A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

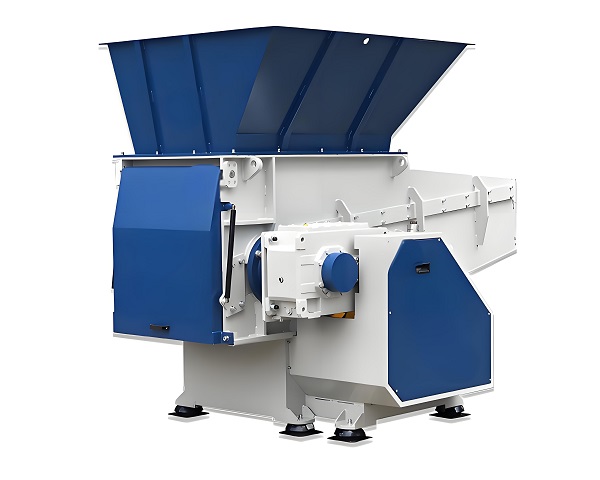

What is the Single Shaft Shredder for Sale

The single-shaft shredder is an important equipment in the field of waste material processing. With its unique structure and excellent performance, it plays a key role in the resource recycling industry.

The single-shaft shredder is mainly composed of a knife shaft, a blade, a box, a drive device, a feed port and a discharge port. The knife shaft is the core component, on which a sharp and sturdy blade is installed. The shape and arrangement of the blade are carefully designed to ensure efficient crushing. The box provides a closed space for the entire crushing process to prevent material splashing and ensure stable operation of the equipment. The drive device provides power to the knife shaft, enabling it to rotate at high speed to crush the material.

After the material enters the shredding chamber from the feed port, as the knife shaft rotates, the blade applies shear, extrusion and tearing force to the material, gradually breaking the large-sized material into small pieces. The crushed material is discharged through the discharge port to complete the entire crushing process.

Its application range is very wide. In the waste plastic recycling industry, various plastic products such as plastic bottles, plastic barrels, and plastic films can be processed; in terms of waste wood processing, wood scraps, wooden pallets, waste furniture, etc. can be crushed; for paper materials such as paper and cardboard, it can also be effectively crushed; in addition, it can also be used to shred small electronic waste, rubber products, etc.

Single-shaft shredders have many advantages. The structure is simple and compact, with a small footprint, easy to install and move; easy to operate, low maintenance cost; high crushing efficiency, can quickly crush materials into the required size; according to the characteristics of different materials, the blade type and knife shaft speed can be adjusted to obtain the best crushing effect; good sealing, reduce dust flying, and meet environmental protection requirements.

With its excellent performance and wide application, the single-shaft shredder provides strong support for the efficient processing and resource recycling of waste materials, and is of great significance in promoting the development of the circular economy.

Operating principle of Single Shaft Shredder for Sale

The single-shaft shredder is a common material crushing equipment. Its working principle is based on mechanical shearing and extrusion. It can crush large-sized materials into small pieces. The following is a detailed introduction to its working principle.

Core structure and power source

The single-shaft shredder is mainly composed of a knife shaft, a blade, a box, a drive device (such as a motor), and a feed port and a discharge port. The knife shaft is the core working part of the entire equipment, and it is driven to rotate by the drive device. As a power source, the motor transmits power to the knife shaft through transmission parts such as belts and gears, so that the knife shaft obtains stable rotational power. This is like the engine of a car transmitting power to the wheels through the drive shaft to make the wheels turn. The motor provides "driving force" for the rotation of the knife shaft.

Material crushing process

When the material enters the box of the shredder from the feed port, the crushing process begins. There are multiple sharp blades installed on the knife shaft, which are arranged at a certain angle and spacing. As the knife shaft rotates, the blades will generate shear force on the material. Imagine using scissors to cut something. The two blades of the scissors cooperate with each other to cut the object. The same is true for the blades of the single-shaft shredder. They cooperate with each other to shear the material.

At the same time, the blade will also exert an extrusion effect on the material. Under the extrusion of the blade, the internal structure of the material is destroyed and the strength is reduced. Under the combined effect of shearing and extrusion, the material is gradually broken into small pieces. Moreover, due to the continuous rotation of the blade, the material will continue to roll and collide in the shredding chamber, further accelerating the crushing process, just like a group of people colliding and squeezing each other in a room, making the originally intact things become broken.

Crushing completion and discharge

When the material is crushed to the set size, it will be discharged from the gap between the blades and the discharge port of the box. The size of the discharge port can be adjusted according to actual needs to control the size specifications of the discharged material. In this way, the single-shaft shredder completes a complete material crushing process.

The single-shaft shredder drives the blade to rotate through the knife shaft, and uses shearing and extrusion to crush the material. It has the advantages of simple structure, convenient operation, and high crushing efficiency. It has been widely used in waste material processing, resource recycling and other fields.

Advantages and features of Single Shaft Shredder for Sale

As a common equipment in the field of material crushing, the single-shaft shredder plays an important role in the resource recycling and processing industry and has many significant features and advantages.

1. Simple and compact structure

The overall structure of the single-shaft shredder is relatively simple, and the core components are a single rotating knife shaft and matching blades, plus a box, a drive device, etc. This simple design makes it occupy a small area, which is convenient for installation and layout in places with limited space. Whether it is a small recycling station or a large factory, it can be easily adapted.

2. Flexible blade design

The blade can be customized according to the characteristics of different materials. For example, when processing hard metals, high-strength and wear-resistant blade materials are used, and the blade angle and shape are optimized to enhance the shear force; when processing soft plastics, the blade design pays more attention to the grabbing and tearing of the material to improve the crushing efficiency.

3. Convenient and easy to understand

The equipment operation interface is simple, and the operator can get started after simple training. The control parameter settings are intuitive, such as speed, crushing time, etc., which can be quickly adjusted according to the material type and crushing requirements, reducing the difficulty of operation and labor costs.

4. High crushing efficiency

The single-shaft shredder has a fast rotating speed, and the blade has a strong shearing and squeezing effect on the material, which can quickly crush large-sized materials into small pieces. Taking the treatment of waste plastics as an example, compared with traditional crushing equipment, its crushing time can be greatly shortened, improving overall production efficiency.

5. Wide range of applications

It can handle a variety of materials, including plastics, wood, paper, rubber, small electronic waste, etc. Whether it is common waste plastic bottles, wooden pallets, or discarded circuit boards, they can be effectively crushed to meet the material processing needs of different industries.

6. Low maintenance cost

The simple structure makes the equipment failure rate relatively low, and daily maintenance work is mainly focused on the inspection and replacement of blades. The blade replacement operation is convenient, and the blade material is wear-resistant and has a long service life, which reduces the cost of equipment maintenance and replacement of accessories.

7. Good environmental performance

The crushing process is carried out in a closed box, which can effectively reduce dust flying and noise pollution, meet environmental protection requirements, and help enterprises achieve green production.

Technical Parameter Table of Single Shaft Shredder for Sale

| Parameter | Unit | SS-400 | SS-600 | SS-800 | SS-1000 | SS-1200 | SS-1500 |

|---|---|---|---|---|---|---|---|

| Shredding Chamber Size | mm | 400×400 | 600×500 | 800×600 | 1000×800 | 1200×1000 | 1500×1200 |

| Main Motor Power | kW | 18.5 | 30 | 45 | 55 | 75 | 90 |

| Hydraulic Pusher Motor Power | kW | 1.5–2.2 | 2.2–3 | 3–4 | 4 | 5.5 | 7.5 |

| Main Shaft Speed | rpm | 70–100 | 70–90 | 60–80 | 60–80 | 60–80 | 50–70 |

| Shaft Diameter | mm | Φ180 | Φ220 | Φ280 | Φ320 | Φ360 | Φ400 |

| Number of Rotating Blades | pcs | 20–30 | 30–40 | 40–50 | 50–60 | 60–80 | 80–100 |

| Blade Material | - | 9CrSi | SKD-11 | SKD-11 | D2 | Cr12MoV | Cr12MoV |

| Number of Fixed Blades | rows | 1–2 rows | 2 rows | 2–3 rows | 3 rows | 3–4 rows | 4 rows |

| Screen Mesh Size | mm | 20–80 (adjustable) | 20–100 (adjustable) | 20–100 | 30–120 | 30–150 | 30–150 |

| Discharge Size Range | mm | 10–80 | 10–100 | 20–120 | 20–150 | 30–150 | 30–200 |

| Processing Capacity | t/h | 0.3–1 | 0.5–2 | 1–3 | 2–5 | 3–8 | 5–12 |

| Weight | t | 1.5 | 2.8 | 4.5 | 6.5 | 9 | 12 |

| Control System | - | Button Control | PLC Control | PLC + Touch Screen | Siemens PLC | Siemens PLC | Smart Control |

| Feeding Method | - | Hydraulic Pusher | Hydraulic Pusher | Hydraulic Pusher | Automatic Hydraulic | Auto Feeding | Intelligent Feeding |

| Applicable Materials | - | Plastic, Fabric | Plastic, Paper | Wood, Plastic Drums | Cables, Rubber | Packing Film, PE Bags | Industrial Waste, Mixed Waste |

If you have any special requirements, we will customize according to your special needs.

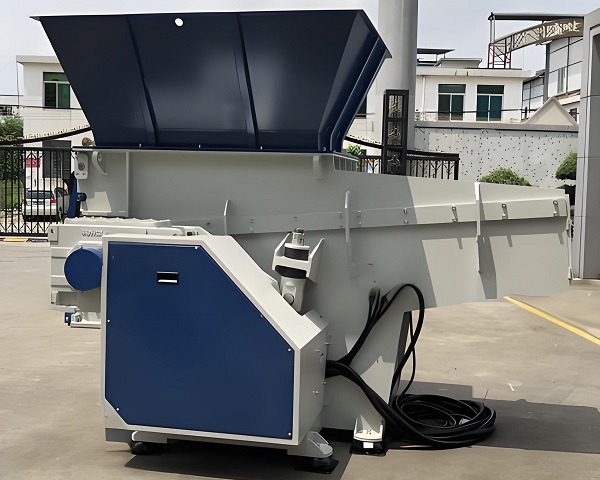

Product Picture Display of Single Shaft Shredder for Sale

FAQ about Single Shaft Shredder for Sale

>1. What is the working principle of a single-shaft shredder?

A single-shaft shredder mainly relies on a single rotating blade shaft to complete the shredding work. The drive device drives the blade shaft to rotate at high speed, and the blade installed on the blade shaft rotates accordingly. After the material enters the shredding chamber from the feed inlet, the blade will exert a shear force on the material, just like scissors cutting things, cutting the material apart; at the same time, the blade will also exert an extrusion effect on the material, destroying its internal structure and reducing its strength. Under the combined action of shearing and extrusion, the material is gradually broken into small pieces and finally discharged from the discharge port. For example, when processing waste plastic bottles, after the plastic bottles enter the machine, they are continuously sheared and squeezed by the rapidly rotating blades, and eventually become small plastic pieces.

>2. What materials are suitable for single-shaft shredders?

Single-shaft shredders have a wide range of applications and can handle a variety of types of materials. In the field of plastics, it can process plastic bottles, plastic barrels, plastic films, plastic pipes, etc.; for wood, it can crush wood scraps, wooden pallets, waste furniture, etc.; paper materials such as waste newspapers, cartons, cardboard, etc. can also be effectively crushed; in addition, it can also process rubber products, small electronic waste (such as waste circuit boards), etc. For example, when the recycling station processes waste plastic products, the single-axis shredder can quickly break them into small pieces for subsequent processing.

>3. How to choose and replace the blade of the single-axis shredder?

The selection of blades should be based on the characteristics of the material. When processing hard materials (such as metals), choose high-strength, wear-resistant alloy steel blades with sharp and strong blades; when processing soft materials (such as plastics), the blade material can be slightly softer, but it must have good gripping and tearing capabilities. When replacing the blade, turn off the power of the device first to ensure safety. Open the box, find the bolt that fixes the blade, unscrew it with professional tools, and remove the old blade. When installing a new blade, pay attention to the installation direction and position of the blade, ensure that the blade and the blade shaft work well together, and then tighten the bolts. For example, when replacing a blade for processing plastic, choose the right material and follow the correct steps to ensure the crushing effect.

>4. What factors affect the crushing efficiency of a single-shaft shredder?

There are many factors that affect the crushing efficiency. The first is the material properties. The hardness, toughness, and size of the material will affect the crushing speed. For example, a hard large piece of metal is more difficult to crush than a soft small piece of plastic, and the efficiency is low. The second is the blade shaft speed. The higher the speed, the more times the blade shears and squeezes the material, and the higher the crushing efficiency may be, but too high a speed may also cause the equipment to be overloaded. Furthermore, the number, shape, and arrangement of the blades will also affect the crushing efficiency. A reasonable blade design can improve the crushing effect. In addition, the feed speed should be moderate. Too fast will cause equipment blockage, and too slow will waste equipment capacity.

>5. What safety protection devices does the single-shaft shredder have?

The single-shaft shredder is equipped with a variety of safety protection devices. There is a common overload protection device. When the equipment encounters an unbreakable hard object or too much material causing excessive load, the device will automatically trigger to stop the equipment from running, avoiding damage to key components such as the knife shaft and blade due to overload. There is also an emergency stop button, which is usually set in a conspicuous position on the equipment operation panel. When the operator encounters an emergency, he can quickly press the button to stop the equipment immediately. In addition, the box is well sealed to prevent material splashing and injuring people, and it can also reduce noise and dust leakage.

>6. How to improve the service life of the single-shaft shredder?

There are many ways to improve the service life of the single-shaft shredder. Regular maintenance is the key. Regularly check the wear of the blade and replace the severely worn blade in time to ensure the crushing effect and normal operation of the equipment. Check the lubrication of the knife shaft, bearings and other parts, add an appropriate amount of lubricating oil, and reduce friction and wear between parts. When operating, strictly follow the specifications, avoid overload operation, and control the feed speed and material size. When the equipment is idle, take moisture-proof and rust-proof measures, and clean and cover the equipment. For example, regularly adding lubricating oil to the bearing can make the bearing run more smoothly and extend its service life.

>7. What are the advantages of single-shaft shredders compared with traditional crushing equipment?

Compared with traditional crushing equipment, single-shaft shredders have obvious advantages. The structure is simpler and more compact, with a small footprint, easy installation and movement, and can adapt to the needs of different sites. In terms of operation, the single-shaft shredder is easy to operate and easy to understand, and the control parameter settings are intuitive. Operators can quickly get started and reduce labor costs. In terms of crushing effect, its blade design is flexible and can be customized according to the characteristics of different materials. It has high crushing efficiency and can crush materials into uniform small pieces. Moreover, the maintenance cost of single-shaft shredders is low, and the failure rate is relatively low. Daily maintenance is mainly focused on blade inspection and replacement.

>8. How to solve the noise and dust of single-shaft shredders?

To solve the noise of single-shaft shredders, a shock absorber can be installed on the base of the equipment to reduce the noise generated by the vibration of the equipment. Soundproof the box, such as adding sound insulation materials, to reduce noise transmission. For dust>, the equipment box should be well sealed to prevent dust leakage. Dust removal devices, such as bag dust collectors, can be installed at the discharge port to collect dust generated during the crushing process to prevent dust from spreading into the air. For example, when processing waste wood, sealed boxes and dust removal devices can effectively reduce the impact of dust on the environment.

>9. What factors affect the price of single-shaft shredders?

The price of single-shaft shredders is affected by many factors. Equipment specifications and models are important factors. Equipment of different specifications has different processing capacities and prices. Large equipment has a large processing capacity and a relatively high price. The material and quality of the blade will also affect the price. High-strength and wear-resistant blade materials will increase the cost of the equipment, thereby increasing the price. Brand factors should not be ignored. Well-known brands are usually more secure in technology research and development, quality control and after-sales service, and the price may be higher than some small brands. In addition, the market supply and demand relationship will also have a certain impact on the price. When the market demand is greater than the supply, the price may rise.

>10. What factors need to be considered when purchasing a single-shaft shredder?

When buying a single-shaft shredder, you should first consider the type and characteristics of the material to be processed, and choose the equipment model and blade type that are suitable for the material. Secondly, determine the specifications of the equipment according to the processing volume to ensure that the equipment can meet production needs. The quality and performance of the equipment are crucial. You should choose equipment with reliable quality and stable performance. You can refer to the manufacturer's reputation and user reviews. After-sales service should not be ignored. Good after-sales service can promptly solve problems that occur during the use of the equipment. In addition, price is also a factor to consider, but you cannot only pursue low prices, but also consider the cost-effectiveness comprehensively. For example, when processing a large amount of waste plastics, you should choose equipment with sufficient processing capacity and reliable quality.