A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Impact Rock Crusher

Impact rock crusher is a kind of high-efficiency crushing equipment that uses impact energy to crush rocks and ore materials. It is widely used in mining, building materials, roads, railways, water conservancy, chemical industry and other fields. It is mainly suitable for brittle materials with medium hardness and below, such as limestone, construction waste, concrete, pebbles, coal gangue, etc., and is particularly suitable for medium crushing, fine crushing and shaping processes with high requirements for finished product particle shape and particle size.

Working principle

The core working principle of the impact crusher is to drive the material to impact and crush through the high-speed rotating rotor. During the working process, the motor drives the rotor to rotate at high speed. After the material enters the crushing chamber from the feed port, it is accelerated and thrown to the surrounding impact plate or wear-resistant lining surface. Due to high-speed impact and rebound, multiple impacts, shearing and grinding are formed, thereby achieving material crushing. The crushed material is discharged from the machine body under the action of gravity and centrifugal force, forming a continuous and efficient crushing process.

According to the different structures and working modes, impact rock crushers are mainly divided into two categories:

1. Impact Crusher: generally used for medium and fine crushing processes, suitable for softer materials;

2. Vertical Shaft Impact Crusher (VSI): mainly used for fine crushing, machine-made sand and material shaping, widely used in artificial sand production lines.

Main structural components

Impact crushers generally consist of feed inlet, rotor, impact plate (or peripheral plate), liner, discharge port, transmission device and base. The core component is the rotor, which is equipped with a plate hammer or a throwing head, which is the key part of energy transmission and crushing. In addition, the impact device or throwing cavity structure has an important influence on the material impact angle and the finished particle shape.

Equipment features and advantages

1. Large crushing ratio and high efficiency: the ideal particle size can be achieved in one crushing, which reduces energy consumption and increases production;

2. Excellent finished product particle shape: mostly cubic, with less needle-like content, especially suitable for high-standard aggregate production;

3. Simple structure and convenient maintenance: the internal structure of the equipment is compact, easy to disassemble and replace wearing parts;

4. Strong adaptability: it can be used for fixed and mobile crushing stations, suitable for a variety of working environments;

5. Good environmental performance: stable operation, dust and noise can be effectively controlled after cooperating with the dust removal system.

As an important secondary or tertiary crushing equipment, impact rock crusher plays an increasingly important role in the modern sand and gravel aggregate and mineral processing industry due to its excellent performance and wide adaptability. With the advancement of the concept of green environmental protection and high-quality development, the machine-made sand production line equipped with efficient impact crusher has become an important direction for the development of the industry.

If you need to know more about the parameters of different models or application cases, please consult professional technical service providers to obtain targeted solutions.

Operating principle of Impact Rock Crusher

Impact rock crusher is a kind of equipment that uses impact energy to crush materials. It is widely used in mining, building materials, metallurgy, highways, railways, water conservancy, artificial sand and gravel aggregates and other industries. This equipment occupies an important position in medium crushing, fine crushing and shaping operations with its advantages of high crushing efficiency, excellent finished product particle shape and simple structure. Its working principle is the core foundation of the entire equipment design and operation, and directly affects the crushing efficiency, equipment life and product quality.

Basic Principle Overview

The core principle of the impact rock crusher is "the material is violently impacted and crushed by the kinetic energy generated by the high-speed rotating parts". When the equipment is running, the motor drives the main shaft and rotor to rotate at high speed through the V-belt or coupling. After the material enters the crushing chamber from the feed inlet, it is thrown to the impact plate, peripheral guard plate or other hard surfaces by the high-speed rotating rotor, generating a huge impact force at the moment of impact, crushing the material. At the same time, the thrown material collides and rubs against other materials in the crushing chamber many times, thereby further achieving fine crushing.

According to different structural forms, impact crushers are mainly divided into two types, and their working principles are slightly different:

1. Horizontal Impact Crusher

2. Vertical Shaft Impact Crusher (VSI)

Working Principle of Impact Crusher

Impact crushers are mainly used for medium and fine crushing of medium-hard materials. The material falls into the equipment through the feed port, and the kinetic energy accumulates rapidly under the drive of the high-speed rotating rotor. The plate hammer fixed on the rotor throws the material to the impact plate at high speed, causing a violent impact. The material after the impact rebounds back to the rotor area and collides with the newly entered material again, and the cycle continues until the particles reach the set particle size and are discharged from the discharge port.

The main crushing process includes the following three stages:

1. The first impact crushing: the rotor plate hammer directly hits the material;

2. The second rebound impact: the material hits the impact plate or the cavity wall to produce a second crushing;

3. The third material collision: the materials collide and rub against each other to form a shaping effect.

Working principle of vertical shaft impact crusher (VSI)

VSI crusher is mainly used for fine crushing or shaping, and is one of the key equipment for machine-made sand production. The material enters the crushing chamber vertically from the top center, and is thrown to the surrounding of the crushing chamber through an acceleration device (such as an impeller) to rotate at high speed. The high-speed material jet hits the surrounding guard plate or the material bed formed by natural falling, causing violent impact and crushing.

The impact rock crusher has become an important equipment in applications such as machine-made sand, aggregate shaping, and construction waste treatment due to its scientific kinetic energy transfer and impact crushing principles. Understanding its working principle not only helps to select and apply it more reasonably, but also improves the operating efficiency and service life of the equipment. In the future, with the advancement of technology, impact crushing equipment will achieve more breakthroughs in the directions of intelligence, high efficiency and energy saving.

Advantages and features of Impact Rock Crusher

Impact rock crusher is an efficient equipment that can crush materials by throwing them out through high-speed rotating parts and violently colliding with hard materials such as impact plates and guard plates. Its main features are simple structure, large crushing ratio, and excellent finished product particle shape. It is widely used in medium crushing, fine crushing, and stone shaping, especially in the production of machine-made sand and building aggregates. The following will systematically summarize the characteristics and advantages of impact rock crusher from multiple aspects:

1. Large crushing ratio and high efficiency

The working principle of impact crusher enables it to have extremely high crushing efficiency. During the crushing process, the material is not only subjected to the impact force brought by the high-speed rotation of the rotor, but also collides with other materials and structures in the crushing chamber many times, forming a composite crushing effect. This "stone hitting stone" or "stone hitting iron" working method can achieve one-time crushing and molding, significantly improve production efficiency, and reduce the energy consumption and investment cost of multi-stage crushing.

2. The finished product has good particle shape and reasonable gradation

Compared with traditional jaw crushers or cone crushers, the aggregate produced by impact crushers has more regular particle shape, is cubic, and has a low content of needle-like flakes, which meets the strict requirements of modern high-grade highways, high-speed railways, water conservancy projects and other projects for aggregate particle shape. Especially in vertical shaft impact crushers, by optimizing the throwing path and impact angle, the particle quality can be further improved to achieve the purpose of crushing stone shaping.

3. Simple structure and convenient maintenance

The overall structure of the impact crusher is relatively compact. The main components include rotor, plate hammer, impact plate, guard plate, main shaft and casing, and assembly and disassembly are relatively simple. The replacement cycle of the equipment's wearing parts (such as plate hammer, throwing head, guard plate) is clear, which is easy to manage and maintain. It is especially suitable for industrial sites with high output and tight maintenance cycle. Some models are also equipped with hydraulic opening devices, which greatly improves maintenance efficiency.

4. Strong adaptability and wide application range

Impact crushers are suitable for a variety of soft to medium hard materials, including limestone, construction waste, coal gangue, concrete blocks, pebbles, etc. According to the different crushing methods, they can be divided into impact crushers (suitable for medium crushing) and vertical shaft impact crushers (suitable for fine crushing and shaping). Its application scenarios extend from traditional mine quarries to multiple industrial fields such as urban construction waste treatment, machine-made sand production, and cement clinker pre-crushing.

5. Smooth operation, energy saving and environmental protection

The impact crusher is reasonably designed, and the dynamic balance of the rotor is strictly controlled, which effectively reduces the vibration and noise during operation. At the same time, by equipping with a closed crushing chamber structure and a dust removal system, green and environmentally friendly production can be achieved, reducing the impact on the surrounding environment. In terms of energy consumption, due to the high crushing efficiency, the energy consumption per unit output is lower than that of traditional crushing equipment, which has a good energy-saving effect.

6. Modular design, easy to combine

Modern impact crushers generally adopt modular design, which is convenient for flexible combination in mobile crushing stations and semi-mobile crushing lines. Users can freely configure auxiliary systems such as vibrating feeders, screening equipment, conveyor belts, etc. according to project requirements to quickly form an efficient crushing operation line, which is especially suitable for variable construction environments and temporary site operations.

7. Obvious trend of intelligent development

With the development of Industry 4.0, many advanced impact crushing equipment have gradually integrated intelligent control systems, such as automatic lubrication, intelligent monitoring, remote fault alarm and maintenance prompts. The application of these technologies not only improves the stability and safety of equipment operation, but also greatly reduces labor costs and extends the service life of equipment.

8. High cost performance and fast return on investment

Compared with hydraulic cone crushers or vertical mill systems, impact crusher equipment has lower cost, shorter installation cycle, and simpler operation. It is especially suitable for users such as small and medium-sized sand and gravel plants and concrete mixing plants. With its high production capacity and low maintenance advantages, users can often recover their investment in a shorter period of time and obtain good economic returns.

As an efficient and energy-saving medium and fine crushing and shaping equipment, impact rock crusher has become the preferred equipment in modern mining, sand and gravel aggregate, construction waste treatment and other industries due to its significant advantages such as high crushing efficiency, excellent particle shape, simple structure and strong adaptability. With the continuous upgrading of technology and the introduction of intelligent systems, the comprehensive performance of impact crushing will be further improved, which will help green and high-quality development. For enterprises pursuing high production capacity, excellent particle shape and low operating costs, impact crusher is undoubtedly a key equipment worthy of key investment.

Technical Parameter Table of Impact Rock Crusher

| Model | Rotor Diameter (mm) | Feed Opening (mm) | Max Feed Size (mm) | Capacity (t/h) | Power (kW) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| PF-1007 | 1000 × 700 | 400 × 730 | 300 | 30–70 | 37–55 | 9300 | 2400 × 1560 × 2660 |

| PF-1010 | 1000 × 1050 | 400 × 1080 | 350 | 50–90 | 55–75 | 12000 | 2530 × 1980 × 2200 |

| PF-1210 | 1250 × 1050 | 400 × 1080 | 350 | 70–130 | 110–132 | 14500 | 2600 × 2400 × 2800 |

| PF-1214 | 1250 × 1400 | 400 × 1430 | 350 | 90–180 | 132–160 | 19000 | 3050 × 2460 × 2800 |

| PF-1315 | 1320 × 1500 | 860 × 1520 | 500 | 160–250 | 180–260 | 22000 | 3180 × 3270 × 2670 |

If you have any special requirements, we will customize according to your special needs.

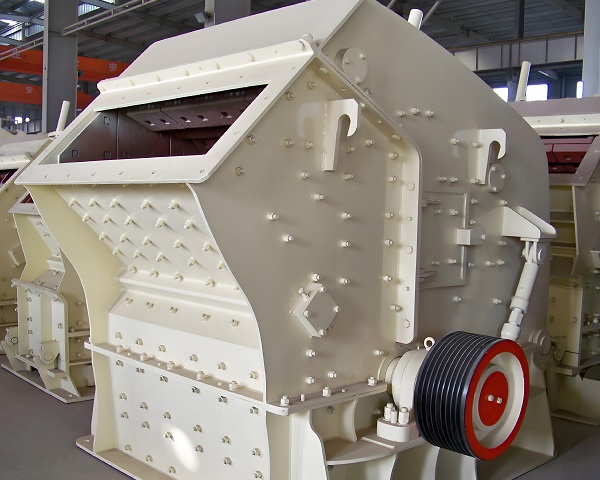

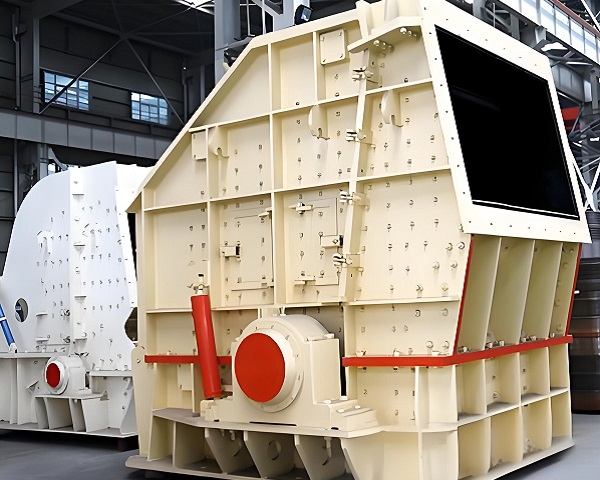

Product Picture Display of Impact Rock Crusher

FAQ about Impact Rock Crusher

>1. What is the main working principle of the impact rock crusher?

The impact rock crusher uses a high-speed rotating rotor to accelerate the material to the impact plate or guard plate in the crushing chamber, and crushes the material into the required particle size through strong impact and multiple rebound impacts. This "stone hitting stone" or "stone hitting iron" crushing method allows the material to be quickly crushed under high-energy impact, and has the characteristics of large crushing ratio and high efficiency.

>2. What types of materials are suitable for impact crushers?

The equipment is suitable for brittle materials with medium hardness and below, such as limestone, coal gangue, concrete, construction waste, pebbles, iron ore tailings, etc. According to the specific structural form (such as impact type or vertical shaft impact type), it can also be used for machine-made sand shaping or high-quality aggregate processing.

>3. Compared with jaw or cone crushers, what are the advantages of impact crushers?

The main advantages of impact crushers are high crushing efficiency, good finished product particle shape, and low needle-like content, which is especially suitable for engineering projects with strict requirements on particle shape. In addition, its structure is relatively simple, maintenance is convenient, and its adaptability is strong, especially in the production of artificial sand and the treatment of construction waste.

>4. What are the main components of the impact crusher?

The main components include the feed port, rotor, plate hammer or throwing head, impact plate or guard plate, housing, discharge port and motor transmission system. Among them, the rotor and plate hammer are the core components, which directly determine the crushing capacity and life of the equipment.

>5. How to judge whether the impact crusher is suitable for a certain production line?

The key to judgment lies in the hardness, humidity, particle size range and requirements for the finished product particle shape of the material. If the material hardness is not high and needs medium and fine crushing or shaping, the impact crusher is a very suitable choice. Especially in artificial sand production and concrete aggregate processing, the impact crusher can provide high-quality particle shape.

>6. What are the common faults of the impact crusher and how to prevent them?

Common faults include overheating of bearings, rapid wear of plate hammers, unbalanced rotors, and uneven particle size of the discharge. Preventive measures include regular inspection of wearing parts, keeping the equipment well lubricated, monitoring the balance of the rotor, and timely cleaning of foreign matter and moisture in the feed.

>7. What are the wearing parts of the impact crusher? What is the service life?

The main wearing parts include plate hammer, guard plate, throwing head and impact liner. Its service life depends on the properties of the material (such as hardness, silicon content), operating conditions and maintenance frequency. Generally, wear-resistant parts with high chromium alloy or ceramic reinforcement have a longer life.

>8. Can it be used for wet material crushing? How to avoid clogging?

The impact crusher has limited processing capacity for wet materials. When the water content is high, it is easy to stick and clog, affecting the discharge. To avoid clogging, the water-containing material should be pre-treated, such as drying or adding vibration screening, and the discharge port should be kept unobstructed, and the wind force should be appropriately increased or dehumidification equipment should be set up.

>9. How to improve the crushing efficiency of the impact crusher?

There are many ways to improve efficiency: optimize feed size, maintain continuous and uniform feed, regularly replace wear parts, adjust the spacing between impact plates to control the discharge size, and keep the motor and rotor running stably. It is also critical to choose the right speed and the right crushing chamber.

>10. With increasingly stringent environmental protection requirements, how can impact crushers achieve green production?

Modern impact crushers effectively control dust and noise emissions by adding dust removal devices, shock absorption and noise reduction systems, and fully enclosed structural designs. At the same time, high crushing efficiency also means lower unit energy consumption and higher raw material utilization, making it an ideal choice for green mines and environmentally friendly gravel fields.

If you need to make these questions and answers into brochures, web pages or PDF manuals, I can also layout and design them for you. Please let me know if you need it!