A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

Industrial Waste Screening and Treatment System Introduce

Suzhou is an industrial powerhouse with developed manufacturing, chemical and other industries. The industrial waste generated in the production process is of various types and complex composition, including metal scraps generated by mechanical processing, waste slag from chemical companies, and scraps from plastic products companies. If these industrial wastes are not handled properly, they will not only occupy a large amount of land resources, but also cause serious pollution to the soil, water and atmospheric environment. In order to achieve the reduction, harmlessness and resource utilization of industrial waste, this industrial waste screening and treatment system is specially designed.

This system mainly uses the following equipment:

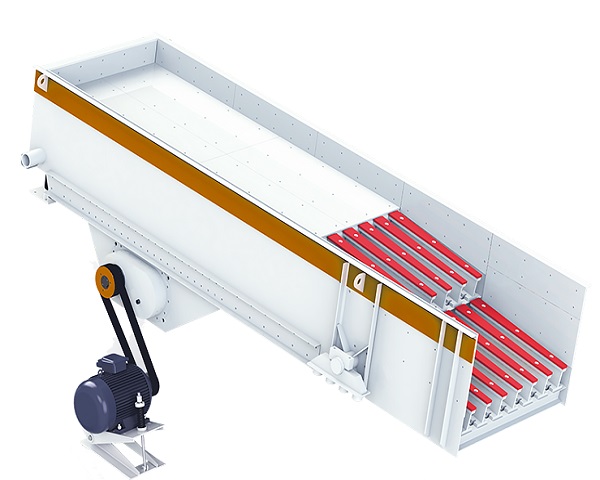

1. Vibrating feeder: It can evenly and continuously transport industrial waste to subsequent processing equipment to avoid blockage due to uneven feeding and ensure stable operation of the system. By adjusting the vibration frequency, the feeding speed can be controlled to adapt to different processing needs.

2. Jaw crusher: As a primary crushing equipment, it is suitable for industrial waste with higher hardness, such as metal alloy waste, ore waste slag, etc. The powerful crushing force can break large pieces of waste into smaller particles for subsequent processing.

3. Drum screen: There are screens with different apertures inside. The waste is screened and graded during the rotation of the drum, and materials of different particle sizes can be separated, such as separating fine metal debris from larger waste slag blocks.

4. Magnetic separator: Using the principle of magnetic field, ferromagnetic materials such as steel debris and scrap iron products are adsorbed and recovered from mixed waste to achieve effective recycling of metal resources.

5. Eddy current separator: For non-ferrous metals such as aluminum and copper, an alternating magnetic field is generated to generate an induced current in metal particles, thereby separating them from non-metallic materials and improving the recovery rate of non-ferrous metals.

6. Wind separator: According to the density and aerodynamic characteristics of different materials, light waste (such as plastic film, paper scraps) and heavy waste (such as stones, metal blocks) are separated to further refine the waste classification.

7. Briquetting machine: The recovered metal debris, plastic sheets, etc. are compressed into blocks to reduce the volume, facilitate storage and transportation, and improve the efficiency of subsequent smelting and reprocessing.

Process flow of the system

Industrial waste is first fed into the jaw crusher through a vibrating feeder for primary crushing; the crushed materials enter the drum screen for screening and grading; the screened materials are separated into metals and non-metals according to their different properties through magnetic separators, eddy current separators and air separators; the separated wastes, such as recyclable metals and plastics, are packaged and stored after being processed by briquetting machines for further resource utilization; non-recyclable hazardous wastes are transported to professional treatment agencies for harmless treatment.

This industrial waste screening and treatment system, through the coordinated operation of multiple equipment, realizes efficient screening and classification of industrial waste, which not only reduces the pollution risk of industrial waste to the environment, but also improves the resource recycling rate, which is of great significance to promoting the green and sustainable development of Suzhou industry.

Advantages and features of Industrial Waste Screening and Treatment System

1. Efficient equipment coordination, adaptable to a variety of wastes

The equipment combination of this solution is deeply adapted to the complex characteristics of Zhejiang's industrial waste. The vibrating feeder can flexibly adjust the feeding speed to evenly "feed" the subsequent crushing equipment to avoid blockage and idling; the jaw crusher can easily handle hard materials such as metal alloy waste and ore waste slag with its powerful crushing force, and the drum screen follows closely for fine screening to achieve accurate classification of material particle size. The magnetic separator and eddy current separator form a "golden partner". The former specializes in the recovery of ferromagnetic materials, and the latter accurately separates non-ferrous metals such as aluminum and copper. The wind separator separates light and heavy wastes, and the briquetting machine compresses and reduces the volume. The equipment has a clear division of labor and seamless connection, and can efficiently handle different types of waste such as mechanical processing debris and chemical waste slag.

2. Advanced technology and precise resource recovery

The magnetic separation, eddy current separation and other technologies used in the solution are at the forefront of industrial waste treatment. The magnetic separator uses a strong magnetic field to achieve an adsorption recovery rate of more than 95% for ferromagnetic materials; the eddy current separator uses an alternating magnetic field to generate an induced current for non-ferrous metals to achieve separation, and the identification and separation accuracy of metals such as aluminum and copper far exceeds that of traditional manual sorting. The wind selection process uses the principle of aerodynamics to accurately distinguish light waste such as plastic film and paper scraps from heavy materials. With precise screening technology, it can achieve in-depth and accurate recovery of various resources in industrial waste and maximize the value of waste.

3. Closed-loop process, efficient processing

Starting from the waste entering the vibrating feeder, it is crushed, screened, sorted, and then compressed into blocks for storage, forming a complete closed-loop process. The system can realize continuous and automated operation of waste treatment, reduce manual intervention, and reduce labor costs and the risk of operational errors. At the same time, unqualified materials can be quickly returned to the corresponding links for reprocessing to ensure stable processing quality, greatly improving the efficiency of industrial waste treatment. Compared with traditional treatment methods, the processing cycle is shortened by nearly 40%.

4. Significant benefits, helping enterprises develop

In terms of economic benefits, the income from resource recycling can quickly cover the equipment cost, and briquetting also reduces storage and transportation costs; in terms of environmental protection, the system realizes harmless waste treatment, helps enterprises avoid environmental penalties, complies with the national green development policy, and is expected to obtain policy subsidies; in terms of social benefits, standardized processing procedures improve the factory environment, enhance the corporate image, help enterprises attract talents and expand business, and promote enterprises to achieve green and sustainable development.

Main Machine

Customer Feedback

As the head of a manufacturing company in Suzhou, we have always had a headache in the past about industrial waste treatment. The accumulated metal scraps and waste residues not only occupy a large amount of space, but also face environmental risks if they are disposed of arbitrarily, and the cost of entrusting a third party to handle them is also high. It was not until the introduction of this industrial waste screening and treatment system that the problem that had lasted for many years was truly solved.

The equipment in the system performs its duties and cooperates efficiently. The vibrating feeder feeds evenly to ensure the smoothness of the subsequent process; the jaw crusher and drum screen crush and screen large pieces of waste, and the processing capacity far exceeds expectations. The magnetic separator and eddy current separator are "treasure equipment" that accurately separate ferromagnetic and non-ferrous metals, turning the originally discarded metals into saleable resources again. After the briquetting machine compresses the waste, the storage and transportation costs are greatly reduced.

From the perspective of economic benefits, the benefits brought by resource recycling basically cover the equipment investment cost; in terms of environmental protection, the risk of illegal treatment has been completely eliminated, and policy support has been obtained due to green production; in terms of production management, the waste treatment process is standardized, the site is clean and orderly, and the working environment of employees has also been improved. This system not only reduces the burden on enterprises and increases efficiency, but also lays a solid foundation for us to achieve sustainable development. It is undoubtedly an excellent choice for industrial waste treatment!