A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

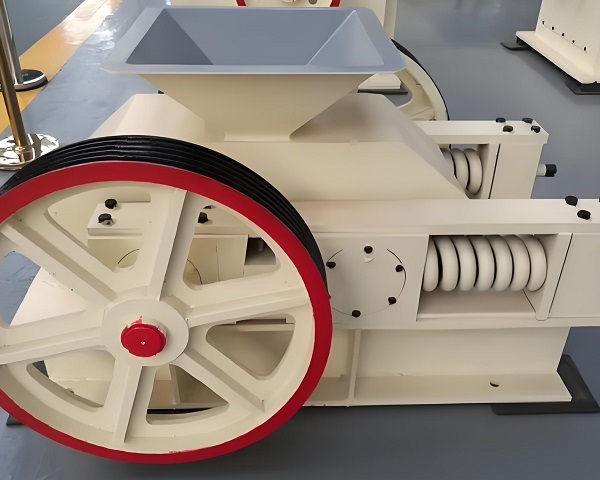

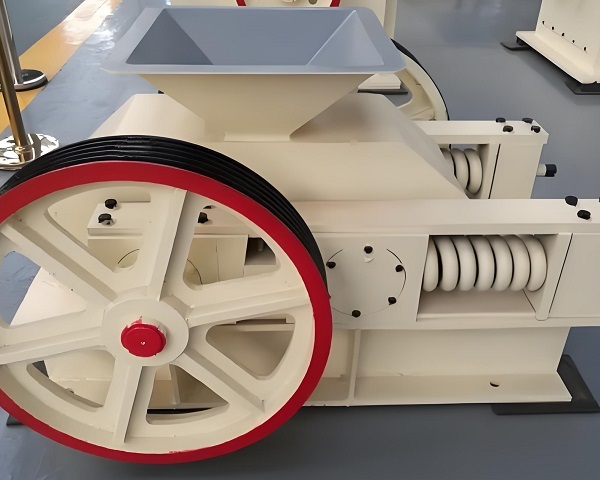

What is the Single Tooth Roll Crusher

The Single tooth roll crusher is a primary crushing equipment with crushing and shearing as the main crushing methods. It is widely used in mining, metallurgy, chemical industry, building materials, power and other industries. It is particularly suitable for crushing brittle materials with medium hardness or below, such as coal, limestone, shale, clinker, salt, etc. It has a simple structure, convenient operation and reliable operation. It is one of the commonly used equipment in traditional coarse crushing process.

The equipment is mainly composed of a horizontally arranged rotating roller and a fixed crushing plate (or movable impact plate). When working, the material falls into the crushing chamber from the feed port, and the rotating roller clamps the material between the crushing plate and crushes it through a strong extrusion force. Some models also have a toothed structure, which can further enhance the shearing and crushing ability of large and harder materials. The crushed material is discharged from the bottom, and the whole process is efficient and stable.

The salient features of the single-roll crusher are compact structure, small footprint, and suitable for installation in places with limited space. At the same time, its transmission part mostly adopts chain or gear transmission, with high transmission efficiency and low energy consumption. The equipment runs smoothly, with low noise, and the crushing chamber is not easy to be blocked, which reduces the failure rate. In addition, the equipment is easy to maintain, the replacement cycle of wear parts is long, and the operating cost is low.

In terms of performance, the single-roll crusher has a certain adjustment function, which can control the discharge particle size by adjusting the gap between the crushing roller and the crushing plate to adapt to different process requirements. Some models are also equipped with spring protection devices or hydraulic devices, which can automatically give way when encountering unbreakable foreign objects to prevent equipment damage and improve the safety and service life of the equipment.

Although the single-roll crusher is not as good as the double-roll or four-roll crusher in crushing ratio and particle shape control, its advantages such as simple structure, low failure rate and strong adaptability make it still occupy an important position in many coarse crushing process scenarios. Especially under working conditions with low particle size requirements and moderate output, the single-roll crusher is still an economical and practical choice.

With its high efficiency, energy saving and easy maintenance, the single-roll crusher plays an important role in a variety of industrial production. With the continuous advancement of manufacturing technology, its structure and performance are also being continuously optimized, and there is still broad room for development in resource recycling, environmental protection treatment and other fields in the future.

Operating principle of Single Tooth Roll Crusher

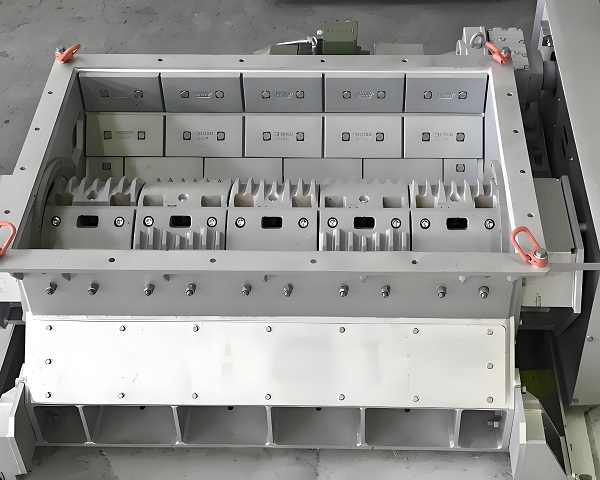

The single tooth roll crusher is a device that mainly uses extrusion and shearing to crush materials. Its working principle is simple and reliable, and it is suitable for the primary crushing of various brittle materials. The device usually consists of a horizontally mounted roller and a fixed crushing plate. Some models can also be equipped with an adjustable clamping mechanism or impact plate to enhance the crushing effect.

In the actual working process, the material falls into the crushing chamber from the upper feed port, and as the roller continues to rotate, it is brought into the gap between the roller and the fixed crushing plate. The rotating roller exerts extrusion and shear force on the material, causing the material to be subjected to strong compressive and shear stresses, resulting in rupture. The surface of the roller may be smooth, toothed or have a groove structure. Different surface forms can be selected according to the nature of the processed material to improve the crushing efficiency and material adaptability.

After the material enters the crushing area, if there are large particles or hard foreign matter, some single-roll crushers are equipped with springs or hydraulic protection systems. When foreign matter enters, the crushing plate or roller can automatically give way to avoid equipment damage. After the foreign matter is discharged, it can automatically reset and resume normal operation. This structural design improves the safety and stability of equipment operation.

In order to control the particle size of the discharge, the user can adjust the gap between the crushing roller and the crushing plate to achieve control of the finished product size. The smaller the gap, the finer the crushing particle size; the larger the gap, the relatively coarse the crushing particle size. This flexible adjustment function enables the single-roll crusher to adapt to production needs under different working conditions.

The single tooth roll crusher has the advantages of strong continuity, low power consumption, and high transmission efficiency during operation. Its structure is simple and has few moving parts, so the failure rate is low and the maintenance is small. It is especially suitable for places with harsh working environments or high requirements for equipment reliability. In addition, some modern models are equipped with chain drive, gear drive or hydraulic drive system, which improves the stability and transmission efficiency of the whole machine.

The single tooth roll crusher with its unique working principle, achieves efficient crushing of materials through extrusion and shearing between the roller and the crushing plate. It is not only suitable for the primary crushing of brittle materials such as coal, limestone, slag, shale, but also plays an irreplaceable role in many industrial applications due to its simple structure, stable operation and easy maintenance. With the development of crushing technology, single-roll crushers have been continuously optimized in terms of energy efficiency, automatic control and safety performance, and have broad application prospects.

Advantages and features of Single Tooth Roll Crusher

As a compact and easy-to-operate coarse crushing equipment, the Single tooth roll crusher is widely used in metallurgy, mining, chemical industry, electric power, building materials and other industries due to its unique working mode and stable performance. Compared with other crushing equipment, the single-roll crusher has many outstanding features and advantages, and is particularly suitable for crushing brittle materials with medium hardness or below, such as coal, limestone, shale, slag, etc.

1. Simple structure and reliable operation are one of the significant advantages of the single tooth roll crusher. The equipment mainly consists of a rotating roller and a fixed or adjustable crushing plate. The transmission mechanism and control system are simple in design and have fewer parts, which reduces the equipment failure rate and improves the stability of operation. This design is not only convenient for daily operation and maintenance, but also greatly reduces maintenance costs and downtime.

2. The single tooth roll crusher has the characteristics of high crushing efficiency and low energy consumption. The extrusion force and shear force generated when the roller rotates are sufficient to crush the material to the required particle size, while avoiding ineffective energy consumption. Especially when crushing softer materials such as coal, salt, gypsum, etc., its energy efficiency performance is particularly outstanding. Compared with jaw crushers or hammer crushers, single roller crushers can usually achieve lower power consumption and more stable output when processing the same materials.

3. The equipment has strong particle size control ability. By adjusting the gap between the roller and the crushing plate, the discharge particle size can be flexibly controlled to meet the production needs of different processes. This adjustment is usually carried out by mechanical or hydraulic systems, which is easy to operate and responds quickly, improving the flexibility of the equipment.

4. The single tooth roll crusher also has good adaptability and scope of application. It is not only suitable for dry materials, but also can handle wet materials containing a certain amount of moisture, and is not prone to clogging. It performs well in coal mines, thermal power plants, raw coal crushing, limestone crushing and other fields. For some materials with stickiness or impurities, the optional toothed roller surface or self-cleaning mechanism can also effectively prevent adhesion and blockage.

5. In terms of safety, some models are equipped with springs or hydraulic protection devices. When unbreakable objects enter the crushing chamber, they can automatically give way to discharge foreign objects to avoid equipment damage. This not only ensures the safe operation of the equipment itself, but also protects the safety of the operator.

In summary, the single roll crusher occupies an important position in the field of industrial crushing due to its advantages of compact structure, low energy consumption, easy operation and maintenance, strong adaptability and high crushing efficiency. With the continuous advancement of equipment technology, its performance and automation level will be further improved, and its application prospects will be broader.

Technical Parameter Table of Single Tooth Roll Crusher

| Model | Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Roller Size (Diameter × Length) (mm) | Motor Power (kW) | Weight (t) | Remarks |

|---|---|---|---|---|---|---|---|

| XPG-φ400×500 | ≤200 | 10–80 | 5–20 | 400×500 | 18.5 | 2.5 | Small type, suitable for medium-soft materials |

| XPG-φ500×500 | ≤300 | 10–100 | 10–40 | 500×500 | 30 | 3.2 | General-purpose model |

| XPG-φ600×600 | ≤400 | 20–100 | 20–60 | 600×600 | 45 | 4.8 | For medium-scale crushing |

| XPG-φ800×800 | ≤500 | 30–120 | 50–100 | 800×800 | 55–75 | 6.5 | Heavy-duty applications |

| XPG-φ1000×1000 | ≤600 | 40–150 | 80–150 | 1000×1000 | 75–90 | 8.5 | High-capacity crushing |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Single Tooth Roll Crusher

FAQ about Single Tooth Roll Crusher

>1. What is the working principle of a single-tooth roller crusher?

The single-tooth roller crusher mainly relies on the large teeth on the surface of the roller to clamp the material and apply shear force and crushing force to crush the material. After the material enters through the feed port, it is captured by the rotating tooth roller and pressed against the body wall or another roller to complete the crushing process. It is suitable for coarse and medium crushing of brittle materials.

>2. What materials are suitable for single-tooth roller crushers?

It is suitable for crushing brittle or medium-hard block materials, such as coal, limestone, shale, clinker, gypsum, slag, etc. It is particularly suitable for materials with moderate water content and not easy to stick. It is widely used in coal mining, cement, metallurgy, power and other industries.

>3. What is the difference between a single-tooth roller and a double-tooth roller crusher?

The single-tooth roller crusher has only one tooth roller, which crushes the material by the shear and extrusion force between the roller and the fixed plate; while the double-tooth roller crusher has two relatively rotating tooth rollers, which can clamp and shear the material in both directions, so the crushing effect is stronger, the application range is wider, and the efficiency is higher.

>4. How to adjust the discharge particle size of a single-toothed roller crusher?

The discharge particle size is mainly achieved by adjusting the gap between the roller and the fixed plate. Modern models are usually equipped with manual or hydraulic adjustment mechanisms, which can quickly change the tooth pitch according to production needs to control the discharge particle size.

>5. What are the advantages of a single-toothed roller crusher?

It has a simple structure, convenient operation, and low maintenance cost. It is suitable for coarse crushing of large pieces of brittle materials; it has low energy consumption, low over-crushing rate, low noise, and low failure rate. It is an economical and practical crushing equipment, especially suitable for small and medium-sized crushing processes.

>6. What are the main wearing parts of a single-toothed roller crusher?

The main wearing parts include the tooth block (tooth head), bearings, and sealing rings on the toothed roller. Among them, the tooth block is in direct contact with the material and wears the fastest. It needs to be checked and replaced regularly to ensure crushing efficiency and safe operation.

>7. What should be paid attention to when installing a single-toothed roller crusher?

During installation, ensure that the foundation is solid and flat, the equipment is installed horizontally, and the direction of the inlet and outlet is reasonable; check that the motor rotation direction is consistent with the tooth roller, and make sure to connect the shock absorption and lubrication system; at the same time, reserve enough maintenance space.

>8. What are the common faults in the operation of the single tooth roller crusher?

Common faults include: tooth roller jamming, overload shutdown, abnormal discharge particle size, loud noise, strong vibration, etc. These problems are usually related to the inconsistency of material properties, severe wear of the tooth block or improper adjustment, and need to be repaired in time according to the fault phenomenon.

>9. How to improve the service life of the single tooth roller crusher?

The tooth block wear should be checked regularly and replaced in time; keep good lubrication; avoid foreign matter entering the machine cavity; reasonably control the feed amount and particle size; avoid long-term no-load or overload operation, and keep the whole machine clean and stable.

>10. Can the single tooth roller crusher be used for wet or sticky materials?

It is not recommended to handle high-humidity or strong sticky materials, because such materials are easy to adhere between the teeth, resulting in blockage or reduced efficiency. If wet material must be processed, consider using a cleaning device or a specially designed wet material crushing model.