A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Coarse Crusher

As a key equipment for material crushing and processing, the coarse crusher plays an irreplaceable role in many industrial fields. The following is an introduction from the aspects of definition, working principle, type, application field, performance characteristics and development trend.

Coarse crusher is mainly used for preliminary crushing of large pieces of materials, breaking large-sized materials into smaller particles, creating conditions for subsequent medium and fine crushing processes. Its working principle is based on extrusion, impact or shearing forces. Taking the jaw coarse crusher as an example, the movable jaw plate periodically approaches and moves away from the fixed jaw plate, forming an extrusion and bending effect on the material, thereby achieving crushing; the hammer coarse crusher uses a high-speed rotating hammer to impact and crush the material.

Common types of coarse crushers include jaw coarse crusher, gyratory coarse crusher, hammer coarse crusher, etc. The jaw coarse crusher has a simple structure, reliable operation, and convenient maintenance. It is suitable for crushing materials of various hardness; the gyratory coarse crusher has a large crushing ratio and high production capacity, and is often used in large mining enterprises; the hammer coarse crusher has high crushing efficiency and uniform product particle size, but has certain requirements for the humidity and viscosity of the material.

In the mining industry, coarse crushers are used to preliminarily process the mined ores, such as iron ore, copper ore, gold ore, etc., to provide raw materials of suitable particle size for subsequent mineral processing. In the field of building materials, limestone, granite and other stones are processed to meet the production needs of cement, concrete and other materials. In the coal industry, raw coal is coarsely crushed to facilitate washing, transportation and combustion. In addition, it also has important applications in chemical, metallurgical and other industries.

Coarse crushers have the characteristics of large crushing ratio, high production capacity and stable operation. Its powerful crushing capacity can quickly process large pieces of materials and improve production efficiency. At the same time, the equipment structure is reasonably designed, and the key components are made of wear-resistant materials, which prolongs the service life of the equipment and reduces maintenance costs.

With the continuous advancement of science and technology, coarse crushers are developing in the direction of large-scale, intelligent, energy-saving and environmental protection. Large-scale equipment can meet the needs of large-scale production; intelligent technology can realize remote monitoring and fault diagnosis of equipment, improve operating efficiency and safety; energy-saving and environmental protection design meets the requirements of sustainable development and reduces energy consumption and environmental pollution.

Operating principle of Coarse Crusher

As a key equipment in the material crushing process, the working principle of the coarse crusher varies according to different types, but the core is to use a specific force to crush large pieces of material into smaller particles. The following is a summary of the working principles of common coarse crusher types.

Jaw coarse crusher

The jaw coarse crusher is mainly composed of movable jaw, fixed jaw, frame, eccentric shaft and other components. Its working process is similar to that of an animal chewing food. The movable jaw is driven by the eccentric shaft and swings periodically around the suspension shaft. When the movable jaw approaches the fixed jaw, the space between the two jaw plates gradually shrinks, and the material is crushed by the combined action of squeezing, splitting and bending; when the movable jaw is away from the fixed jaw, the crushed material is discharged from the discharge port under the action of gravity. For example, when crushing large stones, the stones enter between the two jaw plates and are gradually crushed into small pieces as the movable jaw moves.

Gyratory coarse crusher

The gyratory coarse crusher is mainly composed of a frame, a movable cone, a fixed cone, a transmission device and other parts. The moving cone performs a swinging motion in the frame, and its axis intersects with the axis of the fixed cone at a certain angle. After the material enters the crushing chamber from the feed port, it is squeezed and bent by the moving cone and the fixed cone. During the rotation of the moving cone, the distance between its surface and the surface of the fixed cone changes continuously, and the material is squeezed and crushed in the shrinking space. The crushed material is discharged from the lower discharge port. This working method is similar to placing the material between two conical surfaces that are constantly approaching for extrusion and crushing.

Hammer coarse crusher

The hammer coarse crusher mainly relies on the high-speed rotating hammer to impact and crush the material. After the material enters the crushing chamber, it is impacted by the high-speed rotating hammer and is hit against the crushing plate. At the same time, the materials also collide with each other, resulting in multiple crushing. After multiple impacts and collisions, the material is crushed into a particle size that meets the requirements and discharged from the screen plate hole. It is like using a hammer to continuously hit a large stone to break it into small pieces.

Different types of coarse crushers achieve effective crushing of bulk materials through their unique working principles, providing suitable material particle size for subsequent processing steps.

Advantages and features of Coarse Crusher

The coarse crusher is a key equipment in the material crushing process. It has many significant features and advantages, and provides strong support for the efficient industrial production.

1. Strong crushing capacity

The coarse crusher is designed for processing large pieces of materials and has strong crushing force. Taking the jaw coarse crusher as an example, the strong extrusion effect formed by the movable jaw and the fixed jaw can easily crush large pieces of materials such as ores and rocks with high hardness. The maximum feed particle size can reach several meters, which meets the demand for preliminary crushing of raw materials in large-scale production.

2. Simple and reliable structure

Most coarse crushers have relatively simple structures and fewer parts. For example, the hammer coarse crusher is mainly composed of a casing, a rotor, a hammer head and other parts. This simple structure not only reduces the manufacturing cost of the equipment, but also reduces the probability of failure, improves the reliability and stability of the equipment, and facilitates daily maintenance and repair.

3. Wide range of applicable materials

It can handle a variety of materials with different properties and hardness. Whether it is metal ore (such as iron ore, copper ore), non-metallic ore (such as limestone, gypsum), or coal, construction waste, etc., the coarse crusher can be adjusted according to the characteristics of the material to achieve effective crushing and show good versatility.

4. Improve production efficiency

The coarse crusher can quickly crush large pieces of material into smaller particles, provide raw materials of suitable particle size for subsequent medium and fine crushing processes, reduce the residence time of materials in the crushing process, and thus improve the production efficiency of the entire production line. For example, in large-scale mining, efficient coarse crushing operations can enable subsequent mineral processing and other processes to be carried out continuously and stably.

5. Reduce production costs

Its powerful crushing capacity reduces the crushing process and reduces energy consumption. At the same time, due to its simple structure and convenient maintenance, it reduces the maintenance cost and downtime of the equipment, further reducing the production cost. Moreover, the particle size of the material after coarse crushing is uniform, which reduces the phenomenon of over-crushing and improves the utilization rate of the material.

6. Convenient operation and maintenance

The operation of the coarse crusher is relatively simple, and the operator can get started after a short training. In terms of maintenance, due to the clear structure and easy replacement of parts, maintenance personnel can quickly locate and solve faults, shorten maintenance time and ensure production continuity.

Technical Parameter Table of Coarse Crusher

| Model | Max Feeding Size (mm) | Discharge Size Range (mm) | Capacity (t/h) | Motor Power (kW) | Weight (t) | Feeding Opening Size (mm) |

|---|---|---|---|---|---|---|

| PE250×400 | ≤210 | 20–60 | 5–20 | 15 | 2.8 | 250×400 |

| PE400×600 | ≤340 | 40–100 | 16–64 | 30 | 7 | 400×600 |

| PE500×750 | ≤425 | 50–100 | 40–100 | 55 | 10.1 | 500×750 |

| PE600×900 | ≤500 | 65–160 | 60–130 | 75 | 17 | 600×900 |

| PE750×1060 | ≤630 | 80–180 | 100–200 | 90 | 29 | 750×1060 |

| PE900×1200 | ≤750 | 100–200 | 150–300 | 110 | 50 | 900×1200 |

If you have any special requirements, we will customize according to your special needs.

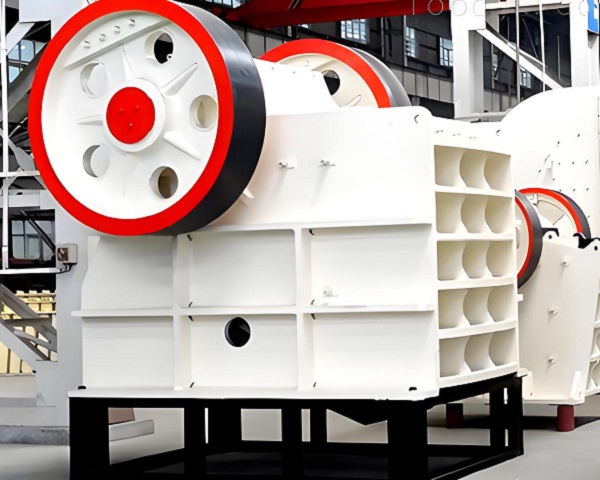

Product Picture Display of Coarse Crusher

FAQ about Coarse Crusher

>1. What are the main types of coarse crushers?

Common types of coarse crushers include jaw coarse crushers, gyratory coarse crushers, hammer coarse crushers, etc. Jaw coarse crushers are similar to animal chewing, and the movable jaw swings to crush materials. It has a simple and reliable structure and is widely used; the gyratory coarse crusher squeezes materials between the conical surfaces through the swinging motion of the movable cone. It has a large crushing ratio and high production capacity, and is often used in large mines; the hammer coarse crusher uses a high-speed rotating hammer to impact the material, with high crushing efficiency and uniform product particle size, but it has requirements for material humidity and viscosity.

>2. What is the working principle of the coarse crusher?

Different types of coarse crushers have different working principles. In the jaw coarse crusher, the movable jaw swings under the drive of the eccentric shaft, and squeezes, splits and bends the material when it is close to the fixed jaw, and the material is discharged when it is far away; the movable cone of the gyratory coarse crusher swings in the frame, and the distance from the fixed cone changes to squeeze and crush the material; the hammer coarse crusher is a high-speed rotating hammer that impacts the material, and the material collides with the crushing plate and itself and is crushed.

>3. What materials are suitable for the coarse crusher?

The coarse crusher is suitable for a wide range of materials, including metal ores such as iron ore, copper ore, gold ore, etc., non-metallic ores such as limestone, granite, gypsum, etc., as well as coal, construction waste, etc. It can be adjusted according to the characteristics of the material, and materials of different hardness and properties can be crushed into suitable particle sizes to meet the needs of subsequent processing.

>4. What role does the coarse crusher play in mining?

In mining, the coarse crusher plays a significant role. The mined ore is large in size and cannot be directly used for subsequent mineral processing. The coarse crusher can crush large pieces of ore into smaller particles, provide raw materials of suitable particle size for mineral processing, improve mineral processing efficiency and quality, and reduce transportation costs, making ore transportation more convenient. It is a key equipment in the mining process.

>5. How to choose a suitable coarse crusher?

Many factors need to be considered when choosing a suitable coarse crusher. First, clarify the properties of the material to be processed, such as hardness, humidity, viscosity, etc. Different types of coarse crushers have different adaptability to materials; then look at the production scale. Large mines need gyratory coarse crushers with high production capacity, and small enterprises may be more suitable for jaw coarse crushers; investment budget, site conditions and subsequent maintenance costs should also be considered.

>6. What are the maintenance points of the coarse crusher?

The maintenance points of the coarse crusher include regular inspection of the wear of each component, such as the jaw plate of the jaw coarse crusher, the hammer head of the hammer coarse crusher, etc., and timely replacement of serious wear; keeping the equipment clean to prevent material accumulation from affecting the operation of the equipment; regularly checking the lubrication system to ensure good lubrication and reduce component wear; and debugging and calibrating the equipment in accordance with regulations to ensure the normal operation of the equipment.

>7. What factors affect the production efficiency of the coarse crusher?

The production efficiency of the coarse crusher is affected by many factors. In terms of material properties, materials with high hardness and high humidity are difficult to crush, which will reduce efficiency; equipment parameters such as feed port size, crushing chamber shape, rotor speed, etc., unreasonable parameters will affect the crushing effect and efficiency; the operator's technical level and operation method are also critical, and unreasonable operation may lead to equipment failure or inefficiency.

>8. What is the difference between a coarse crusher, a medium crusher, and a fine crusher?

The main difference between a coarse crusher, a medium crusher, and a fine crusher lies in the degree of crushing and the applicable material particle size. The coarse crusher is used for preliminary crushing, breaking large pieces of material into larger particles, and the feed particle size is large; the medium crusher further crushes the coarsely crushed material, and the particle size is further reduced; the fine crusher crushes the medium-crushed material into smaller particles to meet the final product particle size requirements, and the three together complete the material crushing process.

>9. What is the development trend of the coarse crusher?

The coarse crusher is developing towards large-scale, intelligent, energy-saving and environmentally friendly directions. Large-scale equipment can meet the needs of large-scale production and improve production efficiency; intelligent technology can realize remote monitoring, fault diagnosis and automatic adjustment, and improve the safety and stability of equipment operation; energy-saving and environmentally friendly design adopts new materials and processes to reduce energy consumption and environmental pollution, and meet the requirements of sustainable development.

>10. What factors affect the price of coarse crusher?

The price of coarse crusher is affected by many factors. Different types of equipment have different prices. The gyratory coarse crusher has a complex structure and high technical content, and its price is usually higher than that of the jaw coarse crusher; the greater the production capacity, the higher the equipment scale and configuration, and the higher the price; the material and manufacturing process affect the quality and durability of the equipment, and high-quality materials and advanced processes will increase the price; the brand and market supply and demand relationship will also have a certain impact on the price.