A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the VSI Sand Maker

As the core equipment of modern machine-made sand production, the vertical shaft impact sand making machine plays a key role in the fields of construction, mining, transportation, etc. with its efficient and high-quality sand making capabilities.

From the perspective of structural design, the vertical shaft impact sand making machine adopts a vertical layout, mainly composed of a feed hopper, a distributor, an impeller, a crushing chamber, a base and a transmission device. The impeller is its core component, which generates strong kinetic energy by high-speed rotation; the distributor can accurately control the flow direction of the material to ensure that the material enters the crushing chamber evenly, thereby improving the efficiency and stability of sand making.

Its working principle is based on the two modes of "stone hitting stone" and "stone hitting iron". The material enters the distributor through the feed hopper and is divided into a central material flow and a peripheral material flow. The central material flow directly enters the high-speed rotating impeller, and is ejected from the impeller flow channel at ultra-high speed under the action of centrifugal force; the peripheral material flow forms an annular material layer in the crushing chamber, which impacts and collides with the material thrown out by the impeller, or violently collides with the inner wall of the crushing chamber and the impact plate to achieve crushing and shaping. By adjusting the proportion of the two modes, the particle size and shape of the finished sand can be flexibly controlled.

In terms of performance advantages, the vertical shaft impact sand making machine performs excellently. The sand making efficiency is extremely high, the processing volume per unit time is large, and it can meet the needs of large-scale production; the machine-made sand produced has excellent particle shape, mostly cubic, low needle-like content, and reasonable grading, which can completely replace natural sand for the production of high-quality concrete, asphalt mixture, etc. In addition, the equipment uses wear-resistant materials to manufacture key components, such as impellers, dividing cones, etc., combined with optimized crushing structures, which greatly reduces wear, extends service life, and reduces maintenance costs. At the same time, the equipment is also equipped with an efficient dust removal device to effectively suppress dust flying, meeting environmental protection production requirements.

With the increasing demand for high-quality sand and gravel in the construction industry, the vertical shaft impact sand making machine is becoming the preferred equipment for machine-made sand production with its advanced technology and reliable performance, driving the industry to develop in a green and efficient direction.

Operating principle of VSI Sand Maker

As a key equipment for sand and gravel production, the vertical shaft impact sand making machine has a working principle centered around the high-speed movement and collision of materials, and achieves efficient crushing and sand making through a unique structural design.

The core structure of the equipment is a vertical layout, consisting of a feeding system, an impeller, a crushing chamber, a transmission device, and other parts. Among them, the impeller is the power hub of the entire equipment, driven by a motor through a belt or a coupling, and can reach an extremely high speed; the crushing chamber is the place where the material collides and crushes, and its inner wall is usually installed with a wear-resistant lining to withstand the impact of the material.

When the material enters the equipment from the feed hopper, it will first pass through the distributor. The distributor divides the material into two parts, one part of the material directly enters the high-speed rotating impeller, which is called the central material flow; the other part of the material is evenly dispersed along the periphery of the distributor to form an annular material curtain, that is, the peripheral material flow.

The central material flow entering the impeller rotates at high speed with the impeller under the drive of the blades inside the impeller. Under the action of strong centrifugal force, the material is ejected from the flow channel outlet of the impeller at a linear speed of up to 60-75m/s, forming a high-speed material flow. This high-speed material flow collides with the annular material curtain formed around the distributor, producing a "stone hitting stone" effect, and the materials impact and rub against each other, and are initially crushed. At the same time, some materials will also hit the wear-resistant lining on the inner wall of the crushing chamber, and after rebounding, they will collide with the subsequent thrown materials again. After multiple collisions and crushing, the particle size of the material continues to decrease.

The vertical shaft impact sand making machine also has a "stone hitting iron" mode. By adjusting the structural layout of the impeller and the crushing chamber, the high-speed thrown materials can be directly hit on the impact plate or anvil inside the crushing chamber, and the material can be crushed by the violent collision between the material and the metal parts. The "stone hitting iron" mode has a stronger crushing force, is suitable for crushing materials with higher hardness, and can further improve the particle shape of the machine-made sand.

In the whole sand making process, by adjusting the parameters such as the impeller speed, feed amount and material distribution ratio, the particle size and shape of the finished sand can be flexibly controlled to meet the diverse needs of different projects for sand and gravel aggregates. The crushed materials are discharged through the discharge port at the bottom of the equipment to complete the sand making operation.

Advantages and features of VSI Sand Maker

As a key equipment in the sand making industry, the vertical shaft impact sand making machine plays an important role in the production of machine-made sand. Its characteristics and advantages are significant. The following is a detailed description for you.

1. Various crushing methods: The vertical shaft impact sand making machine has two crushing principles: "stone hitting stone" and "stone hitting iron". In the "stone hitting stone" mode, the materials collide and rub against each other at high speed in the crushing chamber to achieve crushing. It is suitable for materials with high requirements for particle shape and low abrasiveness, and can produce sand with rounded particles and good grading. In the "stone hitting iron" mode, the material directly impacts the high-speed rotating rotor parts, with strong crushing force, which is suitable for processing 2. Materials with high hardness and high abrasiveness have higher sand making efficiency.

3. Compact and reasonable structure: The overall design of the equipment is compact, with a small footprint, which is easy to install and use in a limited space. Its internal structure layout is scientific, and the components are closely matched, which not only reduces the volume and weight of the equipment, but also improves the stability and reliability of the equipment.

4. High degree of automation: Equipped with an advanced automatic control system, it can realize real-time monitoring and control of the equipment's operating status. Operators can easily adjust the operating parameters of the equipment, such as speed, feed rate, etc., through the control panel, and can also promptly detect and handle equipment failures, greatly reducing the difficulty and labor intensity of manual operation.

5. High sand making efficiency: The vertical shaft impact sand making machine adopts a high-speed rotating rotor and a unique crushing chamber design, so that the material can be fully crushed and shaped in the crushing chamber, with large processing capacity and fast sand making speed. Compared with traditional sand making equipment, its production efficiency can be increased several times, which can meet the needs of large-scale sand production.

6. Good product particle shape: After the crushing process of "stone hitting stone" or "stone hitting iron", the output sand particle shape is cubic, with low needle-like content and reasonable gradation, which meets the national construction sand standards. This high-quality sand can improve the strength and durability of concrete and is widely used in key projects such as high-rise buildings, bridges, and highways.

7. Low operating cost: The key components of the equipment are made of high-strength and wear-resistant materials, with a long service life, which reduces the frequency and cost of component replacement. At the same time, its low energy consumption can effectively reduce production costs. In addition, the maintenance of the equipment is relatively simple, further reducing operating costs.

Technical Parameter Table of VSI Sand Maker

| Model | Capacity (t/h) | Max Feed Size (mm) | Rotor Speed (r/min) | Motor Power (kW) | Dimensions (mm) | Weight (t) |

|---|---|---|---|---|---|---|

| VSI-7611 | 60–180 | 35 | 1700–1890 | 110×2 | 4100×2250×2300 | 10.3 |

| VSI-8518 | 100–260 | 40 | 1520–1690 | 180×2 | 4140×2280×2425 | 12.1 |

| VSI-9526 | 150–380 | 45 | 1360–1510 | 220×2 | 4560×2447×2778 | 14.5 |

| VSI-1140 | 250–480 | 50 | 1180–1310 | 260×2 | 5100×2700×3300 | 17.8 |

| VSI-1145 | 300–600 | 60 | 1100–1310 | 280×2 | 5100×2790×3320 | 18.6 |

If you have any special requirements, we will customize according to your special needs.

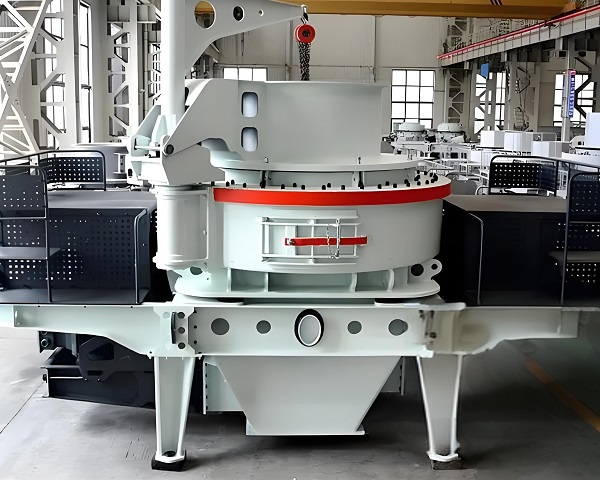

Product Picture Display of VSI Sand Maker

FAQ about VSI Sand Maker

>1. What is the working principle of the vertical shaft impact sand making machine?

The vertical shaft impact sand making machine has two crushing principles: "stone hitting stone" and "stone hitting iron". In "stone hitting stone", the material enters from the feed hopper and is divided into two paths through the distribution plate. One path enters the high-speed rotating impeller, and after being accelerated in the impeller, it is ejected from the three evenly distributed flow channels of the impeller, and the other path collides and rubs against the material that falls freely from the surrounding of the distribution plate at high speed and is crushed. "Stone hitting iron" means that after the material enters the impeller and is accelerated, it directly impacts the counterattack components such as the peripheral guard plate and is crushed. Through these two methods, the material is continuously crushed and shaped, and finally reaches the required particle size and is discharged from the discharge port.

>2. What materials are suitable for vertical shaft impact sand making machine?

This equipment is suitable for sand making of a variety of materials, such as granite, basalt, river pebbles, limestone, quartz stone and other ores with higher hardness can be effectively processed. For example, granite is hard in texture and can be efficiently crushed by the "stone hitting iron" mode of the vertical shaft impact sand making machine; while river pebbles are naturally washed and irregular in shape, and the "stone hitting stone" mode can make their grains more rounded, producing sand that meets the standards for construction sand, which is widely used in various construction projects.

>3. What are the advantages of vertical shaft impact sand making machine compared with other sand making equipment?

Good grain shape. Through the crushing method of "stone hitting stone" or "stone hitting iron", the sand produced is cubic in shape, with low needle-like content and reasonable gradation, which can improve the strength and durability of concrete.

High efficiency. The high-speed rotating rotor and unique crushing chamber design enable the material to be fully crushed and shaped, with large processing capacity and fast sand making speed, which can meet the needs of large-scale production.

Low wear. The key components are made of high-strength and wear-resistant materials, with long service life, reducing the frequency and cost of component replacement.

Strong adaptability. It can handle materials of various hardness and different particle sizes, and can adapt to different production requirements by adjusting the operating parameters.

>4. How to improve the sand making efficiency of the vertical shaft impact sand making machine?

First of all, it is necessary to ensure that the feeding is uniform and stable to avoid material breakage or material accumulation. A feeding device can be installed for control. Secondly, according to the material characteristics and production requirements, reasonably adjust the equipment speed, feed amount and other parameters. For example, when processing materials with higher hardness, appropriately increasing the speed can enhance the crushing force. At the same time, regularly maintain the equipment to ensure the normal operation of each component, such as checking the wear of vulnerable parts such as impellers and peripheral guards, and replacing severely worn parts in time to reduce downtime caused by component failure.

>5. What are the daily maintenance points of the vertical shaft impact sand making machine?

Check the wear of parts. Regularly check the wear degree of vulnerable parts such as impellers, peripheral guards, and impact blocks. If the wear is serious, replace them in time to prevent affecting the crushing effect and equipment safety.

Lubrication and maintenance. Add lubricating oil to each lubrication point of the equipment at the prescribed time interval to ensure the normal operation of the transmission parts and reduce wear.

Clean the equipment. Clean up debris, dust and residual materials inside and outside the equipment in time to prevent blockage and corrosion.

Check the fasteners. Check whether the bolts, nuts and other fasteners in various parts are loose. If they are loose, tighten them in time to avoid excessive vibration of the equipment.

>6. How to adjust the product particle size of the vertical shaft impact sand making machine?

Adjust the size of the discharge port. By changing the opening of the discharge port, the particle size of the finished sand can be controlled. The larger the discharge port, the larger the discharge particle size; the smaller the discharge port, the finer the discharge particle size.

Adjust the impeller speed. Increasing the impeller speed will increase the kinetic energy obtained by the material in the crushing chamber, the crushing will be more complete, and the product particle size may be finer; reducing the speed will be the opposite.

Change the crushing chamber type. Crushing chambers of different shapes and sizes will affect the crushing trajectory and strength of the material, thereby changing the product particle size. Change the appropriate crushing chamber type according to needs.

>7. How to choose the "stone hitting stone" and "stone hitting iron" modes of the vertical shaft impact sand making machine?

"Stone hitting stone" mode. It is suitable for materials with high requirements for particle shape and low abrasiveness, such as limestone. In this mode, materials collide and break each other, the particles are round, the needle-like content is low, and the wear of parts such as the peripheral guard plate is relatively small, and the cost is low.

"Stone-beating-iron" mode. Suitable for processing materials with high hardness and high abrasiveness, such as granite and basalt. The material directly impacts the impact component, the crushing force is strong, and the sand making efficiency is high, but the impact component wears quickly and needs to be replaced regularly.

>8. What are the factors that affect the production capacity of the vertical shaft impact sand making machine?

Material properties. The hardness, humidity, and particle size composition of the material will affect the production capacity. Materials with high hardness are difficult to crush, and the production capacity will be reduced; materials with high humidity are easy to adhere to the equipment, causing blockage and affecting production efficiency; uneven particle size composition will cause unreasonable material distribution in the crushing chamber and reduce production capacity.

Equipment parameters. Improper settings of parameters such as impeller speed and discharge port size will affect the crushing effect and production efficiency.

Feeding conditions. Uneven feeding, excessive or too small feeding amount will cause the equipment to fail to perform at its best and affect production capacity.

>9. What precautions should be taken when installing the vertical shaft impact sand making machine?

Solid foundation. The installation foundation should be flat and solid, able to withstand the weight of the equipment and vibration during operation, and prevent the equipment from tilting or shaking.

Horizontal correction. Use tools such as a level to ensure that the equipment is installed horizontally to avoid unstable equipment operation and increased component wear due to tilting.

Electrical connection. Connect the power supply and control lines correctly according to the electrical drawings to ensure that the electrical system is safe and reliable and well grounded.

Component installation sequence. Strictly follow the requirements of the installation instructions and install each component in sequence to ensure installation accuracy and matching clearance.

>10. What is the future development trend of the vertical shaft impact sand making machine?

Intelligence. Equipped with more advanced sensors and control systems to achieve automatic monitoring, fault diagnosis and remote operation of the equipment, and improve the efficiency and safety of production management.

Large-scale. With the expansion of the scale of mining and construction industries, the processing capacity requirements for sand making equipment are getting higher and higher. Vertical shaft impact sand making machines will develop in the direction of larger specifications and higher processing capacity.

Energy saving and environmental protection. Adopt more efficient crushing technology and energy-saving design to reduce energy consumption; strengthen the control of pollutants such as dust and noise to reduce the impact on the environment.