A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Wind Separator

Wind Separator is a device that uses the difference in the suspension speed of material particles under the action of airflow to achieve separation. With its unique working principle and structural design, it has shown many characteristics and advantages in the field of material sorting.

High efficiency and precision, outstanding separation effect

The wind separator can achieve efficient and accurate separation based on the density, particle size, shape and aerodynamic characteristics of the material by precisely controlling the speed, direction and flow of the airflow. Taking the sorting of domestic waste as an example, it can quickly separate lightweight plastic film and paper from heavier metals and glass, with a separation efficiency of more than 90%, effectively improving the purity of the material and providing convenience for subsequent processing.

Widely applicable to meet diverse needs

The wind separator has strong adaptability to materials and can handle a variety of complex mixtures such as domestic waste, waste plastics, crop straw, industrial waste residue, etc. Whether it is processing light combustibles in municipal waste or sorting impurities and dust in grains, it can do it. In addition, by adjusting equipment parameters and configurations, personalized sorting solutions can be customized for different industries and the characteristics of different materials to meet diverse production needs.

Simple structure and low maintenance cost

The overall structure of the wind sifter is relatively simple, mainly composed of fans, sorting chambers, feeding devices, discharge ports and other parts, without complex transmission parts and wearing parts. This makes the installation, commissioning and operation of the equipment relatively simple, and ordinary operators can get started after simple training. Moreover, daily maintenance only requires regular inspection of the operating status of the fan and cleaning of the accumulated materials and debris in the sorting chamber. The maintenance workload is small and the frequency of parts replacement is low, which greatly reduces the maintenance cost and downtime of the equipment.

Green and environmentally friendly, in line with sustainable development

The air separation process mainly relies on the action of airflow, without the use of chemical agents, avoiding environmental pollution. At the same time, through efficient sorting, recyclable resources in waste can be separated to achieve resource reuse, reduce environmental pollution caused by landfill and incineration, and help the development of circular economy. In addition, the noise generated by the wind sifter during operation is small, and the dust removal device equipped can also effectively collect the dust generated during the sorting process, further reducing the impact on the surrounding environment, which meets the requirements of modern industrial green production.

Flexible configuration and strong scalability

According to actual production needs, the wind sifter can be flexibly combined with crushers, screeners, magnetic separators and other equipment to build a complete material processing production line. This modular design allows the production line to be quickly adjusted and expanded according to the expansion of production scale or changes in material types. It has strong adaptability and scalability, providing strong support for the long-term development of the enterprise.

Operating principle of Wind Separator

Wind Separator, also known as Wind Sifter or Air Separator, is an efficient sorting equipment that separates materials based on the principle of airflow dynamics. It is widely used in solid waste treatment, renewable resource recycling, construction waste treatment, organic waste pretreatment and other industries. By adjusting the wind speed and airflow direction, the wind separator can effectively separate materials of different densities, shapes and weights, and has many unique technical characteristics and significant advantages.

Core features of Wind Separator

1. Airflow sorting principle

Wind Separator blows the material through high-speed air flow, and uses the difference in the suspension characteristics of the material in the airflow to achieve automatic separation of light and heavy materials. It is often used to separate plastics, paper, film, foam, wood and heavy materials such as metal, stone, glass.

2. Highly adaptable structure

Multiple configurations are suitable for different material types and processing scenarios, such as gravity air separation, drum air separation, dual-channel air separation and other structures, which can achieve efficient screening in complex mixtures.

3. High degree of automation

Usually works in conjunction with crushing, conveying, screening, magnetic separation and other equipment to achieve intelligent control of the entire line, automate the sorting process, and improve work efficiency without manual intervention.

4. Adjustable wind speed and flow direction

Operators can adjust the wind pressure, air volume and angle according to the properties of the material to ensure separation accuracy and adapt to the changes in diverse materials.

5. Compact footprint and modular design

Most equipment adopts a modular structure, which is flexible to install and occupies a small area, making it easy to integrate into existing production lines or flow processing systems.

Main advantages of Wind Separator

1. High sorting efficiency

It can achieve a separation accuracy of more than 90%, especially in the removal of lightweight materials, greatly improving the efficiency of subsequent resource recovery.

2. Excellent environmental performance

There is no obvious dust leakage during the operation of the equipment, and it is usually equipped with a dust removal system or air circulation system to reduce secondary pollution and meet environmental protection standards.

3. Energy saving and consumption reduction

Compared with traditional manual sorting or heavy screening equipment, wind sorting equipment has moderate operating power, low energy consumption, and more advantages in long-term operating costs.

4. Easy maintenance

Simple structure, easy to inspect and maintain, long replacement cycle of main wearing parts, low downtime rate, strong equipment reliability.

5. Wide range of applications

It can be applied to everything from urban domestic waste, organic waste to industrial waste, construction waste, etc., meeting the needs of multiple industries and is one of the key equipment for waste resource processing.

With its efficient, intelligent and environmentally friendly sorting capabilities, Wind Separator plays an increasingly important role in modern waste sorting and resource recycling systems, providing strong technical support for the realization of circular economy and sustainable development.

Advantages and features of Wind Separator

Wind Separator is a device that uses the difference in the suspension speed of material particles under the action of airflow to achieve separation. With its unique working principle and structural design, it has shown many characteristics and advantages in the field of material sorting.

1. High efficiency and precision, outstanding separation effect

Wind Separator can achieve high efficiency and precision separation according to the density, particle size, shape and aerodynamic characteristics of the material by precisely controlling the speed, direction and flow of the airflow. Taking the sorting of domestic waste as an example, it can quickly separate lightweight plastic film and paper from heavier metals and glass, with a separation efficiency of more than 90%, effectively improving the purity of the material and providing convenience for subsequent processing.

2. Widely applicable and meeting diverse needs

Wind Separator has strong adaptability to materials and can handle a variety of complex mixtures such as domestic waste, waste plastics, crop straw, industrial waste residue, etc. Whether it is handling light combustibles in municipal waste or sorting impurities and dust in grains, it can do it. In addition, by adjusting equipment parameters and configurations, personalized sorting solutions can be customized according to the characteristics of different industries and different materials to meet diverse production needs.

3. Simple structure and low maintenance cost

The overall structure of Wind Separator is relatively simple, mainly composed of fans, sorting chambers, feeding devices, discharge ports and other parts, without complex transmission parts and wearing parts. This makes the installation, commissioning and operation of the equipment relatively simple, and ordinary operators can get started after simple training. Moreover, daily maintenance only requires regular inspection of the operating status of the fan and cleaning of the accumulated materials and debris in the sorting chamber. The maintenance workload is small and the frequency of parts replacement is low, which greatly reduces the maintenance cost and downtime of the equipment.

4. Green and environmentally friendly, in line with sustainable development

The wind separation process mainly relies on the action of airflow, without the use of chemical agents, avoiding environmental pollution. At the same time, through efficient sorting, recyclable resources in waste can be separated to achieve resource reuse, reduce environmental pollution caused by landfill and incineration, and help the development of circular economy. In addition, the noise generated by Wind Separator during operation is small, and the dust removal device equipped can also effectively collect the dust generated during the sorting process, further reducing the impact on the surrounding environment, which meets the requirements of modern industrial green production.

5. Flexible configuration and strong scalability

Wind Separator can be flexibly combined with crushers, screeners, magnetic separators and other equipment according to actual production needs to build a complete material processing production line. This modular design allows the production line to be quickly adjusted and expanded according to the expansion of production scale or changes in material types. It has strong adaptability and scalability, providing strong support for the long-term development of the enterprise.

Technical Parameter Table of Wind Separator

| Model | Processing Capacity (t/h) | Power (kw) | Fan Brand | Applicable Materials | Dimensions (L×W×H, mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WF-50 | 50 | 30 | South Wind | Municipal Solid Waste, Straw | 5000×2500×3000 | 3500 |

| WF-100 | 100 | 60 | Howden Huayun | Waste Plastics, Light Industrial Waste | 6500×3000×3500 | 5000 |

| WF-150 | 150 | 90 | Climaveneta | Mixed Materials, Grain Impurities | 8000×3500×4000 | 6500 |

| WF-200 | 200 | 120 | Greenheck | Construction Waste, Biomass Waste | 9500×4000×4500 | 8000 |

| WF-300 | 300 | 180 | Kemflo | Urban Solid Waste, Fiber Materials | 12000×4500×5000 | 10000 |

If you have any special requirements, we will customize according to your special needs.

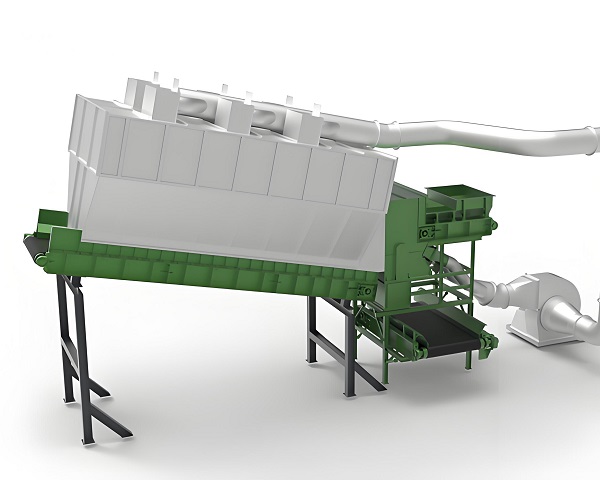

Product Picture Display of Wind Separator

FAQ about Wind Separator

>1. Does Wind Separator have a high return on investment?

Wind Separator has a relatively moderate investment, can greatly improve resource recovery efficiency and reduce manual sorting costs, and is a cost-effective solution for realizing waste resource utilization and intelligent sorting.

>2 How to cooperate with other sorting equipment (such as magnetic separation, vibrating screen)?

Wind Separator is often used in combination with magnetic separators, drum screens, crushers, etc., and plays a role in preliminary light and heavy separation or fine classification on the complete sorting line, which is an important part of the process.

>3. What materials are suitable for Wind Separator?

It is suitable for mixed solid waste, domestic waste, construction waste, renewable resources, agricultural waste, etc., especially for scenes with light impurities or heavy foreign matter that need to be separated.

>4. How high is the sorting accuracy?

The sorting accuracy of modern wind separators can usually reach 85%\~95%. The specific effect is affected by the uniformity of the material, humidity and setting parameters, and the separation efficiency can be optimized by adjusting the airflow.

>5. Can the wind speed be adjusted?

Yes, most wind separators are equipped with a wind speed adjustment system, which can adjust the airflow speed and direction according to the weight and structure of the material to improve the sorting effect.

>6. Is it suitable for wet or sticky materials?

Although it is mainly suitable for dry materials, some models support the processing of wet materials with low moisture content. It is recommended to use them after pretreatment or drying to ensure sorting efficiency.

>7. What is the processing capacity of the wind separator?

The processing capacity of different models ranges from 5 tons/hour to 50 tons/hour. The actual capacity depends on the material density, equipment settings and feeding speed.

>8. Does it occupy a large area?

Compared with heavy screening equipment, wind separators occupy a smaller area, and the modular design makes it easy to integrate into existing production lines. It is also suitable for mobile or vehicle-mounted operations.

>9. Is manual operation required?

The equipment has a high degree of automation and basically does not require manual intervention. It only requires manual inspection and necessary maintenance management to reduce labor costs and operating risks.

>10. Are there dust or pollution problems during use?

High-quality equipment is usually equipped with a dust removal system or closed structure, which can effectively control dust spillage, meet environmental protection standards, and can choose an air circulation system to reduce energy consumption and emissions.

>11. Is the maintenance of the Wind Separator difficult?

The structure is relatively simple, and maintenance mainly involves cleaning the fan, motor, transmission system and air flow channel. Regular maintenance can ensure long-term stable operation of the equipment.