A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Air Separator

Air Separator is a mechanical device that separates materials based on aerodynamic principles. It is widely used in resource recycling, agricultural processing, industrial production and other fields.

The core working principle of the air separator is to use the difference in the force exerted on different materials in the airflow to achieve particle separation. When the equipment is running, the fan generates a directional airflow. After the sorted materials enter the sorting chamber, due to the differences in density, particle size and shape, the balance state between the airflow force exerted on each material particle and its own gravity is also different. Lightweight materials with low density and large volume (such as plastic film and paper) will move farther along the airflow direction under the push of the airflow; while heavy materials with high density and small volume (such as metal, glass and stone) will settle quickly due to the dominant gravity. By reasonably designing the structure of the sorting chamber and the airflow parameters, materials with different characteristics can be accurately separated and collected at their corresponding outlets.

In terms of application, the air separator performs very well. In garbage sorting, it can separate recyclables such as plastics and paper from kitchen waste, bricks and stones in mixed garbage, thereby improving resource recycling rate; in the grain processing industry, it can remove light impurities and deflated grains in grains to improve product quality; in the field of waste plastic recycling, it can separate plastics of different densities to provide pure raw materials for subsequent recycling.

Air sorting machines have many advantages. First, the equipment structure is relatively simple, mainly consisting of a fan, a sorting chamber, a feeding device, a discharging system, etc., without complex and precise components, so installation, operation and maintenance are relatively convenient, reducing the threshold for use and operating costs. Second, the sorting process is green and environmentally friendly, does not require the addition of chemical agents, does not pollute the environment, and can effectively realize the recycling of resources, which is in line with the concept of sustainable development. Third, it has strong adaptability. By adjusting parameters such as air flow velocity and sorting chamber structure, it can process a variety of different types of materials to meet the diverse needs of different industries and different production scenarios. In addition, the air separator can also be combined with crushers, screens, magnetic separators and other equipment to build a complete material processing production line, further improving processing efficiency and sorting effects.

Operating principle of Air Separator

Air Separator is a mechanical device based on aerodynamic principles that uses the force difference of materials in the airflow to achieve separation. It is widely used in resource recycling, mineral processing, agriculture and other fields. Its core principle is to effectively separate mixed materials through the action of airflow according to the density, particle size, shape and air resistance of the materials.

The basic workflow of Air Separator revolves around the generation and control of airflow. The equipment is mainly composed of key parts such as the feeding system, sorting chamber, fan, airflow adjustment device and discharge port. The mixed materials to be sorted are evenly transported to the sorting chamber through the feeding system. At the same time, the fan generates a high-speed and stable airflow, which enters the sorting chamber after being optimized by the airflow adjustment device. In the sorting chamber, the airflow forms a specific flow field, in which the mixed materials are subjected to the combined action of multiple forces such as gravity, airflow thrust, air buoyancy and air resistance.

Materials with low density, fine particle size and flat shape, such as waste paper, plastic film, lightweight fiber, etc., are subject to greater air resistance and are easily suspended and carried by the airflow under the action of airflow, moving in the direction of airflow, and finally discharged from the light material outlet near the airflow outlet; while materials with high density, coarse particle size and regular shape, such as metal blocks, glass, sand and gravel, are subject to insufficient air resistance to suspend them due to their own gravity and inertia, and sink rapidly under the action of gravity and are discharged from the heavy material outlet at the bottom of the sorting chamber.

Some Air Separators will also set up multi-stage sorting structures to achieve more refined material separation by adjusting the airflow speed and direction at different stages. For example, in the secondary sorting stage, slightly heavier materials mixed in light materials can be further separated, or particles with relatively small density can be screened out from heavy materials, greatly improving the sorting accuracy of materials. In addition, some advanced Air Separators are equipped with intelligent control systems that can adjust airflow parameters in real time according to material characteristics to ensure the best sorting effect under different working conditions.

Air Separator, with its unique working principle, can efficiently separate mixed materials without complicated chemical treatment or high-energy mechanical operation. It plays an important role in resource recycling and material pretreatment, laying a solid foundation for subsequent processing and resource regeneration.

Advantages and features of Air Separator

Air Separator is an efficient equipment based on aerodynamic principles, which uses airflow to generate differentiated forces on materials of different densities and particle sizes to achieve material separation. With its unique technical principles and design, it has shown significant characteristics and advantages in the fields of resource recycling and industrial production.

1. High efficiency and precision to improve separation quality

Air Separator can efficiently separate materials according to their density, shape, particle size and other characteristics by precisely controlling the speed, direction and intensity of the airflow. In the process of recycling waste plastics, it can quickly separate plastics of different densities with a purity of more than 90%; when processing domestic waste, it can effectively separate light paper and film from heavier masonry and metal, greatly improving the sorting efficiency and quality, and laying a solid foundation for subsequent resource utilization.

2. Widely applicable to meet diverse needs

The equipment has strong adaptability to materials and can process a variety of complex materials such as domestic waste, scrap metal, industrial waste slag, crop straw, food raw materials, etc. Whether it is sorting mixed waste materials in the recycling industry or screening impurities in grains and nuts in the food processing field, Air Separator can flexibly respond to the sorting needs of different materials by adjusting equipment parameters and structure, and meet the diversified production needs of various industries.

3. Simple structure and low maintenance cost

The Air Separator has a simple structural design, mainly composed of fans, sorting chambers, feeding systems, discharge ports and other components, without complex transmission devices and precision wearing parts. This makes the equipment installation and commissioning process simple, and operators can operate proficiently after simple training. Daily maintenance only requires regular inspection of the fan operation status and cleaning of residual materials in the sorting chamber. The maintenance workload is small, the frequency of parts replacement is low, and the equipment maintenance cost and downtime are greatly reduced to ensure production continuity.

4. Green and environmentally friendly, in line with development trends

The air sorting process uses air as the medium, and no chemical agents need to be added, which avoids chemical pollution from the source. At the same time, through efficient sorting, the maximum recycling of resources can be achieved, the amount of waste landfill and incineration can be reduced, and environmental pollution can be reduced. The equipment produces low noise during operation, and the supporting dust removal system can effectively collect dust generated by sorting, further reducing the impact on the environment, which is in line with the concept of modern green production and sustainable development.

5. Flexible configuration and excellent expansion performance

Air Separator is highly flexible and can be freely combined with crushers, screeners, magnetic separators and other equipment according to actual production needs to build a complete material processing production line. The modular design enables it to quickly adapt to changes in production scale and material type adjustments. Whether it is a simple sorting operation for a small enterprise or a complex production process for a large factory, it can achieve efficient operation through flexible configuration, providing strong support for enterprise development.

Technical Parameter Table of Air Separator

| Model | Processing Capacity (m³/h) | Applicable Materials | Operating Temperature (°C) | Working Pressure (MPa) | Power (kW) | Dimensions (L×W×H, mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| AS-100 | 100 - 150 | Light plastics, paper, dust | 5 - 40 | 0.05 - 0.1 | 5.5 | 3000×1500×2000 | 1500 |

| AS-200 | 200 - 250 | Grain impurities, fiber materials | 5 - 45 | 0.06 - 0.12 | 7.5 | 3500×1800×2200 | 2000 |

| AS-300 | 300 - 400 | Light components in MSW, wood chips | -5 - 50 | 0.08 - 0.15 | 11 | 4000×2000×2500 | 2500 |

| AS-500 | 500 - 600 | Mixed industrial waste, crushed plastic particles | 0 - 50 | 0.1 - 0.2 | 15 | 5000×2500×3000 | 3500 |

| AS-800 | 800 - 1000 | Waste textiles, fluffy materials | 0 - 55 | 0.12 - 0.25 | 22 | 6000×3000×3500 | 5000 |

If you have any special requirements, we will customize according to your special needs.

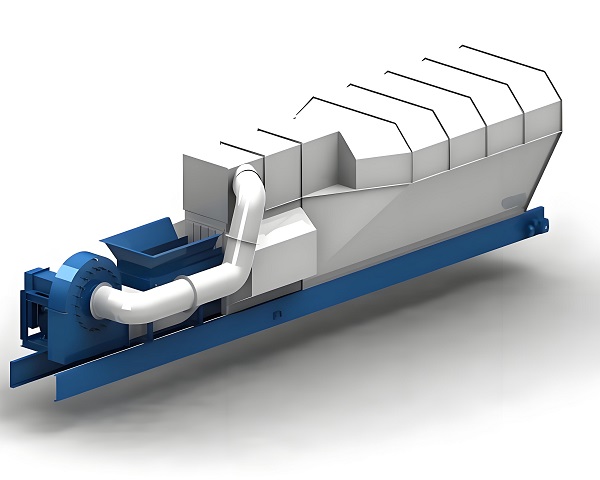

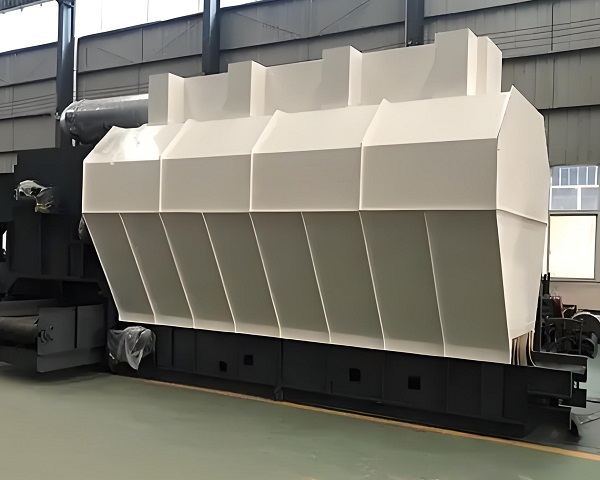

Product Picture Display of Air Separator

FAQ about Air Separator

>What materials are Air Separator mainly suitable for?

It is suitable for separating light and heavy mixed materials, such as separating plastics, paper from metals and stones in domestic waste; separating grains from impurities in the agricultural field; separating plastic films from heavier residues in industrial waste, etc. It is especially suitable for handling loose materials with obvious density differences.

>What are the advantages of Air Separator compared with other separation equipment?

Compared with mechanical screening or magnetic separation equipment, Air Separator has no complex mechanical structure, is not easy to clog, and is easy to maintain; it can achieve dry separation without water, which is energy-saving and environmentally friendly; it can continuously process a large amount of materials with little damage to the materials, and is suitable for the separation of heat-sensitive or easily deformed materials.

>How to choose the right Air Separator model?

It needs to be selected based on the processing volume, material characteristics (density, particle size, humidity), separation accuracy requirements and budget. For processing volume, choose a high air volume model; for materials with high humidity, anti-clogging design should be considered; for high separation accuracy requirements, choose multi-stage sorting equipment.

>What are the precautions during the installation of Air Separator?

During installation, ensure that the equipment is placed horizontally to avoid affecting the sorting effect due to tilt; the connection between the fan and the pipeline must be sealed to prevent air leakage and reduce wind force; the electrical system must be grounded to ensure safe operation, and sufficient space must be reserved for later maintenance.

>What does the daily maintenance of Air Separator include?

Regularly clean the residual materials in the sorting chamber to prevent accumulation from affecting the airflow; check the tightness of the fan belt to avoid slipping; monitor the temperature and vibration of the motor; clean or replace the air filter to ensure smooth airflow and extend the service life of the equipment.

>What may be the cause of poor separation effect of Air Separator?

It may be improper wind speed adjustment, too strong wind force light materials entrain heavy materials, too weak wind force and incomplete separation; uneven feeding leads to local blockage; material humidity exceeds the standard, affecting fluidity; equipment is not tightly sealed, airflow leakage reduces sorting efficiency.

>Is the energy consumption of Air Separator high during operation?

The main energy consumption comes from the operation of the fan, and the energy consumption is related to the equipment model, processing volume and operation time. Large-scale high-air volume equipment has relatively high energy consumption, but by optimizing the fan selection and using variable frequency control to adjust the wind speed, energy consumption can be reduced while meeting the sorting needs.

>Can Air Separator handle wet materials?

Wet materials are easy to agglomerate, which will affect the airflow sorting effect and even block the equipment. It is generally not recommended to handle directly. If treatment is required, the material should be dried and pre-treated first, or a special model of equipment with anti-clogging design and suitable for humid environments should be selected.

>What is the service life of the Air Separator equipment?

Under normal use and maintenance, the service life of the Air Separator can reach 8-10 years. The quality of key components such as fans and motors, as well as the frequency of daily maintenance and environmental factors, will affect the actual service life.

>Does the operation of Air Separator require professional training?

The basic operation is relatively simple, but in order to ensure efficient operation and safe production of the equipment, operators need to receive basic training to learn the equipment start-stop process, parameter adjustment methods, common troubleshooting and safety precautions.

>What should I do if the Air Separator is noisy during operation?

It may be caused by unbalanced fan blades, worn bearings or loose parts. Check whether the fan blades are dusty or damaged, replace worn bearings, and tighten loose screws; you can also install sound insulation devices to reduce the impact of noise on the environment.

>Can Air Separator be used in combination with other equipment?

Yes. Air Separator is often combined with crushers, vibrating screens, magnetic separators and other equipment to form a production line. For example, the material is crushed first, then screened by a vibrating screen, and then separated by an Air Separator from light and heavy materials, and finally separated by a magnetic separator to achieve comprehensive material processing.