A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Gyratory Screen

The gyratory screen is an efficient screening equipment that simulates manual screening action and plays an important role in many industries.

From the working principle, the gyratory screen uses a special transmission mechanism to make the screen body produce a composite movement in the horizontal and vertical directions. This movement mode is similar to manual screening. The material rolls and jumps on the screen surface in three dimensions. Fine particles can quickly pass through the screen holes, while larger particles move forward along the screen surface, achieving efficient and accurate screening.

Its structural characteristics are distinct. The screen body is usually made of high-quality steel, which is sturdy and durable and can withstand greater material impact. The screen can be flexibly replaced according to the characteristics and screening requirements of different materials, and the materials are diverse, such as stainless steel, nylon, etc., to adapt to various working conditions. The unique sealing design effectively prevents material leakage and dust flying, improves the working environment, and also avoids material waste.

The gyratory screen has many advantages. The screening accuracy is high, which can meet the occasions with strict requirements on material particle size and ensure the quality stability of the product. The processing capacity is large. Compared with traditional screening equipment, more materials can be processed in the same time, which improves production efficiency. Moreover, it has a wide adaptability to materials, whether it is dry, wet, sticky or easy to agglomerate materials, it can achieve good screening effects. In addition, the equipment runs smoothly, has low noise, and is relatively simple to maintain, which reduces the cost of use.

In terms of application areas, the gyratory screen is widely used in many industries such as food, medicine, chemical industry, and mining. In the food industry, it is used to screen materials such as flour, starch, and powdered sugar to ensure the purity and taste of the product; in the pharmaceutical industry, it is used to finely screen medicinal powders, granules, etc. to ensure the quality and safety of medicines; in the chemical industry, it is used to screen various chemical raw materials and additives to meet the requirements of production processes.

With its unique working principle, excellent structural characteristics and significant advantages, the gyratory screen occupies an important position in industrial production and provides efficient and reliable solutions for material screening in various industries.

Operating principle of Gyratory Screen

Working principle of gyratory screen

The gyratory screen is an efficient and precise screening equipment. Its working principle is based on imitating artificial screening action and realizing fine classification of materials through unique movement mode.

Movement mechanism

The core of the gyratory screen lies in its special motion trajectory design. After the equipment is started, the screen box generates a composite motion similar to a plane circle under the action of the drive device. This motion can be decomposed into reciprocating swing in the horizontal direction and slight vibration in the vertical direction. The horizontal swing makes the material spirally propel on the screen surface, while the vertical vibration promotes the tumbling and jumping of the material particles. The two work together to form a uniform dispersion state of the material on the screen surface, avoid clogging the screen holes, and improve the screening efficiency.

Screening process

After the material enters the screen box from the feed inlet, it first contacts the screen surface. Driven by the swinging motion, fine particles fall through the screen holes into the lower screen or the discharge port, while larger particles gradually move along the screen surface to the discharge end for discharge. The design of multi-layer screens can realize multi-level screening to meet the separation of materials with different particle size requirements.

Advantages and features of Gyratory Screen

As an efficient screening equipment, the swing screen is widely used in many industries. Its unique characteristics and significant advantages make it stand out in the screening field.

Characteristics of the swing screen

1. Simulate manual screening action: The swing screen uses a special drive device to make the screen body do a planar gyratory motion, which is similar to the manual screening action. The material spreads from the inside to the outside in a spiral shape on the screen surface. The screening process is gentler and causes less damage to the material. It is especially suitable for materials with high requirements for particle integrity, such as food and medicine.

2. High screening accuracy: The screen mesh is reasonably designed, the screen mesh is highly tensioned and flat, and can effectively prevent the material from clogging the screen hole. Combined with the unique screening trajectory, materials of different particle sizes can be accurately separated to ensure uniform product particle size and meet high-precision screening requirements.

3. High screening efficiency: The screen surface area is large, and the material stays on the screen surface for a long time, which increases the contact opportunity between the material and the screen, so that more particles that meet the requirements can pass through the screen quickly, greatly improving the screening efficiency and reducing the processing time.

4. Smooth operation and low noise: The equipment adopts advanced shock absorption system and balancing device, with small vibration and low noise during operation, which not only improves the working environment, but also extends the service life of the equipment and reduces maintenance costs.

Advantages of swing screen

1. Wide range of applications: It can handle materials of various properties, including dry powder, particles, slurry, etc. Whether it is light and easy to fly materials or sticky and high water content materials, it can achieve effective screening and is widely used in chemical, food, medicine, mining and other industries.

2. Easy to maintain and clean: The structural design is reasonable, the screen is easy and quick to replace, and it is convenient for daily maintenance and maintenance. At the same time, the equipment is easy to clean and meets the high requirements of food, medicine and other industries for sanitary conditions.

3. High degree of customization: According to the actual needs of users, screen machines of different specifications and different numbers of layers, as well as screens of different materials can be customized to meet diversified production needs.

4. Energy saving and environmental protection: Compared with traditional screening equipment, the swing screen has lower energy consumption and no dust leakage during operation, which meets environmental protection requirements and helps enterprises achieve sustainable development.

Technical Parameter Table of Gyratory Screen

| Model | Screen Size (L×W mm) | Screen Area (m²) | Number of Layers | Capacity (t/h) | Motor Power (kW) | Amplitude (mm) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|---|---|

| GS-1020 | 1000×2000 | 2.0 | 1–4 | 1–3 | 1.1 | 20–30 | 2300×1400×1100 |

| GS-1230 | 1200×3000 | 3.6 | 1–4 | 2–6 | 1.5 | 20–30 | 3500×1600×1200 |

| GS-1530 | 1500×3000 | 4.5 | 1–4 | 3–8 | 2.2 | 20–30 | 3600×2000×1350 |

| GS-1836 | 1800×3600 | 6.5 | 1–4 | 4–10 | 3.0 | 20–30 | 4200×2300×1500 |

| GS-2040 | 2000×4000 | 8.0 | 1–4 | 5–15 | 4.0 | 20–30 | 4600×2500×1650 |

| GS-2250 | 2200×5000 | 11.0 | 1–4 | 8–20 | 5.5 | 20–30 | 5700×2800×1800 |

If you have any special requirements, we will customize according to your special needs.

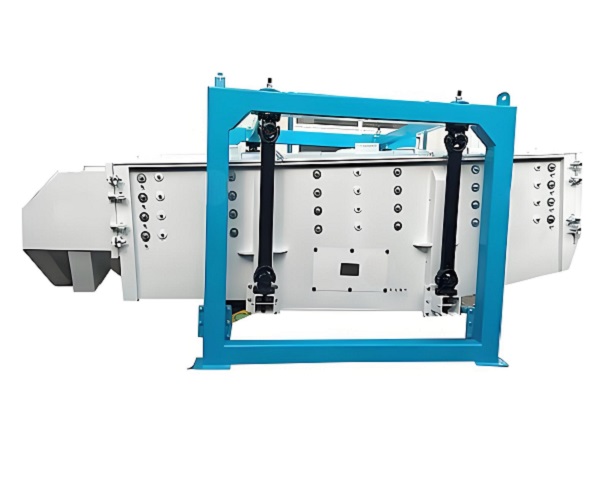

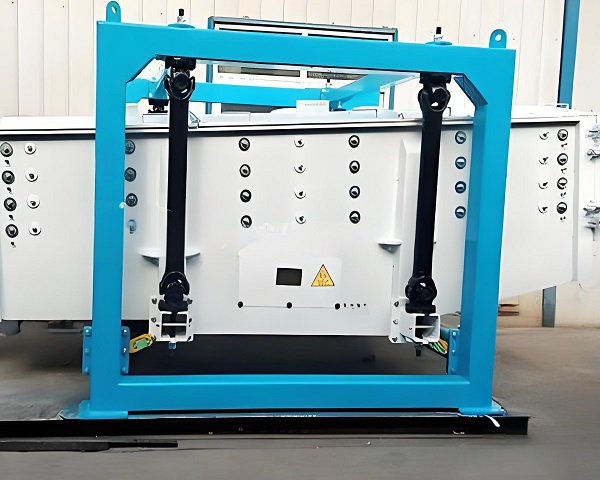

Product Picture Display of Gyratory Screen

FAQ about Gyratory Screen

>1. How to upgrade an existing gyratory screen?

Upgrading an existing gyratory screen can involve several aspects. One common upgrade is to replace the screen mesh with a more advanced type, such as anti-blinding or high-wear-resistant meshes, to improve screening performance. Upgrading the driving device to a more efficient motor or adding a variable-frequency drive can provide better control over the operating parameters. Additionally, installing modern control systems can enable remote monitoring and automation of the screening process, improving efficiency and reducing labor costs.

>2. What are the future development trends of gyratory screens?

The future development trends of gyratory screens include increased automation and intelligence. Smart sensors and control systems will be integrated to monitor the screening process in real-time, optimize operating parameters automatically, and predict maintenance needs. There will also be a focus on developing more energy-efficient and environmentally friendly designs. Additionally, advancements in material science will lead to the use of more durable and high-performance screen meshes and components, further improving the reliability and performance of gyratory screens.

>3. What are the main components of a gyratory screen?

The main components include the screen body, screen mesh, driving device, support frame, and damping system. The screen body provides the structure for the screening process. The screen mesh, available in various materials and mesh sizes, is the key part for particle separation. The driving device, usually an electric motor, generates the power for the gyratory motion. The support frame holds the entire screen in place, and the damping system reduces vibrations transmitted to the surrounding environment, ensuring stable operation.

>4. What materials can a gyratory screen handle?

Gyratory screens can handle a wide range of materials. They are suitable for dry, wet, sticky, and abrasive materials. In the mining industry, they can screen ores, coal, and other minerals. In the food industry, they can process grains, spices, and powdered food products. In the chemical and pharmaceutical sectors, they can screen chemicals, drugs, and pigments. The versatility in material handling makes them a popular choice in various industries.

>5. How to choose the right screen mesh size for a gyratory screen?

The selection of screen mesh size depends on the desired particle size separation. First, determine the particle size distribution of the feed material and the required particle size range of the final products. Then, consider factors such as the material's flowability, moisture content, and tendency to blind the screen. It is often necessary to conduct screening tests to find the optimal mesh size that can achieve the best screening efficiency and product quality.

>6. What factors affect the screening efficiency of a gyratory screen?

Several factors influence screening efficiency. The properties of the material, including particle size, shape, density, and moisture content, play a significant role. The screen mesh parameters, such as mesh size, opening shape, and tension, also affect the separation process. Additionally, the operating parameters, like the amplitude, frequency, and inclination angle of the screen, as well as the feed rate, can impact the screening efficiency.

>7. How to adjust the amplitude and frequency of a gyratory screen?

The amplitude and frequency of a gyratory screen are typically adjusted through the driving device. For amplitude adjustment, some screens are equipped with eccentric weights that can be changed to alter the intensity of the gyratory motion. Frequency adjustment is usually achieved by varying the motor speed. Modern gyratory screens may have electronic control systems that allow for precise adjustment of these parameters to optimize the screening process according to different material characteristics and production requirements.

>8. What are the advantages of a gyratory screen over other types of screens?

Compared to traditional vibrating screens, gyratory screens offer several advantages. They have a higher screening efficiency due to the unique gyratory motion, which provides better material dispersion and particle separation. They also have a larger effective screening area, allowing for higher processing capacity. Additionally, gyratory screens generate less noise and have a longer service life as the gyratory motion reduces the impact on the screen mesh and the screen body.

>9. How to maintain a gyratory screen regularly?

Regular maintenance is crucial for the long-term performance of a gyratory screen. This includes daily inspection of the screen mesh for wear, damage, and blockage. Clean the screen mesh regularly to prevent material buildup. Check the driving device, such as the motor and belts, for proper operation and tension. Lubricate the moving parts according to the manufacturer's recommendations. Also, inspect the support frame and damping system for any signs of instability or damage.

>10. What are the common problems of a gyratory screen and how to solve them?

Common problems include screen mesh blinding, where material gets stuck in the mesh openings, reducing screening efficiency. This can be solved by using anti-blinding screen meshes or installing cleaning devices such as ball trays or ultrasonic cleaners. Another problem is excessive vibration, which may be caused by an unbalanced screen body or worn-out damping components. Balancing the screen body and replacing damaged damping parts can resolve this issue. Additionally, abnormal noise may indicate loose parts or bearing failure, which requires tightening or replacing the affected components.

>11. How to ensure the safety of operating a gyratory screen?

To ensure safety, operators should receive proper training on the operation and maintenance of the gyratory screen. Before starting the machine, check for any loose parts, foreign objects, or signs of damage. Wear appropriate personal protective equipment, such as safety glasses and gloves. Do not reach into the screen while it is in operation. Install safety guards around the screen to prevent accidental contact with moving parts. Also, follow the manufacturer's safety guidelines and local regulations.

>12. Can a gyratory screen be used for multi-layer screening?

Yes, gyratory screens can be designed for multi-layer screening. By installing multiple screen meshes with different mesh sizes on different layers, it is possible to separate materials into multiple particle size fractions in a single screening process. This is particularly useful in industries where multiple product grades are required, as it reduces the number of screening stages and improves production efficiency.

>13. What is the lifespan of a gyratory screen?

The lifespan of a gyratory screen depends on various factors, including the quality of the materials used in its construction, the operating conditions, and the maintenance level. With proper maintenance and under normal operating conditions, a well-built gyratory screen can last for several years. However, in harsh environments or with improper use, the lifespan may be significantly shortened. Regular inspections and timely repairs can help extend the screen's service life.

>14. How to install a gyratory screen?

Installation of a gyratory screen should be carried out according to the manufacturer's instructions. First, ensure that the installation site is level and stable. Place the support frame in the designated position and secure it. Then, carefully lift the screen body onto the support frame and connect it to the driving device. Align the components properly and tighten all the bolts. Connect the electrical connections as per the wiring diagram. After installation, conduct a trial run to check for any abnormal vibrations, noise, or malfunctions.

>15. What are the energy consumption characteristics of a gyratory screen?

The energy consumption of a gyratory screen is mainly determined by the power of the driving motor and the operating parameters. Generally, gyratory screens are relatively energy-efficient compared to some other types of screening equipment. The gyratory motion requires less energy to achieve the desired screening effect. However, factors such as high feed rates, large amplitudes, and frequent starts and stops can increase energy consumption. Optimizing the operating parameters and maintaining the screen properly can help reduce energy consumption.