A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Mobile Crusher for Sale

Definition and working principle of mobile crusher

Mobile crusher is a kind of movable crushing equipment that integrates multiple functions such as feeding, crushing, screening and conveying. It breaks through the site limitation of traditional fixed crushing station and can be quickly moved to different work sites according to production needs to realize on-site crushing and processing of materials.

Its working principle is mainly to drive the crushing host (such as jaw crusher, impact crusher, cone crusher, etc.) through a power device (such as a diesel engine or an electric motor) to crush the material. At the same time, it is equipped with a feeder and screening equipment to feed and grade the material, and finally output the finished product that meets the requirements.

Main types of mobile crushers

According to the different crushing hosts and configurations, mobile crushers are mainly divided into the following types:

Jaw mobile crushing station: with jaw crusher as the host, it is suitable for coarse crushing of materials of various hardness, such as granite, basalt, limestone, etc.

Impact mobile crushing station: with impact crusher as the host, it is suitable for crushing materials below medium hardness, with good finished product particle shape, and is mostly used in construction waste treatment, concrete recycling and other fields.

Cone mobile crushing station: With cone crusher as the main machine, it is suitable for fine and medium crushing of high-hardness materials, such as iron ore, copper ore, etc.

Impact mobile crushing station: With impact crusher (sand making machine) as the main machine, it is mainly used for sand making and shaping of materials, and can produce high-quality sand and gravel aggregates.

Screening mobile crushing station: Equipped with screening equipment such as vibrating screen, it can grade the crushed materials to meet the material output requirements of different particle sizes.

Features and advantages of mobile crusher

Strong mobility: The mobile crusher adopts tire or crawler walking device, which can be quickly moved to different work sites to reduce material transportation costs and time.

Flexible configuration: The crushing host, feeder, screening equipment, etc. can be flexibly configured according to production needs to achieve multi-purpose use of one machine to meet the crushing and processing needs of different materials.

High efficiency and energy saving: Using advanced crushing technology and energy-saving design to improve crushing efficiency and reduce energy consumption.

Good environmental protection performance: Equipped with environmental protection devices such as dust removal and noise reduction to reduce dust and noise pollution and meet environmental protection requirements.

Easy to operate: Adopt intelligent control system to realize automatic operation and remote monitoring, reduce labor costs and improve production efficiency.

Application fields of mobile crusher

Mobile crushers are widely used in mining, construction waste treatment, road construction, water conservancy projects, urban infrastructure and other fields. Especially in the treatment of construction waste, mobile crushers can realize on-site crushing and processing of construction waste, convert it into recycled aggregates, and use it to produce recycled bricks, recycled concrete and other building materials products to achieve resource recycling.

Development trend of mobile crusher

With the continuous advancement of science and technology and increasingly stringent environmental protection requirements, mobile crushers will develop in a more intelligent, environmentally friendly and efficient direction. In the future, mobile crushers will pay more attention to technical innovation and application promotion in energy conservation and emission reduction, noise reduction and dust pollution reduction, so as to meet the market demand for high-quality and environmentally friendly crushing equipment. At the same time, with the application of technologies such as the Internet of Things and big data, mobile crushers will achieve more intelligent remote monitoring and management, improve production efficiency and equipment utilization.

Operating principle of Mobile Crusher for Sale

The working principle, technical characteristics, application scenarios and development trends of mobile crushers are analyzed to provide practitioners with systematic technical references and help the industry upgrade to high efficiency and greenness.

1. Material transportation and pretreatment

The mobile crusher uses a vibrating feeder to achieve stable material transportation, ensuring that the material enters the crushing host evenly and continuously. The feeder can adjust the feeding speed and flow rate to avoid equipment overload, and remove impurities and oversized materials through pre-screening or iron removal devices to provide guarantee for subsequent efficient crushing. This link optimizes the feeding quality and reduces the risk of equipment wear.

2. Multi-stage crushing and particle size optimization

After the material enters the crushing host, different forms of crushing are completed according to the machine model: the jaw crusher achieves coarse crushing through the extrusion of the movable jaw and the fixed jaw, the cone crusher uses the lamination principle to efficiently process high-hardness materials, the impact crusher has both impact and collision and shaping functions, and the impact crusher further refines the material and optimizes the particle shape. The crushing parameters at each stage are adjustable to ensure that the finished product particle size meets the requirements.

3. Screening, grading and closed-loop circulation

The crushed materials enter the vibrating screen through the conveyor belt and complete multi-level sorting through multi-layer screens. Finished products that meet the particle size requirements are directly output, and oversized materials are returned to the crushing host through the return belt for reprocessing, forming a closed-loop circulation. This mechanism ensures the uniformity of product particle size, while improving resource utilization and reducing waste.

4. Power drive and flexible movement

The equipment is driven by a diesel engine or an external power supply, and the hydraulic system controls the operating parameters of each module to achieve collaborative operations such as crushing and screening. The tire-type or crawler chassis supports rapid transfer, and the hydraulic legs adapt to complex terrain to ensure operational stability. The mobile crusher meets the needs of decentralized operations through modular design and intelligent control, and improves production efficiency and flexibility.

Advantages and features of Mobile Crusher for Sale

As the core representative of modern crushing equipment, mobile crusher has shown significant advantages in the engineering field with its integrated design and flexible operation capabilities. The following systematically summarizes its core features and advantages from the two dimensions of technical characteristics and practical applications:

Core features of mobile crusher

1. Highly integrated design

The mobile crusher integrates the crushing host (such as jaw, cone, impact), feeder, screening device, conveyor belt and power system into the mobile chassis to form a "one-stop" operation unit. Users can quickly put into production without additional fixed facilities, which is especially suitable for emergency projects or decentralized operation scenarios.

2. Flexible configuration of multiple models

According to the material characteristics and particle size requirements, the equipment can freely combine different crushing hosts and auxiliary modules. For example, for high-hardness ores, cone crusher + vibrating screen can be selected; when processing construction waste, impact crusher + iron removal device can be used. This modular design enables the equipment to adapt to a variety of complex working conditions.

3. Intelligent control system

The equipment is equipped with an intelligent control system, which can monitor the equipment operating parameters (such as crushing chamber pressure, discharge particle size, etc.) in real time, and optimize the crushing efficiency through automatic adjustment. At the same time, it supports remote monitoring and fault diagnosis, greatly reducing the need for manual intervention.

Significant advantages of mobile crushers

1. Flexible mobility and reduced transfer costs

The equipment can be quickly transferred to different operating points using tire or crawler chassis, avoiding the high disassembly and transportation costs of traditional fixed equipment. For example, in mining, the equipment can move synchronously with the advancement of the mining face, reducing the secondary handling of materials.

2. High efficiency, energy saving and environmental protection compatibility

By optimizing the crushing chamber structure and power matching, the energy consumption of the equipment is reduced by 15%-20% compared with traditional fixed crushing stations. At the same time, it is equipped with a closed conveyor belt, a pulse dust collector and a noise reduction device to effectively control dust and noise pollution, meeting green construction standards.

3. Adapt to complex working conditions and material diversity

The equipment can select matching crushing hosts for materials of different hardness (such as granite, construction waste, and coal gangue), and achieve precise processing by adjusting parameters such as feed particle size and crushing ratio. The crawler chassis can climb slopes and overcome obstacles, adapting to rugged terrain in mines or narrow construction spaces in cities.

4. Significant economic benefits

Taking construction waste treatment as an example, mobile crushers can directly crush waste concrete and bricks into recycled aggregates at the demolition site for road cushions or unburned brick production, saving transportation costs and improving resource utilization. It is estimated that a single device can process up to 500,000 tons of construction waste per year, with significant economic benefits.

Through integrated, intelligent and environmentally friendly design, mobile crushers solve the problems of poor flexibility, high cost and heavy pollution of traditional crushing equipment, and become the preferred equipment for mining, construction waste treatment and emergency projects. Its efficient operation capacity and resource recycling value will provide key support for the sustainable development of the industry.

Technical Parameter Table of Mobile Crusher for Sale

| Model | Type | Crusher Configuration | Max Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) | Mobility | Dimensions (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| MC-100J | Wheel Type Jaw Crusher | PE750×1060 | ≤630 | 80–180 | 90–280 | 110 | Wheel-mounted | 12500 × 2450 × 3950 | 39 |

| MC-110C | Crawler Type Cone Crusher | HPC200 | ≤200 | 13–38 | 100–200 | 160 | Crawler | 13800 × 2800 × 4200 | 42 |

| MC-120I | Crawler Type Impact Crusher | PF1214 | ≤350 | 0–40 | 100–250 | 132 | Crawler | 14000 × 2900 × 4200 | 45 |

| MC-150H | Heavy-Duty Crawler Jaw Crusher | PE900×1200 | ≤750 | 100–200 | 200–400 | 160 | Crawler | 14500 × 3000 × 4300 | 52 |

| MC-160S | Wheel Type Screening + VSI | VSI + Vibrating Screen | ≤50 | Adjustable | 80–150 | 90 | Wheel-mounted | 12000 × 2500 × 4000 | 36 |

| MC-180I PRO | Multi-stage Crawler Crushing Plant | Jaw + Cone + Screening | ≤800 | Adjustable | 300–600 | 2×160 | Crawler | 18000 × 3500 × 4500 | 65 |

If you have any special requirements, we will customize according to your special needs.

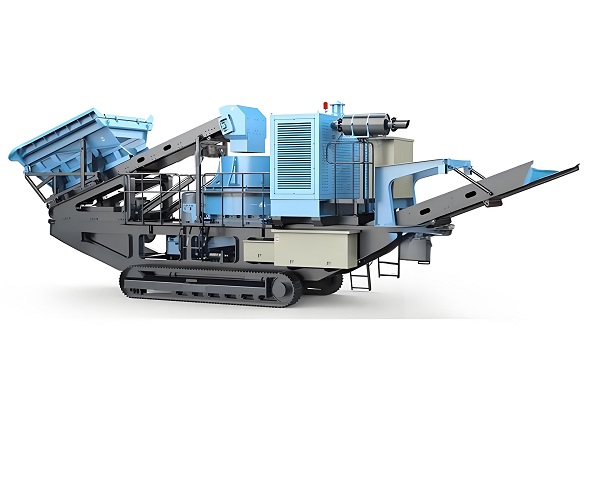

Product Picture Display of Mobile Crusher for Sale

FAQ about Mobile Crusher for Sale

>1. What industries are mobile crushers suitable for?

Mobile crushers are widely used in mining, construction waste treatment, road construction, water conservancy projects, urban infrastructure and other fields. For example, they are used for coarse and medium crushing of ore in mines; in construction waste treatment, waste concrete, bricks, etc. are crushed into recycled aggregates to achieve resource recycling; in road construction, roadbed stones can be quickly processed to meet temporary or decentralized operation needs.

>2. What are the advantages of mobile crushers compared with fixed crushing equipment?

Mobile crushers do not require fixed foundations and can be quickly transferred to different operation points to reduce material transportation costs; the equipment has high integration and small footprint, which is suitable for narrow urban construction environments; modular design supports flexible configuration and adapts to a variety of materials and particle size requirements; intelligent control systems can monitor operating parameters in real time to improve production efficiency and safety.

>3. What are the main types of mobile crushers?

According to the different crushing hosts, they are mainly divided into jaw mobile crushing station (coarse crushing), cone mobile crushing station (medium and fine crushing), impact mobile crushing station (medium crushing and shaping), impact mobile crushing station (sand making and particle shape optimization) and screening mobile crushing station (grading treatment). Users can choose the matching model according to the hardness and particle size requirements of the material.

>4. What is the power source of the mobile crusher?

Mobile crushers are usually driven by diesel engines or external power supplies. Diesel models are suitable for field operations without power supply, such as mining; external power models are suitable for urban construction or scenes with high environmental protection requirements, which can reduce fuel consumption and exhaust emissions. Some models support dual power switching to further improve adaptability.

>5. How does the mobile crusher handle construction waste?

Construction waste contains mixed materials such as concrete, bricks, and asphalt. The mobile crusher is fed evenly by a vibrating feeder, and the jaw or impact crusher is used for coarse and medium crushing, and then the different particle sizes are selected by vibrating screening. For example, waste concrete is crushed into recycled aggregates of 0-5mm, 5-10mm, 10-20mm and other specifications, which are used for road base, unburned bricks or concrete admixtures to achieve resource recycling.

>6. How does the mobile crusher ensure environmental performance?

The equipment controls pollution through multiple measures: the closed conveyor belt reduces dust spillage; the pulse dust collector removes dust from the crushing chamber and screening links, and the emission concentration can be lower than 30mg/m³; the noise reduction device controls the operating noise within 85 decibels; some models are equipped with a spray system to further suppress dust. These designs make it meet environmental protection construction standards and are especially suitable for urban construction waste treatment.

>7. Is the maintenance cost of the mobile crusher high?

The maintenance cost is relatively low. The equipment adopts wear-resistant materials and modular design, and the wearing parts (such as hammers and liners) are easy to replace; the hydraulic system and intelligent control system can monitor the equipment status in real time and warn of faults in advance; daily maintenance only requires regular lubrication and inspection of hydraulic oil and filter elements. In the long run, its comprehensive cost (including the cost savings of transfer) is usually lower than the total investment of fixed crushing station.

>8. Can mobile crusher handle high-hardness materials?

It can handle high-hardness materials. Cone mobile crusher is specially designed for high-hardness ores, such as iron ore and granite, and achieves efficient crushing through the principle of lamination crushing; jaw mobile crusher, as a coarse crushing equipment, can withstand materials with extremely high compressive strength. Users can choose matching models according to hardness and control the discharge particle size by adjusting the size of the discharge port.

>9. What is the production efficiency of mobile crusher?

The production efficiency is relatively high. For example, the output of medium-sized jaw mobile crusher can reach 100-300 tons per hour, and the cone type can handle higher hardness materials with uniform particle size. The equipment supports continuous operation, and the intelligent control system can optimize the crushing parameters and reduce downtime, which is suitable for large-scale engineering needs.

>10. How to choose a suitable mobile crusher model?

The following factors should be considered when selecting: material type (hardness, humidity), feed and discharge particle size requirements, production scale (hourly output), operating environment (topography, frequency of transfer) and budget. For example, impact crusher models can be selected for construction waste processing to optimize particle shape; jaw crusher models are recommended for coarse crushing in mines; crawler chassis are recommended for frequent transfers to improve passability. It is recommended to combine the manufacturer's technical solutions and on-site tests to determine the final configuration.