A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

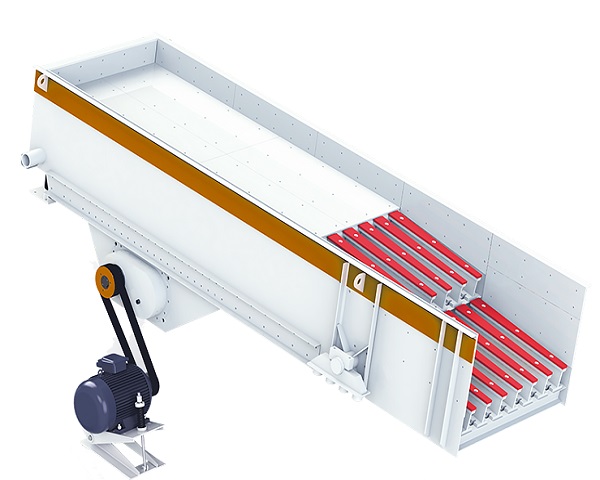

What is the Vibrating Feeder

A vibrating feeder is a mechanical device used for continuous and uniform feeding. It transports materials from a storage bin or hopper to subsequent processing equipment through the vibration generated. Its main structure consists of a feeding trough, a vibrator, a spring support, a drive motor, etc. During operation, the drive motor drives the vibrator to operate, and the vibrator generates a periodically changing exciting force, causing the feeding trough to produce directional continuous vibration. Under the action of the trough vibration, the material jumps forward along the trough surface to achieve uniform and stable feeding.

The vibrating feeder has significant technical advantages. On the one hand, its feeding speed is adjustable. By changing the parameters of the vibrator or the speed of the motor, the material delivery volume can be easily controlled to meet the needs of different production links; on the other hand, the equipment runs stably and reliably, and the spring support can effectively absorb vibration, reduce the impact of the equipment on the foundation, extend its service life, and reduce operating noise. In addition, the vibrating feeder has a simple structure, convenient daily maintenance, and relatively convenient operation. It only requires simple debugging and monitoring.

In actual applications, vibrating feeders are found in many industries. In the mining industry, it can evenly transport the mined ore to the crusher to improve the crushing efficiency; in the metallurgical industry, it is used to transport raw materials such as sintered ore and coke to the blast furnace; in the chemical, building materials and other industries, it can also achieve accurate feeding of powdered and granular materials. With the development of industrial automation, vibrating feeders can also be combined with automatic control systems to achieve remote control and intelligent adjustment, further improving the intelligent level and production efficiency of production, and providing stable and reliable guarantees for material transportation and processing in various industries.

Operating principle of Vibrating Feeder

The vibrating feeder is mainly composed of a feeding trough, an exciter, a spring support, a drive motor and other components. Its working principle is based on the theory of mechanical vibration. By converting electrical energy into mechanical energy, continuous and uniform conveying of materials is achieved.

The drive motor is the power source of the vibrating feeder, and the motor is connected to the exciter. The exciter is usually composed of an eccentric block. When the motor is powered on, it drives the eccentric block to rotate at high speed. Since the center of gravity of the eccentric block deviates from the center of rotation, a periodically changing centrifugal force will be generated during the rotation process, which is the source of vibration of the vibrating feeder. The horizontal and vertical components of the centrifugal force cause the feeding trough to perform reciprocating linear vibration or elliptical vibration in a specific direction and frequency.

During the vibration process, the interaction between the material and the feeding trough is the key to achieving material conveying. When the feeding trough vibrates forward and upward, the material is temporarily separated from the trough by the inertial force and is thrown up and jumps forward; when the trough moves backward and downward, the material falls back to the surface of the trough under the action of gravity. In this way, the material moves forward along the tilt direction of the feed trough in a small jump and is continuously transported to the designated position.

The spring support also plays an important role in the operation of the vibrating feeder. It elastically supports the feed trough. On the one hand, it can absorb part of the energy during the vibration process, reduce the impact of the equipment on the foundation, and reduce the impact of vibration on surrounding equipment and building structures; on the other hand, by reasonably designing the stiffness and damping of the spring, the vibration parameters of the feed trough, such as amplitude and frequency, can be adjusted to control the feeding speed and flow of the material. In addition, some vibrating feeders can also flexibly adjust the vibration intensity by adjusting the motor speed, changing the eccentric block counterweight, etc., to meet the precise control requirements of material conveying volume in different production scenarios.

Advantages and features of Vibrating Feeder

Based on the principle of vibration, the vibrating feeder generates periodic exciting force through a vibrating motor or an electromagnetic exciter, so that the trough body performs periodic reciprocating vibration along the inclined direction. When the exciting force reaches a certain intensity, the material moves forward in a jumping manner in the trough body to achieve uniform and continuous feeding. This unique working method gives it many significant features and advantages.

In terms of feeding accuracy, the vibrating feeder performs well. By adjusting the eccentric block angle of the vibration motor or the current size of the electromagnetic exciter, the feeding speed and flow rate of the material can be accurately controlled, and the error can be controlled within a very small range, meeting the precise requirements of different production processes for material conveying volume, and is particularly suitable for chemical, metallurgical and other industries with high requirements for batching accuracy.

Its structure is simple and compact, and it is easy to install and maintain. The equipment is mainly composed of a trough body, a vibration source and a supporting device, with fewer parts and small space. In daily use, it is convenient to replace wearing parts such as springs and vibration motors, without complicated disassembly processes, reducing downtime and maintenance time, and ensuring production continuity. At the same time, the vibration feeder operates stably and reliably. The vibration parts are made of high-strength wear-resistant materials, have strong impact resistance and wear resistance, long service life, and reduce the cost of equipment renewal for enterprises.

The vibration feeder has a wide range of applications and can convey various forms of materials such as block, granular, and powder. Whether it is ore transportation in mining, sand and gravel feeding in the building materials industry, or raw material distribution in food processing, it can operate stably. In addition, the equipment has low noise and low energy consumption during operation, which meets the requirements of environmental protection and energy saving. The vibration feeding process will not cause extrusion, crushing and other damage to the material, effectively protecting the original characteristics of the material and ensuring product quality.

Technical Parameter Table of Vibrating Feeder

| Model | Capacity (t/h) | Feeding Trough Size (mm) | Vibration Frequency (Hz) | Motor Power (kW) | Double Amplitude (mm) | Installation Angle (°) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| GZD-850×3000 | 80–150 | 850×3000 | 50 | 2×1.1 | 4–8 | 0–10 | 1200 |

| GZD-960×3800 | 120–210 | 960×3800 | 50 | 2×1.5 | 4–8 | 0–10 | 1700 |

| GZD-1100×4200 | 180–300 | 1100×4200 | 50 | 2×2.2 | 4–8 | 0–10 | 2100 |

| GZD-1300×4900 | 300–500 | 1300×4900 | 50 | 2×3.7 | 4–8 | 0–10 | 3200 |

| GZD-1500×6000 | 500–800 | 1500×6000 | 50 | 2×5.5 | 4–8 | 0–10 | 4500 |

If you have any special requirements, we will customize according to your special needs.

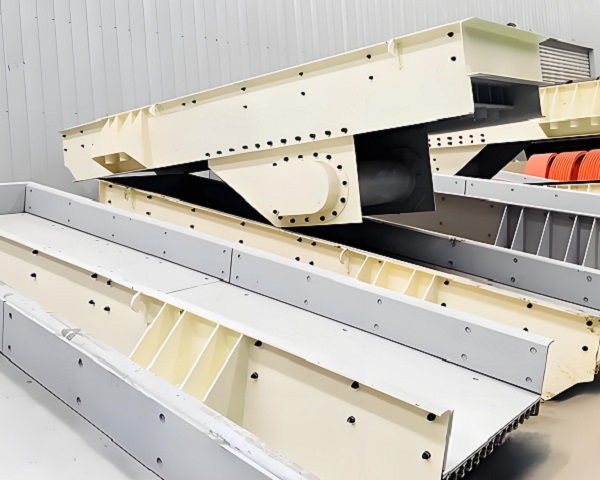

Product Picture Display of Vibrating Feeder

FAQ about Vibrating Feeder

>What types of vibrating feeders are there?

Mainly divided into electromagnetic vibrating feeders and motor vibrating feeders. Electromagnetic vibrating feeders are driven by electromagnetic force and are suitable for fine feeding; motor vibrating feeders rely on vibration motors to generate exciting force, have a large processing capacity, and are suitable for mining, metallurgy and other industries.

>How to choose a suitable vibrating feeder?

The selection should be based on material characteristics (particle size, humidity, density), conveying capacity, feeding accuracy and on-site installation space. For example, for conveying viscous materials, a model with a heating device can be selected; for high-precision batching, electromagnetic vibrating feeders are preferred.

>What is the maximum conveying capacity of a vibrating feeder?

The conveying capacity is affected by the equipment model, vibration parameters and material properties. Small electromagnetic vibrating feeders have an hourly conveying capacity of about 1-10 tons, and large motor vibrating feeders can reach hundreds of tons.

>What are the key points for daily maintenance of vibrating feeders?

Regularly check the tightening of the vibration motor bolts to prevent loosening; clean up residual materials in the tank to avoid agglomeration affecting feeding; monitor the bearing temperature and lubrication status, and replenish grease in time.

>What are the common faults of vibrating feeders?

Common faults include abnormal vibration (such as unstable amplitude), fluctuation of feeding amount, overheating of motor, etc. Abnormal vibration may be caused by improper adjustment of the eccentric block of the vibrator or damage of the spring; overheating of the motor is mostly caused by excessive load or poor heat dissipation.

>Can vibrating feeders convey wet materials?

Ordinary vibrating feeders conveying wet materials are prone to trough blockage. Models with heating function or special trough structure can be selected. However, materials with high water content may still affect the performance and service life of the equipment.

>Is the energy consumption of vibrating feeders high?

Compared with other conveying equipment, vibrating feeders have lower energy consumption. When working, they only need to overcome the friction of material movement, and the vibration motor is highly efficient. The energy consumption per unit conveying amount is only 1/3-1/2 of that of traditional belt conveyors.

>What are the requirements for the installation of vibrating feeders?

The equipment needs to be installed horizontally to avoid uneven feeding caused by tilting; the installation foundation should be solid to prevent resonance; buffer space should be reserved when connecting with other equipment to avoid rigid connection to transmit vibration.

>What is the degree of automation of the vibrating feeder?

Modern vibrating feeders can be integrated with PLC control systems to achieve automatic feeding by adjusting the vibration frequency and amplitude; with weighing sensors and feedback devices, they can accurately control the feeding amount to meet the needs of automated production lines.

>What is the service life of a vibrating feeder?

Under normal use and maintenance, the service life of a vibrating feeder can reach 5-10 years. Wearing parts such as springs and vibration motor bearings need to be replaced regularly, and reasonable maintenance can extend the life of the entire machine.

>Is the vibrating feeder noisy during operation?

By optimizing the structural design and adding shock-absorbing devices, the operating noise of modern vibrating feeders can be controlled below 85 decibels. If abnormal noise occurs, check for looseness or wear of components.