A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Mobile Crush and Screen Plant for Sale

The mobile crushing and screening machine is a modular mobile device that integrates crushing, screening and conveying functions. It integrates the crushing host (such as jaw, cone, impact, etc.), vibrating screening system, feeding device and conveyor belt into the mobile chassis to achieve "one-stop" material processing. Its core advantage is to break the dependence of traditional fixed equipment on sites and infrastructure. Through flexible transfer and efficient collaborative operation, it can significantly reduce transportation costs, shorten construction period, and improve resource utilization.

Technical features and core advantages

1. Highly integrated design

The equipment integrates crushing, screening, conveying and other links into a single platform, and users can quickly put it into production without additional fixed facilities. For example, in the treatment of construction waste, the equipment can be directly stationed at the demolition site to crush waste concrete, bricks, etc. into recycled aggregates, eliminating the need for material transportation and transfer.

2. Flexible combination of multiple models

According to the material characteristics and particle size requirements, the equipment can be freely configured with different crushing hosts and screening modules. For example, when processing high-hardness ores, a combination of "jaw crusher + cone crusher + vibrating screen" can be used; when processing construction waste, the "impact crusher + iron remover + multi-layer screen" solution is selected to achieve precise classification and impurity separation.

3. Intelligent and environmentally friendly compatibility

The equipment is equipped with an intelligent control system, which can monitor parameters such as crushing chamber pressure and screening efficiency in real time, and optimize the operation process through automatic adjustment. At the same time, the application of closed conveyor belts, pulse dust collectors and noise reduction devices makes the dust emission concentration lower than 30mg/m³, and the noise is controlled within 85 decibels, which meets the green construction standards.

Application areas and typical scenarios

1. Mining

In open-pit mines, the equipment can move synchronously with the advancement of the mining face, and the ore can be coarsely crushed, medium crushed and screened to directly produce aggregates that meet the particle size requirements, reducing secondary transportation costs. For example, in iron ore mining, the cone-type mobile crushing and screening integrated machine can handle materials with a compressive strength of 300MPa, and the uniformity of the output particle size is better than that of traditional fixed equipment.

2. Construction waste resource utilization

The equipment can crush concrete, bricks, asphalt and other construction waste into recycled aggregates of 0-5mm, 5-10mm, 10-20mm and other specifications for road base, unburned bricks or concrete admixtures. Taking urban demolition as an example, the daily processing capacity of a single device can reach 2000-5000 tons, and the resource utilization rate exceeds 90%.

3. Road construction and emergency projects

In projects such as highways and railways, the equipment can process roadbed stones on site to avoid the transportation risks of purchased aggregates. After natural disasters (such as earthquakes and floods), crawler-type mobile crushing and screening integrated machines can quickly enter the disaster area, process construction waste and restore infrastructure.

Economic benefits and social value

The mobile crushing and screening integrated machine significantly reduces the total cost of the project by reducing material transportation costs (saving 30%-50%), shortening construction periods (increasing efficiency by more than 40%) and improving resource utilization (reducing waste landfill). At the same time, its environmental performance and flexible operation capabilities help the industry upgrade to green and intelligent directions and promote the development of a circular economy.

With "mobility, efficiency, and environmental protection" as its core competitiveness, the mobile crushing and screening machine has become the preferred equipment in the fields of mining, construction waste treatment, and emergency engineering. With the iteration of technology and the growth of market demand, its application scenarios will be further expanded, providing key support for efficient resource utilization and sustainable development.

Operating principle of Mobile Crush and Screen Plant for Sale

The mobile crushing and screening machine integrates crushing, screening and conveying functions to achieve continuous operation of "crushing and grading" of materials. Its core working principle can be divided into five major links: material conveying, crushing processing, screening and grading, recycling and intelligent control. The following is a detailed description:

1. Material conveying and pretreatment

The equipment uses a vibrating feeder to achieve stable material transportation. Its function is similar to that of an "automatic feeder". It adjusts the feeding speed through the vibration frequency to avoid equipment overload. For example, when processing construction waste, the feeder can evenly convey mixed materials such as concrete blocks and bricks, and remove metal impurities such as steel bars through an iron removal device to reduce wear on subsequent crushing equipment. The pretreatment link ensures the quality of the material and lays the foundation for efficient crushing.

2. Multi-stage crushing and processing

After the material enters the crushing host, different forms of crushing are completed according to the model:

Jaw crusher: Coarse crushing is achieved through the extrusion of the movable jaw and the fixed jaw. It is suitable for high-hardness materials (such as granite). The discharge particle size is usually 100-300mm.

Cone crusher: Uses the lamination principle to crush the coarsely crushed materials in a medium and fine manner, with a compressive strength of up to 350MPa, and the discharge particle size can be controlled to 10-50mm.

Impact crusher: Mainly based on impact collision, with shaping function, suitable for medium and low hardness materials (such as limestone), and the discharge particle size is more uniform.

Impact crusher: Further refines the material through the principle of "stone hitting stone" or "stone hitting iron", often used in sand making operations, and the discharge particle size can be less than 5mm.

3. Screening and grading and product output

The crushed material enters the vibrating screen through the conveyor belt, and completes multi-level sorting through multiple layers of screens (such as 2 layers, 3 layers). For example, a 3-layer screen can divide the material into four specifications: 0-5mm (fine sand), 5-10mm (small stones), 10-20mm (medium stones) and 20mm or more (return material). Finished products that meet the particle size requirements are directly output to the material pile or transport vehicle, and oversized materials enter the return system.

4. Circular return and secondary processing

Oversized materials are re-conveyed to the entrance of the crushing main machine through the return belt to form a closed loop. For example, when processing hard rock in mines, the cone crusher cooperates with the vibrating screen to ensure the uniformity of the discharge particle size through multiple returns. This mechanism improves resource utilization and avoids waste.

5. Intelligent control and parameter adjustment

The equipment is equipped with an intelligent control system, which can monitor parameters such as crushing chamber pressure, screening efficiency, motor load, etc. in real time, and optimize the operation process through automatic adjustment. For example, when the material blockage in the crushing chamber is detected, the system automatically reduces the feed speed or adjusts the size of the discharge port to ensure stable operation of the equipment.

The mobile crushing and screening integrated machine realizes efficient material processing and resource utilization through the collaborative operation of "conveying-crushing-screening-returning-control". Its modular design and intelligent control technology enable it to adapt to a variety of complex scenarios such as mining and construction waste treatment, and become a key equipment in the field of modern engineering.

Advantages and features of Mobile Crush and Screen Plant for Sale

The mobile crushing and screening machine integrates crushing, screening and conveying functions into one to form a mobile "one-stop" material handling platform. Its core features and advantages can be analyzed from four dimensions: technical characteristics, economic benefits, environmental protection performance and operational flexibility:

Technical characteristics: integration and intelligence

1. Modular integrated design

The equipment integrates the crushing host (jaw/cone/impact type), vibration screening system, feeding device and conveyor belt into the mobile chassis. Users can quickly put it into production without building additional fixed facilities. For example, in the treatment of construction waste, the equipment can be directly stationed at the demolition site to crush waste concrete, bricks, etc. into recycled aggregates, eliminating the need for material transportation and transfer.

2. Intelligent control system

Equipped with a PLC intelligent control system, it can monitor the equipment operating parameters (such as crushing chamber pressure, screening efficiency, motor load) in real time and optimize the operation process through automatic adjustment. For example, when the material in the crushing chamber is detected to be blocked, the system automatically reduces the feed speed or adjusts the size of the discharge port to reduce manual intervention and improve safety and efficiency.

Economic benefits: significant cost reduction and efficiency increase

1. Reduce transportation and infrastructure costs

The equipment can be transferred with the operation point to avoid secondary material handling. For example, in mining, the equipment can move synchronously with the advancement of the mining face, directly output aggregates that meet the particle size requirements, and reduce transportation costs by 30%-50%; in the treatment of construction waste, the daily processing capacity of a single device can reach 2000-5000 tons, and the resource utilization rate exceeds 90%, saving landfill costs.

2. Flexible configuration and efficient output

According to the material characteristics and particle size requirements, the equipment can freely combine the crushing host and the screening module. For example, when processing high-hardness ores, the "jaw + cone + vibrating screen" combination is used; when processing construction waste, the "impact + iron remover + multi-layer screen" solution is selected to achieve precise classification and impurity separation, and the production efficiency is increased by more than 40%.

Environmental performance: Green construction benchmark

1. Dust and noise control

The application of closed conveyor belts, pulse dust collectors and noise reduction devices makes the dust emission concentration lower than 30mg/m³ and the noise controlled within 85 decibels. For example, in the treatment of urban construction waste, the equipment can avoid dust pollution and meet environmental protection construction standards.

2. Resource recycling

The equipment converts construction waste, mine waste, etc. into recycled aggregates to reduce the exploitation of natural resources. Taking construction waste as an example, the annual processing capacity of a single device can reach 500,000 tons, and the resource utilization rate exceeds 90%, which helps the development of the circular economy.

Operation flexibility: adapt to complex working conditions

1. Rapid transfer and terrain adaptation

The tire or crawler chassis supports the rapid transfer of equipment. The crawler model can climb slopes and obstacles to adapt to the rugged terrain of mines or narrow construction spaces in cities. For example, in the post-disaster cleaning of construction waste, crawler equipment can quickly enter the disaster area and restore infrastructure.

2. Strong emergency response capability

The equipment can be quickly deployed to temporary operation points to meet emergency engineering needs. For example, in road repair, the equipment can process roadbed stones on site to shorten the construction period.

The mobile crushing and screening machine has the core advantages of "integration, intelligence, environmental protection, and flexibility". By reducing transportation costs, improving resource utilization, and controlling pollution emissions, it has become the preferred equipment in the fields of mining, construction waste treatment, and emergency engineering. Its efficient operation capability and green construction characteristics provide key support for the sustainable development of the industry.

Technical Parameter Table of Mobile Crush and Screen Plant for Sale

| Model | Crusher Type | Screening Unit | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Total Power (kW) | Track/Tire Type | Transport Dimensions (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| MCS-100 | Jaw Crusher + Vibrating Screen | 3-layer Vibrating Screen | ≤500 | 0–100 | 80–150 | 150 | Wheeled | 12800 × 3100 × 3600 | 30 |

| MCS-200 | Impact Crusher + Screen | 3-layer Vibrating Screen | ≤600 | 0–80 | 120–250 | 180 | Wheeled | 13500 × 3200 × 3700 | 35 |

| MCS-300T | Cone Crusher + Vibrating Screen | 2-layer Heavy-Duty Screen | ≤250 | 0–40 | 150–300 | 210 | Tracked | 14000 × 3300 × 3600 | 38 |

| MCS-400T Pro | VSI Crusher + Screen | Dual-deck High Frequency | ≤120 | 0–5 | 80–200 | 220 | Tracked | 14200 × 3500 × 3800 | 42 |

| MCS-500T Heavy | Jaw + Cone + Screen (3 in 1) | 3-layer Vibrating Screen | ≤650 | 0–65 | 200–400 | 280 | Tracked | 15500 × 3800 × 4000 | 55 |

If you have any special requirements, we will customize according to your special needs.

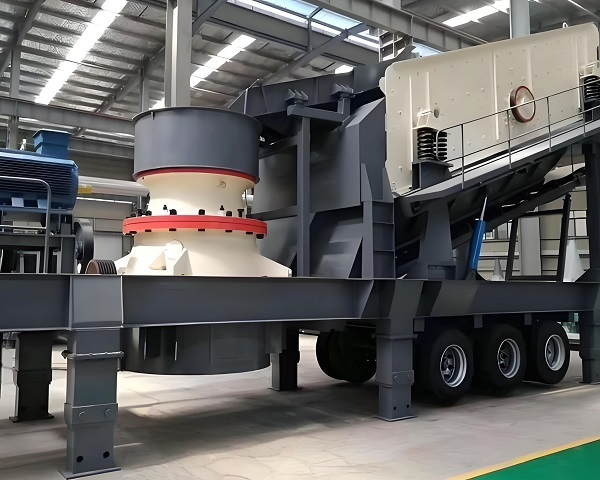

Product Picture Display of Mobile Crush and Screen Plant for Sale

FAQ about Mobile Crush and Screen Plant for Sale

>What scenarios are mobile crushing and screening machines suitable for?

This equipment is suitable for mining (such as coarse crushing and screening of open-pit mines), construction waste treatment (converting waste into recycled aggregates), road construction (on-site processing of roadbed stones), urban infrastructure (rapid cleaning of demolition waste), sand and gravel aggregate production (multi-grade particle size requirements) and emergency rescue (post-disaster waste treatment). Its mobility can be quickly deployed to temporary or dispersed work sites, especially suitable for projects that require frequent transfers, such as remote mines or narrow urban construction areas.

>What are the advantages of mobile crushing and screening machines compared to fixed equipment?

The advantages include: reducing transportation costs (materials are processed on site, saving 30%-50%), shortening construction period (ready to use, production efficiency increased by more than 40%), reducing environmental pollution (integrated dust removal and noise reduction devices), and significantly reducing material transportation costs.

>What are the advantages of mobile crushing and screening machines compared to fixed equipment?

Advantages include: reducing transportation costs (materials are processed on site, saving 30%-50% of transportation costs); shortening construction period (production efficiency increased by more than 40%); integrated environmental protection design (dust emission <30mg/m³, noise ≤85 decibels), and supporting rapid transfer, adapting to the rugged terrain of mines or complex urban environments, with significant comprehensive efficiency and cost advantages.

>What are the advantages of mobile crushing and screening machines compared with fixed equipment?

Mobile crushing and screening machines reduce transportation costs (saving 30%-50%), shorten construction period (efficiency increased by more than 40%), and integrate environmental protection design (dust emission <30mg/m³, noise ≤85 decibels) by processing materials on site. Its tire or crawler chassis can adapt to complex terrain, especially for projects with short infrastructure cycles and high environmental protection requirements.

>What are the main types of mobile crushing and screening machines?

According to the crushing host, it can be divided into four categories: jaw type (coarse crushing of high-hardness materials, such as granite), cone type (medium and fine crushing, high particle size uniformity), impact type (medium and low hardness materials with shaping function) and impact type (sand making operation, excellent particle shape). Users can choose the appropriate model according to the material characteristics and particle size requirements.

> What is the power source of the mobile crushing and screening machine?

The equipment supports three power modes: diesel engine (field without power supply scenes, such as remote mining operations), external power supply (urban construction or high environmental protection requirements, reduce exhaust emissions) and dual power switching (flexible adaptation to different working conditions). For example, in municipal engineering, the external power supply mode can reduce noise and fuel consumption; in post-disaster reconstruction, the diesel mode can ensure continuous operation.

How does the mobile crushing and screening machine handle construction waste?

> How is the environmental protection performance of the mobile crushing and screening machine reflected?

The equipment achieves green construction through closed conveyor belts, pulse dust collectors (dust emission <30mg/m³), noise reduction devices (noise ≤85 decibels) and resource recycling (construction waste resource utilization rate >90%). For example, in the treatment of urban construction waste, the equipment can avoid dust pollution and meet environmental protection standards, while converting waste into recycled aggregates to reduce natural resource mining.

> How does the mobile crushing and screening machine treat construction waste?

After the construction waste is evenly fed and iron removed by the vibrating feeder, it enters the crushing host (such as the impact crusher) for secondary crushing, and then vibrates to select multiple levels of particle size (such as 0-5mm fine sand, 5-10mm small stones). The finished products that meet the particle size requirements are output, and the over-specification materials are returned for recycling to maximize resource utilization.

> How is the environmental protection performance of the mobile crushing and screening machine reflected?

The equipment achieves green construction through closed conveyor belts, pulse dust collectors (dust emission <30mg/m³), noise reduction devices (noise ≤85 decibels) and resource recycling (construction waste resource utilization rate >90%). For example, in the treatment of construction waste, the equipment can reduce more than 90% of natural resource exploitation and reduce environmental pollution.

>Is the maintenance cost of the mobile crushing and screening machine high?

Low maintenance cost: modular design facilitates the replacement of wearing parts (such as hammers and liners), and the intelligent monitoring system can warn of faults and reduce downtime; daily maintenance only requires lubrication and hydraulic oil inspection, and the comprehensive cost (including transfer savings) is lower than that of fixed equipment, with significant long-term benefits

>Can the mobile crushing and screening machine handle high-hardness materials?

Can it efficiently handle high-hardness materials: the cone crushing host adopts the principle of laminated crushing, with a compressive strength of up to 350MPa, and the jaw host can withstand extremely high hardness materials. The combination of the two can reduce equipment wear and extend service life.

>What is the production efficiency of the mobile crushing and screening machine?

Medium-sized equipment has an hourly output of 100-300 tons/hour (jaw type) or higher (cone type), supports 24-hour continuous operation, intelligent control system optimizes parameters to reduce downtime, multi-stage crushing and screening to produce multiple levels of finished products at one time, and has leading efficiency. For example, medium-sized equipment has an hourly output of 100-300 tons/hour (jaw type) or higher (cone type), supports 24-hour continuous operation, intelligent control system optimizes parameters to reduce downtime, multi-stage crushing and screening to produce multiple levels of finished products at one time.

>How to choose a suitable mobile crushing and screening machine model?

The selection needs to be based on the material characteristics (hardness, humidity, particle size), production scale (hourly output demand), operating environment (topography, transfer frequency) and budget configuration (basic type/intelligent type, number of screening layers, return system). For example, a cone crusher host is required for processing high-hardness ores; low-noise, low-emission diesel-electric dual-power models are preferred for urban construction; iron removal devices and multi-layer screening systems are required for construction waste treatment. It is recommended to determine the final model through the manufacturer's technical solution and on-site testing.