A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Mobile Cone Crusher

Mobile Cone Crusher is an advanced material handling equipment that combines mobility and efficient crushing functions. It is widely used in mining, construction aggregate production, road construction and other fields.

From the perspective of equipment composition, Mobile Cone Crusher is mainly composed of cone crushing system, mobile chassis, feeding system, screening system and conveying system. Its core cone crushing system adopts the principle of laminated crushing. The moving cone is driven by the eccentric sleeve to make a swinging motion, so that the material entering the crushing chamber is squeezed, bent and sheared to achieve efficient crushing. The mobile chassis is divided into two types: tire type and crawler type. The tire type is convenient for rapid transfer on flat roads, and the crawler type can adapt to muddy and rugged complex terrain, giving the equipment extremely strong mobility.

During the working process, the material is evenly fed into the cone crusher by the feeder for primary crushing. The crushed material is transported to the screening equipment by the belt conveyor for particle size screening. Qualified finished aggregates are transported to the designated location, and materials that do not meet the particle size requirements are returned to the crusher for re-crushing, forming a cycle operation until the required particle size standard is reached. The entire process is monitored in real time by an intelligent control system, which can automatically adjust the equipment operating parameters according to the material characteristics to ensure efficient and stable production.

Compared with traditional crushing equipment, Mobile Cone Crusher has significant advantages. It does not require complex infrastructure installation, can quickly reach the construction site, and reduce the cost and time of material transportation; the lamination crushing method of the cone crusher not only has high production efficiency, but also can produce high-quality aggregates with uniform particle size and low needle-like content, meeting high-standard engineering requirements. At the same time, the equipment is equipped with a dust removal and noise reduction device to effectively reduce dust and noise pollution during the production process, meeting environmental protection requirements; modular design makes equipment maintenance and repair more convenient, further improving the reliability and service life of the equipment.

Whether it is crushing ore in mining or handling construction waste in urban construction, Mobile Cone Crusher can provide efficient, environmentally friendly and economical material handling solutions for various projects with its excellent performance and flexible mobility. It is an indispensable and important equipment for modern engineering construction.

Operating principle of Mobile Cone Crusher

Mobile Cone Crusher achieves efficient crushing of various ores and stones through the coordinated operation of mechanical transmission, extrusion crushing and intelligent control. Its working process is precise and orderly.

When the equipment is running, the power system provides energy for the entire crushing process. The motor drives the eccentric sleeve to rotate through the pulley and drive shaft, and then drives the moving cone to swing around the center line of the crusher. This unique motion trajectory is the key to the efficient crushing of Mobile Cone Crusher. When the moving cone approaches the fixed cone, the space between the two is reduced, and the material entering the crushing chamber is subjected to strong extrusion, bending and shearing forces and is gradually crushed; when the moving cone is away from the fixed cone, the crushed material is discharged from the crushing chamber under the action of gravity, completing a crushing process.

The material handling process starts with the feeding link. The vibrating feeder feeds the material to be crushed evenly and continuously into the top of the crushing chamber. To ensure the stable operation of the equipment, the feeding amount must match the crushing capacity. Excessive feeding may cause blockage, while insufficient feeding will reduce production efficiency. The material entering the crushing chamber first undergoes preliminary crushing in the upper part of the crushing chamber. With the swinging motion of the moving cone, the material continues to move to the lower part of the crushing chamber, the crushing force gradually increases, the particle size decreases accordingly, and finally discharged from the discharge port.

The crushed material is transported to the screening system by a belt conveyor. The vibrating screen classifies the material according to the size of the screen mesh aperture. Finished aggregates that meet the specifications are transported to the finished product pile; materials that do not meet the particle size requirements are sent back to the crushing chamber through the return belt conveyor for secondary crushing, forming a cyclic operation mode until the material reaches the target particle size.

In addition, the Mobile Cone Crusher is equipped with an intelligent control system that can monitor the equipment operating parameters in real time, such as the eccentric sleeve speed, crushing force, bearing temperature, etc. Once the parameters are abnormal, the system will automatically alarm and adjust the equipment operating status to avoid equipment damage due to overload or failure. At the same time, through the remote control function, the operator can also flexibly adjust the size of the discharge port according to production needs and control the particle size of the finished aggregate to ensure that the entire crushing process is efficient, stable and safe.

Advantages and features of Mobile Cone Crusher

Mobile Cone Crusher, or mobile cone crusher, is an efficient material handling equipment that combines the excellent crushing performance of cone crusher with mobile chassis. With its unique technical characteristics and significant advantages, it has become an ideal choice for mining, sand and gravel aggregate production and other fields.

Efficient crushing and high-quality finished products are the core advantages of Mobile Cone Crusher. The cone crusher adopts the principle of laminated crushing. The moving cone is driven by the eccentric sleeve to make a rotary swing motion, so that the material is squeezed, bent and sheared in the crushing chamber, achieving more crushing and less grinding. This crushing method not only has strong processing capacity, but also can produce high-quality finished aggregates with uniform particle size and low needle-like content, meeting the stringent requirements of highways, high-rise buildings, etc. for high-quality aggregates. In addition, by adjusting the crushing chamber type and the size of the discharge port, the equipment can flexibly adapt to different production needs and realize the switching of various operation modes such as coarse crushing, medium crushing and fine crushing.

In terms of mobility and flexibility, Mobile Cone Crusher performs well. The equipment is equipped with a tire-type or crawler-type mobile chassis, which can be quickly transferred to different construction sites without the need for complex foundation installation and disassembly processes, greatly shortening the project preparation time. In particular, crawler models have strong off-road capabilities and can travel freely in muddy, rugged mines or mountainous areas and other complex terrains, significantly improving the application range and adaptability of the equipment.

From the perspective of intelligence and energy saving and environmental protection, the equipment is also full of highlights. It is equipped with an advanced intelligent control system that can monitor the operating parameters of the equipment in real time, such as crushing force, spindle speed, oil temperature, etc., and automatically adjust the working state according to the material properties and production requirements to ensure that the equipment is always in the best operating efficiency. At the same time, the equipment adopts a fully enclosed crushing chamber and an efficient dust removal and noise reduction device to effectively reduce dust and noise pollution and meet strict environmental protection standards. In addition, the laminated crushing method of the cone crusher consumes less energy than traditional crushing technology, further reducing production and operating costs.

Mobile Cone Crusher also has the characteristics of convenient maintenance and high reliability. The equipment adopts modular design, and key components such as crushing chamber and eccentric sleeve are easy to disassemble and replace, which greatly shortens the maintenance time and improves the utilization rate of the equipment. High-quality wear-resistant materials and exquisite manufacturing technology ensure the long-term stable operation of the equipment, reduce the failure rate, and bring higher economic benefits to users.

Technical Parameter Table of Mobile Cone Crusher

| Model | Cone Crusher Type | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) | Drive Type | Weight (t) | Dimensions (L×W×H, mm) |

|---|---|---|---|---|---|---|---|---|

| MCC-100 | Single Cylinder Hydraulic | ≤200 | 5–25 | 50–120 | 160 | Diesel/Electric | 32 | 11000×3000×3500 |

| MCC-150 | Multi Cylinder Hydraulic | ≤250 | 5–35 | 100–180 | 220 | Electric | 42 | 12500×3200×3700 |

| MCC-200 | Spring Cone Crusher | ≤300 | 6–40 | 120–250 | 250 | Diesel | 46 | 13000×3300×3800 |

| MCC-250 | Single Cylinder Hydraulic | ≤320 | 6–45 | 180–300 | 280 | Diesel/Electric | 50 | 13800×3400×3900 |

| MCC-300 | Multi Cylinder Hydraulic | ≤350 | 8–50 | 250–400 | 315 | Electric | 58 | 14500×3500×4000 |

If you have any special requirements, we will customize according to your special needs.

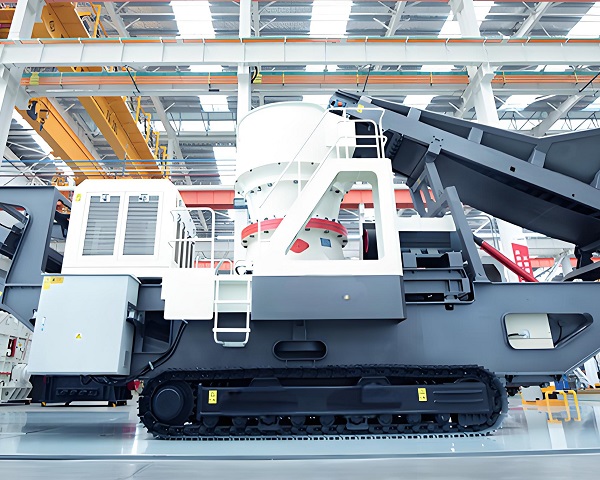

Product Picture Display of Mobile Cone Crusher

FAQ about Mobile Cone Crusher

>1. How to choose a suitable mobile cone crusher model?

The selection of the model requires comprehensive consideration of material properties (hardness, humidity, particle size), production capacity requirements (hourly output, such as 100-400 tons/hour), discharge requirements (particle size specifications) and operating environment (terrain conditions, space restrictions). For example, high-hardness materials require equipment with stronger wear resistance, and short-head type cavities can be preferred for fine crushing requirements. It is recommended to match the manufacturer's technical parameters with actual working conditions, and material testing can be performed if necessary.

>2. What is the difference between a mobile cone crusher and a fixed cone crusher?

The main difference between a mobile cone crusher and a fixed cone crusher lies in flexibility and applicable scenarios: mobile equipment can quickly transfer the operating location and adapt to the needs of multiple sites, especially suitable for the initial mining, construction waste treatment and emergency projects; while fixed equipment requires infrastructure investment, which is suitable for long-term production in large mines or sand and gravel aggregate plants. In addition, the initial investment of mobile equipment is higher but saves transportation and infrastructure costs, while fixed equipment is more suitable for long-term fixed operations.

>3. What materials are suitable for mobile cone crushers?

Mobile cone crushers are suitable for medium-hard and above materials, including mining rocks (such as granite, basalt), metal ores (such as iron ore, copper ore), industrial waste (such as steel slag, tailings) and construction waste (such as concrete blocks). The discharge particle size can be controlled by adjusting the crushing chamber type (standard type or short head type). The short head type is suitable for fine crushing (discharge ≤20mm), and the standard type is suitable for medium crushing to meet the needs of different projects.

>4. What are the core advantages of mobile cone crushers?

The core advantages of mobile cone crushers include efficient crushing (excellent particle shape, low needle-like content), flexible mobility (crawler type adapts to complex terrain, tire type is suitable for short-distance turnover), energy saving and environmental protection (hydraulic system optimizes energy consumption, equipped with dust removal device) and integrated design (reducing material transfer links and reducing infrastructure investment). These features make it an efficient solution for modern projects.

>5. What is the environmental performance of mobile cone crushers?

The environmental performance of mobile cone crushers is reflected in dust control (equipped with sealed crushing chamber, spray device, pulse bag dust collector), noise reduction (adopting soundproof cover, shock-absorbing base, operating noise ≤85dB (A)), waste treatment (construction waste can be recycled as recycled aggregate) and energy consumption optimization (hydraulic system and intelligent control reduce energy waste, and some models support electric drive).

>6. What are the maintenance points of mobile cone crushers?

The maintenance points include regular inspection of lubrication system (oil station, oil temperature, oil pressure) and hydraulic system (pressure, leakage), monitoring the wear of vulnerable parts such as crushing wall and mortar wall and replacing them in time, cleaning the residual materials in the crushing chamber to prevent blockage, strictly following the safety operating procedures to avoid overload operation, and regularly checking the aging of electrical system lines and grounding protection.

>7. What is the investment cost of mobile cone crushers?

The investment cost of mobile cone crushers varies depending on the model, configuration and brand, usually between 1.5 million and 8 million yuan. Small tire equipment (basic configuration) is about 1.5-3 million yuan, and large crawler equipment (high capacity, full hydraulic drive) is about 4-8 million yuan. In addition, transportation costs, post-maintenance costs and equipment depreciation need to be considered. It is recommended to conduct a comprehensive evaluation in combination with the return on investment (ROI).

>8. What is the energy consumption level of mobile cone crushers?

The energy consumption of mobile cone crushers is affected by equipment power, load rate and material characteristics. The main engine power is usually 132-400kW, and some models use hydraulic overload protection and intelligent control systems to reduce ineffective energy consumption. Taking medium-sized equipment as an example, it consumes about 200-300 degrees of electricity per hour when running at full load. It is recommended to choose equipment with high energy efficiency rating to reduce long-term operating costs.

>9. How to optimize the discharge particle size of mobile cone crushers?

Methods for optimizing the particle size of the discharge material include selecting the appropriate crushing chamber type (short head type is suitable for fine crushing, standard type is suitable for medium crushing), accurately adjusting the discharge port width (such as 6-38mm) through the hydraulic system, adjusting the spindle speed to affect the crushing efficiency and particle size distribution, and linking with the mobile screening station to achieve "crushing + screening" closed-loop control.

>10. What is the market application prospect of mobile cone crushers?

With the tightening of global resource development and environmental protection policies, the market prospect of mobile cone crushers is broad. Its application areas include flexible mining of small and medium-sized mines, recycling of construction waste, and emergency engineering ruins treatment. Technology upgrades (such as intelligence and electrification) will further promote market demand, especially in the fields of infrastructure construction and circular economy.

>11. What is the future development trend of mobile cone crushers?

Future development trends include intelligence (integration of Internet of Things technology to achieve remote monitoring and adaptive adjustment), electrification (adopting pure electric or hybrid systems to reduce carbon emissions), large-scale and modularization (increasing single-machine production capacity and supporting rapid linkage of multiple devices) and upgrades to wear-resistant materials (such as high manganese steel and ceramic composite materials to extend the life of wearing parts).