A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

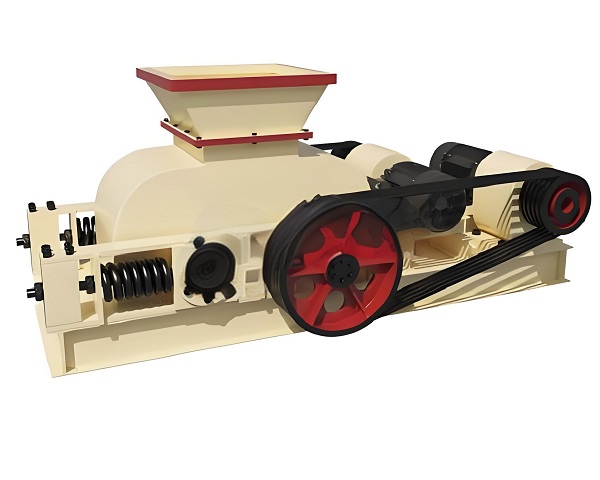

What is the Double Roll Crusher

The double-roll crusher is a crushing equipment commonly used for medium and fine crushing. It mainly squeezes, shears and grinds the material through two relatively rotating rollers to achieve the purpose of crushing. The equipment has a simple structure, convenient operation, low maintenance cost, small size, adjustable discharge particle size, low energy consumption and stable operation. It is one of the commonly used crushing machinery and equipment in coal, electricity, building materials, chemical industry, metallurgy and other industries.

The double-roll crusher is generally composed of a frame, rollers, transmission device, adjustment device and safety protection device. When working, the two rollers rotate in opposite directions, clamping the material between the rollers, using the friction on the roller surface to pull the material into the roller gap, and crushing the material through the extrusion force. The size of the discharge particle size mainly depends on the gap between the two rollers, which can be flexibly controlled by the adjustment device to meet different production needs.

According to the different shapes of the roller surface, the double-roll crusher can be divided into a smooth roller crusher and a toothed roller crusher. The smooth surface is suitable for materials with low hardness and uniform particle size; the tooth surface is more suitable for materials with high viscosity or large block size, and its crushing ability is stronger. In addition, it can be divided into electric drive and hydraulic drive types according to the driving mode. Some equipment is equipped with automatic lubrication system and intelligent monitoring device, which further improves the reliability and intelligence level of the equipment.

Double-roll crusher is widely used in crushing coal, limestone, slag, coke, quartz stone and other materials with medium hardness and below. Due to its moderate crushing ratio, excellent finished product particle shape, and less dust pollution, it is particularly suitable for modern industrial production with high requirements for environmental protection and energy saving. In the process links such as sand making, coal selection, and cement clinker crushing, double-roll crusher is often used as secondary or tertiary crushing equipment, and is combined with other equipment to form an efficient and environmentally friendly crushing system.

Double-roll crusher has become one of the important equipment in the field of industrial crushing due to its advantages of high efficiency, energy saving, compact structure, and strong adaptability. With the continuous development of technology, its intelligence and automation level are constantly improving, and its application scope is also continuously expanding, providing reliable crushing solutions for various industrial production.

Operating principle of Double Roll Crusher

The working principle of the double-roll crusher is based on the "extrusion crushing" mechanism. It is a device that relies on two relatively rotating rollers to apply pressure to the material to achieve material crushing. The material falls between the two rollers through the upper feed port, and is brought into the roller gap area with the help of the friction force on the roller surface. It is subjected to strong compression and shearing forces between the two rollers, causing the material to break or crush, achieving the crushing effect.

During the operation of the equipment, the two rollers rotate in relative directions (generally outward rotation). When the material enters the working area between the two rollers, on the one hand, the friction generated by the rotation of the rollers pushes the material to the middle, and on the other hand, the gap between the rollers is small, which exerts an extrusion effect on the material. For materials with lower strength or brittleness, this force is enough to crush them; for slightly harder materials, it will also produce a certain shear force and grinding effect, thereby further crushing the material into the required particle size.

The output particle size of the double-roll crusher depends on the gap between the two rollers. The roller gap width can be changed by adjusting devices (such as wedge adjustment or gasket adjustment), thereby controlling the particle size of the final product. Generally speaking, the smaller the roller gap, the finer the particle size of the material, but too small a gap may cause blockage or increase the load on the equipment, so it needs to be reasonably set according to the material characteristics and actual process requirements.

In order to prevent metal debris or unbreakable objects from entering the crushing chamber and causing damage to the equipment, the double-roll crusher is usually equipped with a safety protection device, such as a spring protection or a hydraulic protection mechanism. When a hard object enters, the spring or hydraulic cylinder will move the movable roller backward to increase the gap, thereby playing an overload protection role; after the foreign object passes, the roller can automatically reset and resume normal working state.

In order to improve the crushing efficiency and durability, some double-roll crushers use high manganese steel, surfacing alloy and other wear-resistant materials on the roller surface, and even have a toothed roller surface to enhance the bite force and crushing capacity of blocky, wet or sticky materials.

The working principle of the double-roll crusher is simple but efficient. It applies extrusion and shearing to the material through relatively rotating rollers, and achieves a uniform particle size crushing effect under the premise of low energy consumption and compact structure. It is a key crushing equipment widely used in a variety of industrial material processing processes.

Advantages and features of Double Roll Crusher

As a medium and fine crushing equipment widely used in coal, cement, metallurgy, building materials, chemical industry and other industries, the double-roll crusher is widely recognized by users for its compact structure, high crushing efficiency and low energy consumption. It crushes by applying extrusion and shear force to the material through the rotation of two rollers in opposite directions. It is suitable for brittle materials with medium and lower hardness, such as coal, limestone, quartz stone, coke, slag, etc. The main features and advantages are summarized as follows:

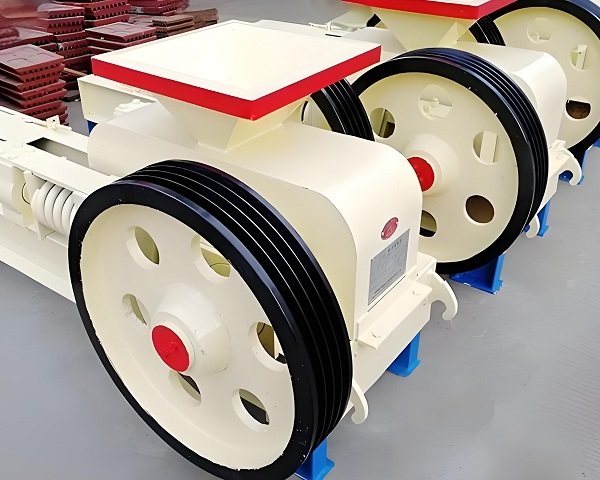

1. The double-roll crusher has a simple structure, relatively low manufacturing cost, and convenient maintenance and operation. The equipment is mainly composed of rollers, frames, transmission devices, adjustment mechanisms and safety protection systems. It has fewer parts, flexible installation, and small footprint, which is suitable for occasions with limited space. At the same time, the equipment runs stably, has low vibration and low noise, meets environmental protection standards, and is especially suitable for enterprises with high requirements for production environment.

2. Its crushed product has uniform particle size and low over-crushing rate, which is an ideal choice for process flows with high requirements for material particle shape. By adjusting the gap between the two rollers, the discharge particle size can be flexibly controlled to meet the needs of products with different particle size grades. In addition, some models also support hydraulic adjustment or automatic control, which improves the convenience and accuracy of adjustment.

3. The double-roll crusher has the significant advantages of low energy consumption and high efficiency. Its crushing process is mainly completed by the extrusion between materials. Compared with the traditional impact crushing method, it has lower unit energy consumption and effectively reduces the operating cost. Especially in the scenario of large-scale continuous operation, its high-efficiency energy-saving performance is particularly outstanding.

4. The equipment has strong safety and overload protection capabilities. The double-roll crusher is generally equipped with a spring or hydraulic protection device. When encountering metal debris or unbreakable objects, the active roller will automatically give way, thereby effectively preventing failures caused by hard objects stuck in the equipment, ensuring the reliability of continuous operation and the service life of the equipment.

5. It has strong adaptability and can handle a variety of materials with different humidity and viscosity. For materials with low water content, its working efficiency is stable; if it is used to handle slightly wet materials, the working effect can also be improved by configuring toothed roller surfaces, cleaning devices, etc., to avoid material sticking to the roller or blocking the material.

The double-roll crusher plays an important role in the medium and fine crushing process with its multiple advantages such as reasonable structure, reliable performance, flexible operation and economical operation. With the development of automation and intelligent technology, modern double-roll crushers can also realize functions such as remote control and status monitoring, which further enhances its industrial application value and development prospects.

Technical Parameter Table of Double Roll Crusher

| Model | Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Roller Diameter × Length (mm) | Motor Power (kW) | Weight (t) | Remarks |

|---|---|---|---|---|---|---|---|

| 2PG-400×250 | ≤25 | 1–8 | 2–8 | 400×250 | 2×5.5 | 1.5 | Lab use / small production |

| 2PG-610×400 | ≤35 | 2–10 | 5–20 | 610×400 | 2×11 | 2.8 | Standard small plant model |

| 2PG-750×500 | ≤40 | 2–15 | 15–30 | 750×500 | 2×18.5 | 3.8 | Medium-scale crushing |

| 2PG-900×700 | ≤50 | 3–20 | 30–60 | 900×700 | 2×30 | 6.2 | General-purpose industrial use |

| 2PG-1000×800 | ≤60 | 5–25 | 50–80 | 1000×800 | 2×37 | 8.5 | Heavy-duty continuous work |

| 2PG-1200×1000 | ≤75 | 5–30 | 80–120 | 1200×1000 | 2×55 | 11.2 | Large capacity, high efficiency |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Double Roll Crusher

FAQ about Double Roll Crusher

>1. What is the working principle of the double-roll crusher?

The double-roll crusher clamps the material into the roller gap through two rollers rotating in opposite directions, and applies strong extrusion and shearing forces to crush or break the material. Its core mechanism is "extrusion crushing". The material is flattened or broken after being compressed to form a product of the required particle size.

>2. What materials are suitable for the double-roll crusher?

This equipment is mainly used for brittle materials with medium and lower hardness, such as coal, limestone, coke, slag, quartz stone, clay, etc. The double-roll crusher is not suitable for high-hardness or strong sticky materials, and is suitable for crushing occasions that require uniform particle size and less over-crushing.

>3. How to adjust the discharge particle size?

The discharge particle size is mainly achieved by adjusting the gap between the two rollers. The smaller the roller spacing, the finer the discharge; the larger the roller spacing, the coarser the discharge. The adjustment method generally uses wedges, gaskets or hydraulic devices, which are convenient for flexible setting according to process requirements.

>4. What types of roller crushers are there?

Mainly divided into smooth roller type and toothed roller type. Smooth surface is suitable for materials with low hardness and high finished product requirements, while toothed surface is used for materials with larger block size or slightly sticky, with stronger bite force and processing capacity.

>5. What are the significant advantages of roller crushers?

The equipment has compact structure, stable operation, low noise, low energy consumption, and easy operation, which is particularly suitable for fine crushing. The finished product particle size is uniform and adjustable, and the over-crushing rate is low, which is conducive to improving the efficiency and quality of subsequent processes.

>6. Does the roller crusher have overload protection?

Yes, most roller crushers are equipped with spring or hydraulic overload protection devices. When unbreakable foreign matter enters the crushing chamber, the roller will automatically give way to avoid equipment damage and enhance the safety and reliability of operation.

>7. What are the wearing parts? What is the service life?

The main vulnerable parts are the roller surface (including roller skin or roller teeth). Depending on the material (such as high manganese steel, alloy steel, cladding layer, etc.), the service life also varies greatly. Regular inspection and replacement of the roller surface is the key to maintaining the crushing effect.

>8. Can the double-roll crusher be used for wet or sticky materials?

It works better for materials with low moisture content (generally ≤10%). When handling wet materials, problems such as sticking to the roller and blocking may occur. It is necessary to use a toothed roller structure and configure a cleaning device or clean it regularly to avoid production interruptions.

>9. How to improve the crushing efficiency of the equipment?

Reasonable control of feed size and speed, regular maintenance of the roller surface, good lubrication, and avoidance of material overload or biased operation are all effective means to improve crushing efficiency. At the same time, the use of a screening system can improve the overall process efficiency.

>10. How long is the service life of a double-roll crusher?

The life of the entire machine depends on the use environment, material characteristics and maintenance. Under normal use, the main machine can run stably for more than 5-10 years. The key is to regularly replace the roller surface, check the bearings, and clean and lubricate them in time to ensure long-term and reliable operation.