A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

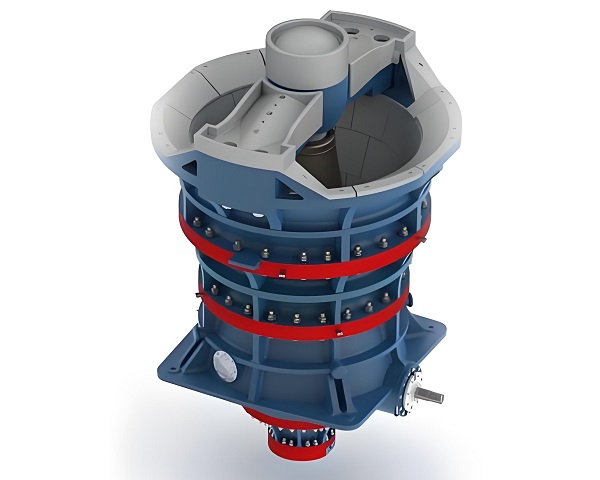

What is the Gyratory Crusher

As an important crushing equipment, the gyratory crusher plays a key role in many industries such as mining and building materials, and is the core force of the coarse crushing link of materials.

Structurally, it is mainly composed of a frame, a moving cone, a fixed cone, a transmission device, an eccentric sleeve and a lubrication system. The frame is supported as a whole and is sturdy and durable; the moving cone performs a gyratory motion driven by the eccentric sleeve, and cooperates with the fixed cone to exert a strong extrusion and bending force on the material to achieve the purpose of crushing; the transmission device transmits power to the eccentric sleeve to drive the moving cone to move; the lubrication system provides good lubrication for each component to ensure the stable operation of the equipment.

In terms of working principle, the material is fed from the upper part of the crusher and enters the crushing chamber composed of the moving cone and the fixed cone. The moving cone swings gyratoryly, the crushing chamber gradually shrinks, and the material is crushed under strong pressure. As the moving cone continues to move, the crushed material is discharged from the bottom to complete the entire crushing process.

The gyratory crusher has many significant advantages. Its crushing ratio is large, and it can crush large pieces of material to a suitable particle size at one time, reducing subsequent crushing processes and improving production efficiency. With high processing capacity, it can meet the needs of large-scale production and performs well in large mines and building materials plants. It has stable operation, solid structure of main components, can withstand large impact and pressure, low failure rate, and ensures the continuity of production. In addition, it can make the particle size of the crushed product uniform and well graded, providing high-quality raw materials for subsequent processing.

In the application field, gyratory crusher is widely used. In the mining industry, it is an indispensable coarse crushing equipment in the mining of metal mines (such as iron ore and copper ore) and non-metallic mines (such as granite and basalt), which can effectively handle hard large pieces of ore. In the field of building materials, it is used for the crushing of raw materials such as limestone and sandstone, providing materials of suitable particle size for cement and concrete production, and promoting the development of the building materials industry. In the ore dressing plant, it serves as a primary crushing equipment, laying the foundation for subsequent ore dressing processes and improving resource utilization efficiency.

Operating principle of Gyratory Crusher

Gyratory crusher is a key equipment for coarse crushing of materials in the fields of mining, building materials, etc. Its working principle is based on the coordinated movement of the moving cone and the fixed cone to achieve material crushing. The following will summarize the overall process, the role of core components, and the details of the crushing process.

Overview of the overall workflow

The workflow of the gyratory crusher starts with material feeding and ends with material discharge. The material enters the crushing chamber from the upper feed port of the crusher. In the crushing space formed by the moving cone and the fixed cone, it is crushed by the strong force generated by the gyratory motion of the moving cone. As the moving cone continues to gyrate, the crushing chamber gradually shrinks, and the material is further squeezed and ground until it reaches the required particle size and is discharged from the lower discharge port to complete the entire crushing process.

Core components and their functions

Moving cone: The moving cone is the main actuator for crushing materials. It is installed on the main shaft and performs gyratory motion driven by the eccentric sleeve. The surface of the moving cone is inlaid with a wear-resistant liner, which is in direct contact with the material and withstands the impact and wear of the material. The gyration of the moving cone causes the material to be continuously squeezed and bent in the crushing chamber, thereby achieving crushing.

Fixed cone: The fixed cone is fixed on the frame and together with the moving cone forms the crushing chamber. The inner wall of the fixed cone is also equipped with a wear-resistant lining, which cooperates with the moving cone to form a gradually shrinking crushing space to squeeze and grind the material.

Eccentric sleeve: The eccentric sleeve is a key component that drives the gyration of the moving cone. It is installed on the main shaft and has a certain eccentricity. When the transmission device drives the eccentric sleeve to rotate, the main shaft and the moving cone will gyrate and swing to provide power for material crushing.

Transmission device: It is usually composed of a motor, a pulley, a V-belt, etc., which is responsible for transmitting the rotation of the motor to the eccentric sleeve, so that the eccentric sleeve can drive the moving cone to gyrate.

Detailed analysis of the crushing process

During the crushing process, after the material enters the crushing chamber, it is first squeezed by the moving cone and the upper lining of the fixed cone. As the moving cone gyrates and swings, the crushing chamber gradually shrinks, and the material is further crushed under strong pressure. At the same time, the materials will squeeze, collide and rub against each other, and these forces will jointly promote the continuous refinement of the materials. When the materials are crushed to a certain particle size, they can be discharged through the discharge port. During the entire crushing process, the particle size of the crushed materials can be controlled by adjusting the size of the discharge port.

The gyratory crusher achieves efficient crushing of large pieces of materials through the coordinated movement of the moving cone and the fixed cone, as well as the close cooperation of various components, providing suitable raw materials for subsequent processing procedures.

Advantages and features of Gyratory Crusher

The gyratory crusher is an efficient coarse crushing equipment. With its unique structural design and excellent performance, it occupies an important position in the mining, metallurgy, building materials and other industries. Its characteristics and advantages are mainly reflected in the following aspects.

In terms of structural design, the gyratory crusher adopts a vertical structure. Compared with traditional crushers, it occupies a smaller area and uses space more efficiently, which is convenient for equipment layout in a limited space. Its crushing chamber is in the shape of an inverted cone. The moving cone swings around the eccentric sleeve, and the crushing space formed by the inner wall of the fixed cone gradually decreases from top to bottom. This design makes the material continuously squeezed, bent and impacted in the crushing chamber. The crushing ratio is large, and large pieces of ore can be crushed to smaller particles at one time, reducing the pressure of subsequent crushing links.

In terms of working performance, the gyratory crusher has a significant advantage of strong processing capacity. Its powerful power system and reasonable structural design enable it to easily cope with ore raw materials with high hardness and large block size. The processing capacity can reach hundreds to thousands of tons per hour, which can meet the large-scale production needs of large mines and stone factories. During the operation of the equipment, the swinging motion of the moving cone is relatively stable with little vibration. The crushing wall and mortar wall made of high-quality wear-resistant materials have relatively uniform wear and long service life, which reduces the maintenance frequency and cost of the equipment. In addition, the crusher also has good environmental performance. Through the sealing design and equipped with dust removal devices, it effectively reduces the dust spillage and reduces the harm to the working environment and the health of operators.

From the perspective of operation and use, the gyratory crusher has a high degree of automation. It is equipped with an advanced control system that can monitor the operating status of the equipment in real time, such as crushing force, speed, temperature and other parameters. Once an abnormal situation occurs, the system can automatically alarm and take corresponding protective measures to ensure the safe operation of the equipment. At the same time, the size of the discharge port of the equipment can be flexibly adjusted according to production needs, so as to control the particle size of the product and meet the diverse requirements of different users for material particle size.

With a series of characteristics and advantages such as compact structure, large crushing ratio, strong processing capacity, stable operation and convenient operation, the gyratory crusher has become an ideal choice for coarse crushing operations in many industries.

Technical Parameter Table of Gyratory Crusher

| Model | Feed Opening Diameter (mm) | Max Feed Size (mm) | Discharge Adjustment Range (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|

| PXZ-0506 | 500 | ≤400 | 50–75 | 150–300 | 90 | 25 |

| PXZ-0710 | 700 | ≤600 | 60–90 | 400–600 | 160 | 58 |

| PXZ-1216 | 1200 | ≤900 | 100–175 | 800–1300 | 315 | 120 |

| PXZ-1417 | 1400 | ≤1100 | 125–200 | 1200–1700 | 400 | 175 |

| PXZ-1600 | 1600 | ≤1300 | 150–230 | 1600–2500 | 560 | 220 |

If you have any special requirements, we will customize according to your special needs.

Product Picture Display of Gyratory Crusher

FAQ about Gyratory Crusher

>1. What is the working principle of a gyratory crusher?

A gyratory crusher uses a moving cone to perform periodic gyratory motion inside a fixed cone to achieve material crushing. The main shaft of the moving cone is suspended on the crossbeam, and the moving cone, driven by the eccentric sleeve, performs a gyratory swing motion around the center line of the crusher. The material is fed from the top and crushed by the squeezing and bending of the moving cone in the crushing chamber composed of the moving cone and the fixed cone. As the moving cone gyrates and swings, the crushing chamber gradually shrinks, and the material is further crushed and discharged from the bottom after reaching the required particle size. It is like two cones that cooperate with each other, one fixed and the other rotating, squeezing and "crushing" the material in the middle.

>2. What materials are suitable for gyratory crushers to crush?

Gyratory crushers are mainly used to crush large, hard ores and rocks, such as iron ore, copper ore, granite, basalt, etc. These materials usually have high hardness and compressive strength. The gyratory crusher can efficiently crush them into a particle size suitable for subsequent processing with its powerful crushing capacity and large crushing ratio. For example, in large-scale metal mining, for huge ore blocks mined from the ore body, the gyratory crusher can be used as a primary crushing equipment to crush them into medium-sized particles, providing suitable raw materials for subsequent mineral processing and other processes.

>3. What are the advantages of gyratory crushers compared with other crushers?

Large crushing ratio. It can crush large pieces of material into smaller particles at one time, reduce the crushing process, and improve production efficiency. For example, crushing ore with a diameter of more than 1 meter into particles of tens of centimeters greatly shortens the crushing process.

High processing capacity. Its unique structure and large crushing chamber design enable more materials to be processed per unit time, which is suitable for large-scale production. In large mines and mineral processing plants, it can meet high production requirements.

Stable operation. The main components such as the moving cone and the fixed cone are sturdy in structure and can withstand large impact and pressure. The failure rate is low during long-term operation, ensuring the continuity of production.

The product particle size is uniform. Through the reasonable crushing chamber design and the motion trajectory of the moving cone, the material is subjected to uniform force during the crushing process, and the particle size distribution of the crushed product is reasonable and the gradation is good.

>4. How to ensure the crushing efficiency of the gyratory crusher?

First of all, ensure that the feeding is uniform to avoid material blockage or insufficient feeding. If the feeding is uneven, it will cause uneven distribution of materials in the crushing chamber, affecting the crushing effect and efficiency. Secondly, it is necessary to regularly check and maintain the various components of the equipment, such as the moving cone, fixed cone, eccentric sleeve, etc., to ensure their good working condition. Severely worn parts should be replaced in time to avoid affecting the crushing performance. In addition, it is also important to reasonably adjust the size of the discharge port. According to the characteristics of the material and production requirements, adjust the discharge port to the appropriate size, which can not only ensure the product particle size, but also improve the crushing efficiency.

>5. What are the main structural components of the gyratory crusher?

Frame. It is the supporting foundation of the entire crusher, bearing various loads during the crushing process. It is usually made of high-strength cast steel or steel plate welding, with good rigidity and stability.

The moving cone is the main component for crushing materials. Its surface is inlaid with wear-resistant lining plates. It realizes gyratory motion through the drive of the eccentric sleeve to squeeze and crush the materials.

The fixed cone is fixed on the frame and together with the moving cone, it forms a crushing chamber. Its inner wall is also equipped with wear-resistant lining plates, which cooperate with the moving cone to complete the crushing operation.

The transmission device includes a motor, a pulley, a V-belt, etc., which provides power for the gyratory motion of the moving cone and transmits the rotational motion of the motor to the eccentric sleeve.

The eccentric sleeve is installed on the main shaft and drives the moving cone to gyratory swing through its eccentric motion. It is a key component for realizing the crushing action.

The lubrication system provides lubrication for each moving part, reduces wear and friction, and ensures the normal operation of the equipment.

>6. How to maintain the gyratory crusher during operation?

In terms of daily maintenance, it is necessary to regularly check whether the fasteners of the equipment are loose, such as bolts and nuts, and tighten them in time to prevent equipment failure due to looseness. Check the oil level and oil quality of the lubrication system to ensure good lubrication. Regularly clean up the debris and dust around the equipment to keep the equipment clean. During regular maintenance, check the linings of the moving cone and the fixed cone, measure their degree of wear, and replace them in time if they are severely worn. Perform a comprehensive inspection of the transmission components, such as whether the belt is loose, whether the gears are worn, etc., and adjust or replace them if necessary. At the same time, check the electrical system of the equipment to ensure the normal operation of the electrical components.

>7. How to adjust the size of the discharge port of the gyratory crusher?

The size of the discharge port of the gyratory crusher is usually achieved by adjusting the position of the bottom of the moving cone. Common adjustment methods include hydraulic adjustment and mechanical adjustment. The hydraulic adjustment method is more convenient and quick. The hydraulic system controls the lifting and lowering of the moving cone to change the size of the discharge port. The operator only needs to set the corresponding parameters on the control panel, and the hydraulic system can automatically complete the adjustment. Mechanical adjustment is to manually operate the adjustment device, such as screws, nuts, etc., to move the moving cone to adjust the discharge port. This method is relatively cumbersome, but the adjustment accuracy is higher. When adjusting the discharge port, it is necessary to gradually adjust it according to the characteristics of the material and production requirements, and observe the crushing effect and product particle size until the optimal state is reached.

>8. What are the factors that affect the production capacity of the gyratory crusher?

Material properties. The hardness, humidity, and particle size composition of the material will affect the production capacity. Materials with higher hardness are more difficult to crush, and the production capacity will be reduced; materials with too high humidity are easy to adhere to the crushing chamber, causing blockage and affecting production efficiency; materials with uneven particle size composition will make the material distribution in the crushing chamber unreasonable and reduce production capacity.

Discharge port size. The smaller the discharge port, the finer the particle size of the crushed product, but the production capacity will be reduced accordingly; conversely, the larger the discharge port, the higher the production capacity, but the product particle size will become coarser.

Feeding amount. Excessive feeding amount will cause material accumulation in the crushing chamber, affecting the crushing effect and production capacity; if the feeding amount is too small, the crushing capacity of the equipment cannot be fully utilized, resulting in waste of resources.

Equipment speed. The speed of the moving cone also affects production capacity. If the speed is too high, the material will stay in the crushing chamber for a short time and may not be fully crushed; if the speed is too low, the production capacity will be reduced.

>9. How to choose the right gyratory crusher model?

First, determine the production scale, that is, the amount of material that needs to be crushed per hour. Choose a model with corresponding processing capacity according to the production scale. Secondly, consider the properties of the material, including hardness, humidity, maximum feed particle size, etc. For materials with high hardness and high humidity, choose a model with strong crushing ability and good wear resistance. In addition, consider the installation conditions on site, such as space size and foundation bearing capacity. If the installation space is limited, choose a compact model; if the foundation bearing capacity is weak, choose a relatively light model. At the same time, refer to the technical parameters and user evaluation of the equipment manufacturer to choose a model with reliable quality and stable performance.

>10. What is the future development trend of gyratory crushers?

Large-scale. With the continuous expansion of mining scale, the processing capacity requirements for crushing equipment are getting higher and higher. Gyratory crushers will develop in the direction of larger specifications and higher processing capacity to meet the needs of large-scale production.

Intelligent. Equipped with advanced sensors and control systems, the equipment can be automatically monitored, fault diagnosed and remotely operated. For example, the operating status of the equipment can be monitored in real time through sensors, and when an abnormality occurs, an alarm can be issued in time and the operating parameters can be automatically adjusted; using the remote control system, the operator can operate and monitor the equipment in the control room to improve the efficiency and safety of production management.

Energy saving and environmental protection. Adopt more efficient crushing technology and energy-saving design to reduce energy consumption. At the same time, strengthen the control of pollutants such as dust and noise to reduce the impact on the environment. For example, optimize the crushing chamber structure, improve crushing efficiency and reduce energy consumption; adopt sealing design and dust removal device to reduce dust leakage.