A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Vibrating Screen for Sale

Vibrating screen is an efficient screening equipment that uses a vibrating motor or exciter to generate vibration force to make the material move in a certain direction on the screen, thereby achieving grading, screening, dehydration, desludging and other operations. It is widely used in mining, coal, metallurgy, building materials, chemical industry, environmental protection, solid waste treatment and other industries, and is one of the key equipment in the material sorting process.

According to different structures and uses, vibrating screens can be divided into many types, such as circular vibrating screens, linear vibrating screens, rolling screens, probability screens and high-frequency vibrating screens. Among them, **circular vibrating screens** are mostly used for coarse and medium screens, and the movement trajectory is circular; **linear vibrating screens** are suitable for fine screening operations and can achieve fine grading processing; and **high-frequency vibrating screens** are suitable for dehydration and desludging of slurry materials with high moisture content.

The main components of the vibrating screen include screen box, screen, exciter, vibration reduction device, chassis and motor. When working, the periodic vibration force generated by the exciter drives the screen box to vibrate, and the material jumps forward on the screen surface, so that it can pass through the screen or remain on the screen surface according to the particle size, realizing graded screening. The vibrating screen can be equipped with single-layer or multi-layer screens to meet the requirements of different materials and sorting accuracy.

Compared with traditional manual screening or heavy separation equipment, the vibrating screen has many advantages. First of all, it has the characteristics of high screening efficiency, large processing capacity, high sorting accuracy, etc., which can greatly improve the automation level of the production line. Secondly, the vibrating screen has a simple structure, stable operation, low energy consumption, low noise, and is easy to install and maintain. At the same time, different types of vibrating screens can be flexibly selected according to needs, adapting to different material particle size, humidity, viscosity and other characteristics, and have a wide range of application scenarios.

Modern vibrating screens mostly use wear-resistant materials to manufacture screens and screen boxes, which greatly extends the service life of the equipment. Some high-end models are also equipped with intelligent monitoring systems that can monitor the operating status in real time to ensure the safe operation of the equipment.

Vibrating screens perform outstandingly in all kinds of material screening situations and are an irreplaceable and important equipment for modern industrial grading and screening. They are of great significance for increasing production capacity, saving costs, and promoting green and environmentally friendly production.

Operating principle of Vibrating Screen for Sale

Vibrating screen is a kind of equipment commonly used for screening, grading, filtering or dehydrating solid particle materials. It is widely used in mining, metallurgy, building materials, chemical industry, food, renewable resources and other fields. Its main working principle is to make the screen surface vibrate periodically through a vibration motor or exciter, so as to drive the material to move on the screen to achieve particle separation and screening.

Vibrating screen usually consists of screen box, vibration source (such as vibration motor or exciter), vibration reduction system (such as spring support), screen and chassis. When the equipment is working, the vibration source converts the rotational motion into an exciting force in a certain direction, driving the screen box and screen to vibrate at a specific frequency. The vibration makes the material jump and roll on the screen surface, and the smaller particles fall through the screen holes, while the larger particles move forward along the screen surface, finally realizing the separation of particles of different particle sizes.

According to the different vibration modes, vibrating screens can be divided into linear vibrating screens, circular vibrating screens and elliptical vibrating screens.

Linear vibrating screen: usually driven by dual motors, it produces a linear vibration trajectory, which is suitable for screening medium and fine particle dry materials.

Circular vibrating screen: driven by a single-axis eccentric exciter or an eccentric block motor, the screen surface moves in a circular motion, suitable for grading medium and coarse particles.

Elliptical vibrating screen: combines the characteristics of circular and linear motion, has strong adaptability and high screening efficiency.

The key performance indicators of vibrating screens include vibration frequency, amplitude, mesh size, processing capacity and screening efficiency. Screening efficiency is affected by many factors, such as material moisture, particle size distribution, screen tension, feeding speed, etc. Therefore, in practical applications, it is necessary to reasonably select the machine model and parameters according to the characteristics of the material.

Modern vibrating screens are increasingly adopting modular design and high-frequency vibration technology, which not only improves screening accuracy and processing capacity, but also reduces energy consumption and noise. Some high-end vibrating screens also integrate intelligent monitoring systems, which can monitor the operating status of amplitude, temperature, vibration frequency, etc. in real time, and improve equipment stability and maintenance convenience.

With its simple structure, high efficiency, strong adaptability and convenient operation, the vibrating screen has become one of the important equipment for industrial solid material screening and plays a key role in various production lines.

Advantages and features of Vibrating Screen for Sale

Vibrating screen is a common material sorting equipment, widely used in mining, metallurgy, coal, building materials, chemical industry, garbage disposal and other industries. It drives the screen box to vibrate periodically through a vibrating motor or exciter, so that the material can be quickly layered and screened on the screen surface, thereby realizing the functions of grading, impurity removal or dehydration of particulate matter. There are various types of vibrating screens, including circular vibrating screens, linear vibrating screens, dehydrating screens and ultrasonic screens. It has stable performance and compact structure, and is an indispensable key equipment in the industrial screening process.

Main features of vibrating screen:

1. High-efficiency screening

The vibrating screen promotes the rapid dispersion of materials and contact with the screen through high-speed vibration, which improves the screening efficiency. It has high grading accuracy and is especially suitable for sorting materials with strict particle size requirements.

2. Multi-layer screen structure

Most vibrating screens adopt a multi-layer screen design, which can achieve simultaneous grading of two or more materials, increase the processing capacity, reduce the number of material transfers, and optimize the process flow.

3. Simple structure and convenient maintenance

The equipment has a compact structure, high degree of standardization of key components, and is easy to install and repair. The screen can be replaced quickly, and daily maintenance is easy, which reduces downtime.

4. Wide applicability

The vibrating screen can handle various dry, wet or sticky materials, and is suitable for coarse screening, medium screening and fine screening processes. According to different needs, you can choose explosion-proof, dust-proof, stainless steel and other material configurations.

5. Low noise and low energy consumption

Modern vibrating screens generally adopt energy-saving design, high operating efficiency of vibration motor, good noise control, suitable for continuous working environment.

6. High degree of automation

It can be equipped with intelligent control system to realize remote monitoring and automatic adjustment, and improve the production efficiency and management level of the whole line.

The core advantages of vibrating screen:

1. High classification accuracy: It can effectively separate materials of different particle sizes to ensure product quality, especially in the screening of fine particles.

2. Large processing capacity: large processing volume per unit time, suitable for large-scale production operations.

3. Modular design: easy to expand and integrate, suitable for mobile stations, fixed stations, environmentally friendly screening stations and other usage scenarios.

4. Long equipment life: High-strength screens and wear-resistant parts extend the service life and reduce overall operating costs.

5. Save labor costs: Reduce manual sorting links, improve automated production efficiency, and reduce labor intensity.

With its advantages of high efficiency, wide adaptability and low maintenance cost, the vibrating screen plays a key role in the screening of various solid materials and is one of the important equipment for modern industrial material processing and resource classification.

Technical Parameter Table of Vibrating Screen for Sale

| Model | Screen Size (mm) | Layers | Mesh Size (Mesh) | Vibration Frequency (Hz) | Double Amplitude (mm) | Motor Power (kW) | Capacity (t/h) |

|---|---|---|---|---|---|---|---|

| ZS-1020 | 1000 × 2000 | 1–2 | 2–200 | 50 | 4–6 | 0.75 × 2 | 3–5 |

| ZS-1230 | 1200 × 3000 | 1–3 | 2–200 | 50 | 4–6 | 1.1 × 2 | 5–10 |

| ZS-1535 | 1500 × 3500 | 1–3 | 2–200 | 50 | 4–6 | 1.5 × 2 | 8–15 |

| ZS-1845 | 1800 × 4500 | 1–4 | 2–200 | 50 | 4–6 | 2.2 × 2 | 12–20 |

| ZS-2060 | 2000 × 6000 | 1–4 | 2–200 | 50 | 4–6 | 3.0 × 2 | 20–30 |

If you have any special requirements, we will customize according to your special needs.

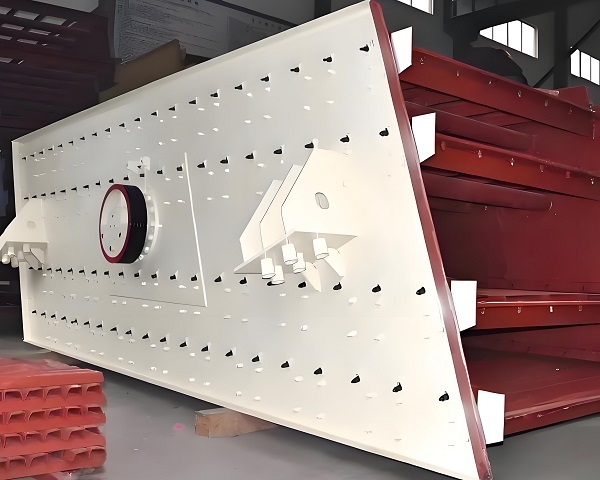

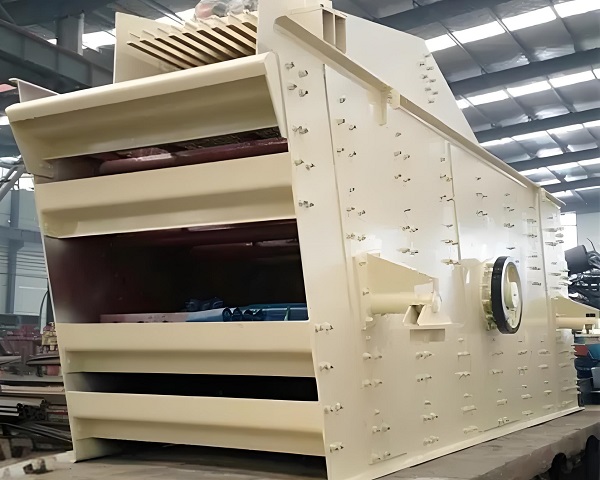

Product Picture Display of Vibrating Screen for Sale

FAQ about Vibrating Screen for Sale

>1. How do the amplitude and frequency of the vibrating screen affect the screening effect?

Amplitude refers to the maximum displacement reached by the screen surface during vibration, and frequency is the number of vibrations per unit time. The combination of amplitude and frequency determines the effectiveness of the screening process. Generally speaking, a larger amplitude and an appropriate frequency help loosen and stratify the material, thereby improving the screening efficiency; high frequency is usually used for fine particle screening.

>2. How to adjust the inclination of the vibrating screen?

The inclination of the vibrating screen has a significant effect on the movement speed and residence time of the material on the screen surface. The inclination is usually adjusted by adjusting the relative angle of the exciter shaft or changing the support structure of the screen machine. By changing the inclination, the conveying speed of the material on the screen surface can be controlled, thereby optimizing the screening effect. For example, a larger inclination is conducive to increasing the conveying speed of the material, but may reduce the screening accuracy.

>3. What are the main types of vibrating screens?

Vibrating screens can be divided into many types according to their motion trajectory and structural characteristics. Common ones include: linear vibrating screens (materials move along a straight line), circular vibrating screens (materials move in a circular or elliptical shape), high-frequency vibrating screens (screens vibrate at high frequencies, suitable for fine particles), horizontal vibrating screens, banana screens (multi-stage inclinations), etc. Each type has its specific application scenarios and advantages.

>4. What industries are vibrating screens mainly used in?

Vibrating screens are widely used in mining, quarrying, building materials, metallurgy, chemicals, food, medicine and other industries. In mining and quarrying, they are used to grade ores and crushed stones; in the building materials industry, they are used to screen sand, gravel and cement clinker; in the chemical and food industries, they are often used for precise separation and impurity removal of powder and granular materials.

>5. What are the advantages of using vibrating screens?

Vibrating screens have many advantages, including high screening efficiency, large processing capacity, wide adaptability (can handle dry and wet materials), high screening accuracy, relatively low maintenance costs, low energy consumption, sturdy and durable structure, and can be customized according to specific needs. These advantages make it an indispensable equipment in many industrial production lines.

>6. What are the potential disadvantages or common problems of vibrating screens?

Although vibrating screens have many advantages, they also have some potential disadvantages and common problems. For example, for high-moisture and high-viscosity materials, the screen holes are prone to clogging; the equipment will generate noise and dust during operation; the initial investment may be relatively high; in addition, if the structural design or material strength is insufficient, it may affect its service life, or there may be problems such as excessive vibration and screen surface overload.

>7. How to perform routine maintenance of vibrating screens?

Routine maintenance of vibrating screens is essential to extend their service life and ensure efficient operation. Maintenance measures include regular inspection of all parts (especially bearings, springs, fasteners), timely lubrication to reduce friction and wear, keeping the screen surface clean to prevent clogging, and monitoring vibration to detect and solve abnormal problems in a timely manner.

>8. What factors should be considered when choosing a vibrating screen?

Choosing a suitable vibrating screen requires comprehensive consideration of multiple factors. Mainly include: the characteristics of the material to be screened (particle size distribution, humidity, viscosity, etc.), the required processing capacity, the screening accuracy requirements (required mesh size), the structural materials of the equipment (should be wear-resistant and corrosion-resistant), and the budget and installation space restrictions.

>9. What are the main components of the vibrating screen and their functions?

The main components of the vibrating screen include: drive system (motor and exciter, providing vibration force), side plate (constituting the main structure of the screen box), screen (key component for separating materials, with a specific size of mesh), crossbeam (increasing structural strength), damping spring (reducing vibration transmission to the supporting structure, protecting equipment) and exciter crossbeam, etc.

>10. What are the common faults of vibrating screens?

Common faults of vibrating screens include mesh blockage (usually caused by high mud content, high moisture or fine particles), severe wear of the screen, uneven feeding, too thick material layer on the screen surface, and asynchronous movement of the excitation block. These problems will lead to reduced screening efficiency and need to be checked in time and corresponding solutions should be taken.

>11. How to calculate the processing capacity of the vibrating screen?

The processing capacity of a vibrating screen is usually expressed in tons of material processed per hour (T/h) or cubic meters (m³/h). Its calculation involves several factors, including the effective screening area of the screen, the percentage of material in the feed that is smaller than the screen hole size, the basic processing capacity of the screen, the screening efficiency coefficient, and the correction factor for different materials and screen types.

>12. What are the cleaning methods for vibrating screens?

Keeping the vibrating screen clean is essential to maintaining screening efficiency. Cleaning methods include: removing residual materials after each use to prevent clogging; using a soft brush, cloth or compressed air to clean the screen; for sticky materials, it may be necessary to install anti-clogging devices (such as bouncing balls, rubber rods); when necessary, the screen can be removed for deep cleaning, and all parts must be thoroughly dried.

>13. What are the common types of motors used for vibrating screens?

The common types of motors used for vibrating screens mainly include electromagnetic vibration motors and eccentric block vibration motors (also known as unbalanced vibration motors). Electromagnetic vibration motors generate vibrations through electromagnetic fields and are usually suitable for fine screening; eccentric block vibration motors generate strong vibrations through rotating eccentric blocks and are widely used in heavy-duty industries such as mining and quarrying. In addition, there are high-frequency vibration motors and linear vibration motors.