irregular waste into particles of controllable size through physical crushing technology, laying the foundation for subsequent sorting, recycling or energy utilization. It not only solves the environmental pollution problems caused by traditional landfill or incineration, but also significantly increases the added value of waste, helping enterprises achieve cost reduction, efficiency improvement and sustainable development goals. This article will systematically analyze the core mechanism of industrial waste shredder from the perspectives of working principle, technical characteristics and application value.

1. Core drive and crushing foundation

The industrial waste shredder uses the motor as the power source, converts high-speed rotation into high-torque output through the reducer, and drives the tool system to operate. The tool system consists of a moving knife and a fixed knife. The moving knife is fixed to the main shaft and rotates at high speed, and the fixed knife is fixed to the inner wall of the crushing chamber. The two work together to form a composite crushing force of shearing, tearing and extrusion. The layout and shape of the cutter (such as hook type, claw type) can be adjusted for different waste materials to ensure efficient crushing. The overall equipment adopts a closed structure to reduce the leakage of dust and noise during the crushing process, while protecting the safety of operators.

2. Crushing process and material handling

After the waste is put into the crushing chamber through the feed port, it is first initially grabbed by the high-speed rotating moving knife and pushed to the fixed knife area. In the shear gap between the moving knife and the fixed knife, the material is subjected to a bidirectional force: the shear force cuts off fibrous or tough materials (such as plastics and rubber), the tearing force tears fabrics or film waste, and the extrusion force causes hard materials (such as metals and wood) to deform and break. The particle size of the crushed material is controlled by the screen aperture or the size of the discharge port. The particles that do not meet the standard may be sent back to the crushing chamber by the pushing device for secondary processing to ensure the uniformity of the discharge.

3. Technical characteristics and adaptability advantages

The equipment has three major technical advantages: First, the combination of high torque output and optimized tool design can handle high-hardness or high-toughness waste, and the crushing efficiency is more than 30% higher than that of traditional equipment; second, the modular tool system supports rapid replacement, adapting to multiple types of waste such as metal, plastic, rubber, and wood, reducing downtime and maintenance time; third, integrated overload protection and anti-stuck material reversal function, when abnormal load is detected, the equipment automatically cuts off power and rotates in the opposite direction for 10-15 seconds to discharge hard objects or entangled objects to avoid equipment damage.

4. Environmental protection and energy saving and industry application

The industrial waste shredder achieves low-energy operation by optimizing the transmission system and tool structure (energy consumption for processing 1 ton of waste is reduced by 20%-25%), and uses sound insulation materials and shock-absorbing bases to control the working noise below 85 decibels. Its applications cover manufacturing, recycling of renewable resources, environmental protection and other fields: crushing scrap metal shells in the automobile dismantling industry, processing scraps in plastic recycling plants, and decomposing waste tires in rubber product companies, helping to reduce the volume of industrial waste, recycle and harmlessly dispose of it, and promote the development of the circular economy.

The industrial waste shredder uses high-torque power to drive the tool system, and through the synergy of shearing, tearing and extrusion, it can achieve efficient crushing of various types of waste such as metal, plastic, rubber, and wood. Its modular tool design, intelligent safety protection (such as overload protection, anti-stuck material reversal) and environmental noise reduction technology give the equipment strong adaptability, high stability and low energy consumption advantages. In the context of the circular economy, the shredder significantly reduces the disposal cost of enterprises and reduces the environmental load through waste volume reduction and resource pretreatment, becoming the core equipment in the manufacturing, renewable resources and environmental protection fields. In the future, with the iteration of technology and intelligent upgrading, the industrial waste shredder will further promote the development of industrial waste treatment towards refinement and low carbonization, injecting new momentum into the global green transformation.

Advantages and features of Industrial waste shredder

With the expansion of industrial production scale and the increase in demand for resource recycling, the proper treatment of industrial waste has become a key link in the sustainable development of enterprises. As the core equipment for waste pretreatment, the industrial waste shredder converts large-sized and complex-structured waste into particles of controllable size through physical crushing technology, providing a basis for subsequent sorting, recycling or energy utilization. It can not only reduce the volume of waste, reduce transportation and storage costs, but also increase the added value of waste through resource utilization, helping enterprises achieve the dual goals of economic benefits and environmental responsibility. This article will systematically analyze the core advantages of industrial waste shredders from four dimensions: technical characteristics, economic value, environmental benefits and operational advantages.

Efficient crushing and strong adaptability

The industrial waste shredder adopts a high-torque power system and modular tool design, which can achieve efficient crushing of waste materials of different materials such as metal, plastic, rubber, and wood. For example, a single device can process 10-20 tons of waste tires or 5-8 tons of metal scraps per hour, with an efficiency increase of more than 30% compared with traditional equipment. The tool system supports quick replacement (such as hook type, claw type, flat tooth type), adapting to the diversified needs from soft plastics to hard metals; the large-size feed port (maximum 2000mm×1500mm) can reduce the pre-treatment cost of large waste materials such as waste furniture and car shells, directly put them into crushing, and improve the continuity of operation.

Resource utilization and environmental protection efficiency

The shredder significantly improves the resource utilization rate of waste materials by accurately controlling the crushing particle size (50-200mm). For example, after the waste tires are crushed, the steel wire and rubber particles can be recycled separately, the rubber particles are used for recycled rubber production, and the steel wire is directly smelted, with an added value of about 500-800 yuan per ton of waste tires; the purity of metal waste is improved after crushing, and the smelting energy consumption is reduced by 15%-20%. In addition, the equipment adopts a fully enclosed crushing chamber and wear-resistant lining design, the dust leakage concentration is less than 30mg/m³, and the volume reduction effect is 70%-90%, which greatly reduces the transportation and storage costs, while reducing the environmental pollution caused by landfill or incineration.

Safe, stable and intelligent operation

The equipment integrates multiple safety protection mechanisms (such as overload protection, anti-stuck material reversal, and emergency stop button). When encountering a hard object, it automatically reverses for 10-15 seconds to avoid damage to the tool or motor, and the failure rate is less than 2%. The PLC intelligent control system supports one-button start and stop, fault self-detection and remote monitoring to reduce manual intervention; the tool can be replaced separately after wear, and the maintenance cost is 30% lower than that of traditional equipment. Key components (such as bearings and seals) use international brands, and the service life is extended to more than 5 years, with significant advantages in comprehensive operating costs.

Economic value and industry application

Industrial waste shredders create direct economic benefits for enterprises through resource pretreatment. Taking scrap metal as an example, the transportation cost per ton after crushing is reduced by 40%, and the recycling rate is increased to more than 90%; after crushing and granulation of plastic waste, the cost of recycled materials per ton is reduced by 2,000-3,000 yuan compared with the original material. Its application covers multiple fields such as manufacturing, recycling of renewable resources, and environmental protection treatment. Especially in industries such as automobile dismantling, home appliance recycling, and construction waste treatment, it has become a key equipment to promote the development of circular economy.

Industrial waste shredders have the core advantages of efficient crushing, strong adaptability, resource utilization and intelligent safety. Through volume reduction, purification and reprocessing, they can transform waste from a "burden" to a "resource". In the context of stricter environmental protection policies and resource shortages, they not only help companies reduce disposal costs and improve competitiveness, but also provide technical support for global green transformation. In the future, with the upgrading of equipment intelligence and material technology, industrial waste shredders will play a greater role in the fields of refined sorting and low-carbon operation, and become an important driving force for the sustainable development of industry.

Technical Parameter Table of Industrial waste shredder

| Parameter / Model | IWS-800 | IWS-1200 | IWS-1600 | IWS-2000 |

|---|---|---|---|---|

| Shaft Length (mm) | 800 | 1200 | 1600 | 2000 |

| Number of Shafts | Dual Shaft | Dual Shaft | Dual Shaft | Dual Shaft |

| Motor Power (kW) | 2 × 22 | 2 × 45 | 2 × 75 | 2 × 90 |

| Shaft Speed (rpm) | 15 - 20 | 10 - 18 | 8 - 15 | 8 - 15 |

| Number of Blades | 20 - 30 | 30 - 40 | 40 - 60 | 60 - 80 |

| Output Size (mm) | 20 - 100 (adjustable) | 30 - 150 (adjustable) | 50 - 200 (adjustable) | 50 - 300 (adjustable) |

| Capacity (tons/hour) | 2 - 5 | 5 - 10 | 10 - 15 | 15 - 25 |

| Materials Handled | Plastic, rubber, wood, industrial packaging, light metals | Industrial scraps, cables, plastic drums, paint buckets | Large industrial waste, mixed plastics, metal casings | Construction formwork, pallets, oil drums, bulky industrial waste |

| Control System | PLC automatic control | PLC automatic control | PLC automatic control | PLC automatic control |

| Overload Protection | Yes | Yes | Yes | Yes |

| Auto-Reverse | Yes | Yes | Yes | Yes |

| Dimensions (L×W×H mm) | 3000×1500×1800 | 4200×1800×2200 | 5200×2200×2500 | 6000×2500×2800 |

| Weight (tons) | 4 - 6 | 8 - 10 | 12 - 16 | 18 - 22 |

If you have any special requirements, we will customize according to your special needs.

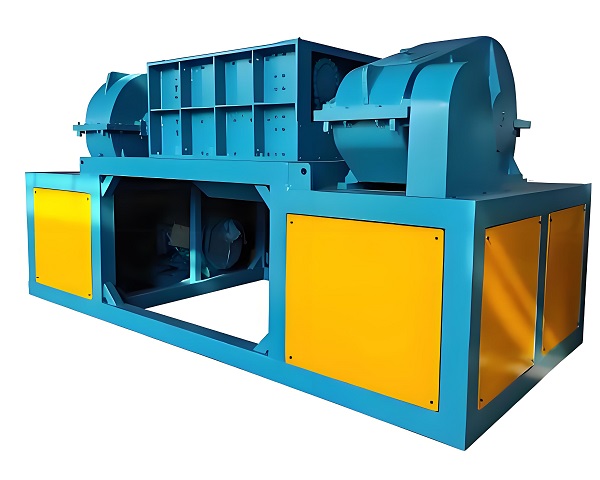

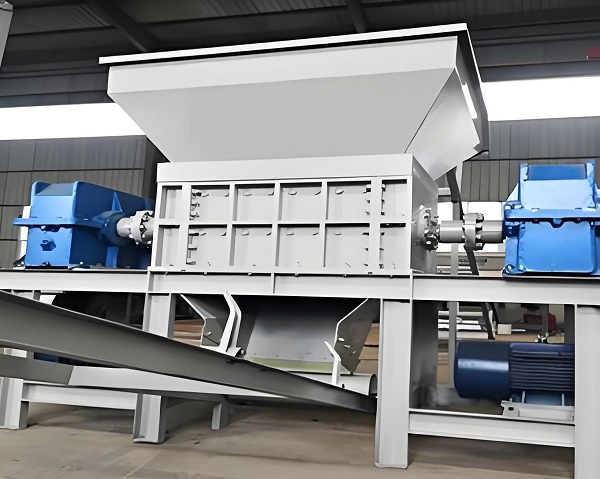

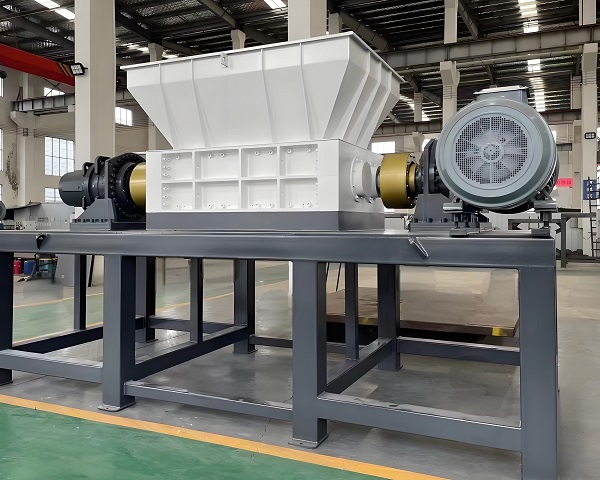

Product Picture Display of Industrial waste shredder

FAQ about Industrial waste shredder

>1. What types of waste are suitable for industrial waste shredders?

Industrial waste shredders can process metals (such as scrap car shells, scraps), plastics (films, pipes), rubber (tires, seals), wood (furniture, pallets), fabrics (clothing scraps), etc. Its modular tool design achieves multi-material compatibility through shearing, tearing and extrusion. For example, hook-type tools process fiber materials, and flat-tooth tools process hard metals to meet the physical property requirements of different wastes.

>2. What is the core working principle of the shredder?

The shredder drives the main shaft to rotate through a high-torque motor, and the moving knife and the fixed knife work together to form a shear gap. After the material is put in, the moving knife grabs the material and cooperates with the fixed knife to cut the fiber, tear and tear the soft material, and squeeze and crush the hard material. For example, when processing tires, the knife first tears the rubber layer, and then separates the steel wire and rubber particles to achieve efficient crushing and component separation.

>3. How to choose a suitable shredder model?

The selection should be based on the characteristics of the waste (size, hardness, composition), processing volume and discharge particle size. Large-sized waste (such as car shells) requires a large feed inlet model (≥1500mm×1000mm), high-hardness waste (such as metal) requires high-strength alloy steel cutters, and fine-grained requirements (such as plastic recycling) require screens to control the discharge (50-100mm). Customized configuration can improve the matching degree between equipment and demand.

>4. What is the energy consumption level of the shredder?

Energy consumption is related to motor power, material characteristics and processing efficiency. For example, the energy consumption of processing 1 ton of scrap metal is about 30-40kWh, which is 20%-25% lower than that of traditional equipment. Energy-saving design includes variable frequency motor automatic power adjustment, optimized transmission system to reduce loss, lightweight cutters to reduce rotation resistance, and comprehensive high-efficiency and low-consumption operation.

>5. Is the maintenance cost of the equipment high?

Maintenance costs mainly come from tool wear and replacement of wearing parts. The modular design supports the independent replacement of a single cutter, reducing costs by 30%; wear-resistant liners, bearings and other components use international brands with a lifespan of 3-5 years. Regular lubrication (such as every 500 hours) can extend the life of the equipment, and the comprehensive maintenance cost accounts for about 10%-15% of the total operating cost.

>6. How does the shredder avoid the problem of material jamming?

The equipment is equipped with an anti-jamming reversal system. When a hard object is stuck, the spindle automatically rotates in the opposite direction for 10-15 seconds to discharge foreign matter. In addition, the large-size feed port reduces the risk of large pieces of waste being stuck, the hydraulic pusher assists the material to fall, and the tool gap is adjustable to adapt to different material thicknesses to ensure continuous and stable operation.

>7. How does the shredder ensure operational safety?

Safety design includes overload protection (automatic power off when the current exceeds the limit), emergency stop button (emergency shutdown), closed crushing chamber (to prevent material splashing), protective cover and safety interlock (locking the spindle during maintenance). Multiple protection mechanisms cover the entire process of equipment operation and maintenance to reduce operational risks.

>8. How to reuse the shredded waste?

The particle size of the shredded waste is controllable (50-200mm), which is convenient for subsequent processing: the purity of metal smelting is improved, and energy consumption is reduced by 15%-20%; the cost of plastic granulation is reduced by 2000-3000 yuan/ton compared with the original material; the tire rubber particles are separated from the steel wire and the value is increased by about 500-800 yuan/ton; wood can be made into biomass fuel or board raw materials.

>9. What is the environmental performance of the shredder?

The equipment controls dust leakage (≤30mg/m³) through a fully enclosed crushing chamber + bag dust collector, and the soundproof cover and shock-absorbing base reduce noise (≤85dB). The volume reduction design reduces the volume of waste by 70%-90%, reducing transportation carbon emissions. The environmental performance is in line with the development trend of low pollution and low energy consumption in industrial waste treatment.

>10. How to choose a suitable shredder model?

It is necessary to comprehensively consider the material characteristics (hardness, size), processing volume requirements and budget space. For example, a double-shaft shredder is used for tire processing, and a four-shaft shredder is used for large metals. Small equipment (single-shaft) is suitable for laboratory or small-scale processing, while large equipment (four-shaft) supports industrial continuous operation. Modular design supports customized configuration and adapts to different scenarios.