A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Circular Vibrating Screen

The Circular Vibrating Screen is a highly efficient screening equipment widely used in various industries. Its working principle is based on the rotation of an eccentric shaft or vibration motor to generate circular vibration. This vibration is transmitted to the screen box, causing the materials on the screen surface to move in a circular trajectory, which effectively promotes the screening process.

Structurally, the Circular Vibrating Screen mainly consists of a screen box, vibration source (usually an eccentric shaft vibrator or vibration motor), damping system, and base frame. The screen box, equipped with high-quality screen meshes, is the core part for material screening. The vibration source, with its adjustable vibration parameters, allows operators to customize the screening intensity according to different material characteristics. The damping system, typically using rubber springs, not only reduces the impact of vibration on the foundation but also ensures stable operation and prolongs the service life of the equipment.

This type of vibrating screen excels in processing large quantities of materials with high screening efficiency. It is capable of handling various materials, from coarse-grained ores to fine powders, making it suitable for applications in mining, metallurgy, building materials, and chemical industries. For example, in the mining industry, it can effectively separate different grades of ores, improving the utilization rate of resources; in the building materials industry, it can screen aggregates of different sizes to meet construction requirements.

One of the significant advantages of the Circular Vibrating Screen is its simple structure and ease of maintenance. The modular design of components enables quick replacement of worn parts, minimizing downtime. Moreover, its strong adaptability to different working environments, such as high humidity or dusty conditions, ensures continuous and reliable operation. Additionally, the equipment is designed with safety and environmental protection in mind, reducing noise and dust emissions during operation.

The Circular Vibrating Screen stands out for its high efficiency, large processing capacity, and wide applicability, making it an ideal choice for industries seeking reliable and efficient screening solutions.

Operating principle of Circular Vibrating Screen

The screen box, where the actual screening process takes place, is supported by damping springs that isolate excessive vibrations from the base and ensure stable operation. As the screen box vibrates, the materials fed onto it are affected by the combined forces of gravity, centrifugal force, and inertia. The circular vibration makes the materials continuously jump and move on the screen surface. Larger particles that cannot pass through the sieve holes remain on the upper layer of the screen, while smaller particles, under the action of vibration, gradually penetrate through the sieve holes and fall into the corresponding collection areas below.The angle of the screen surface and the amplitude and frequency of the vibration can be adjusted according to different screening requirements. A steeper screen surface angle can increase the movement speed of the materials, suitable for handling large quantities of materials; while a shallower angle allows materials to stay on the screen longer, facilitating more thorough screening of fine particles. By adjusting the amplitude and frequency, the intensity of the vibration can be controlled, which is crucial for optimizing the screening efficiency of different materials. For example, when screening wet or sticky materials, increasing the amplitude can prevent the sieve holes from clogging. In summary, the circular vibrating screen realizes the efficient separation and classification of materials through the circular vibration of the screen box, making it widely used in various industries such as mining, construction, and chemical engineering.

Advantages and features of Circular Vibrating Screen

The circular vibrating screen, renowned for its efficient and reliable performance, boasts several distinctive advantages and features. At its core, it operates on the principle of utilizing a cylindrical eccentric shaft exciter and adjustable counterweights to generate vibrations. This design allows for precise control over the amplitude, enabling it to adapt to various screening requirements.

One of the primary strengths of the circular vibrating screen is its high processing capacity. With its robust vibration mechanism, it can handle large volumes of materials in a short time, significantly enhancing production efficiency. Whether screening large - sized ore in mining operations or processing aggregates in construction, it can consistently deliver high throughput.

The screening efficiency of the circular vibrating screen is also remarkable. The strong vibrations ensure that materials are thoroughly separated, maximizing the accuracy of the screening process. The screen mesh, typically made of high - quality spring steel or punched metal, is designed to prevent clogging, further improving the efficiency. This is especially crucial when dealing with materials that have a tendency to stick together or have irregular shapes.

Another notable feature is its durability and low maintenance requirements. Constructed with sturdy materials and a reliable structure, it can withstand harsh working conditions. The use of rubber vibration - isolation springs not only reduces noise but also extends the lifespan of the equipment, as it effectively absorbs shock and reduces mechanical stress. This means less downtime for maintenance and repairs, ultimately saving costs for the users.

The circular vibrating screen is highly adaptable. It can be customized to meet specific operational needs, such as adjusting the screening size, changing the screening angle, or integrating with other production equipment. This flexibility makes it suitable for a wide range of industries, including mining, metallurgy, building materials, and chemical engineering.

The circular vibrating screen combines high - performance, durability, and adaptability, making it an ideal choice for various screening applications. Its ability to efficiently process large quantities of materials with high accuracy, while requiring minimal maintenance, has established it as a preferred option in the field of screening technology.

Technical Parameter Table of Circular Vibrating Screen

| Model | Number of Decks | Screen Area (m²) | Mesh Size (mm) | Capacity (t/h) | Motor Power (kW) | Vibration Frequency (r/min) | Overall Dimension (mm) |

|---|---|---|---|---|---|---|---|

| YK1236 | 1–2 | 4.3 | 5–100 | 30–120 | 11 | 960 | 3600×1800×1500 |

| YK1548 | 1–2 | 7.2 | 5–100 | 50–200 | 15 | 970 | 4800×2000×1800 |

| YK1860 | 1–3 | 10.8 | 5–100 | 80–300 | 18.5 | 980 | 6000×2300×2000 |

| YK2160 | 1–3 | 12.6 | 5–100 | 100–400 | 22 | 980 | 6000×2500×2100 |

| YK2460 | 2–3 | 14.4 | 5–100 | 150–500 | 30 | 980 | 6000×2800×2200 |

If you have any special requirements, we will customize according to your special needs.

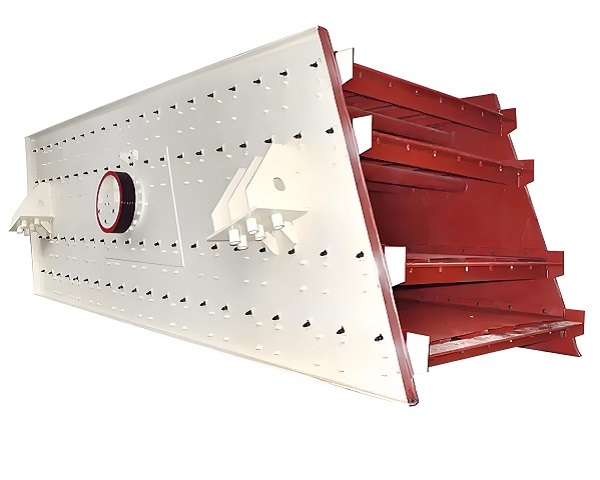

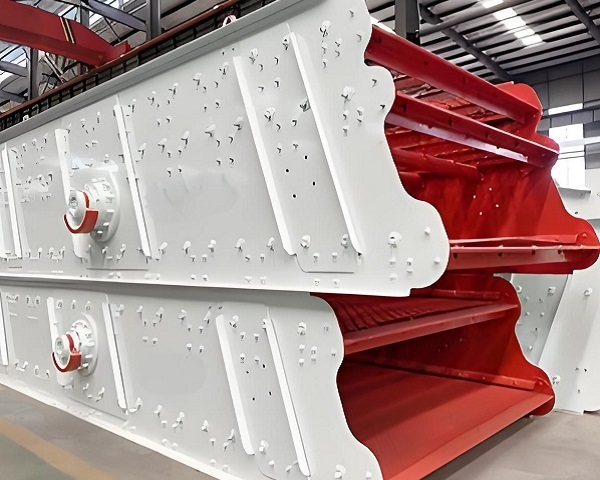

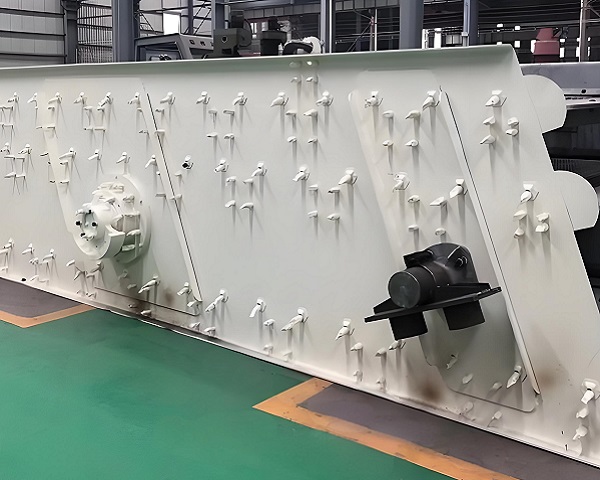

Product Picture Display of Circular Vibrating Screen

FAQ about Circular Vibrating Screen

>What are the main components of a circular vibrating screen?

The main components include the vibrating body (screen box), which holds the screen mesh and is where the vibration occurs. There's also the vibration isolation part, which could be a support spring group for seat - type installation or a spring hanger for hanging - type installation. The power unit is usually a single - axis vibration exciter, and the drive device is an asynchronous motor. Additionally, there are related accessories. In a typical circular vibrating screen used in a quarry, these components work together to screen rocks and stones.

>What are the types of circular vibrating screens based on the screen exciter structure?

There are two main types: the YA series with shaft eccentricity and the YK series with block eccentricity. The YA series shaft - eccentric circular vibrating screen offers high screening efficiency, a scientific and reasonable structure, high strength and rigidity of the whole machine, stable operation, low noise, and convenient maintenance. The YK series, on the other hand, has its own unique features such as using block - eccentric structures which can sometimes provide a different balance of performance characteristics in terms of exciting force and durability.

>What are the advantages of a circular vibrating screen?

It has a high processing capacity, capable of handling large volumes of materials in a short time, which is beneficial for industries with high - volume production requirements like mining. The screening efficiency is remarkable, as the strong vibrations ensure thorough separation of materials. It's also durable, with a structure that can withstand harsh working conditions. Additionally, it has low maintenance requirements, and the use of rubber vibration - isolation springs reduces noise and extends the equipment's lifespan. For example, in a coal - processing plant, these advantages help in efficient coal screening.

>In which industries is a circular vibrating screen commonly used?

It's widely used in the mining industry for separating different - sized ores. In the construction materials industry, it screens aggregates such as sand and gravel. In the energy sector, especially in coal - fired power plants, it's used to screen coal. It also finds applications in the chemical industry for screening various granular materials. For instance, in a fertilizer production plant, it can screen different - sized fertilizer granules.

>How to adjust the amplitude of a circular vibrating screen?

The amplitude can be adjusted using the cylinder - type eccentric shaft vibrator and eccentric block. By changing the position or quantity of the eccentric blocks, the centrifugal force generated during rotation can be altered, thereby adjusting the amplitude of the screen box's vibration. In some industrial settings, operators may need to adjust the amplitude based on the type and size distribution of the materials being screened.

>What types of screen meshes are suitable for circular vibrating screens?

According to material types and user requirements, high - manganese steel braided sieves, punched sieves, and rubber sieves can be used. High - manganese steel braided sieves are durable and suitable for screening hard and abrasive materials. Punched sieves are often used for materials with specific size - separation requirements, and rubber sieves are good for materials that are prone to clogging or need a gentler screening process. In a copper - mining operation, high - manganese steel braided sieves might be chosen due to the abrasive nature of copper ore.

>What is the screening efficiency of a circular vibrating screen affected by?

The screening efficiency is affected by factors such as the nature of the materials being screened, including their particle size distribution, humidity, and stickiness. A higher humidity or stickiness can cause particles to clump and reduce screening efficiency. The condition of the screen mesh, such as wear and clogging, also plays a role. Additionally, the operating parameters of the vibrating screen, like amplitude, frequency, and screen - surface inclination, can impact efficiency. For example, an improper screen - surface inclination may cause materials to move too quickly or slowly across the screen, reducing the chance of proper separation.

>How to install a circular vibrating screen?

Circular vibrating screens can be installed in a seat - type or hanging - type manner. For seat - type installation, the screen angle surface can be adjusted by changing the position and height of the spring support. The vibrating screen should be placed on a stable and level foundation to ensure smooth operation. All components, such as the screen box, vibration exciter, and motor, need to be properly aligned and fastened. In a new construction aggregate production line, careful installation of the circular vibrating screen is crucial for its long - term performance.

>What should be paid attention to during the operation of a circular vibrating screen?

During operation, it's important to regularly check the vibration condition of the screen box to ensure it's operating smoothly. Monitor the temperature of the motor and vibration exciter to prevent overheating. Check the screen mesh for any signs of wear or damage, and clean it regularly to avoid clogging. Also, ensure that the feeding of materials is uniform and continuous. In a busy mining site, regular checks can prevent breakdowns and ensure continuous production.

>How to maintain a circular vibrating screen?

Regularly lubricate the bearings of the vibration exciter to reduce friction and wear. Inspect the screen mesh frequently and replace it when it's severely worn or damaged. Check the bolts and connections of all components to ensure they are tight. Clean the equipment regularly to remove dust and debris. In a long - term operation of a circular vibrating screen in a cement plant, proper maintenance can extend its service life.

>Can a circular vibrating screen be customized according to specific needs?

Yes, it can be customized. Manufacturers can adjust parameters such as the size of the screen box, the number of screen layers, the type of screen mesh, and the power of the motor according to the specific requirements of different industries and materials. For example, for a special - sized material in a pharmaceutical factory, the circular vibrating screen can be customized to meet the precise screening needs.

>How does a circular vibrating screen compare with a linear vibrating screen?

A circular vibrating screen has a circular - motion screen box, which is suitable for materials that need to be screened with a more complex movement pattern for better separation. In contrast, a linear vibrating screen has a linear - motion screen box, which is often better for materials that require a more straightforward, linear - path screening process. Circular vibrating screens may have higher processing capacities in some cases, while linear vibrating screens can be more effective for certain types of fine - material screening. In a recycling plant, a circular vibrating screen might be used for separating mixed - size waste materials, while a linear vibrating screen could be used for screening fine - grained recycled plastics.

>What are the latest technological developments in circular vibrating screens?

Some of the latest developments include the use of more advanced materials for the screen mesh to increase durability and reduce clogging. There are also improvements in the vibration - isolation systems to further reduce noise and vibration transmission. Smart monitoring systems are being integrated into circular vibrating screens to enable real - time monitoring of operating parameters, such as vibration amplitude, motor temperature, and screening efficiency. This allows for more proactive maintenance and optimization of the screening process. In modern mining operations, these technological advancements are being adopted to improve productivity and reduce costs.