A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Multi-Roll Crusher

As an important equipment in the industrial crushing field, the multi-roll crusher plays a key role in many industries by virtue of its unique advantages.

Structurally, it consists of multiple rollers arranged in parallel. According to the number of rollers, it can be divided into three rollers, four rollers and even more. These rollers rotate relative to each other through the driving device. After entering the crushing chamber, the materials are crushed due to extrusion and grinding between rollers.

The crushing performance of the multi-roll crusher is excellent. It has a large crushing ratio, which can crush large materials to a small particle size at one time, reduce subsequent processing procedures and improve production efficiency. By adjusting the roller gap, the discharging particle size can be accurately controlled, the product particle size is uniform, and the over-crushing phenomenon is less, which can meet the strict requirements of different industries on the material particle size. For example, in cement production, it can provide appropriate particle size raw materials for the subsequent grinding process, which is conducive to improving cement quality.

In terms of application range, multi-roll crusher is widely used. In the mine industry, it can be used to crush various metal ores, such as iron ore and copper ore, and non-metallic ores, such as limestone and quartz, to provide basic raw materials for subsequent processes such as beneficiation. In the field of building materials, it can handle gypsum, clay, shale, etc. to help produce cement, brick and tile and other building materials. In the chemical industry, some chemical raw materials with moderate hardness can be crushed to facilitate subsequent chemical reaction and processing. For coal, coke and other materials, it can also achieve efficient crushing.

Multi-roll crushers also have some significant advantages. It has strong adaptability to materials, and can effectively crush ores with high hardness or materials with certain moisture. With good operation stability, key components are manufactured with high-quality materials and advanced processes, which can withstand large working pressure and material impact, reduce equipment failure rate and maintenance cost. At the same time, its energy consumption is relatively low, which can effectively save energy and reduce production costs when the same crushing effect is achieved.

Multi-roller crusher also has some limitations, such as relatively high equipment investment and high skill requirements for operators. However, with the continuous progress of technology, these problems will be gradually solved, and the application prospect of multi-roll crusher in industrial production will be broader.

Operating principle of Multi-Roll Crusher

Multi-roller crusher is a kind of equipment that realizes material crushing through the interaction of multiple rollers. Its working principle is based on the extrusion, shearing and grinding between rollers, which can crush large materials into fine particles meeting the requirements.

Multi-roll crushers typically consist of multiple rollers arranged in parallel, mounted on a sturdy frame and driven by a drive such as an electric motor, belt or gear drive to achieve relative rotation. The material enters the crushing chamber from the feed inlet of the equipment and first contacts the uppermost roller.

When the material enters the gap between two adjacent rollers, due to the continuous rotation of the rollers, it will exert a huge extrusion force on the material. This extrusion force makes the material subject to strong compression, and its internal structure begins to crack and gradually crumble. As the roller continues to rotate, the material is continuously conveyed forward and further squeezed by the subsequent rollers. In this process, the material is not only subject to vertical extrusion force, but also shear force due to relative movement of roller. The shear force will act on the weak layer inside the material and accelerate the crushing of the material. Especially for some layered or fibrous materials, the shear effect is more obvious.

In addition to extrusion and shearing, grinding also plays an important role in the working process of the multi-roll crusher. With the multiple extrusion and shearing of materials between rollers, the particle size is continuously reduced. At this time, the friction between the roller surface and the materials is increased, and the materials are ground on the roller surface. This grinding can further refine the material particles, so that the particle size of the product is more uniform and the surface is more smooth.

In the multi-roll crusher, the rollers at different positions undertake different crushing tasks. The upper roller is mainly used for primary crushing to crush large pieces of materials into medium-grained particles; The rollers at the lower part are finely crushed to further grind the medium-grained particles into fine particles meeting the requirements. By reasonably adjusting the clearance between rollers, the discharging particle size can be accurately controlled to meet the requirements of different production processes.

Advantages and features of Multi-Roll Crusher

As an important crushing equipment, the multi-roll crusher shows unique characteristics and obvious advantages in many industrial fields, providing efficient and reliable solutions for material crushing.

Compact and reasonable structure

Multi-roller crusher is composed of multiple rollers arranged in parallel, with compact overall structure and small floor area. This design makes it flexible to adapt to different production sites, especially suitable for the operation environment with limited space, which not only saves the site cost, but also facilitates the installation and layout of equipment.

Precise grain size control

The discharge particle size can be precisely controlled by adjusting the clearance between rollers. The operator can crush the materials to a specific particle size range according to the production requirements, meet the strict requirements of different industries on material particle size, and ensure the consistency and stability of product quality.

Various crushing methods

It combines crushing methods such as extrusion, shearing and grinding. When the material enters the crushing chamber, it is squeezed by the roller to produce cracks, and then further crushed under the shear force generated by the relative movement of the roller. Finally, the particle size is more uniform and fine through grinding, which effectively improves the crushing efficiency and quality.

Large crushing ratio

Multi-roller crusher can crush large materials to smaller particle size at one time, reduce crushing process and improve production efficiency. When processing materials such as ores with high hardness, its strong crushing capacity is especially obvious, which can greatly reduce the difficulty and cost of subsequent processing.

Uniform grain size of product

Due to multi-stage crushing and precise particle size control, the crushed product has uniform particle size distribution and less over-crushing. This not only improves the utilization rate of materials, but also reduces the workload of subsequent screening and other processes, and reduces the production cost.

Low energy consumption

Compared with other types of crushing equipment, the multi-roll crusher has lower energy consumption when reaching the same crushing effect. Its efficient crushing mode and optimized structure design reduce the loss of energy in the crushing process, save energy cost for enterprises, and comply with the development trend of energy conservation and emission reduction.

Wide application range

It can handle a variety of hardness and properties of materials, including metal ore, non-metal ore, coal, chemical raw materials, etc., and has a wide range of applications in mining, building materials, chemical industry, power and other industries.

Technical Parameter Table of Multi-Roll Crusher

| Model | Max Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Number of Rollers | Roller Diameter (mm) | Roller Length (mm) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| 3PG0605 | ≤100 | 0–20 | 10–25 | 3 | 600 | 500 | 3×15 | 4.5 |

| 4PG0806 | ≤120 | 0–30 | 20–50 | 4 | 800 | 600 | 4×22 | 6.8 |

| 3PG1010 | ≤150 | 0–35 | 40–90 | 3 | 1000 | 1000 | 3×30 | 10.2 |

| 4PG1212 | ≤180 | 0–40 | 60–120 | 4 | 1200 | 1200 | 4×45 | 14.7 |

| 4PG1614 | ≤200 | 0–50 | 90–160 | 4 | 1600 | 1400 | 4×55 | 20.8 |

| 3PG1815 | ≤220 | 0–60 | 100–180 | 3 | 1800 | 1500 | 3×75 | 24.5 |

If you have any special requirements, we will customize according to your special needs.

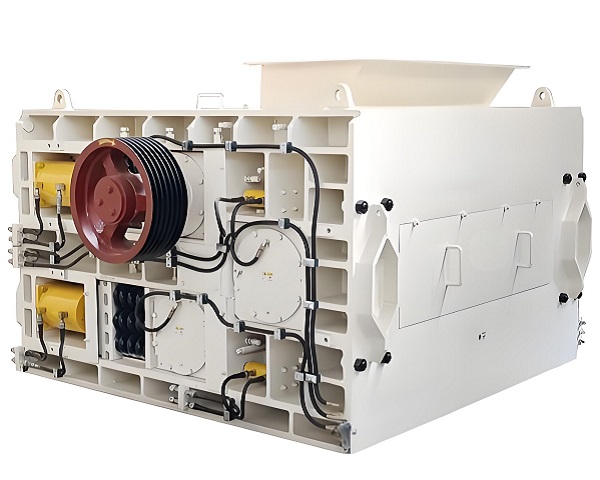

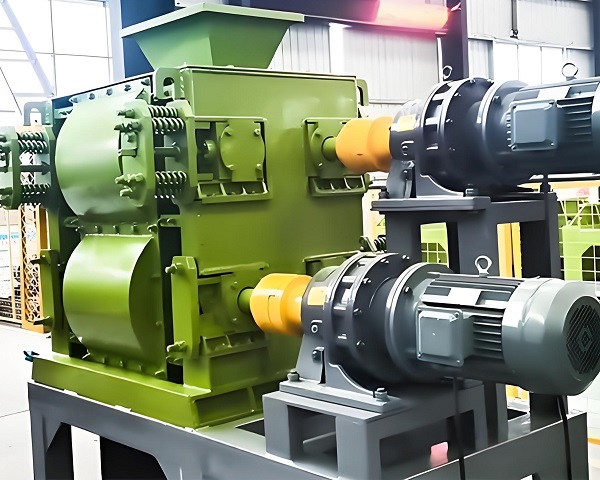

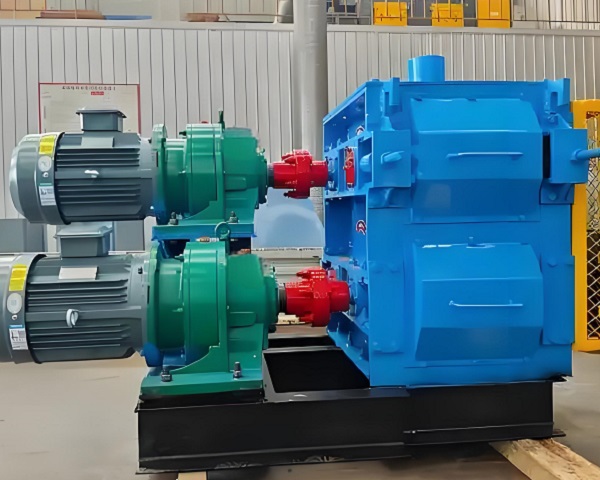

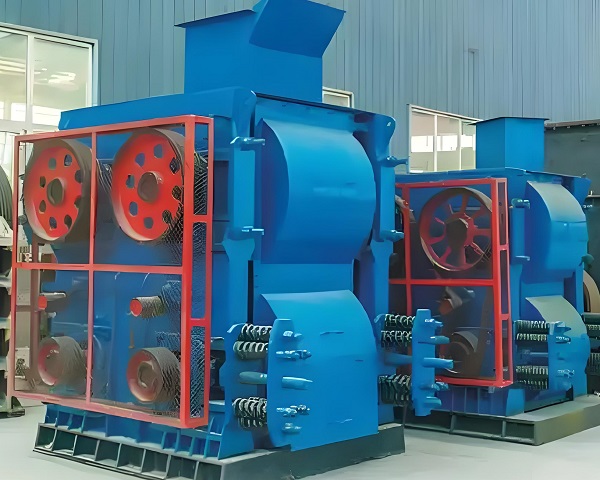

Product Picture Display of Multi-Roll Crusher

FAQ about Multi-Roll Crusher

>What are the advantages of multi-roll crusher compared with single-roll or double-roll crusher?

Significant advantages of multi-roll crusher. From the crushing effect, it has multiple rollers, which can squeeze and grind the materials for many times and more fully. The crushing ratio is larger, which can crush large pieces of materials to finer particle size and reduce subsequent processing procedures. In terms of processing capacity, the multi-roller design makes the materials distributed more evenly in the crushing chamber, more materials are processed per unit time, and the production efficiency is greatly improved. Moreover, by reasonably adjusting the clearance between rollers, the discharge particle size can be flexibly controlled, the product particle size is more uniform and the quality is more stable, which can meet the strict requirements of different industries on material particle size.

>What industries and materials are multi-roll crushers suitable for?

Multi-roller crusher is widely used. In the mine industry, it can be used to crush various metal ores, such as iron ore and copper ore, as well as non-metallic ores, such as limestone and quartz, so as to provide appropriate particle size raw materials for subsequent processes such as beneficiation. In the building materials industry, it can handle gypsum, clay, shale, etc., and be used to produce building materials such as cement, brick and tile. In the chemical industry, some chemical raw materials with moderate hardness can be crushed to facilitate subsequent chemical reaction and processing. For coal, coke and other materials, it can also achieve efficient crushing to meet the needs of different industrial production.

>How to select the proper model of multi-roll crusher?

The selection of suitable model of multi-roll crusher requires comprehensive consideration. The production requirements shall be defined first, including the type of material to be processed, hardness, maximum feed size, expected discharge size and hourly processing capacity. For example, for processing iron ore with high hardness, the model with strong crushing capacity and wear-resistant roller material shall be selected; If the processing capacity is large, select the equipment with matching capacity. Then inspect the equipment performance and pay attention to its crushing efficiency, energy consumption, failure rate, etc. Meanwhile, considering the price, after-sales service and reputation of the manufacturer, the model with high cost performance and meeting the long-term stable production needs shall be selected after comprehensive comparison.

>How does the roller material of the multi-roll crusher affect the equipment performance?

Roller material has a significant impact on the performance of multi-roll crusher. If high chrome cast iron is used, it has extremely high hardness and abrasion resistance, which can effectively resist material abrasion, extend the service life of roller and reduce equipment maintenance cost when crushing materials with high hardness, but the cost is relatively high. Manganese steel has good toughness and is not easy to crack when bearing large impact. It is suitable for crushing some materials containing more hard impurities. The alloy steel can be added with specific alloy elements according to different working conditions to achieve the best balance in hardness, toughness, corrosion resistance and other aspects, so as to improve the overall performance and reliability of the equipment.

>How to adjust the discharge particle size when the multi-roll crusher is in operation?

The discharging grain size of the multi-roll crusher is adjusted mainly by adjusting the clearance between rollers. Generally, the moving roll is moved by hydraulic or mechanical device to change the distance between two rolls. To obtain finer discharging grain size, gradually adjust the roller gap to make the materials subject to stronger extrusion and grinding when passing through; If the discharge grain size needs to be increased, the roller gap shall be appropriately increased. The operator shall accurately control the gap size according to the actual production requirements, and pay attention to the slow and uniform adjustment process to avoid equipment damage or unstable crushing effect due to fast adjustment.

>What are the key points for daily maintenance of multi-roll crusher?

Routine maintenance is the key to stable operation of multi-roll crusher. One of the key points is to regularly check the wear of the roller, check whether the surface has cracks, peeling, etc., and repair or replace the seriously worn roller in time. The second is to check the tension of transmission parts, such as belt and chain, and lubrication of gear, so as to ensure smooth power transmission and prevent equipment operation due to transmission failure. Clean the accumulated materials and sundries inside the equipment to avoid blocking and affecting the crushing effect. Fourth, check whether the fasteners of the equipment, such as bolts and nuts are loose, and tighten them in time. Fifth, lubricate the equipment according to the specified period, and use the appropriate lubricant to reduce the wear of parts.

>What is the possible reason for abnormal noise of multi-roll crusher?

The abnormal noise of the multi-roll crusher may be caused by many reasons. First, the roller is improperly installed. If the roller axis is not parallel, vibration and collision will be caused during operation, and abnormal noise will be generated. Second, the transmission component failure, belt looseness and slipping, gear wear or poor engagement will cause unstable power transmission and noise. Third, there are foreign matters inside the equipment, such as hard objects such as metal blocks in the crushing chamber, which will make sharp noises when collided with the roller. Fourthly, the bearing is damaged. The bearing is an important part supporting the rotation of the roller. If it is damaged, the roller will not operate stably and generate large noise.

>What factors affect the energy consumption of multi-roll crusher?

The energy consumption of multi-roll crusher is affected by many factors. Material property is an important factor. The higher the material hardness and particle size, the more energy required for crushing and the higher the energy consumption. In terms of equipment parameters, the rotating speed and clearance of the roller and the structure of the crushing chamber will affect the energy consumption. Too high rotating speed will increase the crushing resistance and energy consumption; Too small clearance between rollers will make it difficult for materials to pass through and increase energy consumption. In addition, the load of the equipment will also affect the energy consumption. Too large or too small load is not conducive to energy conservation. Maintaining a proper load can reduce the energy consumption while the equipment operates efficiently.

>What are the requirements for the installation environment of the multi-roll crusher?

The installation environment of multi-roll crusher has strict requirements. The site shall be flat and solid, able to bear the weight of equipment and vibration during operation, so as to avoid equipment failure due to unstable foundation. The installation environment shall be dry and ventilated. Good ventilation conditions are conducive to heat dissipation of the equipment and prevent the performance and service life of the equipment from being affected due to excessive temperature. At the same time, the equipment shall not be installed in a wet, corrosive gas or high dust concentration environment, so as to avoid corrosion of equipment parts and affecting the normal operation of the equipment. In addition, sufficient operation space shall be ensured to facilitate equipment installation, commissioning, maintenance and overhaul.

>What are the features of multi-roll crusher in terms of environmental protection?

Multi-roller crusher has certain characteristics in environmental protection. In terms of dust control, the crushing chamber is usually designed with seal, which can effectively reduce the dust spillover during crushing and reduce the pollution to the surrounding environment. Some advanced multi-roll crushers are also equipped with dust removal devices to further collect and process the dust generated. In terms of noise control, the equipment adopts vibration reduction and noise reduction measures by optimizing the structural design, such as installing shock pad, optimizing transmission parts, etc., to reduce the noise during operation and the impact on operators and the surrounding environment. At the same time, its high-efficient crushing characteristics also help to reduce energy consumption and environmental burden caused by energy production and use.