A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Compound Crusher

The compound crusher is a non-screen, adjustable fine crushing equipment that integrates multiple crushing principles and advantages. It is suitable for crushing medium-hard and lower materials and is widely used in mining, metallurgy, building materials, refractory materials, cement, glass, ceramics and other industries. Through its unique structural design, it can efficiently and stably complete the material crushing operation and provide suitable raw material particle size for subsequent production.

Working Principle

The compound crusher mainly uses the mutual impact, extrusion and grinding between materials to achieve crushing. When the material enters the crushing chamber, it is impacted by the high-speed rotating hammer head and gains kinetic energy, and flies to the lining plate on the inner wall of the casing at high speed. The lining plate rebounds the material back to the crushing area and collides with the subsequent materials. At the same time, the material is also squeezed and ground between the hammer head and the lining plate, and between the material and the material in the crushing chamber. The combined effect of multiple crushing methods enables the material to be gradually crushed into the required particle size. This unique crushing method reduces the phenomenon of over-crushing and improves the crushing efficiency and product quality.

Structural composition

Feed hopper: used to guide materials into the crushing chamber. Its shape and size are reasonably designed to ensure that materials enter the equipment evenly and smoothly, reducing the blockage and jamming of materials.

Rotor: one of the core components of the compound crusher, composed of the main shaft, hammer disc, hammer head, etc. The main shaft drives the hammer disc and hammer head to rotate at high speed, generating a strong centrifugal force, so that the hammer head impacts and crushes the materials. The material and shape of the hammer head have an important influence on the crushing effect, and it is usually made of high-strength and wear-resistant materials.

Liner: installed on the inner wall of the crushing chamber, it plays a role in protecting the casing and participating in crushing. The material of the liner is generally made of alloy steel with good wear resistance. Its surface is specially treated to increase the friction with the material and improve the crushing efficiency.

Discharge port: controls the discharge particle size of the material after crushing. By adjusting the size of the discharge port, the requirements of different users for product particle size can be met. There are generally two ways to adjust the discharge port: manual adjustment and hydraulic adjustment.

Frame: supports the weight of the entire equipment to ensure the stability of the equipment during operation. The frame is welded with high-strength steel and has good rigidity and vibration resistance.

Transmission device: It is composed of motor, pulley, V-belt, etc., which provides power for the rotation of the rotor. The motor transmits power to the rotor through the pulley and V-belt, so that the rotor reaches the required speed.

Performance characteristics

Large crushing ratio: It can crush large pieces of materials into smaller particles at one time, reduce the crushing process, and improve production efficiency. For example, for some medium-hardness ores, the compound crusher can crush them from blocks of tens of centimeters to fine powders of several millimeters.

Uniform product particle size: Due to the combination of multiple crushing methods, the material is subjected to uniform force during the crushing process, so that the particle size of the crushed product is uniform and the grading is reasonable, which can meet the requirements of different industries for raw material particle size.

Less over-crushing: Compared with traditional crushing equipment, the compound crusher has less over-crushing of materials during the crushing process, which can effectively reduce energy consumption and production costs, while improving the quality and value of the product.

Simple structure and easy operation: The equipment has a compact structure, few parts, and is relatively convenient for installation, commissioning and maintenance. Operators can start operation after simple training, which reduces the technical requirements for operators.

Stable operation and high reliability: key components are made of high-quality materials and advanced manufacturing processes. After strict quality inspection, they have good wear resistance and impact resistance, can operate stably for a long time in harsh working environments, and reduce equipment failures and downtime.

Wide range of applications: It can crush a variety of materials, such as limestone, coal gangue, shale, slag, slag, etc., and has low requirements for the humidity and viscosity of the materials. Even if the materials contain a certain amount of moisture and soil, they can be crushed normally.

Application areas

Mining industry: In the mining and beneficiation process of metal mines and non-metallic mines, compound crushers can be used to crush ore into suitable particle sizes to provide raw materials for subsequent grinding, sorting and other processes. For example, in the beneficiation plants of iron ore, copper ore, gold ore, etc., compound crushers are one of the important crushing equipment.

Building materials industry: It is an important equipment for the production of building materials such as cement, lime, and gypsum. In cement production, compound crushers can crush raw materials such as limestone and clay into the required particle size, and then batch and calcine. In lime production, it can crush limestone into small pieces for easy calcination and digestion.

Refractory industry: used to crush various refractory raw materials, such as bauxite, magnesia, silica, etc., to provide qualified raw materials for the production of refractory products. The refractory raw materials after crushing have uniform particle size, which can improve the quality and performance of refractory products.

Glass industry: In glass production, raw materials such as quartz sand, feldspar, and soda ash need to be crushed and mixed. Compound crushers can effectively crush these raw materials to ensure that the particle size and quality of the raw materials meet the requirements of glass production.

Ceramic industry: used to crush ceramic raw materials, such as kaolin, porcelain stone, quartz, etc., to provide fine powder raw materials for the production of ceramic products. The fineness of the crushed ceramic raw materials is uniform, which is conducive to improving the firing quality and appearance of ceramic products.

Operating principle of Compound Crusher

The compound crusher integrates multiple crushing methods and can efficiently process medium-hard and lower materials. The following summarizes its working principle from the aspects of crushing process, functions and advantages of each component.

Crushing process

When the material enters the feed port of the compound crusher, it is first strongly impacted by the high-speed rotating hammer. Driven by the motor, the hammer rotates at high speed, generating huge centrifugal force, which makes the material instantly obtain high kinetic energy and fly to the lining of the inner wall of the crushing chamber at high speed. This is like hitting a stone with a hammer, and the stone will be broken due to the huge impact force.

After the material hits the lining, it will rebound back to the crushing area and collide with the subsequent materials. At this time, the materials form a mutual extrusion and grinding effect. Just like in a closed space, many stones collide and squeeze each other, causing friction and wear between each other, further refining the material.

The material is also squeezed and ground between the hammer and the lining in the crushing chamber. During the rotation process, the hammer continuously applies pressure to the material, while the lining plays a supporting and matching role. The material is repeatedly squeezed and ground between the two until the required particle size is reached.

Component Function

Hammer: It is the main crushing component. The impact force generated by its high-speed rotation is the main power source for material crushing. The material and shape of the hammer directly affect the crushing effect and efficiency. It is usually made of high-strength and wear-resistant materials to ensure its service life.

Liner: It is installed on the inner wall of the crushing chamber. It can not only protect the casing from direct impact and wear of the material, but also participate in the crushing process of the material. The surface of the liner has been specially treated to increase the friction with the material, which helps to improve the crushing efficiency.

Rotor: It drives the hammer to rotate at high speed and is the power core of the entire crushing process. The balance and stability of the rotor are crucial to the normal operation of the equipment.

Advantages

This working principle of combining multiple crushing methods makes the compound crusher have the advantages of large crushing ratio, uniform product particle size, and less over-crushing. It can crush the material to a smaller particle size in one crushing process, reduce the subsequent crushing process, improve production efficiency, and at the same time ensure product quality to meet the requirements of different industries for material particle size.

Advantages and features of Compound Crusher

As a high-efficiency crushing equipment, the compound crusher plays an important role in many industries. It has significant characteristics and advantages. The following will summarize it from multiple aspects.

Excellent crushing performance

Large crushing ratio: The compound crusher can crush large pieces of material into smaller particles at one time, reducing the intermediate crushing links. For example, in mining, for the ore with a diameter of tens of centimeters, it can directly crush it into particles of several centimeters or even smaller, which greatly improves production efficiency and reduces production costs.

Uniform product particle size: It adopts a combination of multiple crushing methods, and the material is subjected to uniform force in the crushing chamber, so that the particle size distribution of the crushed product is reasonable and the grading is good. In the production of building aggregates, uniform particle size can ensure the quality and performance of concrete and improve the strength and stability of buildings.

Less over-crushing: Compared with traditional crushing equipment, the compound crusher can better control the crushing force during the crushing process and reduce excessive crushing of materials. This not only reduces energy consumption, but also improves the utilization rate of products and reduces resource waste.

Structural and operational advantages

Simple and compact structure: The overall structural layout of the equipment is reasonable, the number of parts is relatively small, and the footprint is small. This makes it more convenient and quick during installation, commissioning and maintenance, reducing installation costs and maintenance difficulties. For some work sites with limited space, such as small mines or construction sites, compound crushers can adapt well.

Stable and reliable operation: key components are made of high-quality materials and advanced processes, with good wear resistance and impact resistance. During long-term operation, it can maintain stable performance, reduce equipment failures and downtime, and improve production continuity.

Convenient operation and maintenance: operators can get started after simple training, and the human-machine interface design of the equipment is friendly, which is convenient for real-time monitoring and adjustment of operating parameters. At the same time, the maintenance of the equipment is relatively simple. Daily maintenance mainly involves inspection and replacement of wearing parts, which reduces the technical requirements for operators.

Scope of application and environmental protection and energy saving

Wide scope of application: It can crush a variety of materials, including limestone, coal gangue, shale, slag, etc., and has low requirements for the humidity and viscosity of the materials. Whether it is dry material or wet material with a certain amount of moisture, it can be crushed normally and has strong adaptability.

Environmental protection and energy saving: During the crushing process, less dust is generated, and the equipment can be equipped with a dust removal device to further reduce dust pollution. At the same time, its efficient crushing performance reduces energy consumption, which is in line with the current trend of energy conservation and emission reduction.

Technical Parameter Table of Compound Crusher

| Model | Rotor Diameter × Height (mm) | Max Feeding Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) |

|---|---|---|---|---|---|---|

| PFL-800 | Φ800×850 | ≤60 | ≤5 | 10–20 | 30–45 | 3.5 |

| PFL-1000 | Φ1000×1050 | ≤80 | ≤5 | 20–40 | 45–55 | 4.8 |

| PFL-1250 | Φ1250×1250 | ≤100 | ≤5 | 40–70 | 75–90 | 7.1 |

| PFL-1500 | Φ1500×1500 | ≤120 | ≤5 | 60–100 | 90–110 | 11.3 |

| PFL-1750 | Φ1750×1750 | ≤150 | ≤5 | 80–120 | 132–160 | 15.6 |

| PFL-2000 | Φ2000×2000 | ≤180 | ≤5 | 100–160 | 160–200 | 19.8 |

If you have any special requirements, we will customize according to your special needs.

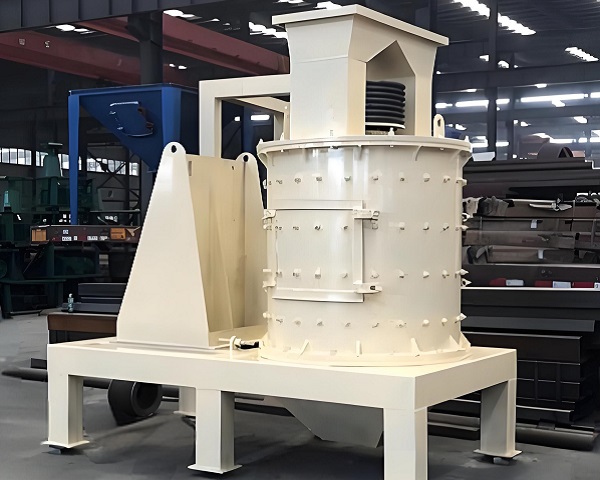

Product Picture Display of Compound Crusher

FAQ about Compound Crusher

>1. What materials are suitable for compound crusher?

Compound crusher is suitable for a wide range of materials, covering medium hardness and below. Common materials such as limestone and coal gangue have moderate hardness, and compound crusher can easily handle them and crush them into the required particle size. Shale is relatively soft in texture and can also be efficiently crushed in compound crusher. In addition, industrial waste such as slag and slag is also applicable. It can crush these wastes into fine pieces to achieve resource recycling. For some wet materials containing a certain amount of moisture, as long as the humidity is within a reasonable range, the compound crusher can also work normally, reflecting its good adaptability.

>2. Why is the crushing ratio of compound crusher large?

The large crushing ratio of compound crusher comes from its unique crushing method. It combines multiple crushing principles such as impact, extrusion and grinding. After the material enters the crushing chamber, it is first impacted by the high-speed rotating hammer to obtain high kinetic energy, and then collides, squeezes and grinds with the liner and other materials. The comprehensive application of multiple forces enables the material to be fully crushed in a short time. For example, after a large piece of ore enters, it can be quickly broken into multiple small particles under the action of multiple forces, which greatly reduces the crushing process and improves production efficiency.

>3. How to ensure the uniform particle size of the compound crusher product?

This is due to its structural design and working principle. The compound crusher adopts a special crushing chamber structure and a reasonable rotor speed to make the material subject to uniform force in the crushing chamber. The layout and movement trajectory of the hammer head and liner can ensure that the material can be effectively crushed in all directions. At the same time, the materials constantly collide and rub against each other during the crushing process, further ensuring the uniformity of the particle size. Just like in a regular space, the material is uniformly "polished", and the final particles are similar in size and reasonable in gradation.

>4. What is the reason for the less over-crushing phenomenon of the compound crusher?

The less over-crushing phenomenon of the compound crusher is mainly due to its precise crushing control. It can accurately control the crushing force by reasonably designing the gap between the hammer head and the liner and adjusting the rotor speed. The impact and extrusion force of the material in the crushing chamber is just right, and the material will not be over-crushed. For example, during the crushing process, the equipment can automatically adjust the crushing parameters according to the characteristics of the material and the required particle size, avoiding excessive "squeezing" of the material, thereby reducing the phenomenon of over-crushing and improving the utilization rate of the product.

>5. What are the aspects of the simple and compact structure of the compound crusher?

From the overall layout, the components of the compound crusher are closely connected, and there is no extra redundant space. Its main components such as the feed port, crushing chamber, and discharge port are reasonably distributed, making the equipment occupy a small area. In terms of parts, the number is relatively small. For example, the transmission system has a simple structure and no complex gear transmission mechanism. Moreover, its key components such as hammers and liners are reasonably designed and easy to install and disassemble. This is like a well-designed box with various components compactly combined, which not only saves space, but also facilitates the installation, transportation and maintenance of the equipment.

>6. What are the key factors for the stable and reliable operation of the compound crusher?

The key lies in its high-quality component materials and advanced manufacturing technology. Key components such as rotors, hammers, liners, etc. are made of high-strength and wear-resistant materials, which can withstand the strong impact and wear of materials. During the manufacturing process, the quality is strictly controlled to ensure the processing accuracy and assembly quality of each component. At the same time, the equipment is also equipped with a complete lubrication system and cooling system, which can effectively reduce the wear and temperature of the components, ensure the stable performance of the equipment during long-term operation, and reduce the probability of failure.

>7. Where is the convenient operation and maintenance of the compound crusher reflected?

In terms of operation, its control system is humanized, the operation interface is simple and easy to understand, and the operator can get started after simple training. The equipment is equipped with intuitive indicator lights and display screens, which can display the operating status and parameters of the equipment in real time, making it convenient for operators to monitor and adjust. In terms of maintenance, daily maintenance mainly involves the inspection and replacement of wearing parts such as hammer heads and linings. These parts are easy to replace and do not require complex tools and a lot of time. Moreover, the structure of the equipment is easy to repair, and maintenance personnel can quickly reach the parts that need to be repaired, reducing maintenance costs and downtime.

>8. What are the advantages of the compound crusher in terms of environmental protection?

In terms of dust control, the compound crusher adopts a sealed design to reduce the leakage of dust during material crushing. At the same time, it can be equipped with an efficient dust removal device to collect and treat the generated dust, effectively reducing dust pollution. In terms of noise, the equipment reduces the noise during operation by optimizing the structural design and adopting shock-absorbing measures. For example, sound insulation materials are set around the crushing chamber to reduce the spread of noise. In addition, its efficient crushing performance reduces energy consumption, reduces the environmental impact caused by energy consumption, and meets environmental protection requirements.

>9. How to choose a suitable compound crusher model according to production needs?

First, it is necessary to clarify the production scale, that is, the amount of material that needs to be crushed per hour. If the production scale is large, it is necessary to choose a model with strong processing capacity. Secondly, the properties of the material, including hardness, humidity, particle size, etc., should be considered. For materials with higher hardness, models with good wear resistance and strong crushing force should be selected; for materials with higher humidity, models with better anti-blocking performance should be selected. In addition, the requirements for the discharge particle size should also be considered. Different models of compound crushers have different discharge particle size ranges, and they should be selected according to actual needs.

>10. What is the future development trend of compound crushers?

In the future, compound crushers will develop in the direction of intelligence, large-scale, energy-saving and environmental protection. In terms of intelligence, the equipment will be equipped with advanced sensors and control systems to realize functions such as remote monitoring, fault diagnosis and automatic adjustment, and improve the efficiency and accuracy of production management. Large-scale is to meet the needs of large-scale production and improve the production capacity and processing volume of equipment. Energy saving and environmental protection is to follow the development trend of the times, adopt more efficient crushing technology and energy-saving design, reduce energy consumption and dust and noise pollution, and achieve green production.