A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

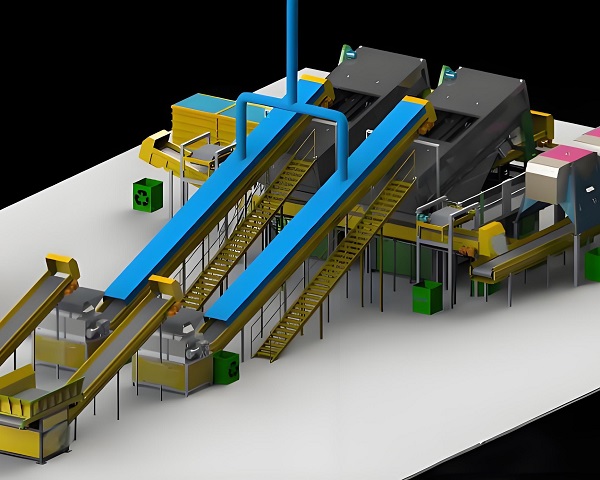

Stale waste screening and treatment system Introduce

Project Background

Stale waste screening equipment

In Indonesia, the acceleration of urbanization and the continuous growth of population have led to a sharp increase in the amount of domestic waste. A large amount of garbage is landfilled without effective treatment, and over time, a large amount of stale garbage has been formed. These stale garbage not only occupies extremely valuable land resources, but also continues to cause serious pollution to the soil, groundwater and surrounding ecological environment due to its complex composition. The harmful gases released have a negative impact on air quality and pose a potential threat to people's health. At the same time, Indonesia has rich natural resources and a huge consumer market, and the demand for resource recycling is becoming increasingly urgent. The implementation of the stale garbage screening and treatment system project is imminent, which is of great significance for improving the environment and realizing resource recycling.

Analysis of stale garbage composition

Stale waste screening equipment

Through the collection and analysis of stale garbage samples in many places in Indonesia, it was found that its composition is extremely complex. Organic matter (such as kitchen waste, plant residues, etc.) has been partially converted into humus after long-term degradation, but it still contains incompletely decomposed high-water content organic matter, accounting for about 30%-40%; plastics (including various plastic bags, plastic bottles, plastic packaging, etc.) are present in large quantities in stale garbage due to their difficult-to-degrade characteristics, accounting for about 25%-35%; metals (such as cans, iron sheets, discarded metal products, etc.) account for about 5%-10%; in addition, there are inert materials such as bricks, slag, etc., accounting for about 20%-30%, which are mixed with other garbage, increasing the difficulty of processing. A deep understanding of the composition of stale garbage is the key basis for the precise design of the screening and processing system.

Introduction to main equipment

Stale waste screening equipment

1. Plate feeder conveyor

As the starting equipment of the entire processing system, the plate feeder conveyor is responsible for smoothly and evenly transporting stale garbage from the storage area to the subsequent processing links. It adopts a high-strength chain plate structure, which can withstand the impact of the large weight and irregular shape of stale garbage and adapt to the complex characteristics of garbage. The surface of the chain plate has been specially treated to have good wear resistance and anti-stickiness, which effectively prevents garbage from sticking and ensures smooth transportation. The conveying capacity can be flexibly adjusted according to the scale of the project, and the conveying volume can reach [X] tons per hour. During operation, the variable frequency speed control device can accurately control the conveying speed according to the processing capacity of the subsequent equipment, realize efficient and stable material supply, and lay a solid foundation for the entire screening process.

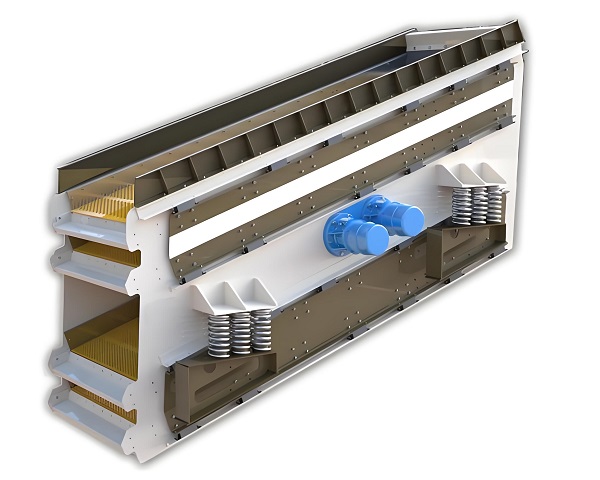

2. Composite screening machine

The composite screening machine is one of the core equipment of the entire system. Through the organic combination of multiple screening technologies, it can achieve fine screening of stale garbage. It uses multiple layers of screens with different apertures. The upper large-aperture screen first performs preliminary screening of the garbage to separate larger bricks, stones, wood blocks and other debris to prevent them from damaging subsequent equipment; the middle and lower screens further subdivide the garbage according to different particle size requirements. The unique vibration structure design enables the screen to generate high-frequency vibration during operation, promotes the full dispersion and screening of materials on the screen surface, and effectively improves the screening efficiency and accuracy. At the same time, the screen adopts a modular design, which is convenient for quick replacement when wear or blockage occurs, reducing equipment maintenance costs. For the complex components in Indonesian stale garbage, the composite screening machine can efficiently separate the materials with recycling value and provide high-quality raw materials for subsequent deep processing.

3. Trommel screen

Waste Screening Trommel Screen

As a secondary screening equipment, the trommel screen further screens the materials after being processed by the composite screening machine. The drum is made of high-quality stainless steel, which has good corrosion resistance and can adapt to the humid and corrosive environment of stale garbage. There are spiral guide blades inside the drum. During the rotation of the drum, the material rolls and moves forward in the drum along the guidance of the blades, and is screened by screens of different apertures. Large particles of materials (such as larger bricks and stones, agglomerated garbage, etc.) are discharged from the front end of the drum, while fine particles of materials (such as humus, fine plastic particles, etc.) are discharged from the discharge port on the side of the drum through the screen. The drum screen has high screening efficiency and large processing capacity. It can process [X] tons of materials per hour, which can effectively ensure the thoroughness of the separation effect, further improve the purity of the materials, and provide more satisfactory raw materials for the subsequent resource utilization link.

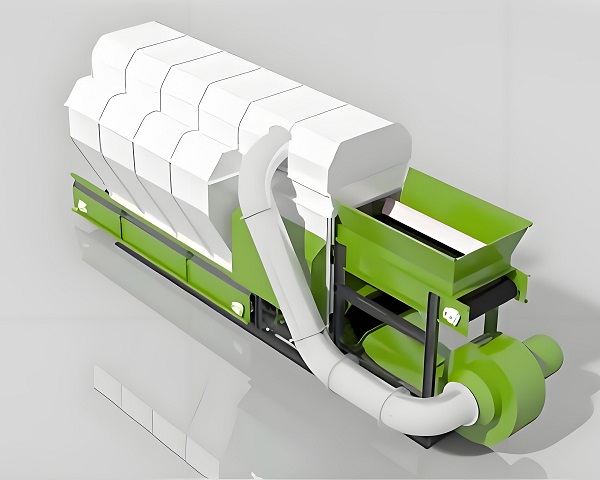

4. Air separator

The air separator uses the difference in aerodynamic characteristics of different materials in the air flow to effectively separate light materials from heavy materials in stale garbage. Inside the air separator, a strong air flow is generated by a high-power fan, and the materials enter the air separation area at a uniform speed on the conveyor belt. Light materials (such as plastic film, paper fragments, dry plants, etc.) are blown to the distant collection area under the action of the air flow; while heavy materials (such as metal, masonry, glass, etc.) are less affected by the air flow due to their own gravity and fall directly into the collection device below. The wind speed of the air separator can be accurately adjusted through the intelligent control system. According to the actual composition and processing requirements of the stale garbage, the wind speed can be flexibly adjusted to ensure the efficient separation of light materials from heavy materials. In the treatment of stale garbage in Indonesia, the wind separator can effectively separate light combustibles such as plastics from other heavy inorganic materials, providing convenience for subsequent incineration power generation or plastic recycling.

5. Magnetic separator

Waste screening magnetic separator

The magnetic separator is mainly used to separate magnetic metal substances such as iron, cobalt, nickel, etc. from stale garbage. Its working principle is to use a strong magnetic field. When stale garbage containing magnetic substances passes through the magnetic field area of the magnetic separator, the magnetic metal is adsorbed on the surface of the drum of the magnetic separator. As the drum rotates, it is brought to the magnetic field-free area and falls into a special collection container under the action of gravity and scrapers. The magnetic field strength of the magnetic separator can be adjusted according to actual needs to adapt to the treatment of stale garbage with different contents of magnetic substances. For metal cans, iron sheets, etc. in Indonesian stale garbage, the magnetic separator can efficiently recycle them to realize the reuse of metal resources, while avoiding damage to subsequent processing equipment caused by metal, and ensuring the stable operation of the entire processing system.

6. Intelligent sorting robot (optional)

With the continuous development of science and technology, the application of intelligent sorting robots in the field of garbage disposal has gradually increased. In the Indonesian stale garbage screening and processing system, intelligent sorting robots can be selectively introduced according to the project budget and processing needs. These robots are equipped with advanced AI visual recognition systems, which can quickly and accurately identify various materials in the garbage, such as plastics, glass, metals, etc. of different materials through deep learning algorithms. Once the target material is identified, the robot grabs and sorts it through a high-precision robotic arm and places it in the corresponding collection area. Intelligent sorting robots can greatly improve the accuracy and efficiency of sorting and reduce the intensity of manual labor. They are especially suitable for scenarios with high requirements for refined garbage sorting. Although its initial investment cost is high, in the long run, it can significantly improve the intelligence level and economic benefits of the entire processing system.

Project benefit analysis

Stale waste screening equipment

1. Environmental benefits

Reducing land occupation: Through the screening and resource utilization of stale garbage, the amount of landfill is greatly reduced, effectively alleviating the pressure of landfill on land resources, and releasing more valuable land for urban development.

Reduce environmental pollution: Reduce the risk of soil and groundwater contamination by leachate generated by stale garbage during landfill, and reduce the impact of harmful gases generated by garbage decomposition on air quality, improve the quality of the surrounding ecological environment, and protect the health of the people.

Promote resource recycling: Recycling organic matter, plastics, metals and other resources in stale garbage reduces the exploitation and consumption of primary resources, reduces the damage to the environment during resource development, promotes the recycling of resources, and achieves the goal of sustainable development.

2. Economic benefits

Resource recovery benefits: Recovered humus, plastic particles, metals and other resources can obtain considerable economic benefits by selling them to related companies. With the continuous development and improvement of the resource recycling market, the benefits are expected to increase further.

Reduce processing costs: Compared with traditional landfill and incineration treatment methods, this screening treatment system realizes the transformation of some waste into treasure through resource recycling, reduces the overall cost of garbage treatment, and improves the economic benefits of garbage treatment.

Industry driving effect: The implementation of the project has driven the development of related industries such as equipment manufacturing, transportation, and resource recycling and processing, created new employment opportunities, and promoted the growth of the local economy.

3. Social benefits

Improve the city's image: The successful implementation of the project has significantly improved the city's environmental sanitation, enhanced the city's overall image and competitiveness, and created a good environment for the city's sustainable development.

Enhance environmental awareness: Through the publicity and implementation of the project, the importance of garbage classification and resource recycling has been popularized to the public, the public's environmental awareness has been improved, and the formation of environmental protection behaviors in the whole society has been promoted.

Ensure social sustainable development: It provides a solid guarantee for the sustainable development of the city, ensures the rational use of resources and the effective protection of the environment, and creates a better living environment for future generations.

The Indonesian stale garbage screening and treatment system solution, through the reasonable selection of plate feeder conveyors, composite screening machines, drum screens and other advanced equipment, designs scientific and efficient process flows, and can effectively screen and recycle stale garbage. After the implementation of the project, it will bring significant environmental, economic and social benefits, and provide strong support for Indonesia to solve the problem of stale garbage pollution, achieve resource recycling and sustainable development. During the project implementation process, it is necessary to strictly follow the project implementation plan, strengthen equipment installation and commissioning, personnel training, operation management and other work to ensure the smooth implementation of the project and its long-term stable operation.

Advantages and features of Stale waste screening and treatment system

1. The equipment has strong adaptability and can accurately deal with complex components. The equipment configuration in the solution closely matches the high humidity and complex composition characteristics of Indonesian stale garbage. The high-strength chain plate and anti-stick surface of the plate feeder conveyor can withstand the impact of irregular shapes of garbage to ensure smooth transportation; the multi-layer screen of the composite screening machine cooperates with the high-frequency vibration structure to achieve fine screening from coarse to fine, and effectively separate materials of different particle sizes such as masonry and plastic; the drum screen is made of corrosion-resistant stainless steel and has an internal spiral guide blade design to ensure efficient screening of fine particles such as humus in a humid environment. The equipment combination accurately solves the problem of stale garbage treatment in Indonesia.

2. Advanced technology to achieve intelligence and efficiency

Introduce intelligent sorting robots (optional) and intelligent control systems to improve the level of intelligent processing. AI visual recognition technology can quickly distinguish garbage of different materials, and the robotic arm can accurately sort, greatly improving sorting efficiency and accuracy; wind separators, magnetic separators and other equipment can optimize the separation effect in real time according to the composition of garbage by intelligently adjusting the wind speed and magnetic field strength. At the same time, all equipment operates efficiently and collaboratively, from plate feeding and conveying, composite screening, to deep screening and resource utilization, the whole process is highly automated, reducing manual intervention and significantly improving processing efficiency.

3. Scientific process, comprehensive resource recovery

The design of the treatment process is scientific and reasonable, forming a closed-loop treatment system. From the anti-secondary pollution design of garbage excavation and transportation, to the precise separation of pretreatment and deep screening links, to the diversified transformation in the resource utilization stage, humus soil is used for agriculture, plastics are made into recycled particles, metal smelting and reuse, etc., to maximize the recovery of organic matter, plastics, metals and other resources in stale garbage, reduce resource waste, and improve resource utilization.

4. Significant benefits, both environmental protection and economic value

Environmentally, it reduces the amount of landfill, reduces leachate and harmful gas pollution, and improves soil, water and air quality; economically, resource recovery brings direct benefits, reduces garbage disposal costs, and drives the development of equipment manufacturing, resource recovery and other industries; socially, it improves the quality and image of the urban environment, enhances people's environmental awareness, promotes Indonesia's sustainable development, and achieves the unity of environmental, economic and social benefits.

Main Machine

Customer Feedback

As a representative of the operator of this solution, I deeply feel the revolutionary changes it has brought to the treatment of stale garbage in Indonesia. The high adaptability of the equipment is amazing. The plate feeder conveyor operates stably in a high-humidity and mixed garbage environment. The composite screening machine and drum screen efficiently separate various materials, which completely solves the previous treatment problems caused by the complex composition of garbage.

Intelligent and efficient technical applications are a highlight. The intelligent sorting robot accurately identifies and sorts, greatly improving work efficiency; the intelligent control system allows the wind separator and magnetic separator to automatically adjust parameters, and the resource separation effect is far beyond expectations. The entire processing process is scientifically closed-loop, from excavation and transportation to resource utilization, each link is closely connected, and humus, plastic, metal and other resources are fully recycled and utilized, truly turning waste into treasure.

After the project was put into operation, the environmental improvement was immediate, the risk of soil and water pollution in the surrounding area was reduced, and the air quality was improved. Economically, the benefits brought by resource recycling have increased year by year, and it has also driven the development of local related industries. This is not only a garbage treatment solution, but also an important boost to promote the sustainable development of Indonesia, and it is worth promoting to more regions!