A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Stone Crusher

As a key equipment in the field of ore and stone processing, stone crusher plays an irreplaceable role in many industries.

There are many types of stone crushers, each with its own advantages. Jaw crusher is the "pioneer" of crushing operations. It crushes stones through the extrusion and bending of the movable jaw and the fixed jaw. It has a large crushing ratio, a simple structure and reliable operation. It can adapt to stones of various hardness. It is often used in the first process of stone crushing to provide raw materials of suitable particle size for subsequent processing. Cone crusher is famous for its efficient crushing and uniform product particle size. It uses the conical surface of the crushing wall and the mortar wall to extrude and grind the stone. It adopts the principle of laminated crushing and has low energy consumption. It is suitable for medium and fine crushing of stones of various hardness. It is widely used in large mines and mineral processing plants.

The impact crusher has the characteristics of large crushing ratio and good product particle size. The high-speed rotating hammer impacts and crushes the stone, making the product particle size uniform and cubic, with low needle-like content. The product particle size can also be controlled by adjusting the gap between the impact plate and the hammer. It performs well in the field of medium-hard and brittle stone crushing and is often used in sand and gravel aggregate production and construction waste treatment. The hammer crusher achieves efficient crushing with its powerful impact force, compact structure, small footprint, and can flexibly adjust the product particle size by replacing the screen plate. It is suitable for the crushing of medium-hard and brittle stones and is widely used in industries such as coal and building materials. The mobile crusher integrates multiple functions in one, integrating the crushing equipment on a movable frame, with strong mobility and adaptability to complex working environments. It has obvious advantages in scenes such as open-pit mining and construction waste treatment that require frequent site transfers.

Different industries have different needs for stone crushers. In the mining industry, a large amount of ores of different hardness need to be processed, which places high demands on the crushing capacity and durability of the equipment; the construction industry pays more attention to the particle size and shape of the product to meet the requirements of building materials such as concrete and mortar; the road construction industry has specific standards for the particle size and grading of stones to ensure the quality and stability of the road. With the continuous advancement of science and technology, stone crushers are developing in the direction of high efficiency, energy saving, intelligence, and large-scale to better meet market demand.

Operating principle of Stone Crusher

Stone crusher is the core equipment for processing stone. Different types of crushers achieve stone crushing based on different working principles. The following is a detailed summary of the working principles of common types.

Extrusion crushing

Representative models: jaw crusher, cone crusher.

Principle: Relying on two hard working surfaces (such as jaw plate and cone surface) to exert huge pressure on the stone, so that stress concentration is generated inside the stone. When the stress exceeds its compressive strength, the stone is crushed.

Specific process:

Jaw crusher: The movable jaw plate periodically approaches and moves away from the fixed jaw plate, and the stone is squeezed, split and bent in the crushing chamber formed by the two jaw plates. Just like squeezing a walnut with both hands, the squeezing force applied by both hands causes the walnut shell to crack. The effect of the jaw plate on the stone is similar. When the movable jaw plate approaches, it squeezes the stone, and the stone is crushed under squeezing and bending.

Cone crusher: The movable cone performs a pendulum motion driven by the eccentric shaft sleeve, forming a crushing chamber with the fixed cone. The stone is squeezed and ground by the moving cone and the fixed cone in the crushing chamber, just like grinding grains with two millstones. The stone is squeezed and ground into smaller particles between the millstones (moving cone and fixed cone).

Applicable scenarios: Suitable for crushing high-hardness stones, such as granite, basalt, etc. It can efficiently handle large stones and is the first choice for mining and coarse crushing operations.

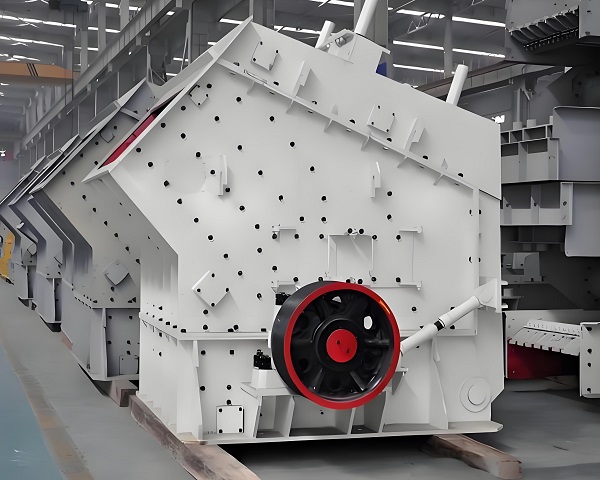

Impact crushing

Representative models: impact crusher, hammer crusher.

Principle: Use high-speed rotating parts (such as plate hammers and hammer heads) to exert huge impact force on the stone, so that the stone obtains high kinetic energy, collides with the impact plate, other stones, or breaks itself.

Specific process:

Impact crusher: The plate hammer rotates at high speed. After the stone enters the crushing chamber, it is impacted by the plate hammer, obtains high speed to hit the impact plate, and then rebounds and collides with other stones. Multiple impacts and collisions break the stone, similar to using a slingshot to shoot a stone and hit the wall and then rebound and collide with other stones. Hammer crusher: The hammer head rotates at high speed to hit the stone. After the stone is crushed, some qualified particles are discharged through the screen plate, and the unqualified ones continue to be impacted and ground by the hammer head, just like hitting the stone with a hammer. The large stone is broken into small particles under the repeated hitting of the hammer.

Applicable scenarios: Commonly used for crushing medium-hard and brittle stones, such as limestone, coal, etc., with a large crushing ratio and uniform product particle size. It is widely used in sand and gravel aggregate production and construction waste treatment industries.

Shearing crushing

Representative model: Roller crusher.

Principle: Use two relatively rotating rollers to apply shear force to the stone, so that the stone is torn and broken under the action of shear force.

Specific process: The stone enters from the top of the two rollers and is squeezed and sheared by the rollers, just like cutting paper with scissors. The paper is cut under the shear force of the scissors blade, and the stone is broken under the shear force of the roller. The product particle size can be controlled by adjusting the gap between the two rollers.

Applicable scenarios: Suitable for crushing brittle and soft stones, such as coal, coke, clay, etc., and is widely used in coal washing, building materials, chemical industry and other industries.

Advantages and features of Stone Crusher

Stone crushers are widely used in many fields such as ore mining, construction, and road construction. Different types of equipment have unique characteristics and significant advantages.

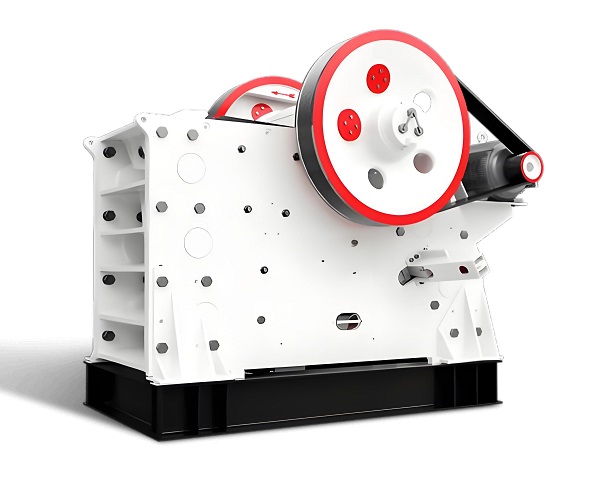

Jaw crusher

1. Simple structure: It is mainly composed of a frame, a movable jaw, a fixed jaw, an eccentric shaft and other components, with few parts and easy to manufacture and install.

2. Large crushing ratio: It can crush large stones into smaller sizes at one time. For example, a stone with a diameter of 1 meter can be crushed into pieces of tens of centimeters.

3. Wide adaptability: It can handle stones of various hardness, whether it is hard granite or relatively soft limestone, it can be effectively crushed.

4. Reliable operation: It can operate stably even in harsh working environments, with low failure rate and relatively low maintenance cost.

5. Low investment cost: The equipment price is relatively affordable, which is a good choice for companies with limited budgets.

6. Wide range of applications: It is often used as the first process equipment for stone crushing and is widely used in mining, building materials and other industries.

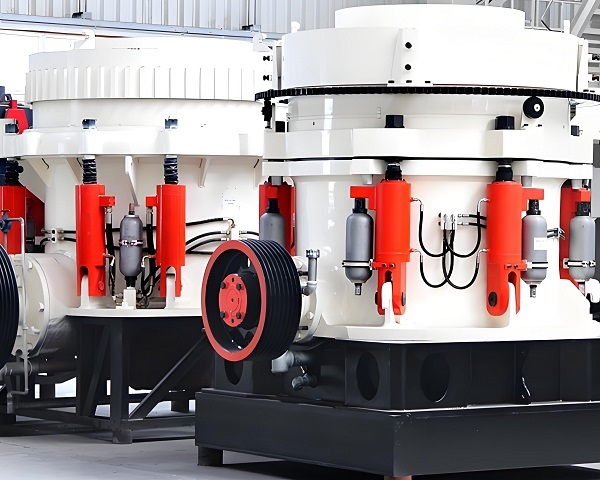

Cone Crusher

1. High crushing efficiency: adopting the lamination crushing principle, the stone is squeezed and ground multiple times in the crushing chamber, and the crushing effect is good.

2. Uniform product particle size: the product particle size can be accurately controlled by adjusting the size of the discharge port, the particle size is uniform, and the grading is reasonable.

3. Low energy consumption: compared with other crushing equipment, when crushing stones of the same hardness, the energy consumption can be reduced by 15% - 30%.

4. Large production capacity: suitable for large-scale production, can meet the needs of large mines and mineral processing plants.

5. Long service life: key components are made of high-strength wear-resistant materials, with a long service life, reducing the cost of equipment replacement.

6. High degree of automation: can be equipped with advanced automation control system to achieve remote monitoring and operation, improve production efficiency and management level.

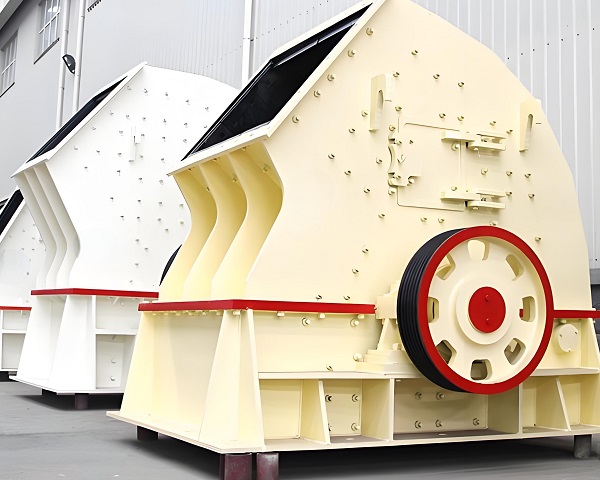

Impact Crusher

1. Large crushing ratio and good product particle size: the stone can be crushed into smaller particles in one crushing, and the product particle size is uniform, cubic, and the needle-like content is low.

2. Strong adjustability: By adjusting the gap between the impact plate and the hammer, the product particle size can be flexibly controlled.

3. Less over-crushing: Due to impact crushing, the material is subjected to less extrusion force during the crushing process, and the over-crushing phenomenon is relatively rare.

Technical Parameter Table of Stone Crusher

| Model | Max Feeding Size (mm) | Discharge Size Range (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) | Feeding Opening Size (mm) |

|---|---|---|---|---|---|---|

| PE250×400 | ≤210 | 20–60 | 5–20 | 15 | 2.8 | 250×400 |

| PE400×600 | ≤340 | 40–100 | 16–64 | 30 | 7 | 400×600 |

| PE500×750 | ≤425 | 50–100 | 40–100 | 55 | 10.1 | 500×750 |

| PE600×900 | ≤500 | 65–160 | 60–130 | 75 | 17 | 600×900 |

| PE750×1060 | ≤630 | 80–180 | 100–200 | 90 | 29 | 750×1060 |

| PE900×1200 | ≤750 | 100–200 | 150–300 | 110 | 50 | 900×1200 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Stone Crusher

FAQ about Stone Crusher

>1. What are the common types of stone crushers?

Common types of stone crushers include jaw crusher, cone crusher, impact crusher, hammer crusher and mobile crusher. Jaw crusher is similar to "two jaws clamping objects", crushing stones by squeezing and crushing the movable jaw and fixed jaw, and is often used for coarse crushing; cone crusher uses the conical surface of the crushing wall and the mortar wall to squeeze and grind, suitable for medium and fine crushing of hard stones; impact crusher is like "slingshot hitting stone", the plate hammer rotates at high speed to impact the stone to break it, and the product particle size is good; hammer crusher is similar to "hammer hitting", the hammer head hits the stone to complete the crushing, and the structure is compact; mobile crusher integrates the crushing equipment on the movable frame, which is flexible and can adapt to different work sites.

>2. What hardness of stone is jaw crusher suitable for crushing?

Jaw crusher is suitable for crushing stones of various hardness, whether it is high-hardness granite, basalt, or relatively soft limestone, shale, etc. can be effectively processed. It is like a "strongman". With its powerful squeezing and bending force, it can crush large stones into smaller sizes at one time. In mining, when facing ores of different hardness, jaw crushers can start the crushing process and provide raw materials of suitable particle size for subsequent processing. Its wide adaptability makes it a common equipment in the field of stone crushing.

>3. How does the cone crusher achieve laminated crushing?

The cone crusher achieves laminated crushing mainly by its unique crushing chamber structure and movement mode. The moving cone is driven by the eccentric shaft sleeve to make a swinging motion and form a crushing chamber with the fixed cone. When the stone enters the crushing chamber, it is squeezed and ground by the moving cone and the fixed cone. At this time, the stone will form a state of multiple layers of materials squeezing each other in the crushing chamber, just like multiple books stacked together and squeezing each other. This laminated state makes the stone squeezed and ground multiple times during the crushing process, resulting in better crushing effect, more uniform product particle size, more reasonable grading, and can effectively improve crushing efficiency and quality.

>4. What is the reason for the good particle size of the impact crusher product?

There are two main reasons for the good particle size of the impact crusher product. On the one hand, it adopts the principle of impact crushing. The high-speed rotation of the plate hammer exerts a huge impact force on the stone, so that the stone obtains high kinetic energy to hit the impact plate and other stones. Multiple impacts and collisions make the stone more fully broken. On the other hand, the product particle size can be accurately controlled by adjusting the gap between the impact plate and the plate hammer, just like adjusting the size of the scissors to control the thickness of the cut paper strips. This flexible adjustment method, coupled with the characteristics of impact crushing, makes the product particle size produced by the impact crusher uniform, cubic, and low in needle-like content.

>5. What are the aspects of the compact structure of the hammer crusher?

The compact structure of the hammer crusher is reflected in many aspects. First, it integrates functions such as crushing and screening into one, reducing the footprint of the equipment. For example, compared with some crushing systems that require additional screening equipment, the hammer crusher itself can complete the process from crushing to preliminary screening. Secondly, its overall layout is compact, the components are closely connected, and there is no excessive redundant space. Furthermore, its transmission components and crushing components are reasonably designed, while ensuring the crushing effect, the equipment volume is relatively small, easy to install and arrange, and is particularly suitable for use in places with limited space.

>6. What are the advantages of mobile crushers in open-pit mining?

Mobile crushers have obvious advantages in open-pit mining. It has strong mobility and can be quickly transferred to different work sites. It does not need to be disassembled and reinstalled like fixed crushing equipment, which saves a lot of time and cost. Open-pit mining sites are usually large and scattered, and mobile crushers can flexibly adapt to this working environment. In addition, it integrates feeding, crushing, screening and other functions, reduces the material transportation links between equipment, and improves production efficiency. At the same time, the integrated design also reduces transportation costs and facilitates equipment management and maintenance.

>7. How to choose a suitable crusher according to the hardness of the stone?

Choose a suitable crusher according to the hardness of the stone. For high-hardness stones such as granite and basalt, cone crushers are preferred. Its laminated crushing principle can efficiently process such stones, and the parts are wear-resistant and have a long service life. For medium-hardness stones such as limestone, jaw crushers can be used as coarse crushing equipment, while impact crushers are suitable for medium and fine crushing, and the product particle size is good. For soft stones such as coal, hammer crusher is a good choice, with compact structure and high production capacity. If the work site needs to be frequently transferred, mobile crusher can adapt to the crushing needs of various hardness stones, with strong flexibility and can improve production efficiency.

>8. What aspects should be paid attention to in the daily maintenance of stone crusher?

There are many aspects to pay attention to in the daily maintenance of stone crusher. Regularly check the fasteners of the equipment, such as bolts and nuts, to ensure that they are firmly connected to prevent equipment failure due to loosening. The lubrication system is very important. Lubricating oil should be added or replaced on time to ensure good lubrication of all moving parts and reduce wear. For wearing parts, such as the jaw plate of the jaw crusher and the liner of the cone crusher, the wear should be checked regularly and replaced in time to avoid affecting the crushing effect and equipment life. In addition, the equipment should be kept clean, and the debris and dust in the crushing chamber should be cleaned in time to prevent blockage and affect heat dissipation.

>9. What factors affect the market price of stone crusher?

The market price of stone crusher is affected by many factors. Equipment type is one of the important factors. Different types of crushers have different structures, functions and working principles, and the price difference is large. For example, mobile crushers are usually more expensive due to their high integration and multiple functions. The scale of production will also affect the price. Large crushers have large production capacity, high manufacturing costs, and relatively expensive prices. Brand and quality are also critical. Well-known brand equipment has guaranteed quality and advanced technology, and the price will also be higher. In addition, fluctuations in raw material prices, market supply and demand, etc. will also have a certain impact on the market price of stone crushers.

>10. What is the development trend of stone crushers in the future?

In the future, stone crushers will develop in the direction of high efficiency, energy saving, intelligence, and large-scale. In terms of high efficiency and energy saving, more advanced crushing technology and energy-saving design will be adopted to reduce energy consumption and improve crushing efficiency. Intelligent development will enable equipment to have functions such as remote monitoring, fault diagnosis and automatic adjustment, and improve the convenience and accuracy of production management. The large-scale trend is to meet the needs of large-scale production and increase the production capacity and processing volume of equipment. At the same time, environmental protection requirements will also prompt crushers to pay more attention to the control of dust, noise and other pollution during the design and manufacturing process to achieve green production.