A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Roll Crusher for Sale

Roller crusher is a kind of crushing equipment commonly used in medium and fine crushing operations. It mainly relies on two rollers rotating in opposite directions to clamp the material in it, and crush it by applying extrusion force and shear force. Its working principle is simple and efficient, the structure is compact, and the operation and maintenance are convenient. It is widely used in coal, metallurgy, building materials, cement, chemical industry, power and other industries. It is especially suitable for crushing brittle materials with medium and lower hardness, such as coal, coke, limestone, clay, slag, etc.

According to the different forms of roller surface, roller crusher can be divided into smooth roller crusher and toothed roller crusher. Smooth roller is suitable for materials with small particle size and fine crushing requirements, and can obtain more uniform finished particle size; while toothed roller is suitable for crushing larger block or certain sticky materials, with strong bite force and high crushing efficiency. The output particle size of the equipment can be controlled by adjusting the gap between the two rollers. The adjustment method is flexible and can meet the needs of various crushing processes.

Roller crusher has many significant advantages. First of all, the equipment runs smoothly, with small vibration and low noise, which meets the environmental protection requirements of modern industry. Secondly, it has low energy consumption and high efficiency, which is more energy-saving than impact or hammer crushers. Thirdly, it has a simple structure, low failure rate and small maintenance workload. Fourthly, there is less over-crushing and the finished product has uniform particle size, which has a significant effect on improving the efficiency of subsequent processes. In addition, in order to enhance the reliability of the equipment, most roller crushers are also equipped with spring or hydraulic overload protection devices, which can automatically give way when hard objects enter to prevent equipment damage.

In practical applications, roller crushers are often used for secondary or tertiary crushing of materials, and can be used in conjunction with screening equipment to form an efficient crushing and screening system. With the development of industrial automation technology, some high-end models also have intelligent monitoring and automatic adjustment functions, which further improves the convenience of operation and production safety.

Roller crushers play an important role in many industrial fields with their high efficiency, energy saving, low maintenance and strong adaptability. In the future, with the advancement of technology and the improvement of environmental protection requirements, roller crushers will continue to optimize and upgrade in terms of intelligence and greening, and expand their application space in new materials, new energy and other fields.

Operating principle of Roll Crusher for Sale

The working principle of the roller crusher is based on the "extrusion crushing" method. Through a pair of rollers rotating in opposite directions, the material entering the crushing chamber is clamped between the rollers for compression, thereby achieving material crushing. The material enters the machine from the upper feed port, and is rolled into the roller gap under the action of the two rollers, and is subjected to strong pressure between the rollers. When the compressive stress on the material exceeds its compressive strength, it will break and form crushed materials of the required particle size.

During the operation of the equipment, the two rollers usually rotate outward, one on the left and one on the right to "bite" the material in the middle to complete the crushing action. The surface of the roller can be smooth or have tooth patterns or surfacing structures to enhance the grip and crushing efficiency of the material. For harder or larger block materials, the toothed roller can provide stronger bite force, making it easier to be pulled into the crushing area and complete the crushing process.

The crushed material is discharged from the bottom of the roller, and the size of the discharge particle size is mainly achieved by adjusting the gap between the two rollers. The adjustment device usually adopts wedge adjustment, gasket adjustment or hydraulic adjustment. When fine crushing is required, the roller gap is adjusted to a smaller size; when the material is hard or the output requirement is high, the roller gap can be appropriately increased to reduce the equipment load.

In order to ensure the safe operation of the equipment, most roller crushers are equipped with overload protection devices. When unbreakable objects such as metal debris enter the crushing chamber, the movable roller will move outward under the action of the spring or hydraulic system, automatically increasing the gap to allow hard objects to pass smoothly, thereby preventing equipment damage. Subsequently, under the action of the protection device, the movable roller will automatically reset and the equipment will continue to work normally.

In order to reduce the phenomenon of sticking and blocking materials, for materials with high humidity, a toothed roller structure can be selected, and an automatic cleaning device can be configured to keep the roller surface clean and improve continuous working capacity. Some high-end equipment also introduces technologies such as automatic lubrication and intelligent monitoring to achieve real-time control of the operating status, improve operational safety and maintenance efficiency.

The working principle of the roller crusher is simple and efficient. It realizes the crushing of materials through mechanical extrusion and shearing. It has the advantages of low energy consumption, controllable particle size, and strong overload protection. It is one of the important equipment for medium and fine crushing operations in many industrial fields.

Advantages and features of Roll Crusher for Sale

As an efficient and energy-saving medium and fine crushing equipment, the roller crusher is widely used in coal, metallurgy, chemical industry, building materials, power and other industries. It has a simple structure, convenient operation and stable operation, and shows significant performance advantages in the crushing of medium and low hardness materials. The following is a systematic summary of the characteristics and advantages of the roller crusher:

1. The roller crusher has a compact structure, reasonable design, and a relatively simple overall mechanical structure, which is easy to manufacture, install and maintain. It is mainly composed of two rollers rotating in opposite directions, equipped with a feeding device, a discharge port, an adjustment mechanism and an overload protection device. It has few parts and a clear structure, which reduces the possibility of equipment failure and maintenance costs.

2. The equipment consumes less energy during operation. Compared with impact crushers, hammer crushers and other crushers, the roller crusher adopts the extrusion crushing principle. The material is crushed by two rollers, which can effectively reduce the power consumption. It is especially suitable for production lines with high energy-saving and environmental protection requirements. At the same time, it runs smoothly, with low noise and light vibration, which meets the basic requirements of modern green factories for environmental protection.

3. The particle size of the crushed product of the roller crusher is adjustable, the finished product particle size is evenly distributed, and the over-crushing rate is low. By adjusting the gap between the two rollers, the coarseness of the discharged material can be flexibly controlled to meet the requirements of different processes and finished products. This refined control is particularly suitable for application scenarios with strict requirements on material particle size, such as sintering raw material preparation, cement mixture processing, etc.

4. The equipment has strong adaptability and processing capacity. According to the characteristics of different materials, smooth rollers, toothed rollers or combined roller surfaces can be selected to meet the crushing needs of materials with different strengths, particle sizes and humidity. Toothed rollers are more suitable for handling block materials with slightly higher humidity and stronger viscosity to prevent blockage or slipping.

5. Roller crushers are usually equipped with spring or hydraulic overload protection devices. When encountering unbreakable materials, the movable rollers can automatically give way to avoid equipment damage due to jamming or overload, thereby improving work safety and equipment life. After the overload is released, the system automatically resets to ensure production continuity.

6. With the development of technology, modern roller crushers can also integrate intelligent monitoring systems to achieve real-time monitoring of operating conditions such as bearing temperature, vibration, and load, further improving the operating efficiency and management level of the equipment.

Roller crushers have multiple advantages such as simple structure, low energy consumption, adjustable particle size, stable operation, strong adaptability, and perfect safety protection. They are indispensable and important equipment in the medium and fine crushing process, and are particularly suitable for application scenarios with high requirements for energy efficiency, environmental protection, and product particle shape.

Technical Parameter Table of Roll Crusher for Sale

| Model | Max Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Roller Size (Diameter × Length mm) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|

| 2PG-250×400 | ≤25 | 1–10 | 2–8 | 250×400 | 2×5.5 | 1.2 |

| 2PG-400×610 | ≤35 | 2–12 | 5–20 | 400×610 | 2×11 | 2.6 |

| 2PG-610×750 | ≤40 | 2–15 | 15–30 | 610×750 | 2×18.5 | 3.5 |

| 2PG-750×1000 | ≤50 | 3–20 | 30–60 | 750×1000 | 2×30 | 6.0 |

| 2PG-900×1200 | ≤60 | 5–25 | 50–80 | 900×1200 | 2×45 | 8.2 |

| 2PG-1200×1500 | ≤75 | 5–30 | 80–120 | 1200×1500 | 2×75 | 11.5 |

If you have any special requirements, we will customize according to your special needs.

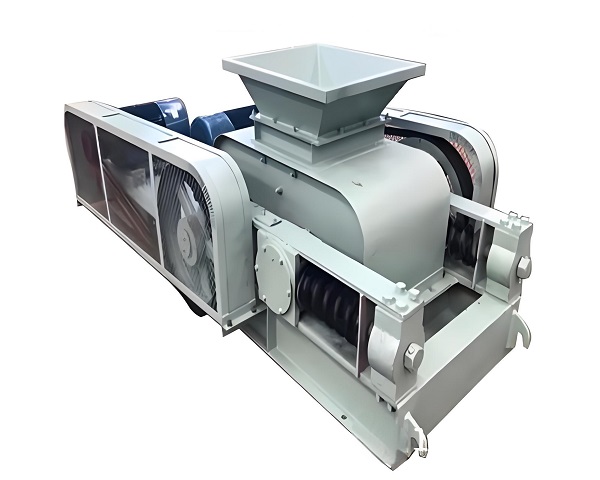

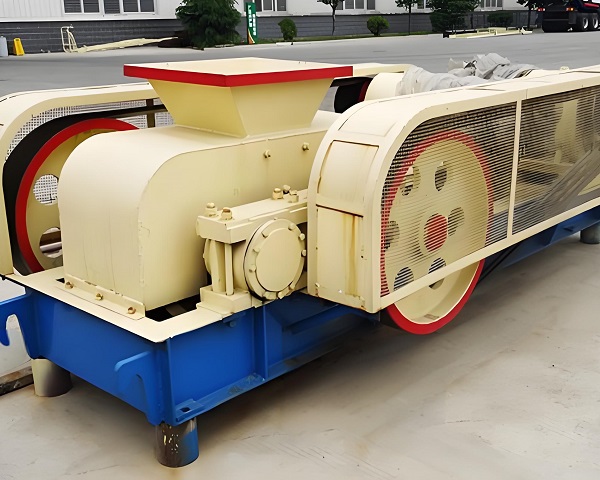

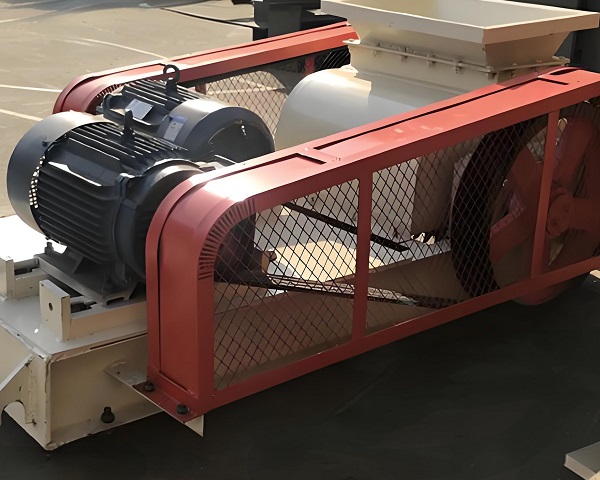

Product Picture Display of Roll Crusher for Sale

FAQ about Roll Crusher for Sale

>1. What is the main working principle of the roller crusher?

The roller crusher squeezes and shears the incoming materials through two relatively rotating rollers. The materials are subjected to strong pressure between the rollers. When the stress exceeds the strength of the materials, they break and form products of the required particle size.

>2. What materials are suitable for roller crushers?

It is mainly suitable for brittle materials with medium and lower hardness, such as coal, coke, limestone, slag, clay, etc. It is not suitable for hard materials with high hardness or containing a large amount of impurities.

>3. How to adjust the discharge particle size of the roller crusher?

The discharge particle size can be achieved by adjusting the gap between the two rollers. The smaller the gap, the finer the finished product; the larger the gap, the coarser the finished product. The adjustment methods include wedge adjustment, gasket adjustment or hydraulic control.

>4. What is the difference between smooth rollers and toothed rollers?

Smooth rollers are suitable for crushing materials with finer finished product particle size requirements, and have a low over-crushing rate; toothed rollers are suitable for materials with large particle size, water content or strong viscosity, and have stronger bite and conveying capabilities.

>5. What are the significant advantages of roller crushers?

The equipment has a simple structure, stable operation, low energy consumption, low noise, low over-crushing rate, controllable discharge particle size, strong adaptability, and convenient maintenance. It is especially suitable for occasions where there are control requirements for finished product particle size.

>6. Does it have an overload protection function?

Yes. Most roller crushers are equipped with spring or hydraulic overload protection devices. When foreign objects enter, the rollers can give way to protect the equipment from damage, and then automatically reset and resume operation.

>7. What are the common faults during operation?

Common faults include bearing overheating, severe roller surface wear, material blockage, belt slippage, etc. Regular maintenance, lubrication and roller surface replacement are the key to ensuring stable operation of the equipment.

>8. Can wet materials be crushed?

Roller crushers can handle materials with a certain humidity, but high humidity may cause problems such as sticking to the roller and blocking. It is recommended to use it with dewatering equipment or use a toothed roller structure to improve adaptability.

>9. How to extend the service life of the equipment?

By regularly checking and replacing wearing parts (such as the roller surface), maintaining good lubrication, avoiding overload, and removing incoming debris, the equipment life and operating efficiency can be significantly extended.

>10. In what areas are roller crushers used in industry?

It is widely used in coal crushing, ore fine crushing, metallurgical slag processing, cement raw material processing, ceramic industry and other fields. It is an important equipment commonly used in crushing processes with fine requirements for particle size.