A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Four Roll Crusher

As an important equipment in crushing field, four-roll crusher plays a key role in many industrial production.

From the structure, it is mainly composed of four rollers arranged in parallel, divided into two pairs. The upper and lower rollers rotate relative to each other through different transmission modes, and this unique design provides the basis for efficient material crushing.

In terms of crushing principle, after entering the crusher, the materials will successively pass through the extrusion and grinding of the upper and lower pair of rollers. The materials of the first pair of rollers are crushed preliminarily to reduce the particle size; Then, the material enters the second pair of rollers for further fine crushing, and finally fine particles meeting the requirements are obtained. This graded crushing method makes the crushing process more efficient and accurate, and can better control the particle size of the product.

The four roll crusher offers many significant advantages. First, the crushing ratio is large, which can crush large materials to smaller particle size at one time, reducing the crushing process and improving the production efficiency. Secondly, the product grain size is uniform, which benefits from the accurate clearance adjustment between rollers and the relatively stable crushing process, which can meet the strict requirements of different industries on material grain size. Third, the energy consumption is relatively low. Compared with other types of crushing equipment, it can save a lot of energy and reduce the production cost when the same crushing effect is achieved.

In the application field, four-roll crusher is widely used. In the mine industry, it can be used to process various metal ores and non-metallic ores to provide suitable raw materials for subsequent beneficiation and other processes; In the metallurgical industry, it can crush the waste slag and furnace burden produced in the smelting process to realize the recycling of resources; In the building material industry, it also plays an important role in the crushing and processing of limestone, gypsum and other raw materials, which is conducive to the production of high-quality building materials.

The four-roll crusher also has some limitations, for example, there are certain requirements for the humidity and viscosity of the materials, and the excessively wet or sticky materials may lead to roller blockage and other problems. However, in general, four-roll crusher plays an important role in industrial production due to its unique structure, efficient working performance and wide application range, providing reliable solutions for material crushing demands of various industries.

Operating principle of Four Roll Crusher

The four-roll crusher is a kind of equipment that realizes material crushing through the interaction of multiple rollers. Its working principle is mainly based on the extrusion, shearing and grinding of rollers. The following is a summary from three aspects: structure foundation, crushing process and crushing mechanism.

The structural foundation lays a foundation for crushing

The four-roll crusher is mainly composed of four rollers arranged in parallel, which are divided into upper and lower pairs. In each pair of rollers, one is a fixed roller with relatively stable position; The other is a movable roller, which can be adjusted by hydraulic or spring device to change the gap between the two rollers and adapt to the crushing operation with different particle size requirements. The roller surface usually has tooth or wavy pattern, which can increase the friction with the material and improve the crushing efficiency. In addition, the equipment is also equipped with a transmission system to enable the upper and lower rollers to rotate according to the set speed and direction.

Crushing process to realize material refinement

The material enters the four-roll crusher from the feed inlet and first contacts the first pair of rollers. Due to the relative rotation of the two rollers, the materials are strongly extruded and the large materials are preliminarily crushed into smaller particles. These initially crushed materials then fall between the second pair of rollers and are again crushed and ground. The rotating speed and clearance of the second pair of rollers are usually different from those of the first pair, which can further reduce the particle size of the material by fine crushing of the material. The materials meeting the requirements are discharged from the outlet after two-stage crushing, while the few materials not meeting the particle size requirements may continue to participate in the crushing cycle in the equipment until the requirements are met.

Crushing mechanism guarantees crushing effect

Squeezing effect: when the material enters between two rollers, the rollers exert huge pressure on the material, so that the stress inside the material is concentrated. When the stress exceeds the compressive strength of the material, the material will be crushed. This extrusion is the main way for four-roll crusher to realize material crushing.

Shearing action: the tooth shape or wavy pattern on the roller surface will generate shear force on the material during rotation. The shear force can cut off the fibrous structure in the material or break the material along the weak surface, which helps to improve the crushing efficiency and product uniformity.

Grinding: the materials are continuously rolled and rubbed between two rollers, and are subject to grinding. This effect can make the material surface more smooth and the particle size more uniform, further improving the product quality.

Advantages and features of Four Roll Crusher

As an important crushing equipment, four-roll crusher is widely used in many industrial fields, and has the following obvious characteristics and advantages:

Efficient crushing with considerable capacity

The four-roll crusher has four rollers arranged in parallel. After entering the crushing chamber, the materials will successively pass through the upper and lower pair of rollers for extrusion and grinding. Compared with the traditional double-roll crusher, it increases the crushing stage, significantly improves the crushing ratio, and can crush the large materials to a smaller particle size at one time, reduces the intermediate links, and greatly improves the crushing efficiency. Taking limestone processing as an example, the hourly processing capacity of four-roll crusher can reach dozens of tons or even hundreds of tons, which can meet the demand of large-scale production.

Controlled grain size, high quality product

By adjusting the gap between the upper and lower rollers, the four-roll crusher can accurately control the discharging particle size. Either medium grained material requiring coarse crushing or fine particles resulting from further fine crushing can be easily achieved. Moreover, due to the adoption of graded crushing, the particle size of the product is uniform, and the over-crushing phenomenon is less. In cement production, using four-roll crusher to process raw materials can provide materials with uniform particle size for the subsequent grinding process, which is conducive to improving cement quality and production efficiency.

Reasonable structure and stable operation

The compact and reasonable structure design and the scientific layout of four rollers make the equipment bear even force during the operation process and reduce vibration and noise. At the same time, key components such as rollers and bearings are made of high-quality materials and advanced manufacturing processes, which have high strength and wear resistance, can withstand large working pressure and material impact, ensure long-term stable operation of equipment, and reduce equipment failure rate and maintenance cost.

Strong adaptability and wide application

The four-roll crusher has strong adaptability to materials and can crush various hardness ores, rocks, coal, coke and other materials. It can be used for crushing iron ore and copper ore in the mine industry; It can process gypsum, clay and other raw materials in the building material industry. In addition, it can adjust the working parameters according to the characteristics of different materials and production requirements to achieve the best crushing effect.

Energy conservation, environmental protection and low cost

In the crushing process, the energy consumption of four-roll crusher is relatively low, which can effectively reduce the production cost. At the same time, the sealing performance is good, the dust spillover is reduced, the environmental protection requirements are met, and a good working environment is created for the operators.

Technical Parameter Table of Four Roll Crusher

| Model | Max Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Roller Diameter (mm) | Roller Length (mm) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|---|

| 4PG0605 | ≤100 | 0–30 | 10–30 | 600 | 500 | 2×15 | 3.5 |

| 4PG0806 | ≤120 | 0–30 | 20–50 | 800 | 600 | 2×22 | 5.2 |

| 4PG1010 | ≤150 | 0–40 | 30–80 | 1000 | 1000 | 2×37 | 8.9 |

| 4PG1212 | ≤180 | 0–50 | 50–100 | 1200 | 1200 | 2×45 | 12.5 |

| 4PG1614 | ≤200 | 0–60 | 80–150 | 1600 | 1400 | 2×75 | 18.2 |

| 4PG1815 | ≤220 | 0–70 | 100–180 | 1800 | 1500 | 2×90 | 21.5 |

If you have any special requirements, we will customize according to your special needs.

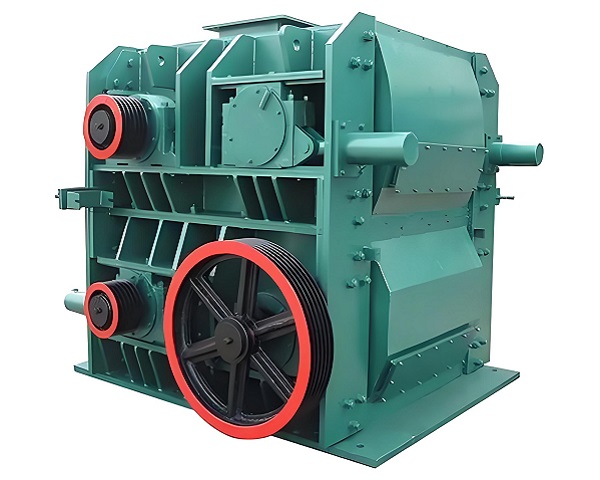

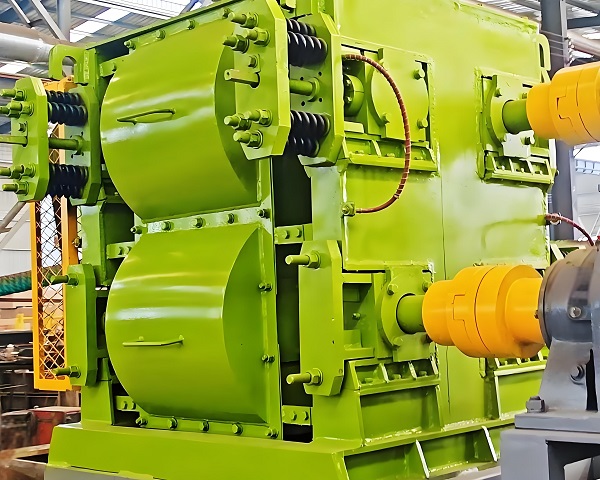

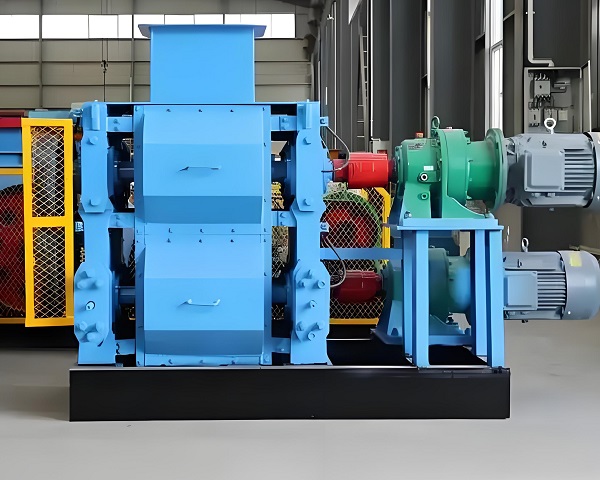

Product Picture Display of Four Roll Crusher

FAQ about Four Roll Crusher

>What is the working principle of four-roll crusher?

The four-roll crusher has four rollers arranged in parallel, which are divided into upper and lower pairs. When the material enters, it first contacts the first pair of rollers, and the two rollers rotate relative to each other to exert great pressure on the material, so that it is crushed into small particles. These particles then fall between the second pair of rollers and are again extruded and ground. The rotating speed and clearance of the second pair of rollers are different from those of the first pair, which can crush the materials more finely and further reduce the particle size. Finally, the materials meeting the requirements are discharged from the outlet. The unqualified materials may be crushed in the equipment until they are qualified.

>What materials are suitable for four-roll crusher?

The four-roll crusher has strong adaptability to materials and can crush various types of materials. In the ore field, it can process metal ores such as iron ore, copper ore and gold ore, and non-metallic ores such as limestone and quartz; In the coal industry, it can be used to crush coal and coke; In the building materials industry, it can handle gypsum, clay, shale and other raw materials; Crushing operation can also be carried out for some chemical raw materials with moderate hardness to meet the requirements of different industrial production for material crushing.

>How to adjust the discharge size of four-roll crusher?

The discharging grain size of the four-roll crusher is adjusted mainly by adjusting the gap between the upper and lower rollers. Generally, the movable roller is moved by hydraulic or spring device to change the distance between two rollers. If finer discharging grain size is required, the roller gap shall be reduced, so that the materials will be subject to stronger extrusion and grinding and crushed finer when passing through; To increase the discharging grain size, properly increase the roller gap. The operator can accurately adjust the gap size according to the actual production requirements to obtain the ideal discharge particle size.

>What are the advantages of four-roll crusher compared with other crushers?

Obvious advantages of four-roll crusher. First, the crushing ratio is large, which can crush the large materials to a smaller particle size at one time, reduce the crushing process and improve the efficiency; Second, the product particle size is uniform, and the discharge particle size is effectively controlled through the graded crushing and the adjustable roller gap to reduce the over-crushing; Third, the energy consumption is relatively low, which can save energy and reduce costs when the same crushing effect is achieved; The fourth is that it has strong adaptability to materials, can handle a variety of hardness and properties of materials, and has a wide range of applications.

>How does the roller material of four-roll crusher affect the crushing effect?

Roller material directly affects the crushing effect of four-roll crusher. If high manganese steel is used, it has high strength and good abrasion resistance. It can effectively resist material abrasion when crushing materials with high hardness, and keep the shape and size of the roller stable, so as to ensure crushing efficiency and product quality, but the cost is relatively high. Alloy steel has better performance under specific working conditions. Appropriate alloy elements can be added according to the characteristics of different materials and crushing requirements to improve the hardness, toughness and corrosion resistance of the roller and further improve the crushing effect.

>What is the possible reason for excessive vibration of four-roll crusher during operation?

Excessive vibration during operation of four-roll crusher may be caused by many reasons. First, the foundation is not firmly installed, and the equipment vibrates due to loose foundation during operation; Second, the uneven wear of the roller causes uneven surface of the roller, and the uneven stress during rotation causes vibration; Thirdly, transmission component failure, such as belt looseness and poor gear engagement, will cause unstable power transmission and equipment vibration; The fourth is that the materials enter non-uniformly. If the materials are distributed unevenly in the crushing chamber, the stress on the roller will be unbalanced, and then large vibration will be generated.

>What are the daily maintenance points of four-roll crusher?

Routine maintenance is essential for the normal operation of the four-roll crusher. Firstly, regularly check the abrasion of the roller, repair or replace the seriously worn roller in time to ensure the crushing effect; Second, check the tension of transmission parts, such as belt and chain, and lubrication of gear to ensure smooth power transmission; Clean the accumulated materials and sundries inside the equipment to prevent blocking and affecting the equipment performance; Fourth, check whether the fasteners of the equipment, such as bolts and nuts are loose, and tighten them in time; Fifth, lubricate the equipment regularly and operate according to the specified lubrication period and lubricant type.

>What factors affect the energy consumption of four-roll crusher?

The energy consumption of four-roll crusher is affected by many factors. Material property is one of the important factors. The higher the material hardness and particle size, the more energy required for crushing and the higher the energy consumption. In terms of equipment parameters, the rotating speed and clearance of the roller and the structure of the crushing chamber will affect the energy consumption. Too high rotating speed or too small clearance will increase crushing resistance and energy consumption. In addition, the load of the equipment will also affect the energy consumption. Too large or too small load is not conducive to energy conservation. Maintaining a proper load can reduce the energy consumption while the equipment operates efficiently.

>How to select the appropriate four-roll crusher model?

The selection of suitable four-roll crusher model requires comprehensive consideration of various factors. First of all, the production requirements shall be clarified, including the type of materials to be processed, hardness, maximum feed particle size, discharge particle size and hourly processing capacity, etc. Based on these parameters, preliminarily screen out the model range that can meet the production requirements. Secondly, the performance and reliability of equipment shall be considered, and the technical parameters, crushing efficiency, energy consumption and failure rate of different types of equipment shall be understood. Finally, the price of equipment, after-sales service and reputation of the manufacturer shall be taken into consideration, and the model with high cost performance and meeting the production requirements shall be selected after comprehensive weighing.

>What are the precautions for installation of four-roll crusher?

Precautions for installation of four-roll crusher:. The installation site shall be flat and solid to ensure that the equipment foundation can bear the weight of the equipment and the vibration during operation. Carefully check whether all parts of the equipment are intact, damaged or missing before installation. During the installation process, the operation shall be carried out in strict accordance with the installation instructions to ensure the installation accuracy of the equipment, especially the parallelism and clearance adjustment of the roller shall be accurate. When installing the transmission parts, ensure that the belt or chain tension is appropriate and the gear mesh is good. Comprehensive inspection and commissioning shall be carried out after installation to ensure stable operation of equipment without abnormal noise and vibration.