A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

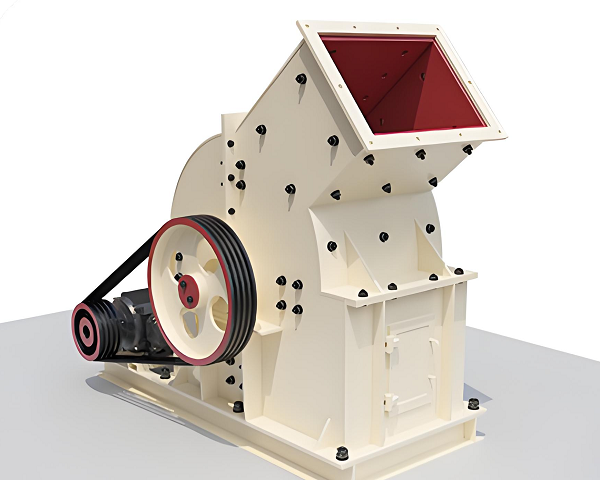

What is the Fine Crusher

Fine crusher is a key equipment in the material crushing process. It is mainly used to further crush the medium-crushed materials into finer particles to meet the fine requirements of different industries for material particle size.

There are various types of fine crushers, and the working principles of different types are different. Taking the common impact fine crusher as an example, it is mainly composed of rotors, impact plates, impact plates and other components. The motor drives the rotor to rotate at high speed. After the material enters from the feed port, it is strongly impacted by the hammer on the rotor and obtains high speed, and then rushes to the impact plate at high speed, collides with the impact plate and breaks. At the same time, the materials will also collide with each other, resulting in multiple crushing, until they reach the required particle size and are discharged from the discharge port. The roller fine crusher squeezes and shears the material through two relatively rotating rollers, and controls the particle size of the product by adjusting the gap between the rollers.

Fine crushers have many advantages: in terms of efficient crushing, they adopt advanced crushing principles and structural design, and can crush materials into fine particles in a short time. For example, the impact fine crusher has a large crushing ratio, and a high fine crushing effect can be obtained in one crushing, which greatly improves production efficiency; in terms of uniform particle size, they can accurately control the particle size of the material after crushing, and the product particle size is uniform and the gradation is reasonable, which is conducive to subsequent processing and use. The roller fine crusher can stably produce materials of a specific particle size by adjusting the gap between the rollers; low energy consumption, the design focuses on energy saving, and adopts an optimized transmission system and crushing chamber structure to reduce energy loss and reduce production costs; stable operation, key components are made of high-strength and wear-resistant materials, with high reliability and stability, which can reduce equipment failure rate and maintenance costs.

Fine crushers are widely used in many industries. In the mining industry, it is used to crush various metal ores and non-metallic ores to provide suitable raw materials for mineral processing; in the building materials industry, it can process limestone, granite, basalt, etc. to produce machine-made sand and stone powder for the production of concrete, cement and other products; in the chemical industry, it can crush chemical raw materials to meet the requirements of chemical reactions on material particle size.

Operating principle of Fine Crusher

Fine crushers play a key role in the field of material processing. The working principles of different types of fine crushers have their own characteristics. The following summarizes the working principles of common fine crushers.

Working principle of impact fine crusher

The impact fine crusher is mainly composed of core components such as rotor, impact plate, and impact plate. When the equipment is started, the motor drives the rotor to rotate at a very high speed, and the material enters the crushing chamber from the feed port. At this time, the material will encounter a strong impact from the high-speed rotating hammer head on the rotor, just like hitting a stone with a hammer, and the material will instantly gain a very high speed. Subsequently, these high-speed moving materials will rush to the impact plate, collide violently with the impact plate and break.

Moreover, the materials do not collide only once in the crushing chamber, they will also collide with each other, forming multiple crushing effects. This continuous impact and collision process allows the material to be continuously refined until it reaches the required particle size and is discharged from the discharge port. The impact fine crusher has a large crushing ratio, which can crush large pieces of material into smaller particles at one time, and has a high production efficiency.

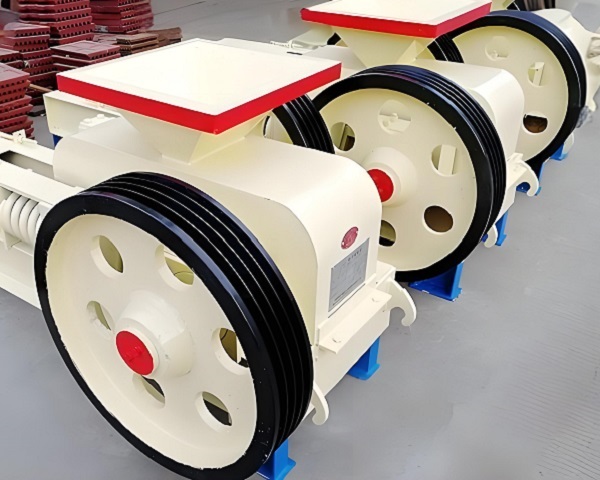

Working Principle of Double Roller Fine Crusher

The double roller fine crusher mainly relies on two rollers rotating relative to each other to complete the crushing work. The material enters from the feed port above the two rollers and is squeezed and sheared by the two rollers. It can be imagined as two huge rollers squeezing the material, and the material is gradually crushed under the strong squeezing and shearing force.

By adjusting the gap between the two rollers, the particle size of the crushed material can be accurately controlled. When finer materials are needed, the gap between the rollers is adjusted to a smaller size; conversely, if larger particle size materials are needed, the gap is appropriately increased. This adjustability enables the double roller fine crusher to stably produce materials of a specific particle size to meet different production needs.

Working Principle of Compound Fine Crusher

The compound fine crusher combines a variety of crushing methods. After the material enters the crushing chamber, it is first impacted by the hammer head and is initially crushed. Then, the material is further refined by the impact of the impact plate and the collision between the materials in the crushing chamber. At the same time, the material will be squeezed and ground, just like being repeatedly ground in a millstone, and finally broken into fine particles. This combination of multiple crushing methods makes the compound fine crusher have the advantages of high crushing efficiency and uniform product particle size.

Advantages and features of Fine Crusher

As an important equipment in the field of material crushing, fine crusher has many significant characteristics and advantages, and plays a key role in many industries.

1. Efficient crushing, improve production efficiency

The fine crusher adopts advanced crushing principle and unique structural design, which can quickly crush materials into fine particles in a short time. Taking the impact fine crusher as an example, its rotor rotates at high speed, and the hammer head produces a strong impact force on the material. The material instantly obtains high kinetic energy, collides with the striking plate and itself, and achieves efficient crushing. Compared with traditional crushing equipment, the fine crusher has a large crushing ratio, and can achieve a high fine crushing effect in one crushing, which greatly shortens the crushing process, significantly improves production efficiency, and meets the needs of large-scale production.

2. Controllable particle size to ensure product quality

The fine crusher can accurately control the particle size of the material after crushing, and the product particle size is uniform and the grading is reasonable. The double-roll fine crusher can stably produce materials of a specific particle size by adjusting the gap between the two rollers. Users can flexibly adjust the roller gap according to actual production needs to obtain fine crushing products that meet the standards. Uniform particle size distribution is conducive to subsequent processing and use. For example, in concrete production, sand and gravel with uniform particle size can improve the strength and stability of concrete and ensure product quality.

3. Energy saving and consumption reduction, reducing production costs

In terms of design, the fine crusher focuses on energy saving and adopts an optimized transmission system and crushing chamber structure. The reasonable transmission system reduces the loss of energy in the transmission process and improves the energy utilization rate; the optimized crushing chamber structure makes the material subject to more effective crushing force during the crushing process, avoiding energy waste. In addition, the efficient crushing capacity of the fine crusher also reduces the equipment operation time, further reduces energy consumption, thereby effectively reducing production costs and improving the economic benefits of the enterprise.

4. Stable and durable, reducing maintenance costs

The key components of the fine crusher are made of high-strength and wear-resistant materials, with high reliability and stability. These wear-resistant materials can withstand the strong impact and wear of the material, extending the service life of the equipment. At the same time, stable operating performance reduces the failure rate of the equipment, reduces maintenance costs and downtime, and ensures the continuity and stability of production.

Technical Parameter Table of Fine Crusher

| Model | Max Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Rotation Speed (r/min) | Weight (t) |

|---|---|---|---|---|---|---|

| PXJ800×400 | ≤120 | ≤5 | 20–40 | 2×22 | 800–1000 | 3.5 |

| PXJ800×600 | ≤150 | ≤5 | 25–50 | 2×30 | 800–1000 | 4.8 |

| PXJ1000×1000 | ≤180 | ≤5 | 50–100 | 2×55 | 800–1000 | 7.5 |

| PXJ1200×1000 | ≤200 | ≤5 | 60–120 | 2×75 | 800–1000 | 9.2 |

| PXJ1400×1200 | ≤220 | ≤5 | 90–160 | 2×90 | 800–1000 | 11.5 |

| PXJ1600×1600 | ≤240 | ≤5 | 120–200 | 2×110 | 800–1000 | 14.6 |

If you have any special requirements, we will customize according to your special needs.

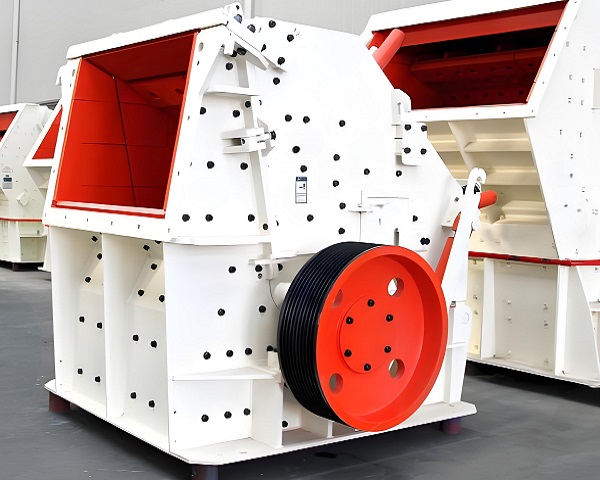

Product Picture Display of Fine Crusher

FAQ about Fine Crusher

>1. What are the common types of fine crushers?

Common types include impact fine crusher, roller fine crusher, compound fine crusher, etc. Impact fine crusher uses high-speed rotating parts to impact materials and crush them, with high efficiency and large crushing ratio; roller fine crusher can accurately control the particle size through two rollers extrusion and shearing crushing; compound fine crusher combines multiple crushing methods, has multiple advantages, and adapts to different crushing needs.

>2. What is the working principle of fine crusher?

Different types have different principles. The impact type is that the rotor rotates at high speed, the hammer impacts the material, and the material collides with the striking plate and itself to crush; the roller type is that two relatively rotating rollers extrude and shear the material, and the particle size is controlled by adjusting the roller gap; the compound type combines impact, counterattack, extrusion and grinding to crush the material.

>3. What materials are suitable for fine crusher?

It is suitable for a wide range of materials, including metal ores such as iron ore and copper ore, non-metallic ores such as limestone and granite, as well as coal, ceramic raw materials, glass raw materials, etc. It can crush the material into fine particles that meet the needs of subsequent processing according to the hardness, humidity and other characteristics of different materials.

>4. What role does the fine crusher play in the mineral processing process?

In the mineral processing process, the fine crusher plays a key role. It further crushes the ore after medium crushing into finer particles, increases the specific surface area of the ore, is conducive to subsequent grinding and sorting operations, improves the mineral processing recovery rate and concentrate grade, reduces the mineral processing cost, and improves the economic benefits of the mineral processing plant.

>5. How to choose a suitable fine crusher?

When choosing, you need to consider the properties of the material, such as hardness, humidity, viscosity, etc. Different types of fine crushers have different adaptability to materials; the production scale determines the equipment model, and large-scale and efficient equipment is selected for large-scale production; you must also pay attention to the investment budget, site conditions, maintenance costs, equipment quality and after-sales service.

>6. What are the maintenance points of the fine crusher?

Maintenance points include regular inspection of wearing parts, such as hammers, rollers, linings, etc., and timely replacement of severely worn parts; keeping the equipment clean to prevent material accumulation from affecting operation; regularly lubricating key parts to reduce wear; regularly checking the tightness of the equipment to ensure stable operation.

>7. What factors affect the production efficiency of the fine crusher?

Affected by material factors, high material hardness and high humidity will increase the difficulty of crushing and reduce efficiency; unreasonable equipment parameters such as speed and crushing chamber structure will affect the crushing effect; improper operator technical level and operation methods, such as uneven feeding and overload operation of equipment, will also lead to a decrease in efficiency.

>8. What is the difference between a fine crusher and a coarse crusher and a medium crusher?

The difference lies in the degree of crushing and the applicable material particle size. The coarse crusher is used for the initial crushing of large pieces of material, and the feed particle size is large; the medium crusher further crushes the coarse crushed material, and the particle size is reduced; the fine crusher crushes the medium crushed material into finer particles to meet the particle size requirements of the final product, and the three complete the material crushing in turn.

>9. What is the development trend of the fine crusher?

It is developing towards high efficiency, energy saving, intelligence and large-scale. In terms of high efficiency and energy saving, new technologies are used to reduce energy consumption; in terms of intelligence, remote monitoring, fault diagnosis and automatic adjustment are realized; large-scale meets the needs of large-scale production and improves production efficiency and competitiveness.

>10. What factors affect the price of fine crusher?

There are large price differences between different types of equipment. For example, the price of impact type and roller type is different due to different structures and performances; the greater the production capacity, the higher the equipment scale and configuration, the higher the price; the material and manufacturing process affect the quality and durability, and high-quality materials and advanced processes increase the price; brand awareness and market supply and demand will also affect the price.