A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Magnetic Separator Machine

Magnetic Separator Machine is a mechanical device that achieves efficient separation based on the magnetic difference of materials. It is widely used in many fields and plays a key role in resource recovery, material purification and other links.

The core working principle of the magnetic separator is to use the magnetic field force to adsorb magnetic materials. When the mixed material enters the magnetic field area of the magnetic separator, the magnetic material will be attracted by the magnetic force and adhere to the surface of the magnetic component of the magnetic separator. Then it will be taken away from the magnetic field area through mechanical movement to achieve separation; non-magnetic materials are not affected by the magnetic field and are directly discharged under the action of external forces such as gravity and centrifugal force. According to the way of generating the magnetic field, magnetic separators are mainly divided into three types: permanent magnet, electromagnetic and superconducting. Permanent magnet magnetic separators use permanent magnets to generate magnetic fields. They have a simple structure and low energy consumption. They are suitable for processing materials with strong magnetism; electromagnetic magnetic separators use electric current to generate magnetic fields. The magnetic field strength can be flexibly adjusted and can cope with complex working conditions; superconducting magnetic separators use superconducting materials to generate super-strong magnetic fields. The separation efficiency is extremely high and they are often used in scenes with strict requirements on separation accuracy.

In practical applications, magnetic separators are found in many industries. In the mining industry, it is an important equipment for the beneficiation and purification of metal ores. Through magnetic separation, it can effectively enrich iron ore, manganese ore, etc. and improve the grade of ore; in the environmental protection industry, magnetic separators can treat industrial wastewater and urban sewage, separate magnetic pollutants, and help purify water bodies; in the food processing industry, magnetic separators can remove magnetic impurities in raw materials to ensure food safety; in industries such as electronic waste recycling and glass manufacturing, magnetic separators can also accurately separate magnetic substances to achieve efficient utilization of resources.

Compared with other separation equipment, magnetic separators have significant advantages. It has high separation efficiency, can quickly and accurately separate magnetic substances, and the separation process does not require the addition of chemical agents, which is green and environmentally friendly; it is easy to operate, and can adapt to the separation needs of different materials by adjusting parameters such as magnetic field strength; at the same time, the maintenance cost of magnetic separators is low, and the key components of permanent magnetic and electromagnetic magnetic separators are durable and have a long service life. With the continuous advancement of technology, magnetic separators are developing in the direction of intelligence and efficiency, and will play a greater role in more fields in the future.

Operating principle of Magnetic Separator Machine

Magnetic Separator Machine is a device that uses the principle of magnetic force to separate magnetic substances from non-magnetic substances in materials. It is widely used in mining, metallurgy, building materials, chemicals, waste treatment and other industries. Its core working principle is based on the fact that magnetic substances deviate from their original motion trajectory under the action of magnetic force in the magnetic field, thereby achieving effective separation.

Magnetic separators are usually composed of a feeding device, a magnetic separation area, a discharging device and a drive system. The material enters the magnetic separator evenly through the feeding device and moves forward driven by the conveyor belt or rotating cylinder. At this time, the permanent magnet or electromagnet set inside generates a stable and powerful magnetic field. When a mixture containing magnetic substances enters the magnetic field area, the magnetic particles are adsorbed on the surface of the conveyor belt or cylinder under the action of magnetic force, while the non-magnetic particles continue to move in a straight line under the action of inertia and gravity, and finally fall into different collection areas, thereby achieving the separation of magnetic and non-magnetic substances.

Different types of magnetic separators have slight differences in structure and principle. For example, dry magnetic separators are mainly suitable for dry materials with coarse particle size and low moisture content; while wet magnetic separators are suitable for the separation of fine particles or slurry materials, and are usually used in conjunction with hydraulic systems to enhance the separation effect. In addition, high-gradient magnetic separators and ultra-strong magnetic field magnetic separators are used to separate weakly magnetic or extremely fine magnetic materials.

In order to improve the separation efficiency, magnetic separators usually adopt a multi-level magnetic field design, which can not only ensure that the magnetic particles are fully stressed, but also effectively reduce the mixing of impurities. During the magnetic separation process, not only valuable metal minerals can be recovered, but also harmful impurities can be removed to improve the purity of the final product. By adjusting the magnetic field strength, barrel speed and feeding speed, it can adapt to different materials and different production needs, thereby achieving the best separation effect.

Advantages and features of Magnetic Separator Machine

Magnetic Separator Machine is an efficient equipment that uses magnetic field to separate and purify magnetic materials. It is widely used in mining, metallurgy, building materials, chemical industry, electric power, recycling and other industries. Its biggest advantage is that it can efficiently remove ferromagnetic impurities in materials, improve product purity and added value, improve production efficiency and reduce equipment wear.

The separation effect of magnetic separator is stable and reliable. By adjusting the magnetic field strength and structural design, different types of magnetic separators can adapt to the separation needs of weakly magnetic or strongly magnetic minerals and achieve high-precision magnetic separation. Especially when processing ores such as iron ore, manganese ore, and ilmenite, magnetic separation technology can greatly improve the recovery rate and comprehensive utilization rate of resources.

The magnetic separator has the advantages of simple structure, convenient operation and low energy consumption. Most models are equipped with an automatic control system, and the operator can control the parameters through the panel or remotely adjust the parameters, saving manpower and maintenance costs. At the same time, the magnetic source of the equipment usually adopts high-performance NdFeB or electromagnetic method, which has the characteristics of strong magnetic force, high stability and long life.

The magnetic separator supports multiple process configurations and can be used as a key link in dry or wet process flows to meet the needs of different production environments. Whether it is roughing, concentrating or sweeping, the magnetic separator can play a highly efficient separation role. For the solid waste treatment industry, it can also be linked with crushing, screening and air separation equipment to achieve automated continuous operation.

The magnetic separator has become an indispensable and important equipment in modern industrial production due to its high sorting efficiency, strong adaptability, stable operation and easy maintenance, especially in terms of resource recycling and environmental protection treatment. It has shown great potential.

Technical Parameter Table of Magnetic Separator Machine

| Model | Magnetic Intensity (Gauss) | Capacity (t/h) | Power (kW) | Belt Width (mm) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| MS-600 | 3000 | 5-10 | 1.5 | 600 | 750 | 1200×800×1100 |

| MS-800 | 3500 | 8-15 | 2.2 | 800 | 980 | 1500×950×1150 |

| MS-1000 | 4000 | 10-20 | 3.0 | 1000 | 1250 | 1700×1100×1250 |

| MS-1200 | 4500 | 15-25 | 4.0 | 1200 | 1480 | 1900×1300×1350 |

| MS-1500 | 5000 | 20-35 | 5.5 | 1500 | 1760 | 2200×1500×1450 |

| MS-1800 | 6000 | 30-50 | 7.5 | 1800 | 2100 | 2500×1800×1550 |

If you have any special requirements, we will customize according to your special needs.

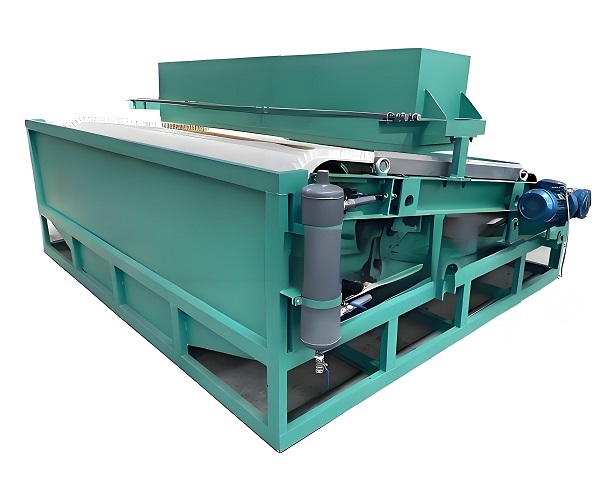

Product Picture Display of Magnetic Separator Machine

FAQ about Magnetic Separator Machine

Q: What are the main types of magnetic separator machine?

A: magnetic separator machine can be divided into many types according to the magnetic source, magnetic field strength, magnetic system structure, separation medium and separation process. Common types include permanent magnetic separator machine, electromagnetic magnetic separator machine, and dry magnetic separator machine and wet magnetic separator machine according to the separation process. There are also weak magnetic field separators, medium magnetic field separators and strong magnetic field separators according to the magnetic field strength.

Q: What is the difference between permanent magnetic separator machine and electromagnetic magnetic separator machine?

A: Permanent magnetic separator machine use permanent magnets (such as ferrites, neodymium iron boron, etc.) to generate magnetic fields. Their advantages are simple structure, low energy consumption and easy maintenance, but the adjustment range of magnetic field strength is limited. Electromagnetic separator machine generate magnetic fields through energized coils. Their advantages are a large adjustable range of magnetic field strength and the ability to obtain higher magnetic field strength, but their structures are relatively complex, with high energy consumption and the need for a cooling system.

Q: What situations are dry magnetic separator machine and wet magnetic separator machine suitable for?

A: Dry magnetic separator machine are mainly used to process dry, fluid powder or block materials, especially for water-scarce areas or process flows where water is not desired. Wet magnetic separator machine are used to process materials in a slurry state in a water medium, usually with better sorting accuracy and can process finer-grained materials.

Q: What are the main factors affecting the sorting effect of magnetic separator machine?

A: There are many factors that affect the sorting effect of magnetic separator machine, mainly including the magnetism of the material, particle size, feed rate, magnetic field strength, magnetic field gradient, length of the magnetic field action zone, working gap, slurry concentration (wet type), and the structure and operating parameters of the equipment itself.

Q: What are the magnetic field strength and magnetic field gradient of a magnetic separator?

A: Magnetic field strength refers to the magnitude of the magnetic force at a certain point in the magnetic field, usually expressed in magnetic induction intensity (unit Tesla T or Gauss Gs), which determines the magnitude of the magnetic force on the magnetic particles. Magnetic field gradient refers to the rate of change of magnetic field intensity in space. The greater the gradient, the more drastic the change of magnetic force on magnetic particles, which is more favorable for the capture of fine or weak magnetic particles.

Q: What are the applications of magnetic separator machine in mineral processing?

A: In mineral processing, magnetic separator machine are widely used for the separation of ferrous metal ores (such as iron ore and manganese ore) to improve their grade; they are also used for the separation or iron removal of non-ferrous metals and rare metal minerals (such as tungsten, tin, ilmenite, wolframite, monazite, etc.); and the purification and impurity removal of non-metallic minerals (such as kaolin, quartz, feldspar, nepheline, etc.).

Q: How to choose a suitable magnetic separator model?

A: Choosing a suitable magnetic separator model requires comprehensive consideration of the properties of the material to be processed (such as magnetism, particle size distribution, moisture content, processing capacity, etc.), separation targets (purification, impurity removal, recovery, etc.), process conditions (dry or wet separation), and economic costs and site conditions. It is best to determine it through small-scale tests or consulting professional manufacturers.

Q: What aspects should be paid attention to in the daily maintenance of magnetic separator machine?

A: The daily maintenance of magnetic separator machine includes regular inspection of whether the magnetic system is loose or damaged, the lubrication and operation of transmission parts (such as motors, reducers, bearings), the wear of the barrel or belt surface, whether the feeding and discharging devices are unobstructed, and the safety and reliability of the electrical system, and timely cleaning of dust and debris inside and outside the equipment.

Q: What is a high gradient magnetic separator? What are its characteristics?

A: A high gradient magnetic separator is a magnetic separation device that can generate high magnetic field gradients and high magnetic field strengths. It usually uses magnetic media (such as steel wool, steel mesh, steel plate mesh, etc.) to generate uneven strong magnetic fields. Its main features are that it can effectively sort fine-grained and weakly magnetic materials, with high sorting efficiency and high recovery rate. It is widely used in non-metallic mineral purification, wastewater treatment and other fields.

Q: What are the applications of magnetic separator machine in the field of environmental protection?

A: In the field of environmental protection, magnetic separator machine can be used to treat magnetic pollutants in industrial wastewater, such as iron-containing wastewater; to recycle magnetic metals in waste electrical appliances, automobiles and other wastes to achieve resource recycling; and can also be used for garbage sorting to separate magnetic substances.

Q: How is the magnetic system of the magnetic separator designed?

A: The magnetic system design of the magnetic separator is one of the core technologies. It is usually composed of multiple magnetic blocks of different polarities arranged in a certain pattern to form an open or closed magnetic circuit. The design goal of the magnetic system is to generate a magnetic field of specific intensity and gradient in the sorting area to meet the sorting needs of different materials. Common magnetic system structures include fan-shaped, horseshoe-shaped, and cylindrical.

Q: What errors should be avoided in the operation of the magnetic separator?

A: In the operation of the magnetic separator, overload feeding should be avoided to avoid blockage and reduce sorting efficiency; uneven feeding or bias to one side should be avoided; adjustments or repairs should be avoided during equipment operation; for electromagnetic magnetic separator machine, long-term overcurrent operation should be avoided; at the same time, ferromagnetic debris (such as tools and bolts) should be prevented from entering the magnetic separation area to avoid damage to the equipment.

Q: What is the development trend of magnetic separator machine?

A: The development trend of magnetic separator machine is mainly towards large-scale, high-efficiency, energy-saving, automation and specialization. For example, develop permanent magnetic materials and electromagnetic technology with higher magnetic field strength and gradient, optimize magnetic circuit design to improve sorting efficiency and recovery rate, use intelligent control systems to achieve operation automation and parameter optimization, and develop new special magnetic separation equipment for specific difficult-to-select materials.

Q: Where does the energy consumption of magnetic separator machine mainly come from?

A: The energy consumption of magnetic separator machine mainly includes the power consumed by the drive motor (used to rotate the cylinder or conveyor belt), the power consumed by the electromagnetic magnetic separator coil (used to generate a magnetic field), and the energy consumption of possible auxiliary equipment (such as feeders, water pumps, cooling systems, etc.). Permanent magnetic separator machine have great advantages in this regard because their magnetic field is provided by permanent magnets and no additional power is required.

Q: What is magnetic agglomeration? What impact does it have on magnetic separation?

A: Magnetic agglomeration refers to the phenomenon that magnetic particles gather together to form larger particle clusters due to mutual attraction in a magnetic field. Moderate magnetic agglomeration is sometimes beneficial to the recovery of strongly magnetic minerals, but excessive or undesirable magnetic agglomeration (especially for fine-grained materials) may contain gangue particles, reduce the concentrate grade and recovery rate, so it is necessary to control magnetic agglomeration by controlling the slurry concentration, adding dispersants or adopting special magnetic system design during magnetic separation.

Q: What non-metallic minerals can be processed by magnetic separator machine?

A: magnetic separator machine can process a variety of non-metallic minerals. The main purpose is to remove iron-containing impurities to improve their whiteness or purity. For example, the purification of minerals such as kaolin, quartz sand, feldspar, sillimanite, fluorite, barite, calcium carbonate, talc, etc., remove trace ferromagnetic or paramagnetic impurities such as hematite, limonite, pyrite, tourmaline, etc.

Q: How to evaluate the performance of magnetic separator machine?

A: The performance of magnetic separator machine is usually evaluated based on several key indicators: concentrate grade (i.e. the content of useful components in the obtained magnetic product), tailings grade (i.e. the content of useful components remaining in the non-magnetic product), recovery rate (i.e. the percentage of useful components entering the concentrate in the feed), processing capacity (the amount of material processed per unit time), and equipment stability and energy consumption.

Q: What are the applications of magnetic separator machine in the food industry?

A: In the food industry, magnetic separator machine are mainly used to remove tiny ferromagnetic impurities that may be mixed into food raw materials or finished products, such as iron filings, screws, nails, etc., to ensure food safety and quality. For example, in the processing of flour, sugar, tea, spices, grains, etc., and for testing and separation of finished products before packaging.