A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the European Version Jaw Crusher

The European version jaw crusher is a new type of high-performance crushing equipment developed based on the traditional jaw crusher technology and combined with European advanced design concepts and manufacturing processes. The equipment is mainly used in mining, building materials, metallurgy, chemical industry, highways, railways, water conservancy and other fields. It is suitable for primary crushing of various high-hardness and large-block materials, and has significant advantages such as high efficiency, energy saving and durability.

Compared with the traditional jaw crusher, the European version of the jaw crusher has been optimized and improved in terms of structural design, power configuration, crushing chamber type, and operating efficiency. It adopts a "V-shaped crushing chamber" and a symmetrical feeding design, which makes the material more evenly stressed during the crushing process and has a larger crushing ratio, effectively improving the feeding capacity and crushing efficiency. At the same time, the wedge-type discharge port adjustment structure replaces the traditional gasket-type adjustment device, making the adjustment of the discharge particle size simpler and faster, and improving the flexibility of operation.

The movable jaw and fixed jaw plate of the European version of the jaw crusher are made of high-strength wear-resistant materials and have a long service life. In the transmission part, the equipment usually adopts heavy eccentric shaft and high-quality bearings to ensure that the machine can run stably under high load conditions and reduce maintenance costs. Some models are also equipped with hydraulic cover opening devices, which are convenient for replacing jaw plates and maintenance, greatly improving the operability and safety of the equipment.

In terms of environmental performance, the European version of the jaw crusher has also been significantly improved. Its structure is more compact, and some models are equipped with a dustproof sealing system to effectively reduce dust leakage, which meets the requirements of modern green mine construction. In addition, its energy-saving effect is obvious. Under the same output conditions, its energy consumption is lower than that of traditional equipment, and it has good economy and environmental protection.

In summary, the European version of the jaw crusher is an advanced coarse crushing equipment that combines modern crushing technology with humanized design concepts. With its advantages of high efficiency, high adaptability, and easy maintenance, it has become the preferred crushing equipment in many large-scale sand and gravel aggregate production lines and mining projects. With the increasing demand for intelligent and green equipment in the mining industry, the market application prospects of the European version of the jaw crusher will be broader.

Operating principle of European Version Jaw Crusher

European Version Jaw Crusher is an advanced coarse crushing equipment. Its working principle is to optimize and upgrade the traditional jaw crusher based on the mature European design concept, adopt a more reasonable crushing chamber structure and more efficient motion parameter configuration, so as to achieve efficient primary crushing of various hard materials.

Its working principle is basically the same as that of the traditional jaw crusher. It mainly relies on the periodic movement between the movable jaw and the fixed jaw to squeeze, split and bend the materials entering the crushing chamber to achieve material crushing. The specific process is: the motor drives the eccentric shaft to rotate through the pulley, driving the movable jaw to swing back and forth. When the movable jaw is close to the fixed jaw, the material sandwiched between the two is strongly crushed; when the movable jaw is far away from the fixed jaw, the crushed material is discharged from the discharge port at the bottom of the crushing chamber under the action of gravity, completing a crushing cycle.

The European version jaw crusher is optimized in the motion trajectory of the movable jaw. It adopts a more reasonable movable jaw suspension method and eccentric shaft structure, so that the swing angle of the movable jaw is moderate, the friction is reduced, and the crushing efficiency is improved. The equipment often adopts a "V-shaped" deep cavity design. This structure effectively increases the feeding depth of the material, reduces the probability of material clogging in the crushing chamber, and increases the feeding volume per unit time.

In order to improve the convenience and accuracy of adjustment, the European version of the jaw crusher generally adopts a wedge-type discharge port adjustment mechanism to replace the traditional gasket-type adjustment method. Users only need to adjust the wedge position hydraulically or manually to achieve rapid adjustment of the discharge particle size to meet different production needs.

In addition, the European version of the jaw crusher emphasizes operational stability and equipment safety. Its eccentric shaft is made of high-strength forged steel and equipped with large bearings to ensure that the equipment can continue to operate stably under high-intensity crushing conditions. Some high-end models are also equipped with a hydraulic cover opening device and an overload protection system, which is convenient for maintenance and can effectively avoid equipment damage caused by foreign matter entering during the crushing process.

In short, although the working principle of the European version of jaw crusher continues the basic crushing mechanism of the traditional jaw crusher, it has higher crushing efficiency, wider application range and lower operating cost through comprehensive optimization in structure, power and function. It is an indispensable key equipment in modern mines and sand and gravel aggregate production lines.

Advantages and features of European Version Jaw Crusher

European Version Jaw Crusher is an optimized and upgraded product based on the traditional jaw crusher. It combines the advanced design concepts and manufacturing processes of Europe and has many advantages such as high efficiency, energy saving, stability and easy maintenance. It is widely used in mining, metallurgy, building materials, roads, water conservancy and other fields, especially suitable for primary crushing of high-hardness and large-block materials.

1. The European version jaw crusher has significant advantages in crushing efficiency. It adopts a "V-shaped" deep cavity structure design, which increases the actual feeding depth, avoids the problem of material blockage during the feeding process, and increases the crushing processing capacity per unit time. At the same time, the motion trajectory of the movable jaw has been optimized, and a reasonable eccentricity and speed configuration are adopted to make the movable jaw form a more ideal composite swing trajectory, thereby enhancing the extrusion ability of the material and improving the crushing efficiency and crushing ratio.

2. The equipment is more convenient to adjust. Traditional jaw crushers mostly use a gasket-type discharge port adjustment method, while European-version jaw crushers are mostly changed to a wedge-type or hydraulic adjustment device, which makes the discharge particle size adjustment faster and more accurate, reduces the downtime caused by adjustment, and improves the continuity and operating efficiency of the production line.

3. In terms of durability, the European-version jaw crusher has a solid structure and exquisite materials. The frame is mostly made of integral cast steel or heavy-duty welded steel structure, which has strong pressure resistance and good impact resistance; key parts such as movable jaw, fixed jaw, toggle plate, etc. are made of high-strength wear-resistant materials, which extends the service life of the equipment. The eccentric shaft is made of forged steel and equipped with heavy-duty rolling bearings to ensure smooth operation under high-intensity working conditions.

4. The European-version jaw crusher also shows great advantages in maintenance. Some models are equipped with hydraulic cover opening devices and centralized lubrication systems, which greatly simplifies inspection and daily maintenance work, reduces the labor intensity of operators, and improves the maintainability and safety of the equipment.

5. In terms of environmental protection and energy saving, the European version of the jaw crusher adopts a more compact and sealed structural design, which effectively reduces dust emission. At the same time, it has high operating efficiency and reasonable motor power configuration, which significantly reduces energy consumption while ensuring production capacity, and meets the construction requirements of modern green mines and sustainable development.

The European version of the jaw crusher has shown strong comprehensive performance in practical applications due to its efficient crushing capacity, optimized structural design, simple operation and maintenance, good wear resistance and energy saving, and has become one of the most popular main equipment in the modern mining and aggregate processing industry.

Technical Parameter Table of European Version Jaw Crusher

| Model | Feed Opening Size (mm) | Max Feed Size (mm) | Discharge Adjustment Range (mm) | Capacity (t/h) | Motor Power (kW) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| PEW250×1000 | 250 × 1000 | 210 | 25–60 | 15–70 | 37 | 1100 × 1850 × 1390 | 6,500 |

| PEW400×600 | 400 × 600 | 350 | 35–85 | 30–80 | 55 | 1700 × 1800 × 1300 | 9,000 |

| PEW760 | 760 × 1100 | 630 | 75–200 | 150–350 | 110 | 2600 × 2200 × 2300 | 18,000 |

| PEW860 | 860 × 1100 | 720 | 100–225 | 200–450 | 132 | 2700 × 2400 × 2500 | 22,000 |

| PEW1100 | 1100 × 1200 | 930 | 150–275 | 300–650 | 160–200 | 3300 × 2500 × 2700 | 29,000 |

If you have any special requirements, we will customize according to your special needs.

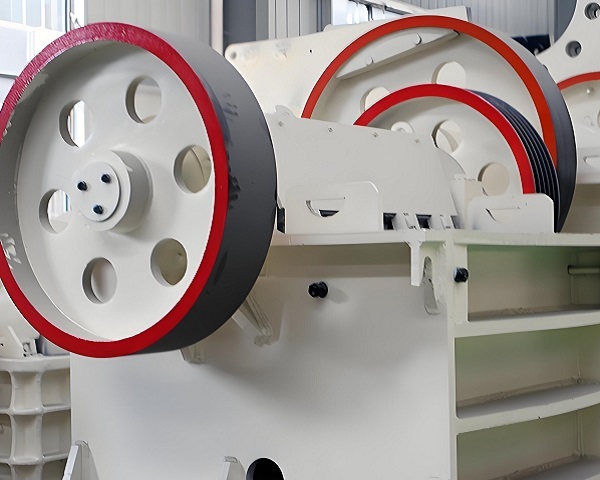

Product Picture Display of European Version Jaw Crusher

FAQ about European Version Jaw Crusher

>What is the difference between the European version of the jaw crusher and the traditional jaw crusher?

The European version of the jaw crusher has been significantly improved in terms of structural design, crushing efficiency, ease of operation and durability compared to the traditional jaw crusher. It uses a V-shaped crushing chamber, a hydraulic adjustment system, high-strength materials and an optimized power system, making it more efficient, with lower energy consumption and longer service life, while also being easier to maintain and adjust.

>What materials are suitable for the European version of the jaw crusher?

The European version of the jaw crusher is suitable for a variety of medium-hard and high-hardness materials with a compressive strength not exceeding 300MPa, such as granite, basalt, iron ore, quartz stone, pebbles, construction waste, etc., and is an ideal equipment for the primary crushing stage.

>What is the working principle of the European version of the jaw crusher?

The European version of the jaw crusher drives the movable jaw to swing back and forth through the motor-driven eccentric shaft, so that the material is squeezed and crushed between the movable jaw and the fixed jaw. After multiple compressions and releases, the material is discharged from the discharge port to complete the crushing process.

>How to adjust the discharge particle size of the European version of the jaw crusher?

European version jaw crusher usually adopts wedge block or hydraulic discharge port adjustment system. You only need to adjust the wedge block or operate the hydraulic mechanism to accurately control the discharge particle size. The operation is simple, fast and safe.

> What are the main components of European version jaw crusher?

Its main components include: frame, movable jaw, fixed jaw, eccentric shaft, flywheel, toggle plate, wedge block adjustment device, motor and foundation. Each part works together to ensure the efficient and stable operation of the equipment.

> Is European version jaw crusher energy-saving and environmentally friendly?

Yes, European version jaw crusher adopts efficient power transmission system and deep cavity crushing design, which can significantly reduce unit energy consumption. At the same time, its compact structure and good sealing can reduce dust and noise pollution, which meets the environmental protection standards of modern green mines.

> What is the service life of European version jaw crusher?

Because its key parts are made of wear-resistant materials such as high manganese steel and high chromium alloy, the frame is strong and the bearing selection is excellent, so under normal use and maintenance conditions, European version jaw crusher has a long service life and low failure rate.

>What is the output range of the European version of the jaw crusher?

Depending on the model, the production capacity of the European version of the jaw crusher generally ranges from 15 tons/hour to 650 tons/hour. Users can choose the appropriate model according to the production scale and material characteristics.

>How to maintain the European version of the jaw crusher?

Daily maintenance includes regular inspection of the lubrication system, bearing temperature, bolt tightening, jaw plate wear status, etc.; at the same time, the lubricating oil should be replaced regularly to keep the equipment clean to prevent material blockage and abnormal wear of components.

>Is the European version of the jaw crusher suitable for mobile crushing stations?

Very suitable. Due to its compact structure, strong adaptability and high degree of automation, the European version of the jaw crusher can be flexibly mounted on the mobile crushing station and is widely used in a variety of scenarios such as construction waste recycling and quarry mobile operations to improve operating efficiency and flexibility.