A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

Construction waste crushing and screening solution Introduce

With the rapid development of Shanghai's urban construction, the renovation of old cities, subway construction, new real estate development and other projects are constantly advancing, and the amount of construction waste generated continues to rise. A large amount of untreated construction waste not only occupies land resources, but may also cause environmental pollution. In order to achieve the reduction and resource utilization of construction waste, this crushing and screening plan is specially formulated.

Construction waste crushing and screening equipment

The main equipment used in this plan is as follows:

1. Jaw crusher: As a primary crushing equipment, it has the characteristics of large crushing ratio, high output and stable operation. Its high-strength movable jaw and fixed jaw can effectively crush large pieces of construction waste, such as concrete blocks, bricks, etc., and crush them into smaller particles, reducing the pressure for subsequent processing.

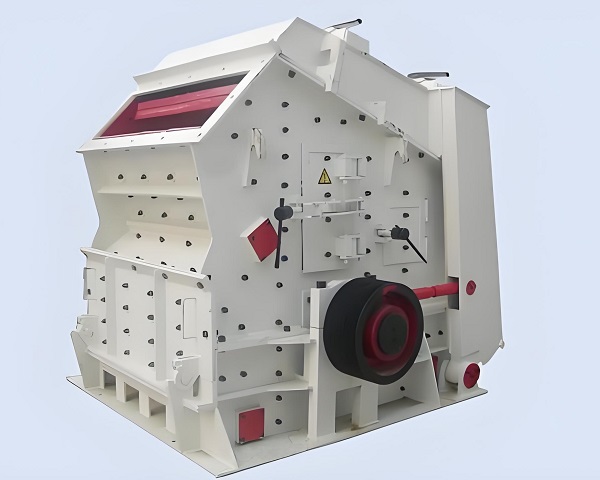

2. Impact crusher: Suitable for medium and fine crushing operations, using a high-speed rotating rotor to hit the material onto the impact plate to achieve multiple crushing. The material that has been initially crushed by the jaw crusher can be further refined. For construction waste with moderate hardness, it can efficiently crush aggregates with uniform particle size.

3. Vibrating screen: used to screen and grade the crushed material. Its multi-layer screen design can screen out aggregates of different particle sizes according to demand, such as coarse aggregates (for road base paving) and fine aggregates (for making recycled bricks, etc.), ensuring that the aggregates meet the requirements of different resource utilization scenarios.

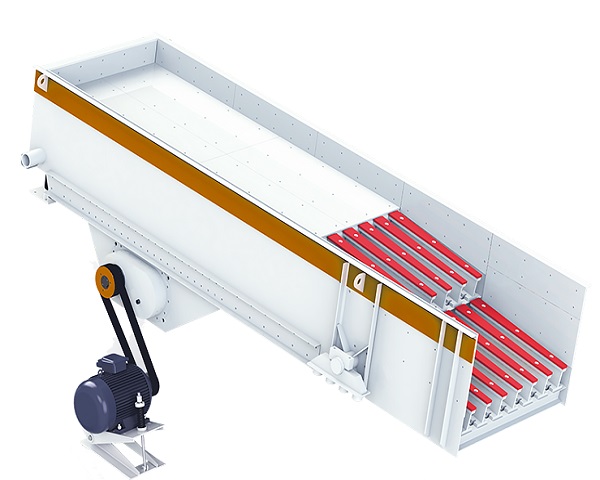

4. Feeder: Feed construction waste into the crusher evenly and continuously to avoid equipment blockage or idling due to uneven feeding, and ensure the smooth operation of the entire crushing and screening process.

5. Belt conveyor: Responsible for the transportation of materials, transporting crushed and screened aggregates to designated locations, connecting various equipment to form a coherent production line.

Construction waste crushing and screening equipment

The specific process is: after the construction waste is transported to the treatment site by the transport vehicle, it is evenly fed into the jaw crusher for primary crushing through the feeder; the crushed material enters the impact crusher for secondary crushing; then, the material is transported to the vibrating screen for screening, and aggregates of different specifications are screened out; unqualified materials are returned to the crusher for re-crushing. The entire process realizes efficient material transmission through the belt conveyor, forming an automated processing process.

Through this plan, Shanghai's construction waste can be effectively converted into recycled aggregates and used in road engineering, construction engineering and other fields, reducing dependence on natural sand and gravel, reducing the impact of construction waste on the environment, and at the same time creating certain economic benefits, helping Shanghai's green city construction and sustainable development.

Advantages and features of Construction waste crushing and screening solution

1. The equipment combination is highly targeted and adaptable to complex working conditions

The composition of Shanghai's construction waste is complex, covering a variety of materials such as concrete blocks, bricks, and metals. The equipment combination of this solution closely fits this feature. With its high-strength movable jaw and fixed jaw, the jaw crusher can easily crush large pieces of hard materials. Its large crushing ratio and high output characteristics can quickly handle a large amount of concrete waste generated by old city renovation and subway construction, laying the foundation for subsequent processes; the impact crusher has a significant effect on the fine crushing of materials with moderate hardness. Through the synergistic effect of the rotor and the impact plate, the primary crushed materials are further refined to produce aggregates with uniform particle size; the multi-layer screen design of the vibrating screen can accurately screen out aggregate particle sizes that meet different needs. Whether it is coarse aggregates required for road base paving or fine aggregates required for recycled brick production, they can be efficiently produced. The whole set of equipment combination shows strong targeting and adaptability.

2. The process flow is scientific and efficient, realizing closed-loop processing

The solution adopts a closed-loop process flow of "feeding - primary crushing - secondary crushing - screening - return material and re-crushing". The feeder feeds evenly to avoid idling or clogging of the crusher, ensuring stable operation of the equipment; the belt conveyor runs through the entire process to achieve efficient material transmission, so that each device is seamlessly connected, greatly improving the processing efficiency; for materials that fail to meet the screening standards, they are promptly returned to the crusher for re-crushing to ensure that all output aggregates meet the quality standards. This scientific process design not only improves the processing speed of construction waste, but also ensures the quality of recycled aggregates, forming an efficient and orderly automated processing system.

3. High resource recycling rate and significant economic benefits

Through this solution, construction waste can be efficiently converted into recycled aggregates for use in road engineering, construction engineering and other fields, effectively replacing natural sand and gravel, and reducing dependence on natural resources. Taking road base paving as an example, the use of recycled aggregates is not only cheaper than natural sand and gravel, but also can digest a large amount of construction waste and reduce waste disposal costs. At the same time, the production of building materials such as recycled bricks and recycled concrete has created new profit growth points for enterprises, achieved the dual improvement of resource recycling and economic benefits, and met the needs of sustainable development of Shanghai's urban construction.

4. Outstanding environmental value, helping green development

The plan reduces the accumulation of construction waste from the source, reduces the occupation of land resources and environmental pollution risks of landfill. By converting construction waste into recycled aggregates, it reduces ecological damage in the process of natural sand and gravel mining, reduces carbon emissions, and is of great significance to improving Shanghai's urban ecological environment and promoting green city construction, helping Shanghai achieve the "dual carbon" goal and practice the concept of green development.

Main Machine

Customer Feedback

When we participated in several large-scale urban construction projects in Shanghai, we introduced this set of construction waste crushing and screening solutions, and its outstanding performance far exceeded expectations.

The equipment combination is fully adapted to the complex composition of Shanghai's construction waste. The jaw crusher easily gnaws the hard concrete blocks in the old city renovation, and the impact crusher further refines the materials. With the precise vibrating screen, it can stably produce aggregates of different specifications. The entire processing process is smooth and efficient, and the project has never been delayed due to equipment problems.

The scientific closed-loop process saves us worry and effort. The feeder and the belt conveyor work together to ensure the orderly flow of materials. The unqualified materials are automatically returned to the furnace for reprocessing, which not only improves efficiency but also ensures the quality of aggregates. We once processed tens of thousands of tons of construction waste in one month, and the recycled aggregates produced were directly used for the paving of the surrounding road base. The cost was reduced by nearly 30% compared with the use of natural sand and gravel, and the economic benefits were very considerable.

More importantly, the environmental benefits brought by the solution are significant. A large amount of construction waste has been "turned into treasure", reducing the pressure of landfill and contributing to the green development of the city. Today, this solution has become the "standard configuration" of our projects. We hope that more colleagues can benefit from it and jointly promote the resource utilization of construction waste.