A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Mobile Crusher Machine

Mobile Crusher Machine is an intelligent mobile device that integrates crushing, screening and conveying functions, providing efficient and flexible material handling solutions for modern engineering construction.

The equipment consists of multiple core systems. The frame chassis is a mobile carrier, which is divided into two types: tire type and crawler type. The former is suitable for fast transfer on flat roads, while the latter can move freely on complex terrains such as mountains and swamps. The crushing system is the core component. According to the characteristics of the material, jaw crusher (suitable for coarse crushing), cone crusher (medium and fine crushing), impact crusher (shaping crushing) can be selected to achieve targeted processing of materials of different hardness such as ore, concrete, stone, etc. The screening system uses a vibrating screen to grade the crushed materials to form finished products of different specifications.

Compared with traditional fixed crushing equipment, Mobile Crusher Machine has significant advantages. It does not require infrastructure installation and can be operated when it arrives on site, greatly shortening the project preparation cycle; the equipment can monitor the operating parameters in real time through the PLC intelligent control system, automatically adjust the crushing force and feeding speed, and ensure production stability. At the same time, the application of fully enclosed crushing chamber and dust removal and noise reduction device effectively reduces dust and noise pollution and meets environmental protection requirements. In addition, the equipment also supports the crushing of construction waste into recycled aggregates to achieve resource recycling, with both economic benefits and environmental value.

At present, Mobile Crusher Machine has been widely used in mining, road construction, urban demolition and reconstruction and other fields. In mining, it can operate directly in the mining area to reduce material transportation costs; in urban construction, it can quickly handle construction waste generated by demolition, reduce the pressure of garbage removal, and provide strong support for the green and intelligent development of the engineering construction industry.

Operating principle of Mobile Crusher Machine

Mobile Crusher Machine uses multiple systems to work together to crush various materials into finished aggregates that meet the needs. Its working process is closely linked, showing a high degree of automation and precision.

Material processing starts with the feeding system. Vibrating feeders or belt feeders serve as "entrances" to stably feed materials such as ore, construction waste, and stone into the crushing system through uniform vibration or uniform speed conveying. This uniform and quantitative feeding method can not only prevent the crusher from being blocked due to excessive feeding, but also ensure the stable operation of the equipment, laying the foundation for subsequent processes.

The crushing system is the core link of the Mobile Crusher Machine. Depending on the hardness of the material and the particle size requirements of the finished product, the equipment can be equipped with different types of crushers. For materials with high hardness such as granite and iron ore, jaw crushers are often used for coarse crushing. Through the periodic reciprocating motion of the movable jaw plate, the materials are squeezed, split and bent; in the medium and fine crushing stage, cone crushers may be used to further reduce the particle size of the materials by using the lamination crushing principle between the movable cone and the fixed cone; and for brittle materials such as limestone that need to be shaped, the impact crusher throws the materials to the impact plate through the high-speed rotating rotor, and achieves crushing and shaping through multiple impacts.

The crushed materials enter the screening system. The vibrating screen generates high-frequency vibrations with the eccentric block driven by the motor, causing the materials to jump on the screen surface, and the materials are separated into different particle size grades according to the size of the screen mesh. Finished products that meet the specifications are transported to the material pile by the belt conveyor, and unqualified materials are sent back to the crusher for secondary crushing through the return belt conveyor, forming a "crushing-screening-re-crushing" cycle until all materials reach the target particle size.

During the entire working process, the intelligent control system monitors the operating status of the equipment in real time. Once overload, abnormal vibration, etc. occur, the system will automatically adjust the feeding speed or issue an alarm. In addition, the conveying system is like the "blood vessels" of the equipment. The belt conveyor that runs through the entire process closely connects all links to ensure smooth material transportation and efficient production.

Advantages and features of Mobile Crusher Machine

As a new generation of material handling equipment, Mobile Crusher Machine has demonstrated incomparable characteristics and advantages in engineering construction, resource mining and other fields with a series of innovative designs and technological breakthroughs.

Its core highlight is its highly flexible mobility. The equipment adopts a tire or crawler chassis design, which can quickly respond to different construction needs. The tire type is suitable for road transportation and can complete cross-regional transfers in a short time; the crawler type has a strong ability to adapt to terrain and can move freely in complex environments such as mountains and swamps, avoiding the long-distance material transportation costs and time loss caused by site restrictions of traditional fixed crushing equipment.

Functional integration and high efficiency are the significant advantages of Mobile Crusher Machine. It integrates feeding, crushing, screening, conveying and other functions into one to form a complete production line. Users can flexibly configure a variety of crushers such as jaw, cone, and impact according to material characteristics and finished product requirements to achieve accurate crushing and grading of materials of different hardness. At the same time, the intelligent control system monitors the equipment operating parameters in real time, automatically adjusts the feeding speed and crushing force, ensures that the equipment always maintains the best working state, and greatly improves production efficiency.

In terms of environmental protection and sustainable development, the equipment performs well. The combination of a fully enclosed crushing chamber and an efficient dust removal system can effectively suppress dust diffusion; the application of noise reduction devices can control the operating noise within the environmental protection standard range. In addition, the equipment supports the processing of construction waste, tailings and other waste materials into recycled aggregates to achieve resource recycling, which not only reduces the pollution of waste to the environment, but also creates additional economic benefits, which is in line with the concept of green development.

From the perspective of operation and maintenance costs and safety, Mobile Crusher Machine is also competitive. The modular design makes the installation, maintenance and replacement of parts of the equipment more convenient, reduces the difficulty of maintenance and labor costs; the intelligent fault warning system can detect equipment hidden dangers in advance to avoid sudden downtime and safety accidents. Its compact structural design not only saves floor space, but also adapts to narrow construction spaces, further expanding the application scenarios.

Technical Parameter Table of Mobile Crusher Machine

| Model | Crusher Type | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) | Drive Mode | Weight (t) | Dimensions (L×W×H, mm) |

|---|---|---|---|---|---|---|---|---|

| MC-100 | Jaw Crusher | ≤500 | 50–150 | 80–120 | 200 | Diesel | 35 | 12000×3000×3500 |

| MC-150 | Impact Crusher | ≤600 | 0–40 | 100–180 | 250 | Electric | 45 | 13500×3200×3800 |

| MC-200 | Cone Crusher | ≤700 | 5–30 | 150–250 | 320 | Diesel/Electric | 52 | 14500×3300×4000 |

| MC-250 | Hammer Crusher | ≤400 | 0–10 | 100–160 | 180 | Electric | 38 | 12800×3100×3700 |

| MC-300 | Jaw + Cone Crusher | ≤800 | 0–50 | 200–350 | 420 | Diesel | 60 | 16000×3500×4200 |

If you have any special requirements, we will customize according to your special needs.

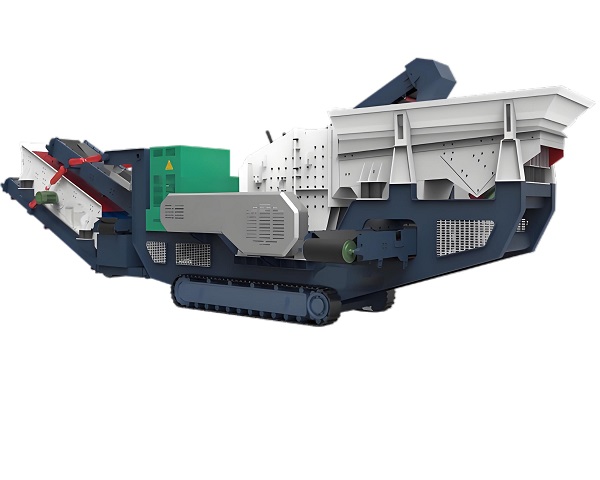

Product Picture Display of Mobile Crusher Machine

FAQ about Mobile Crusher Machine

>1. What is a Mobile Crusher Machine?

A mobile crusher machine is a portable stone or material crushing unit that integrates crushing, screening, and conveying equipment onto a mobile platform. It is designed for easy transportation and efficient on-site processing, widely used in mining, construction, recycling, and road building.

>2. What types of crushers are used in mobile crusher machines?

Mobile crusher machines typically use jaw crushers, impact crushers, cone crushers, or hammer crushers. The selection depends on the material hardness, required output size, and production capacity.

>3. What materials can a mobile crusher process?

Mobile crushers can process a wide range of materials, including granite, basalt, limestone, concrete, asphalt, brick, and construction waste. They are suitable for both primary and secondary crushing applications.

>4. What are the advantages of using a mobile crusher?

The main advantages include high mobility, flexibility, reduced transportation costs, quick setup time, and the ability to process materials directly at the job site, which improves efficiency and lowers operational costs.

>5. How is a mobile crusher powered?

Mobile crusher machines are usually powered by diesel engines, electric motors, or a hybrid of both. The power source depends on the model and working conditions, with electric options often preferred in environmentally sensitive areas.

>6. How to choose the right mobile crusher model?

Choosing the right model depends on several factors such as material type, required output size, desired capacity, site conditions, and budget. Consultation with a supplier or engineer can help identify the best solution.

>7. Can mobile crushers be used in urban areas?

Yes, mobile crushers are ideal for urban demolition and recycling projects because they are compact, low-noise, and often equipped with dust suppression systems to minimize environmental impact.

>8. What maintenance is required for mobile crushers?

Routine maintenance includes checking wear parts, lubricating components, cleaning dust filters, and monitoring hydraulic systems. Regular inspections ensure optimal performance and prolong machine life.

>9. Are mobile crushers cost-effective?

Yes, mobile crushers are cost-effective for many projects, especially where on-site crushing reduces material transport, dumping fees, and processing time. Over time, the operational savings often outweigh the initial investment.

>10. Is training required to operate a mobile crusher?

Yes, operators should receive proper training on machine controls, safety procedures, maintenance protocols, and troubleshooting to ensure safe and efficient operation. Many manufacturers offer on-site training or manuals.